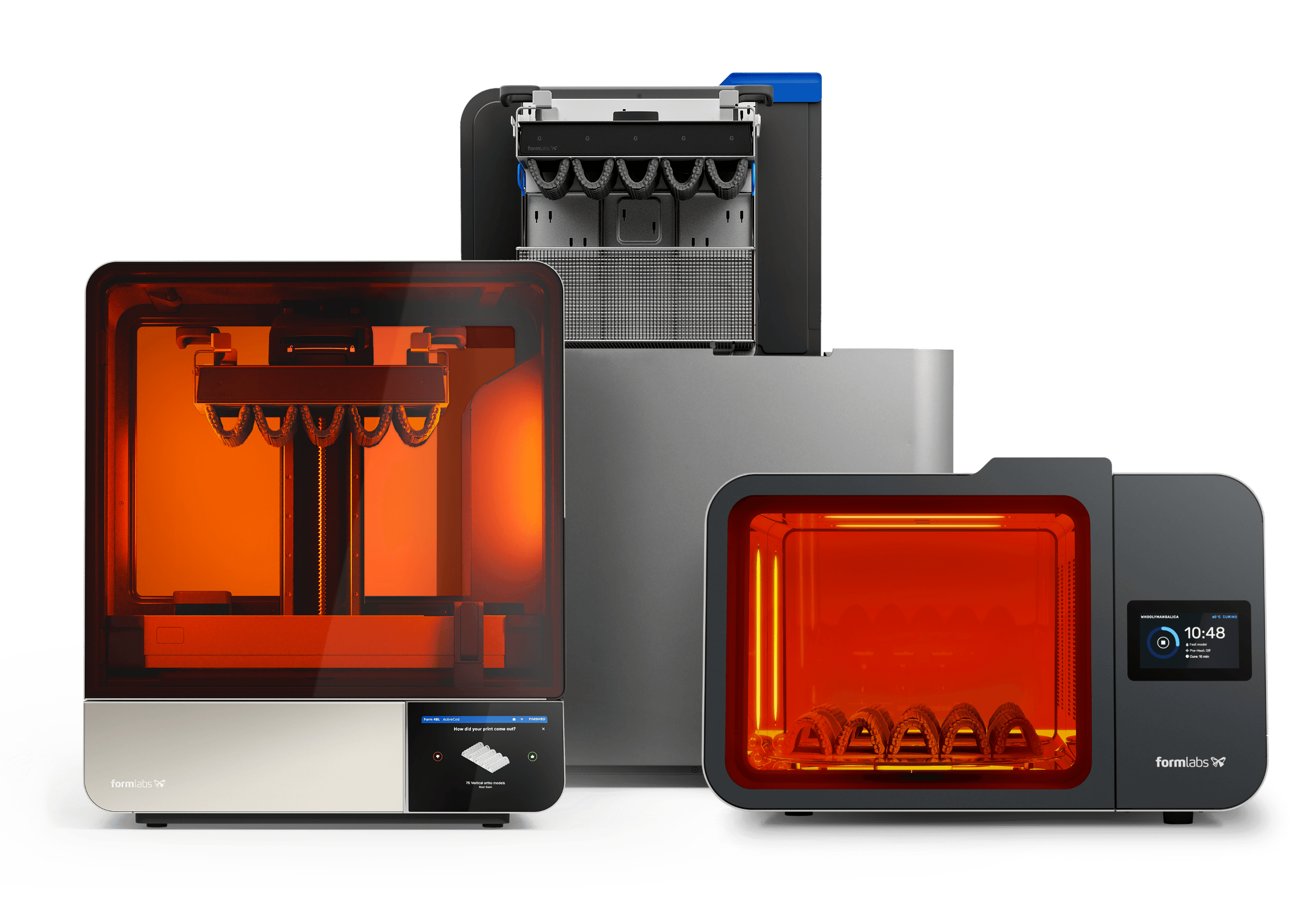

Outstanding Performance for any Dental Application

