Synergy 3D is a full-service dental lab with a heavy emphasis on digital dentistry workflows and supporting dental customers in adopting digital data collection. Located in Wappingers Falls, New York, but serving the entire United States, Synergy 3D has been able to achieve the following thanks to their focus on digital workflows:

-

A three to five day turnaround on restorations compared to the industry average of two weeks

-

The same output as an analog lab, even with half the staff

-

Fewer remakes and more predictability

-

Half the appointments for dentists delivering dentures and overdentures

“Something that used to take five or six appointments, or multiple remakes from a clinician side, now turns into a two or three appointment affair, which saves us time.”

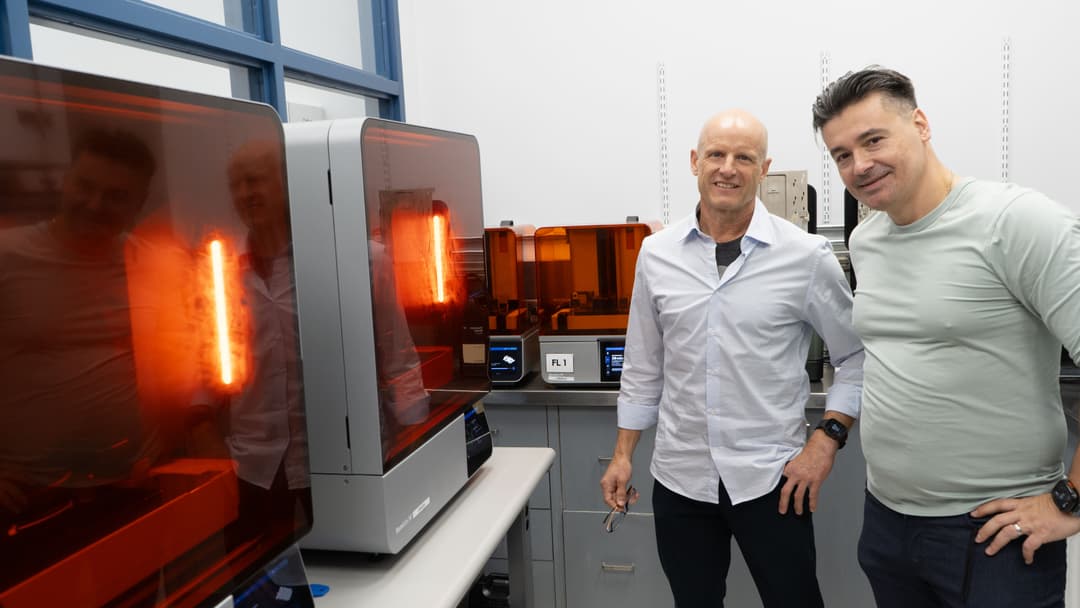

Milos Markovic, Vice President of CAD/CAM and Implantology, Synergy 3D

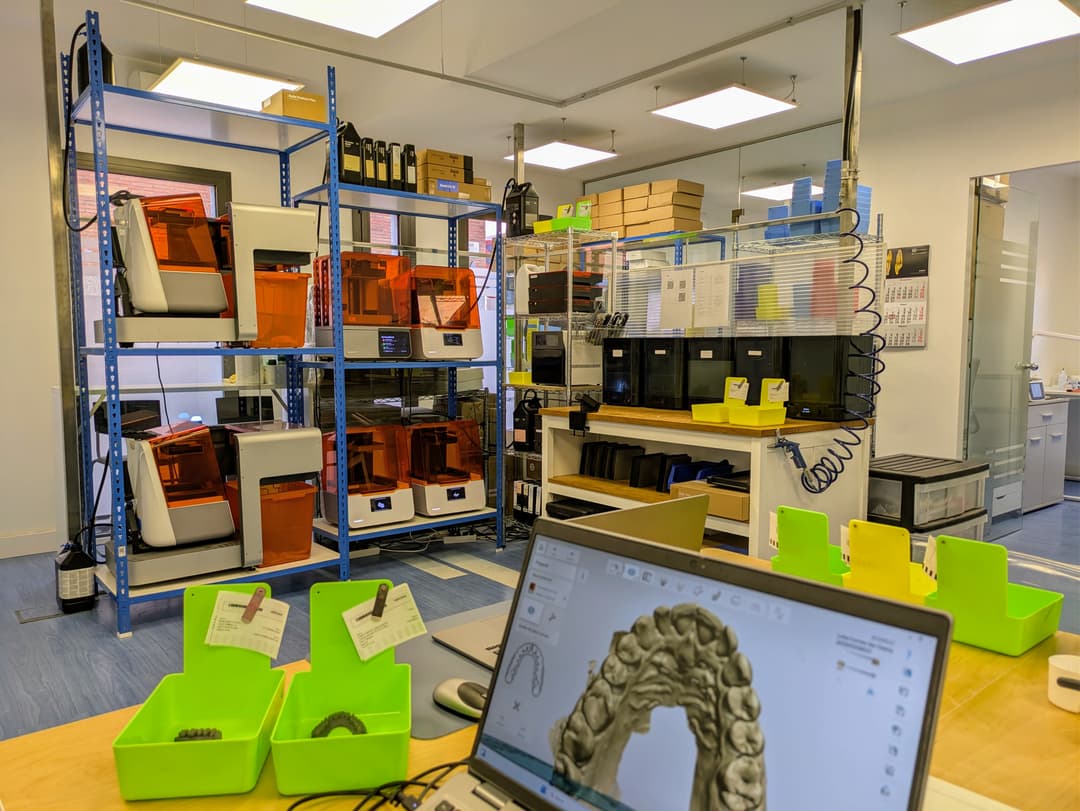

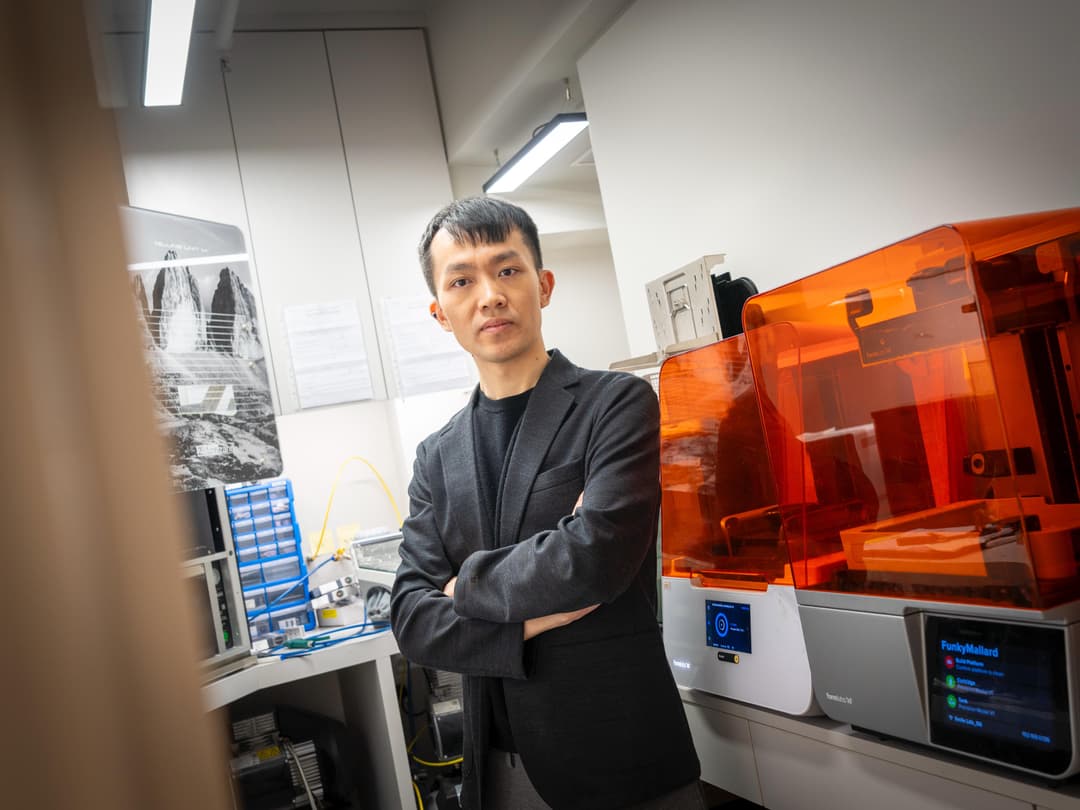

In order to meet throughput and quality standards, Synergy 3D requires accurate, reliable 3D printers. For 15 years, Milos Markovic, Vice President of CAD/CAM and Implantology, has put 3D printers from many manufacturers through their paces, selecting the best printers to meet Synergy 3D’s exacting requirements. Currently, the majority of those printers are Formlabs Form 4B and Form 4BL stereolithography (SLA) 3D printers.

