“At Alvetro Orthodontics, in-house 3D printing means that we can produce a very high-quality product. We can do it very efficiently, we can do it very cost-effectively, and we have total control.”

Dr. Lisa Alvetro, DDS, Orthodontist at Alvetro Orthodontics

Dr. Lisa Alvetro, DDS, is the sole orthodontist at Alvetro Orthodontics, supported by a staff of 22 employees and serving offices in both Sidney and Tipp City, Ohio, USA. Seeing 125 patients on an average day, Dr. Alvetro produces all appliances in-house, relying on Formlabs 3D printers and the versatile Formlabs Dental material library for the production of indirect bonding trays, occlusal guards, and models for thermoforming retainers and aligners. Dr. Alvetro says, “I want the ideal outcome for patients, and I want it to be a great experience. To do that, we really have to provide the technology that's available because that enhances patient experience — it's really helped grow my practice.”

The cutting-edge technology of the Form 4B 3D printer has had an immediate impact on Alvetro Orthodontics, with the speed, reliability, and precision enabling the elimination of appointments and a decrease of 6-8 weeks in treatment time for patients with braces. Additionally, the ease of use and intuitive workflows make it easy to onboard staff, for efficient, streamlined production.

“We have found that we can eliminate appointments for patients because we can produce models so quickly on our Form 4B.”

Dr. Lisa Alvetro, DDS, Orthodontist at Alvetro Orthodontics

Product Demo: Form 4B Dental 3D Printer

Blazing speed meets unmatched accuracy in the next generation of dental 3D printing. Explore the latest innovations in our webinar.

The Benefits of In-House 3D Printing With Formlabs

Dr. Alvetro has always produced appliances in-house, for control over production timelines and quality. She began with an analog lab, transitioning over to a 3D print lab 10 years ago. At the start, Dr. Alvetro says, “It was very expensive. I can still remember how excited we were when we got our EnvisionTEC printer, and then we realized the print platform was so small you could only get a couple models, and a lot of the consumables were expensive — from the tanks to the resin. We were so proud of what we were able to accomplish, but it was tricky, it was difficult, and we really couldn't teach everybody in the office to do it.”

Dr. Alvetro has stayed on the cutting edge of technological developments. She says that now, “3D printing is so efficient, so quick, and so cost-effective. But really the big thing is the control, and that you can do an immediate turnaround. If something isn't exactly what you wanted or we need to change course, it can happen immediately. If you're trying to outsource everything, you're delaying treatment and that's inefficient.”

Alvetro Orthodontics has a dedicated print lab for producing appliances in house. Dr. Alvetro tests new technological developments, staying on the cutting edge of digital orthodontics.

As an expert in 3D printing, Dr. Alvetro is experienced with most dental 3D printers. Since Form 2, she has relied on the Formlabs ecosystem as it’s easy to use, easy to teach, and delivers the outcomes she needs in a busy practice. With current 3D printing technology, she’s found that, “We are 20% more productive in 10% less time.”

“We really rely on our Formlabs systems based on the accuracy, precision, reliability, and predictability of what our end product is going to be. We do a lot of production and it's so nice to know that whatever we put on that print platform, it's going to print successfully for us.”

Dr. Lisa Alvetro, DDS, Orthodontist at Alvetro Orthodontics

Getting Staff On-Board With Formlabs

Doctors bringing 3D printing in-house must also get their staff on board. Prior to coming to Alvetro Orthodontics, Patricia Mitchell, Clinical Coordinator, had no experience in digital dentistry or 3D printing. Mitchell says, “Being in an office where the doctor had already implemented that was honestly, truly amazing to me. I actually learned how to 3D print first using a Formlabs printer.”

“When you're looking at a Formlabs system, there are so many things that are already dialed in for you. You can teach anyone to do it very, very quickly and it has such a high success rate. If you buy a Formlabs printer, within a day, you should be up and running.”

Dr. Lisa Alvetro, DDS, Orthodontist at Alvetro Orthodontics

Form 4B is easy enough to set up and use that anyone can learn it in 15-minutes. Intuitive workflows, smart sensors, and touchscreen prompts make printing easy and efficient. Mitchell adds, ”Formlabs also provides you with all of the steps and guides that you need to be successful in 3D printing. And if you can't figure something out or you need additional help, Formlabs support is honestly so helpful and great, to guide you through any steps that you need.”

Talk to Our Dental Sales Team

Whether you need to produce occlusal splints in-house, or are looking for high-throughput production of dental models, we're here to help. The Formlabs Dental Team are dedicated specialists who know exactly how to support you and your company's needs.

Eliminating Appointments With Form 4B: Ultimate Debonds

“The technology in the Form 4B is just incredible. You can use all of these different materials — and then at the speed that you're able to print. With Fast Model Resin, getting a full build plate of models in such a small amount of time creates an efficiency in the office that we have never experienced before.”