Blazing Fast Post-Processing

From print to final part in as little as 6 minutes*

11 models

in 9 minutes

5-10

minutes

1-10

minutes

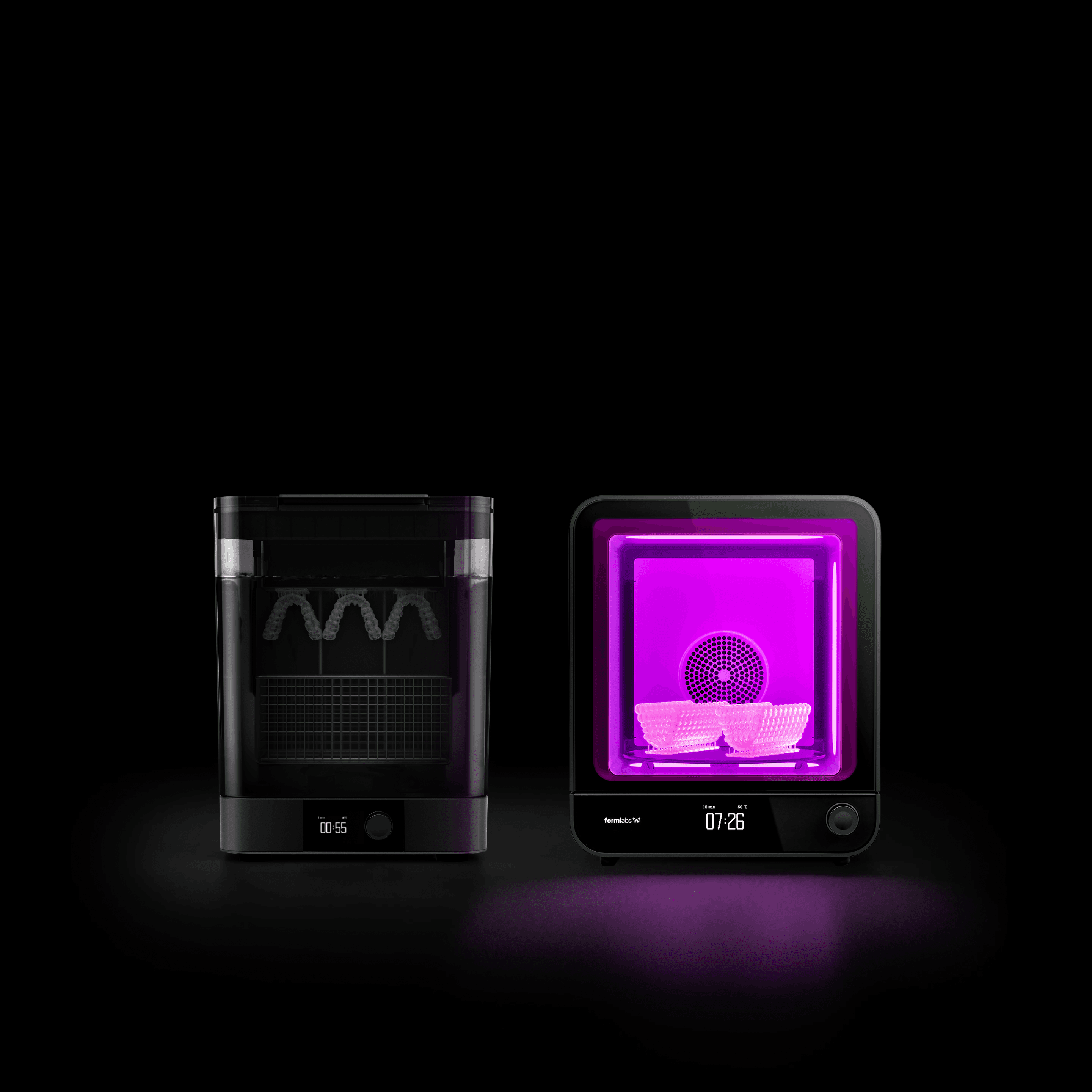

