In the field of dental care, precision and efficiency are critical to patient experience and treatment outcomes. Founded in 2018, Smile Lab began as a single-person department within a large dental clinic in Hong Kong. With a keen focus on digital innovation, it has grown into a specialized workshop dedicated to digital orthodontics and cosmetic dentistry. The adoption of Formlabs 3D printing technology has been the cornerstone of Smile Lab’s ability to deliver highly accurate and efficient services.

From Traditional To Digital: Smile Lab’s Journey

Smile Lab’s growth mirrors the dental industry’s shift toward digitization. In 2019, when traditional impressions and plaster casts were still the norm, Smile Lab’s parent clinic embarked on a digital transformation. They introduced intraoral scanners to replace conventional impression tools and acquired their first Formlabs Form 3B 3D printer, enabling a fully digital workflow of scan, design, print. By 2022, with expanding operations, Smile Lab spun off into an independent entity, becoming a specialized workshop for crafting digital dental appliances.

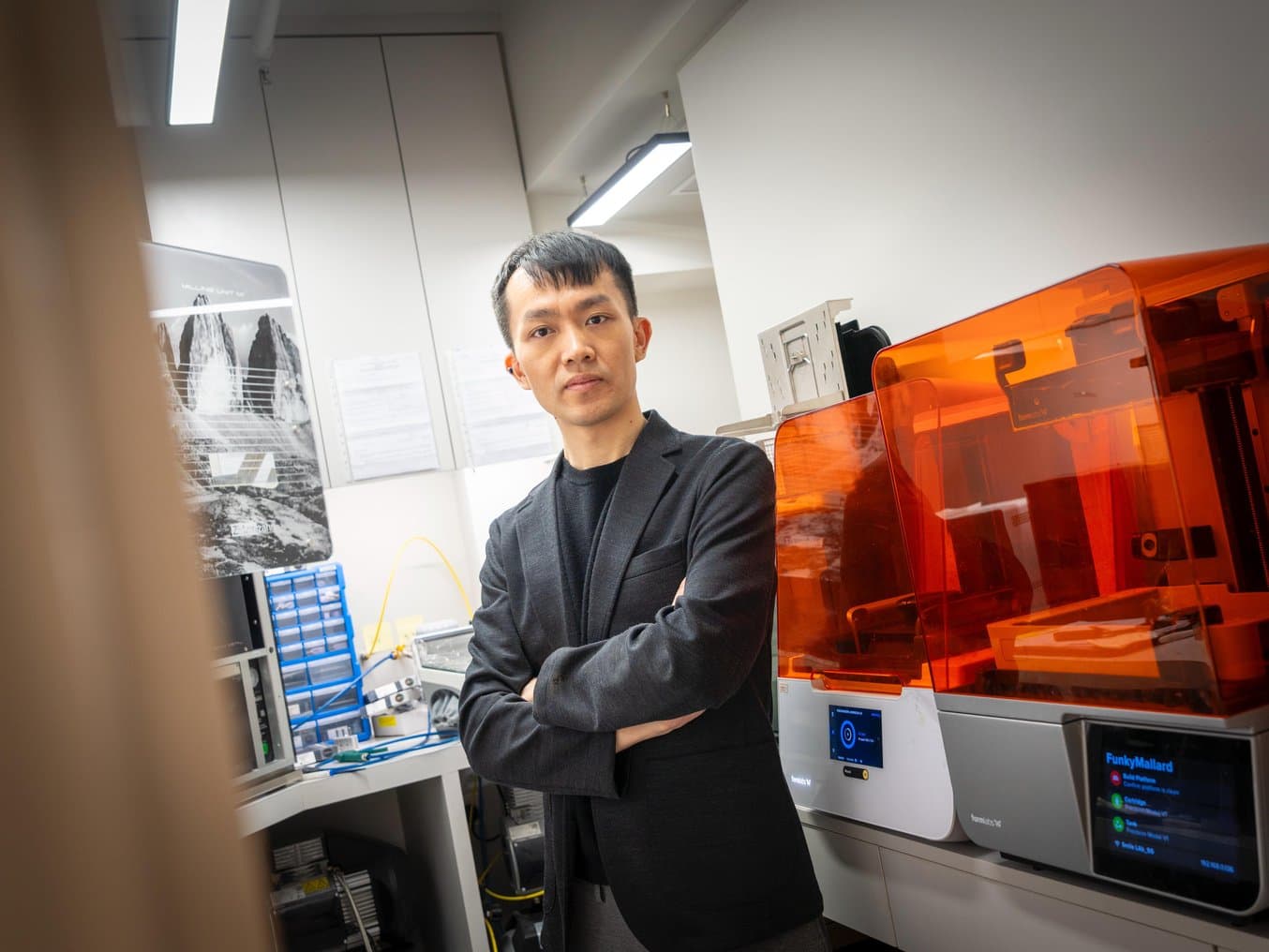

Kin Wong, Chief Dental Technician and Director, has witnessed this transformation firsthand. Starting his career in 2004 with no exposure to digital techniques, he now leads a team producing high-precision dental appliances using 3D printing.

