With today’s launch of Form Wash L and Form Cure L, our automated large-format post-processing machines, Formlabs is excited to bring to market a complete ecosystem for high-volume dental production. From setting up your print to post-processing your part, our suite of products streamline the 3D printing workflow to produce high-quality dental parts around the clock with minimal intervention.

With our new automated large-format post-processing machines and a wide range of dental materials, the Form 3BL ecosystem raises the bar for dependable high-volume dental production.

Announcing the Form Wash L and Form Cure L: Form 3L Ecosystem Demo

Want to learn more about the Form 3L and Form 3BL ecosystem, and the new large format post-processing machines?

In this demo, Kyle and Chris will expain how to navigate the Form 3L end-to-end workflow, including post-processing.

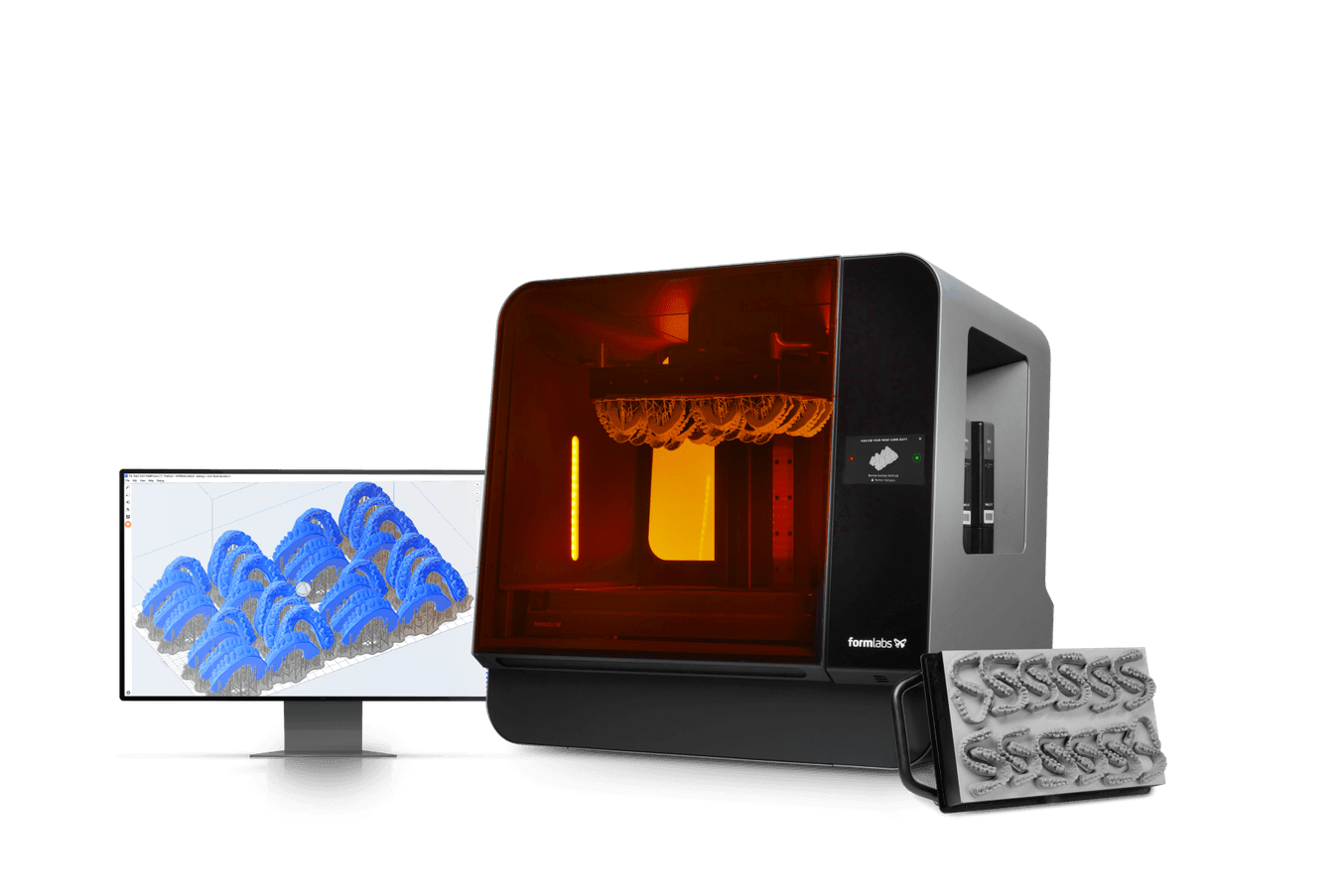

A Large-Format 3D Printer For Batch Production Of Dental Parts

The Form 3BL is at the center of the large-format ecosystem. It boasts an enormous build volume—33.5 × 20 × 30 cm (13.2 × 7.9 × 11.8 in)—enabling you to print up to 120 models in a day, with just a few printer interactions. Rich with features such as a state-of-the-art Light Processing Unit, remote printing, and automatic resin dispensing, the Form 3BL is simple to use and highly efficient.

The Form 3BL is compatible with the majority of our dental materials library, including biocompatible materials manufactured in our ISO 13485 certified facility.

Automated Post-Processing for Large-Scale SLA 3D Prints

All SLA 3D printed parts require washing to remove residual resin and most benefit from post-curing to achieve maximum material properties. Automated washing and post-curing are also critical requirements in many material’s Instructions For Use for producing biocompatible end-use parts.

Similar to our automated desktop post-processing solutions, Form Wash L and Form Cure L are large-format post-processing solutions that streamline and automate this workflow and consistently produce high-quality parts.

Smooth, Clean, High-Quality Parts Every Time

Form Wash L agitates solvent to remove residual resin from printed parts, leaving you with smooth, clean, high-quality parts every time.

Form Wash L is optimized for all Formlabs SLA materials and has pre-programmed recommended wash settings for each material to minimize time with the machine. Already producing dental parts at scale with the Form 3B? Form Wash L supports one Form 3L build platform or two Form 3 build platforms with the included build platform adapter, allowing you to seamlessly integrate into any Formlabs SLA workflow.

Rapid, High-Intensity Curing For Peak Performance

Form Cure L brings parts to their peak dimensional accuracy and properties using heat, UV light, and consistent universal exposure.

Form Cure L contains a reflective inner cavity and rotating glass turntable to ensure UV light reaches all surfaces of your part for a consistent cure, while two 500W heaters bring temperatures up to 80°C in less than 15 minutes for fast, effective curing.

Similar to Form Wash L, Form Cure L also has pre-programmed cure settings for each material to maximize efficiency.

A Complete Ecosystem for High-Volume Dental Production

The Form 3BL ecosystem raises the bar for dependable high-volume dental production. Our suite of products work around the clock with minimal intervention. Alongside our automated post-processing machines and wide range of dental materials, the Form 3BL ecosystem is the ideal 3D printing solution for cost-effective, efficient, dental production.