New Precision Model Resin for 3D Printing Restorative Models With Industry-Leading Accuracy and Precision

It’s not just printers that matter, it’s what you can print. Formlabs Dental’s new Precision Model Resin empowers dental professionals to 3D print restorative models with over 99% of printed surface area within 100 μm of the digital model, for industry-leading accuracy and precision.

Formlabs Dental users have printed over 15 million dental parts with our 15+ dental-specific resins, but we are always looking for ways to set new standards in digital dentistry, so we took advantage of the new hardware of Form 4B to develop new industry-leading materials. By developing resins in tandem with software and hardware, our new 3D printing ecosystem optimizes for print speed, accuracy, and mechanical performance.

Request a Free 3D Printed Restorative Dental Model

Curious to see the quality firsthand? Pick a material and we'll ship you a free sample part 3D printed on the Form 4B to evaluate.

Precision Model Resin

Precision Model Resin is the next generation of Model Resin, formulated to leverage the new Form 4 ecosystem for faster print speeds, more accuracy, and enhanced aesthetics. This high-accuracy 3D printing resin was uniquely formulated to create restorative models with industry-leading accuracy, fine feature resolution, and consistency.

Precision Model Resin is optimal for printing:

- Restorative models

- Crown fit test models

- Implant models

- Removable die models

Formlabs’ in-house materials experts solve for the pain points of dental professionals. For restorative models, visualizing margin lines is key. Precision Model Resin is more opaque than Model Resin, with matte aesthetics and a gypsum-like appearance to better distinguish margin lines. The color, too, was carefully formulated. Dr. Christopher Baer, DMD, of Baer Dental, says, "Precision model looks fantastic. I really like the color of crowns on these models. The team at Formlabs did a great job nailing the color."

Form 4’s new hardware also enables print speeds that are three times faster than previous formulations, meaning eight restorative models can be printed in as little as 90 minutes at a 50 μm layer thickness, with a cost per part of $2-4.

Precise and Accurate

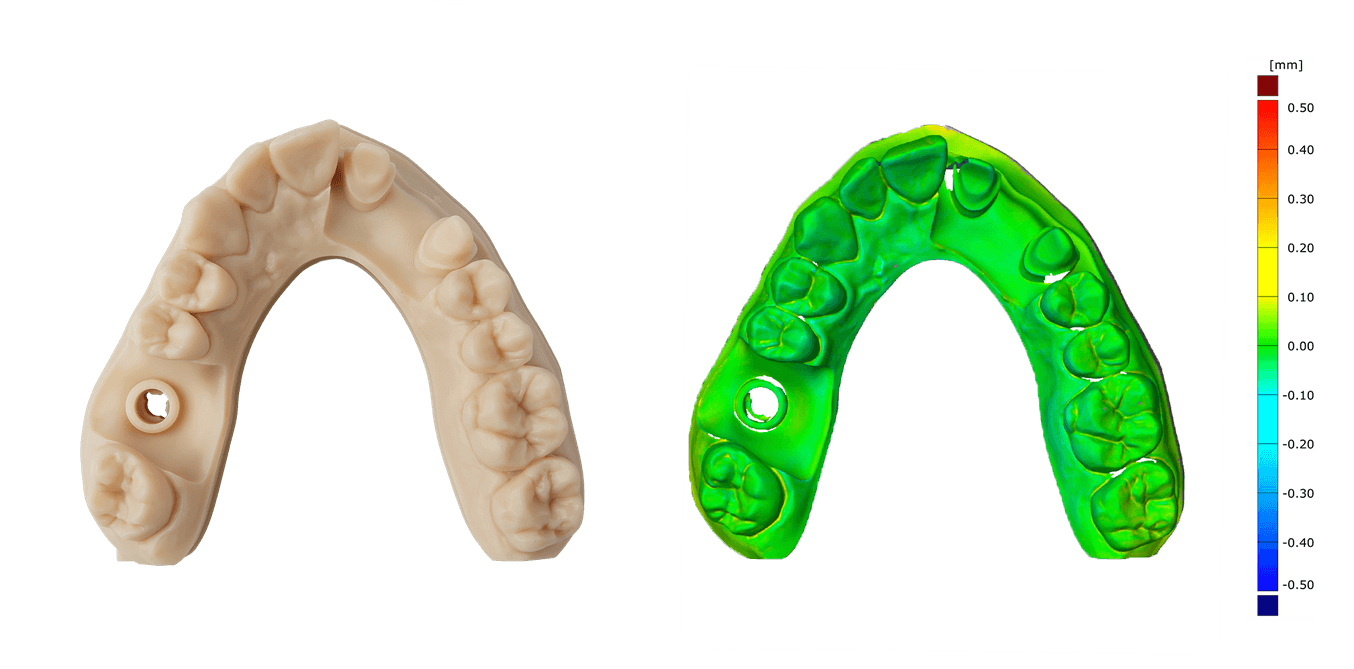

Restorative models printed on Form 4B with Precision Model Resin at 50 μm layer height have 99.7% of the printed surface within 100 μm of the CAD model, and 95% of printed surface within 50 μm of the CAD model. Minimal variability and high consistency across printers, print batches, and the build platform, make for reliable production of high-accuracy models.