“Formlabs has allowed us to truly keep pace with the digital evolution in dentistry.”

Kin Wong, Chief Dental Technician and Director, Smile Lab

Get in Touch

Whether you need to produce occlusal splints in-house, or are looking for high-throughput production of dental models, we're here to help. Get in touch with a dental expert to find the right solution for your business.

Formlabs Dental: Precision and Efficiency Combined

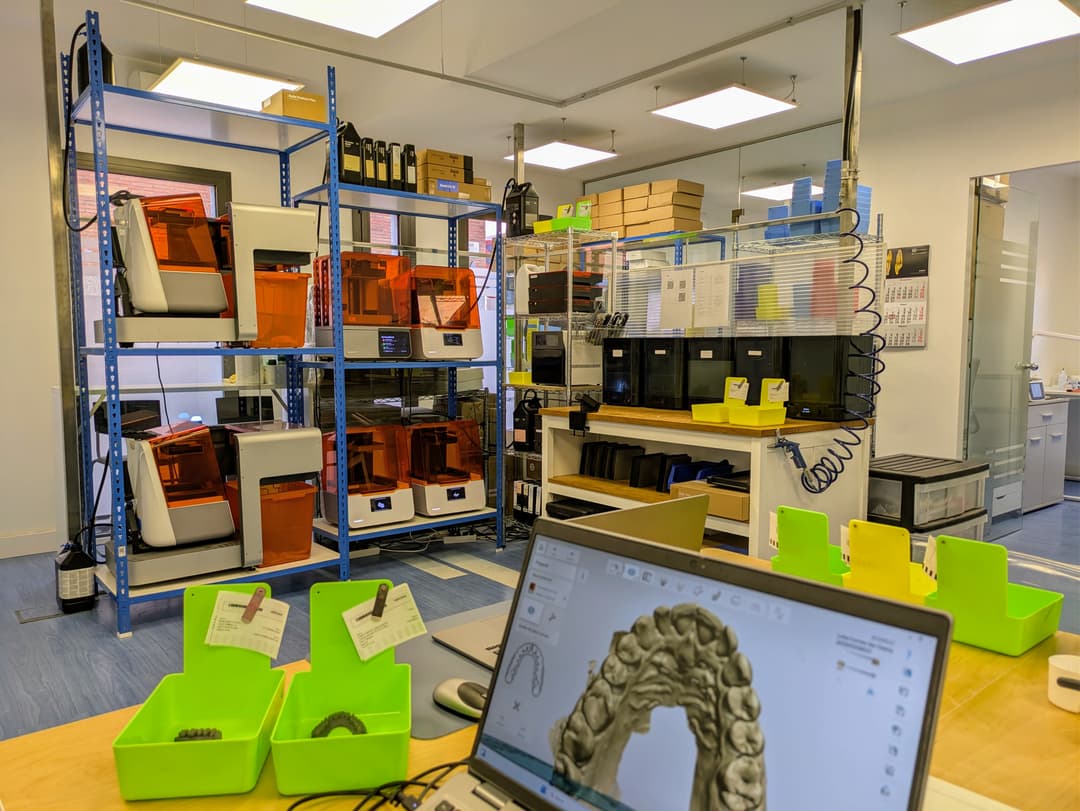

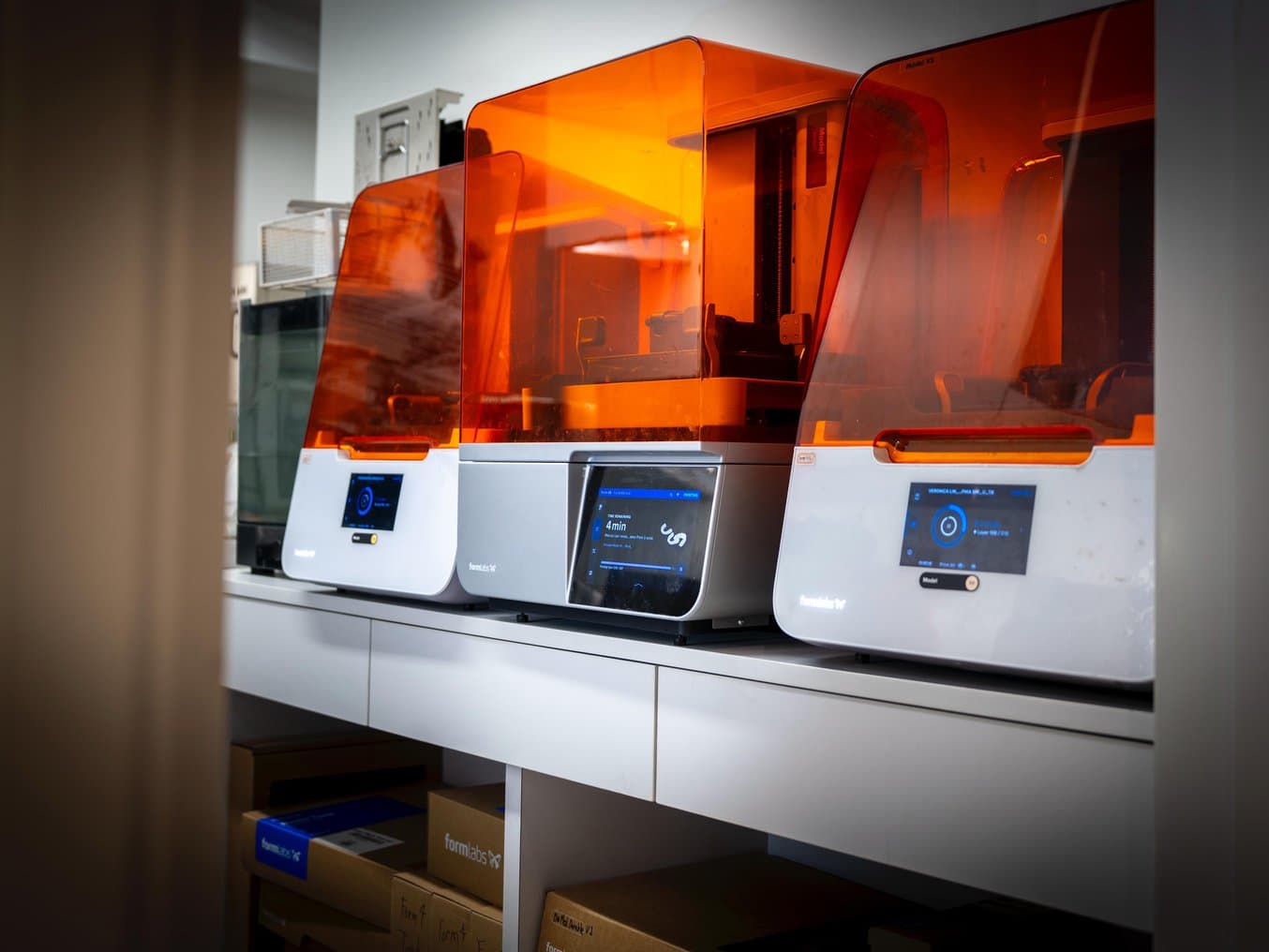

Formlabs equipment is now a cornerstone of Smile Lab’s operations. The workshop is equipped with two Form 3B printers, one Form 4B printer, and Formlabs post-processing solutions, producing approximately 300 dental models monthly for applications ranging from restorations to orthodontic treatments.

Four dental technicians at Smile Lab manufacture appliances including retainers as well as temporary and permanent restorations.

Printers at Smile Lab include Form 3B and Form 4B, enabling the fast, accurate production of a range of models and appliances.

Materials and Applications: Tailored for Dental Needs

Smile Lab carefully selects Formlabs materials, from biocompatible to model resins, to meet stringent dental requirements. Materials include:

-

Surgical Guide Resin: For precise surgical guides used for implant placement, ensuring accuracy during surgery.

-

Dental LT Clear Resin: A durable, clear material for printing rigid occlusal splints.

-

Permanent Crown Resin: For end-use single crown printing, balancing strength and aesthetics.