“Over the last year, we really had a chance to observe the Form 4B and Form 4BL. In terms of speed, reliability, print fails, we've just had nothing but success — especially compared to other printers which have multiple mechanical failures weekly or bi-weekly that we have to service, re-calibrate, call support teams… It's really such a stark difference.”

Milos Markovic, Vice President of CAD/CAM and Implantology, Synergy 3D

Get in Touch

Whether you need to produce occlusal splints in-house, or are looking for high-throughput production of dental models, we're here to help. Get in touch with a dental expert to find the right solution for your business.

More Predictability, Fewer Remakes

“When you do things digitally and fewer people manually touch the product, you're much less susceptible to variations and problems or diagnosing problems.”

Milos Markovic, Vice President of CAD/CAM and Implantology, Synergy 3D

At one point, Synergy 3D had 3D printers from Carbon, Heygears, and EnvisionTEC 3D printers alongside Form 2 and Form 3 3D printers. But in the last two years they’ve redone the room, replacing these printers with Form 3Bs, Form 4B, three Form 4BLs, plus a RapidShape and an Origin Two.

When it comes to selecting printers, Markovic says reliability is top of mind. “We have all our printers in the same room. So it's very easy to see which ones are successful and which ones are failing.”

“If I walk in once a week in that room, I'm going to see one of the competitors' printers not working and I'm going to see the Formlabs working in the background. And that's just been an undeniable fact of using these printers.”

Milos Markovic, Vice President of CAD/CAM and Implantology, Synergy 3D

“Since we're doing hundreds of models a day, it's really easy to break in the machine within the first week or a month to really see how reliable it is. If I throw 2,500 models at my machine over 15 days, it's going to give me a pretty reasonable picture of how reliable it is,” says Markovic. This reliability is necessary in order to deliver the volume of cases in the three to five days Synergy 3D promises.

Predictability comes down not just to the reliability of a printer accurately delivering what’s in a build, but also the workflow. Markovic gives an example of an assembly line where 10 people are touching a product; if there’s an issue, it could’ve come from any of those 10 people. But if only three people touch a product in the digital workflow, it’s much easier on a mass-production scale to diagnose the issue.

Automated post-processing solutions Form Wash and Form Cure help to ensure a predictable process, with preset washing times, automatic lifting of parts out of the wash when the cycle completes, and presets for post-curing in Form Cure. Having both fewer steps in a digital process and automated solutions makes consistency easier.

Product Demo: Form 4B Dental 3D Printer

Blazing speed meets unmatched accuracy in the next generation of dental 3D printing. Explore the latest innovations in our webinar.

How Important Is Speed?

“The technology of Form 4B is nothing like the Form 2 or 3. Even though it's still SLA, which blows my mind, the speed is there, the build platform size is there, the reliability is there, the ease of use that was always there is there.”

Milos Markovic, Vice President of CAD/CAM and Implantology, Synergy 3D

Talk to any dental professional about 3D printing and they’ll mention speed. Five years ago, Markovic says that speed was the most important factor, but since then, the speed gap between technologies has closed. “Most printers are now within a reasonable time frame,” he says. Due to this, and the high throughput required by Synergy 3D, reliability is the most important metric, followed by speed. Even if one 3D printer is slightly faster, if it breaks or needs servicing, this is downtime when it can’t be utilized, meaning the overall throughput is less. For this reason, Markovic relies on printers like Form 4B, which were shown to have 99% reliability in third-party testing.

Why 3D Print Models for High-Throughput Production?

As of late 2025, Synergy 3D averages between 100 and 200 cases per day, from single quadrants to full cases (upper and lower models), 98% of which are printed on Formlabs 3D printers. Occasional special requests might include 2,500 sets (5,000 models) in 20 days.