Patricia Mitchell, Clinical Coordinator, Alvetro Orthodontics

Prior to having Form 4B, debonding took several steps. In one 40-60 minute appointment, the patient would have the wires on their braces removed. The patient would be scanned, and the wires put back in. Then, the staff would make a digital model from the scan and manually remove the brackets. This model would then be used to produce the patient’s retainer, which they would receive at their next appointment.

Digital Debond in Two Appointments With Form 3B+

| First appointment | 1. Wire removal: 10 min 2. Scan: 5 min 3. Insert wire: 5 min |

|---|---|

| Lab work | 4. Design (digital debond): 45 min 5. Print time: 46 min 6. Post-processing time: 10 min 7. Thermoforming & polishing: 5 min |

| Second appointment | 8. Bracket and wire removal: 20 min 9. Delivery: 5 min |

| Total time | 2 h 31 min |

Issues with this process include teeth shifting between scanning and debonding or gingivitis from poor patient hygiene, resulting in an ill-fitting retainer. This process also took a lot of staff time as brackets were manually removed from the model.

When Dr. Alvetro saw the speed of Form 4B, she realized she could print a model for thermoforming, thermoform a retainer, polish it, and deliver it in less than 30 minutes. This has resulted in what the staff call ultimate debonds. Now, patients have their braces removed, and their teeth polished. Then, an intraoral scan is done and, while a staff member is printing the model and producing the retainer, the patient is doing all their final photo documentation and paperwork. At the end of the 60-minute appointment, the retainer is delivered. “We know it's going to fit because we just took the braces off 20 minutes ago,” says Dr. Alvetro.

Single Appointment Ultimate Debond With Form 4B

| Single appointment | 1. Brackets and wire removal: 20 min 2. Scan: 5 min 3. Design: 5 min 4. Print time: 9 min 5. Post-processing time: 10 min 6. Thermoforming and polishing: 5 min |

|---|---|

| Total time | 54 min |

This new process eliminates the early appointment of wire removal and scan, plus the time it takes staff to digitally remove brackets from the scan. Without the need for this wire removal and scanning appointment, the practice has freed up an entire day of appointments.

“We have found that not only have we eliminated that appointment, we've really reduced treatment time because there's obviously a wait time to get in for the next appointment. So we may be saving 6 to 8 weeks on their treatment time, but also the accuracy of the fit. It really has produced a much more accurate product than when we're trying to digitally debond. One thing that makes me really comfortable being able to do a debond and deliver retainers at the same time is the reliability of my Formlabs printer.”

Dr. Lisa Alvetro, DDS, Orthodontist at Alvetro Orthodontics

With Form 4B, Alvetro Orthodontics is eliminating an entire appointment and decreasing treatment times by 6-8 weeks.