-

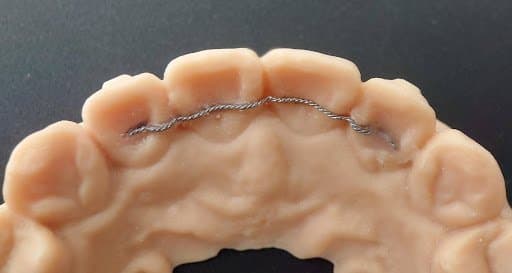

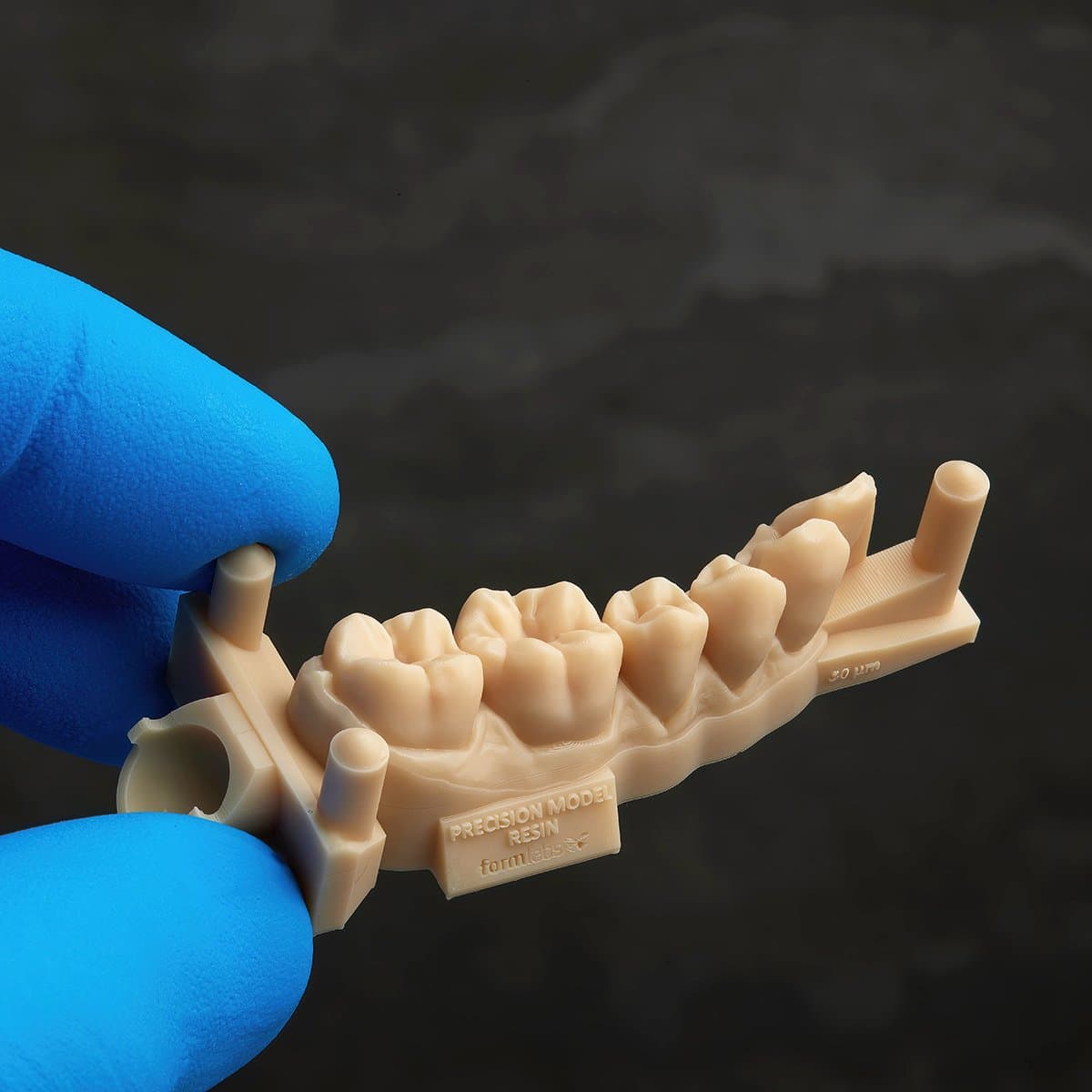

Model Resins (including Model Resin and Precision Model Resin): For highly precise restorative model production.

Fixed wire retainer fabricated on a model printed in Precision Model Resin.

A clear aligner thermoformed on a 3D printed model.

Permanent Crown Resin is a biocompatible resin available for Form 3B series 3D printers.* The 3D printed restoration is finished with surface staining and glazing, achieving a lifelike appearance in as little as 1.5 hours. This production speed addresses the inefficiencies of traditional ceramic crowns, which typically require at least two days, making 3D printed crowns suitable for both temporary and long-term restorations.