Reliable, scalable production is the only way to deliver this volume, especially with the precision and quality required of restorative dental models.

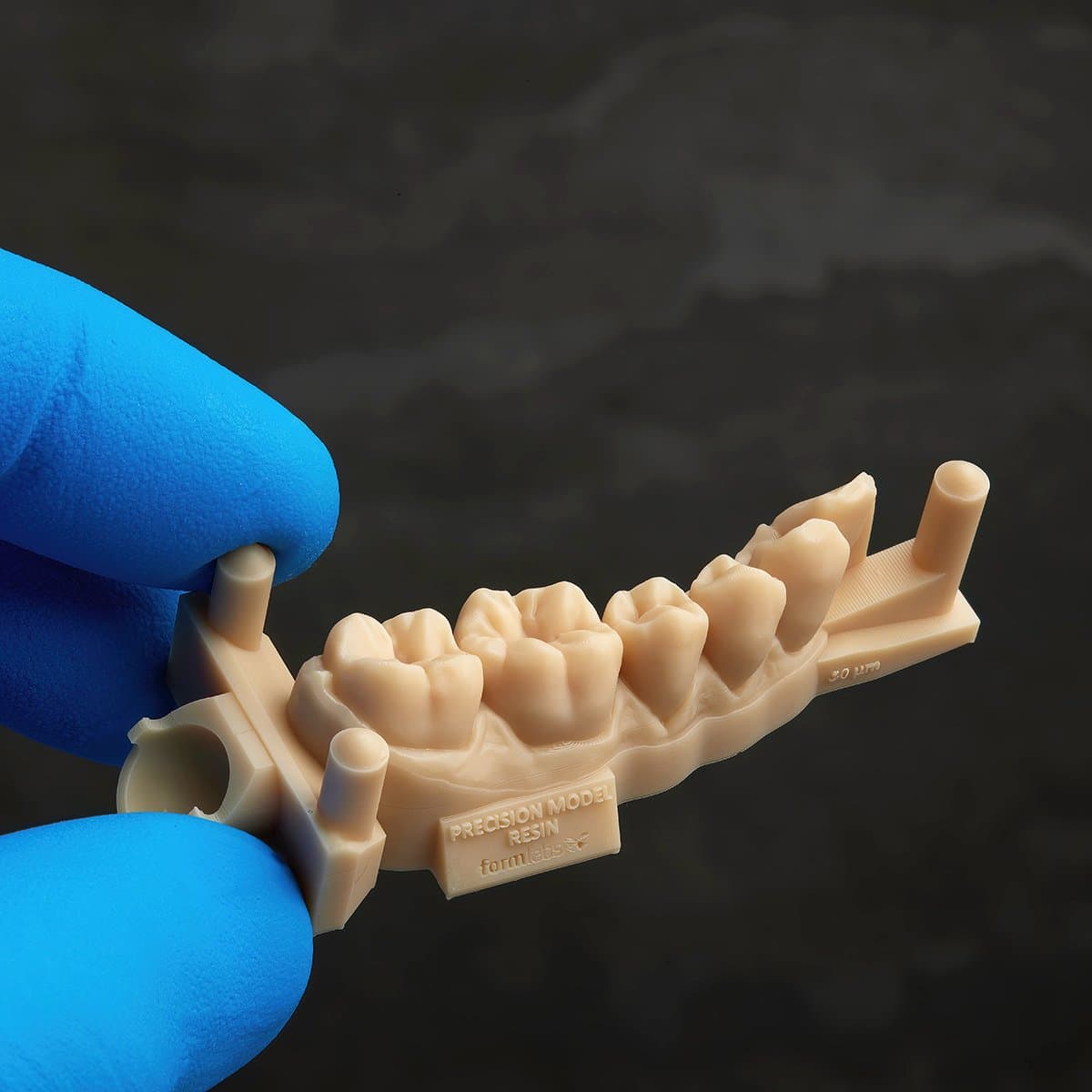

Models printed on Form 4B.

“There's different types of dental stone, different purity, different strengths, but no matter what, the expansion of plaster fluctuates based on water and environmental conditions. So a ton of variation is introduced before production on the case even begins,” says Markovic. In contrast, digital methods are highly precise, without the fluctuations caused by environmental conditions.