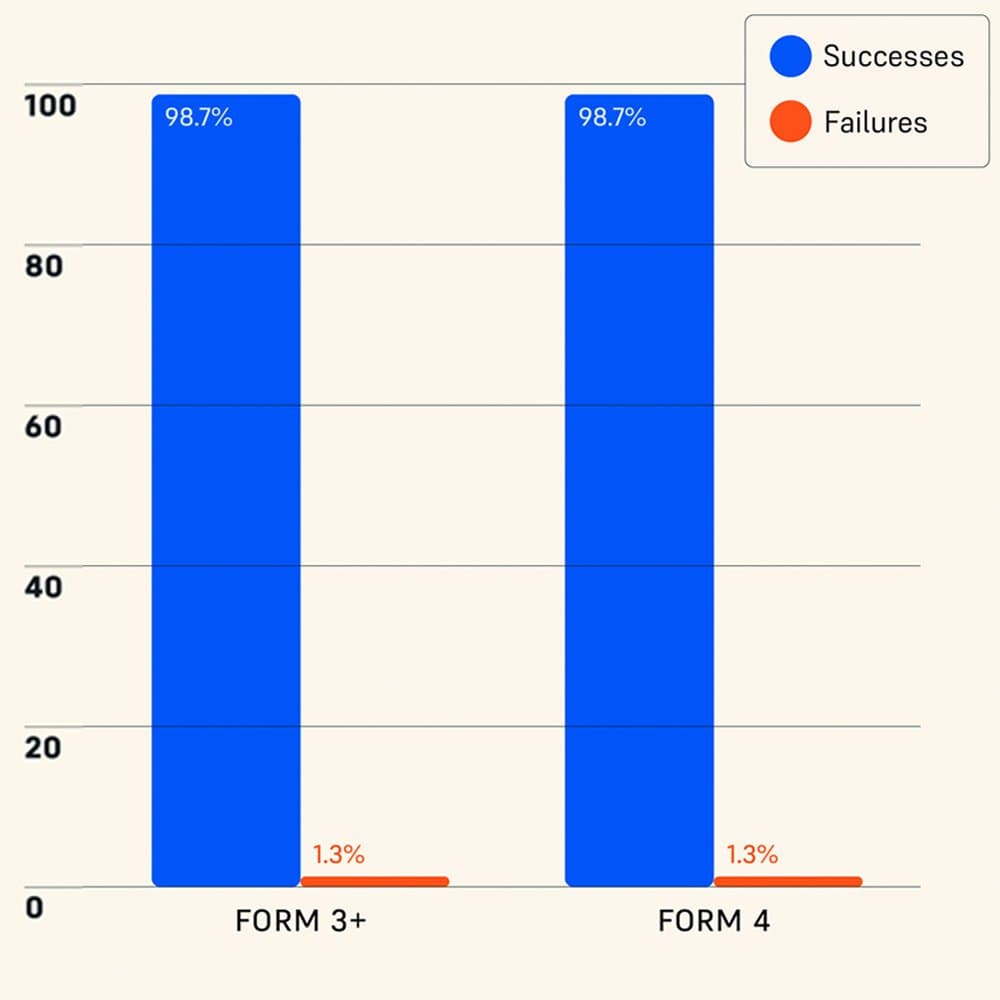

Independently Tested Reliability of Form 4 and Other Resin 3D Printers

Formlabs Form 4 was measured to have a 98.7% print success rate by an independent global leader in product testing. Read a complete description of the test methodology and see the results in our white paper.

Material Science Advancements Enable New Applications

“One of the things that changes our digital workflow the most is the introduction of new materials. In particular, if you look at something like the Fast Model Resin that can produce a model so quickly for us, or advancements in the IBT Flex Resin, the material science is really what continues to change what we're doing.”

Dr. Lisa Alvetro, DDS, Orthodontist at Alvetro Orthodontics

The Formlabs Dental material library includes 15+ resins, including biocompatible materials designed and manufactured within our robust Quality Management System that is ISO 13485 and EU MDR certified.

Alvetro Orthodontics uses:

- Fast Model Resin, our fastest printing resin, for producing models for thermoforming same-visit retainers

- IBT Flex Resin for the production of clear indirect bonding trays

- Dental LT Comfort Resin for flexible occlusal guards

The ease of changing resin cartridges and resin tanks empowers the staff at Alvetro Orthodontics to quickly switch between materials, meeting the needs of the practice and patient if a replacement retainer or adjustment in treatment is required.

“The ability to 3D print has really allowed us to create our in-house aligner system, and that has allowed me to provide a service for patients. The effect on my practice has been amazing because people want aligners and so many people come here, particularly because we make them ourselves.”

Dr. Lisa Alvetro, DDS, Orthodontist at Alvetro Orthodontics

The largest application is by far models for Alvetro Orthodontics’ in-house aligner system – about 150 models a day are printed on Formlabs 3D printers. Second to that are indirect bonding trays printed with IBT Flex Resin, about 10-12 a day, depending on the number of cases being started.

The optical clarity of appliances printed with IBT Flex Resin make it easy to see the proper seeding of brackets.

Indirect bonding trays are printed in IBT Flex Resin and allow for faster, easier bracket placement.

“Using the Form 4B for indirect bonding trays has been such a great experience. The PreForm software is super user-friendly and easy to use, and the speed of the Form 4B is incredible. It allows us to turn over and get a patient bonded that same day if needed. The clarity of the IBT Flex Resin is incredible. It allows you to truly see the bracket in that bracket slot to ensure that you're getting a successful seating of that tray in the patient's mouth to ensure that you're getting a proper bonding.”

Patricia Mitchell, Clinical Coordinator, Alvetro Orthodontics

IBT Flex Resin: Announcing Formlabs' New Indirect Bonding Tray Material

Discover the IBT Flex Resin, designed for highly accurate 3D printing of indirect bonding trays and direct composite restoration guides. Learn about its unique features, including enhanced flexibility, tear resistance, and translucency, making it a great fit for both techniques.