*For Form 4B users, permanent restorations can be printed with BEGOTM VarseoSmileⓇ TriniQⓇ Resin.

A crown 3D printed using Formlabs Permanent Crown Resin.

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part printed on the Form 4B to your office.

Streamlined Workflow: From 113 Minutes to 67 Minutes

Traditional dental appliance production is labor-intensive and error-prone. For example, creating a clear retainer involves nine steps, taking about 113 minutes. Errors, such as inaccurate impression taking, impression distortion due to material instability or damaged plaster molds, often necessitated costly reworks and additional patient visits. With Formlabs 3D printing, the process is drastically simplified.

Traditional Workflow

| Workflow Step | Time |

|---|---|

| Tray selection & adjustment | 2 min |

| Mixing impression material | 1 min |

| In-mouth impression and waiting for material to set | 5 min |

| Disinfection | 15 min |

| Plaster model production | 15 min |

| Transportation to lab | 10 min |

| Undercut analysis and blocking with plaster | 30 min |

| Plaster setting time | 15 min |

| Retainer fabrication | 20 min |

| Total Time | 1 h 53 min |

Digital Workflow

| Workflow Step | Time |

|---|---|

| Intraoral scanning & file transfer | 10 min |

| Digital model processing | 5 min |

| Model Production: 3D printing | 20 min at 100 µm or |

| Post-Processing: washing and post-curing | 45 min at 50 µm |

| Retainer Fabrication | 20 min |

| Total Time | 1 h 7 min 1 h 32 min if the model is at 50 µm |

This streamlined workflow takes just 67 minutes — a 40% reduction in time — while reducing human error by 80%.

Additionally, eliminating physical impressions removes infection risks associated with contaminated molds.

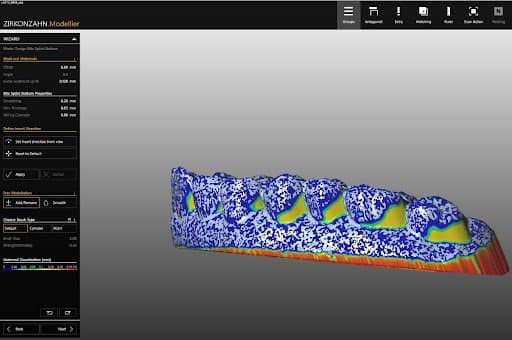

Manual marking and plaster filling of undercuts adds additional time to the traditional workflow and can be eliminated with 3D printing.

Software-based filling of undercuts is much more efficient than manual filling.

Product Demo: Form 4B Dental 3D Printer

Blazing speed meets unmatched accuracy in the next generation of dental 3D printing. Explore the latest innovations in our webinar.

Why Formlabs Dental?

According to Wong, Formlabs stands out not only for its professional-grade equipment and materials but also for its deep alignment with dental needs including:

-

Precision and Reliability: Unlike other “dental-specific” printers, Formlabs delivers consistent micro-level accuracy, ensuring appliances fit patients perfectly.

-

Automation and Safety: High automation and built-in safety checks minimize errors.

-

Continuous Innovation: Regular software and hardware updates, paired with responsiveness to customer feedback, optimize resin performance for dental applications.

-

Cost Efficiency: Printing a model from a digital scan costs ~HKD 20 per arch, one-fifth of the price of traditional impression materials, while maintaining comparable quality

"We’ve visited other workshops, and many struggle with inconsistent precision, outdated materials, or poor technical support. Formlabs is the most reliable and hassle-free solution we’ve used, and it’s why we recommend it to peers."

Kin Wong, Chief Dental Technician and Director, Smile Lab

Looking Ahead: From Models To Direct Appliance Printing

Wong envisions a future where 3D printing technology further transforms dentistry. “Currently, we print models and then craft appliances on them. Our goal is to print final end-use appliances like retainers and aligners directly with the precision and flexibility this technology promises,” he says.

“Formlabs provides reliable and efficient digital solutions that help us serve patients faster and more accurately. We look forward to new materials tailored to clinical needs, driving the next wave of dental innovation.”

Kin Wong, Chief Dental Technician and Director, Smile Lab

From boosting efficiency to ensuring quality, optimizing costs to expanding applications, Formlabs Dental’s 3D printing technology empowers Smile Lab to push the boundaries of digital dentistry. By delivering superior patient experiences, Smile Lab exemplifies how technology can transform healthcare.

Explore Form 4B to learn more about printing with Formlabs Dental, or contact a reseller to start printing.