Create restorative models with over 99% of their printed surface area within 100 μm of the design parameters.

Precision Model Resin was put to the test against leading competitors. Comparing parts printed at 50 μm, Precision Model Resin proved to be more accurate when comparing all measured tolerance ranges.

| Formlabs Precision Model Resin 3D printed on Form 4B | Asiga DentaMODEL 3D Printed on Asiga Max UV | SprintRay Die and Model 2 3D Printed on SprintRay Pro 95 | |

|---|---|---|---|

| +/- 100 μm tolerance | 99.9 | 99.7 | 90.4 |

| +/- 50 μm tolerance | 97.4 | 91.3 | 62.0 |

| +/- 25 μm tolerance | 75.7 | 62.8 | - |

Product Demo: Form 4B+ Dental 3D Printer

Blazing speed meets unmatched accuracy in the next generation of dental 3D printing. Explore the latest innovations in our webinar.

Production-Optimized Workflow

Speed improvements are not limited to just print time, but post-processing time as well, for an accelerated end-to-end workflow.

Scan and Design

Once the patient's dentition is scanned and the model is designed in your dental CAD software, the digital models and dies can be imported into Formlabs' free printing software, PreForm Dental, as an STL or OBJ file.

In PreForm, orient parts directly on the build platform. For the best results, dies should be manually oriented and supported.

Once parts are oriented, upload the print and prepare the printer by inserting a resin tank, Precision Model Resin cartridge, and clean build platform into the printer.

Post-Process

Remove parts from the build platform, using a part removal tool if chamfer features were added to models, or flush cutters for cases without chamfers.

Wash the printed parts in 99% isopropyl alcohol (IPA) in the Form Wash for five minutes. Modify this wash time based on part geometry and solvent purity.

Allow parts to dry before curing in the Form Cure for five minutes at 35 °C, or Fast Cure for 30 seconds at Light Intensity 2, to achieve optimal mechanical properties.

Improved Material Properties

Precision Model Resin was designed to be a tougher, stronger, stiffer, and more impact-resistant material than its predecessor, Model Resin. Post-cured prints in Precision Model Resin therefore don’t break as easily. This improved toughness means greater resistance to fracture when pressing in dies or implant analogs.

Material Properties for Post-Cured Prints

| Precision Model Resin | |

|---|---|

| Ultimate Tensile Strength | 50.0 MPa |

| Tensile Modulus | 2.2 GPa |

| Elongation at Break | 8.6% |

| Flexural Strength | 87 MPa |

| Flexural Modulus | 2.3 GPa |

| Notched Izod | 32 J/m |

| Unnotched Izod | 262 J/m |

Case Study at Hybridge Implants

Hybridge Implants is a nationwide network providing full-mouth implant-supported prosthetic appliances. These parts are produced by technicians over a 3D printed implant model, a process that requires the highest precision and accuracy as metal components (implant analogs) need to be screwed into the printed model. Not only do the Hybridge technicians need parts printed quickly, but implant models need to be both extremely precise and strong to withstand the metalwork.

“The team and I have been blown away by the Precision Model Resin and the speed at which it prints. My metal department has to screw implant screws into models we make and the threads often do not hold. This issue is non-existent in the new model material.”

Shawn Simpson, CAD/CAM technician, Hybridge Implants

Before printing Precision Model Resin on Form 4B, Hybridge would print two models, one for the metal department in Rigid 10K Resin, and another for the assembly team in Model Resin V3. Screwing metal components into the models requires tight tolerances and a strong, tough material, while assembly is delicate, precise work.

The tight tolerances and strength of Precision Model Resin printed on Form 4B allow the Hybridge metal department and assembly team to work on the same models.

Metal components can be screwed directly into models printed using Precision Model Resin.

Christina Rivet, Vice President of Lab at Hybridge Implants, had her team try printing models in Precision Model Resin on Form 4B. She found that, “Material print speed is phenomenal. The new model material I've raved about. It's strong. It prints fast. It has a lot of options for our prints.” The dimensional accuracy, toughness, and ease of cleaning in the ultrasonic bath mean Hybridge can now print just one model in Precision Model Resin to be used by both the metal team and the assembly team, saving time and resources.

Print Restorative Models With Industry-Leading Accuracy

With the release of Form 4B came the opportunity for our in-house materials team to develop resins optimized for printing on the new hardware. Guided by feedback from dental professionals, Precision Model Resin was developed specifically for the printing of dental models with industry-leading accuracy, fine feature resolution, and consistency — all at production-ready speeds.

To assess a part printed in Precision Model Resin for yourself, request a free sample to be mailed to your office, or start printing with this high-accuracy material now.