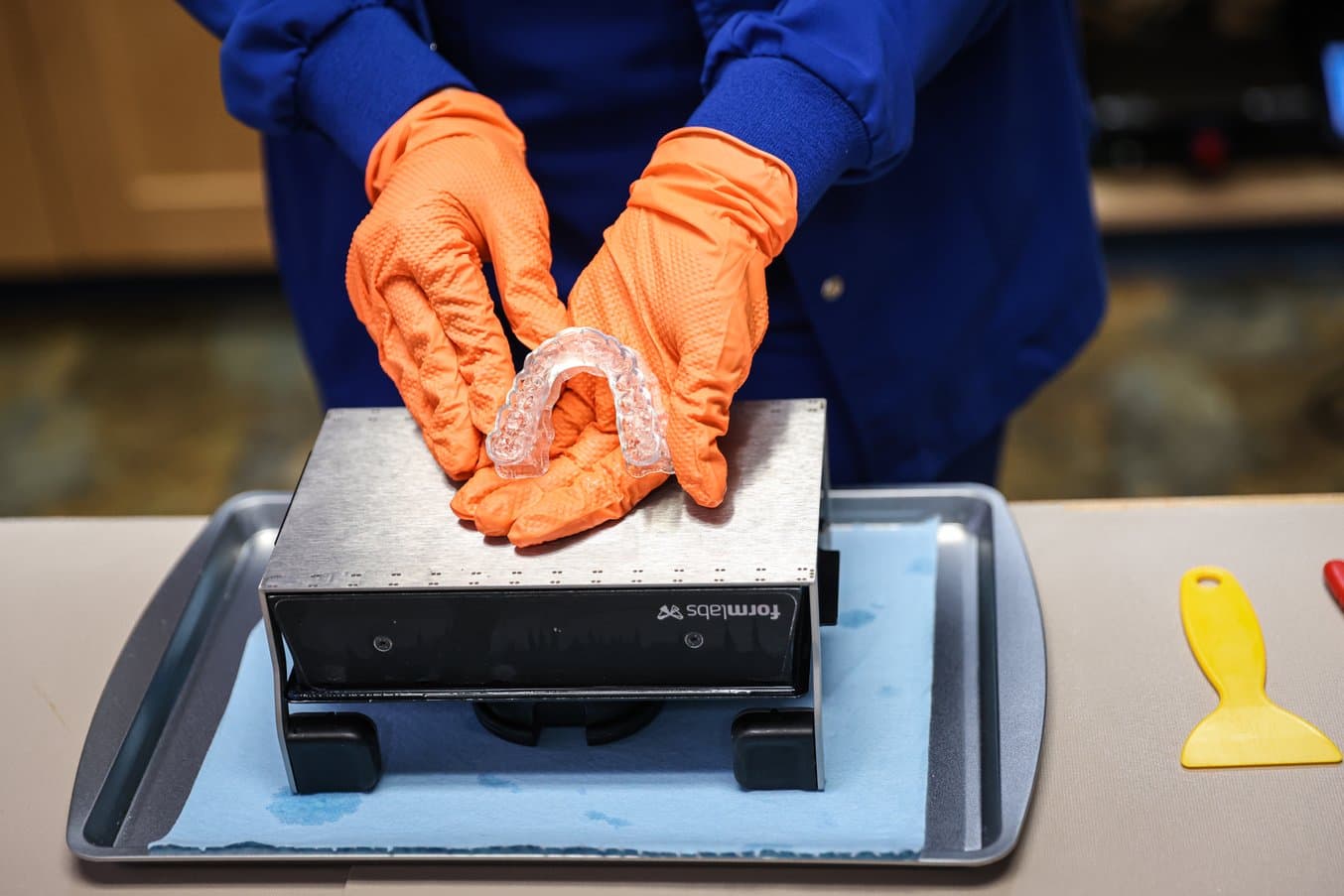

Additionally, Alvetro Orthodontics prints occlusal guards in-house with Dental LT Comfort Resin, a flexible, biocompatible material easily polished to high optical transparency.

After models, occlusal guards are an easy application to start producing in-house.

“Printing occlusal guards with Dental LT Comfort Resin has been great. There's not a lot of post-processing involved and the polishing is very minimal, if any.You're going to be getting an appliance that is super accurate for your patient.”

Patricia Mitchell, Clinical Coordinator, Alvetro Orthodontics

To learn more, visit the Formlabs Dental material library or request a free sample part to evaluate the quality for yourself.

Bring 3D Printing In-House

“I can't imagine practicing orthodontics without 3D printing. I can't even imagine having to outsource, when it would be so inefficient, it would be so bad for patient experience, and it would be so expensive. Using a Formlabs printer, you're going to get what you need when you need it. It's going to be accurate. There's really no guesswork anymore.”

Dr. Lisa Alvetro, DDS, Orthodontist at Alvetro Orthodontics

3D printing in-house gives orthodontists and dental professionals control over timelines and appliance quality. The speed of Form 4B empowers same-appointment and same-day production, ensuring uninterrupted treatments, and even the elimination of chair time and appointments.

Additionally, 3D printing opens up the pool of potential staff. Dr. Alvetro says, “I think my colleagues don't realize that 3D technology and printing has really opened up the potential pool of people that we can employ, because there may be someone who really likes technology that doesn't really like the dental side of it. They're perfect for your print lab.”

Start printing with Form 4B, or check out our ROI calculator to see how much time and cost you can save. To learn more or discuss your unique business goals, contact a dental specialist.