“On average, the typical dental stone expansion fluctuation, based on research, is about 140 microns. When a scan gets digitally designed, there's no variation whatsoever. It's a mathematical calculation of the software, and then it goes straight into the printer, whose output I can control down to 25 microns.”

Milos Markovic, Vice President of CAD/CAM and Implantology, Synergy 3D

Highly precise models translate to fewer remakes, and fewer appointments as appliances and restorations have a perfect fit.

Empowering Clinicians

Synergy 3D works with clinicians, laying the groundwork to ensure best practices are followed during digital data collection and helping clinicians shift from impressions to digital workflows. “On the clinician side, it just saves them a ton of time, which in their case, time is literally money,” says Markovic. “They can book more patients within a day, or see that patient less.”

Building streamlined digital workflows has enabled Synergy 3D to help their customers cut denture and overdenture appointments from five to six down to two or three. Additionally, the time savings of digital model production enables the delivery of cases to clinics in three to five days, versus the two weeks that are the industry average.

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part printed on the Form 4B to your office.

Set Up for Growth With Open Material Mode

Open Material Mode (OMM) enables users of Formlabs resin printers to print with any 405 nm resin, expanding the number of resins that can be printed. Markovic cautions against 3D printers that are not open, saying, “If you lock yourself in a system, even if a new resin comes along, you can't use it on that particular printer. So you have to buy another printer and jump into another ecosystem to use that resin.”

“Open Material Mode allows you to have a sort of long-term redundancy, so you're ready for any new material that comes along. It’s a great tool for us to be better prepared for what comes in the future.”

Milos Markovic, Vice President of CAD/CAM and Implantology, Synergy 3D

Denture Bases With Lucitone: A Game-Changer

Synergy 3D prefers using Lucitone for 3D printing denture bases as the material behaves like a traditional denture in the sense that it can be serviced and repaired like an acrylic denture — important for clinicians who need to be able to service dentures for at least five years for insurance purposes.

The main problem facing Synergy 3D was that only a few printers that supported Lucitone, and those that did were very expensive. But, with OMM on Form 4B, Synergy 3D had a cost-effective solution for printing Lucitone.

“Every two hours we're just knocking out dentures and we have no failures,” says Markovic.

Synergy 3D runs 16-20 dentures a day with bases printed on Form 4B in Lucitone.

“The build platform on the Form 4B is pretty competitive to some of the other highly expensive printers. So now we are getting the speed, that reliability, that great finish, and printing dentures on the desk. And this is really what changed the game for us.”

Milos Markovic, Vice President of CAD/CAM and Implantology, Synergy 3D

He adds, “What gave us further excitement is after we actually printed a couple of those Lucitone dentures, we realized that they actually printed faster than some of the DLP solutions, which is insane.”

Lucitone Denture Bases

| Production per day | Quantity Per day (8 h) | Time to produce per print run | Cost of labor per arch | Cost per denture, materials |

|---|---|---|---|---|

| Form 4B | 16-20 | 3 h (2 h printing + 1 h finishing) | $12.11 | $38.46 total (including milled PMMA teeth) $15.96 cost of lucitone base |

| Traditional production | 10-12 | 8 h | $86.00 | $30.11 |

By 3D printing dentures bases, Synergy 3D is saving close to two days of production per denture since they are cutting out pouring impressions, a setup, try in, and then boiling out, packing acrylic, and finishing — all multiplied by about 20 dentures a day.

In the next five years, as the baby boomer generation fully retires, the demand for dentures is going to increase, and Synergy 3D is set to scale to meet the growing demands. Part of this is producing overdentures in two or three appointments versus five or six, giving clinicians an additional option for patients.

“Our goal is to digitize, streamline, and create definitive and strong SOPs so that we can scale the company, providing that three to five day turnaround which ultimately gives the best experience for the patient, and more predictable experience for the doctor and the whole team.”

Milos Markovic, Vice President of CAD/CAM and Implantology, Synergy 3D

As Synergy 3D continues to scale, so, too, will their Form 4B and Form 4BL printer fleet.

Explore Formlabs 3D printers to learn more or contact a reseller to start printing. To evaluate the quality of Formlabs for yourself, request a free sample part.