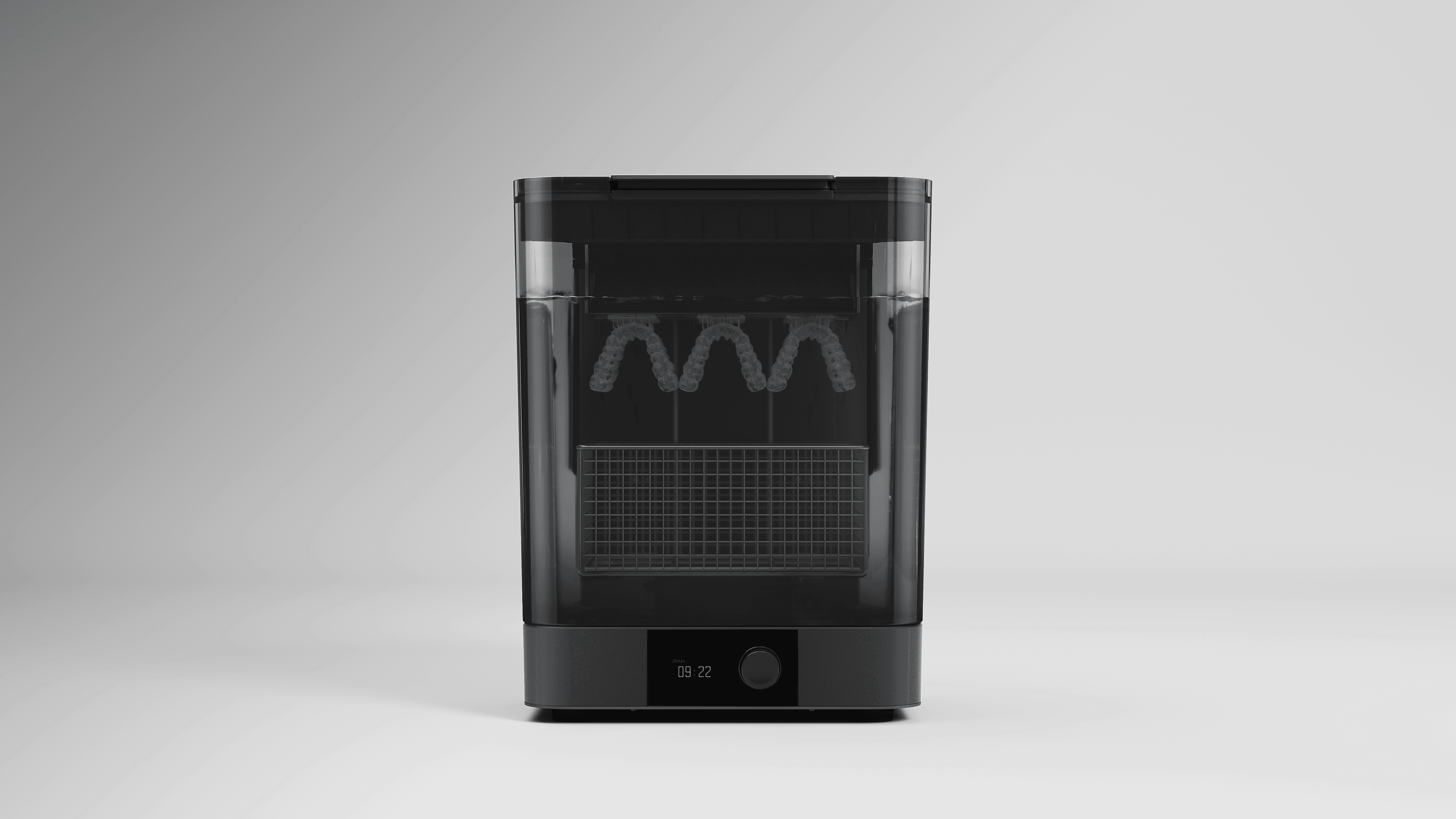

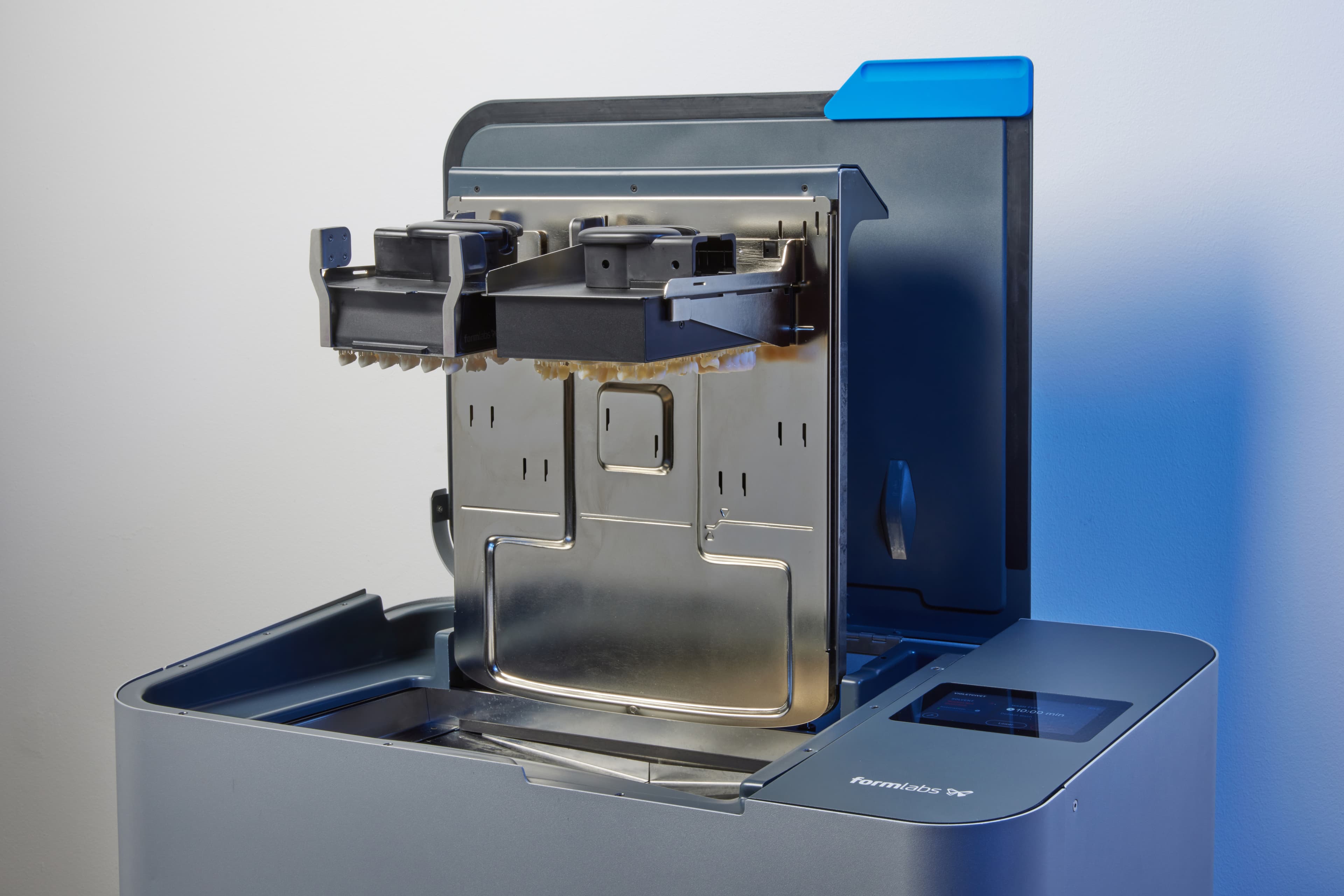

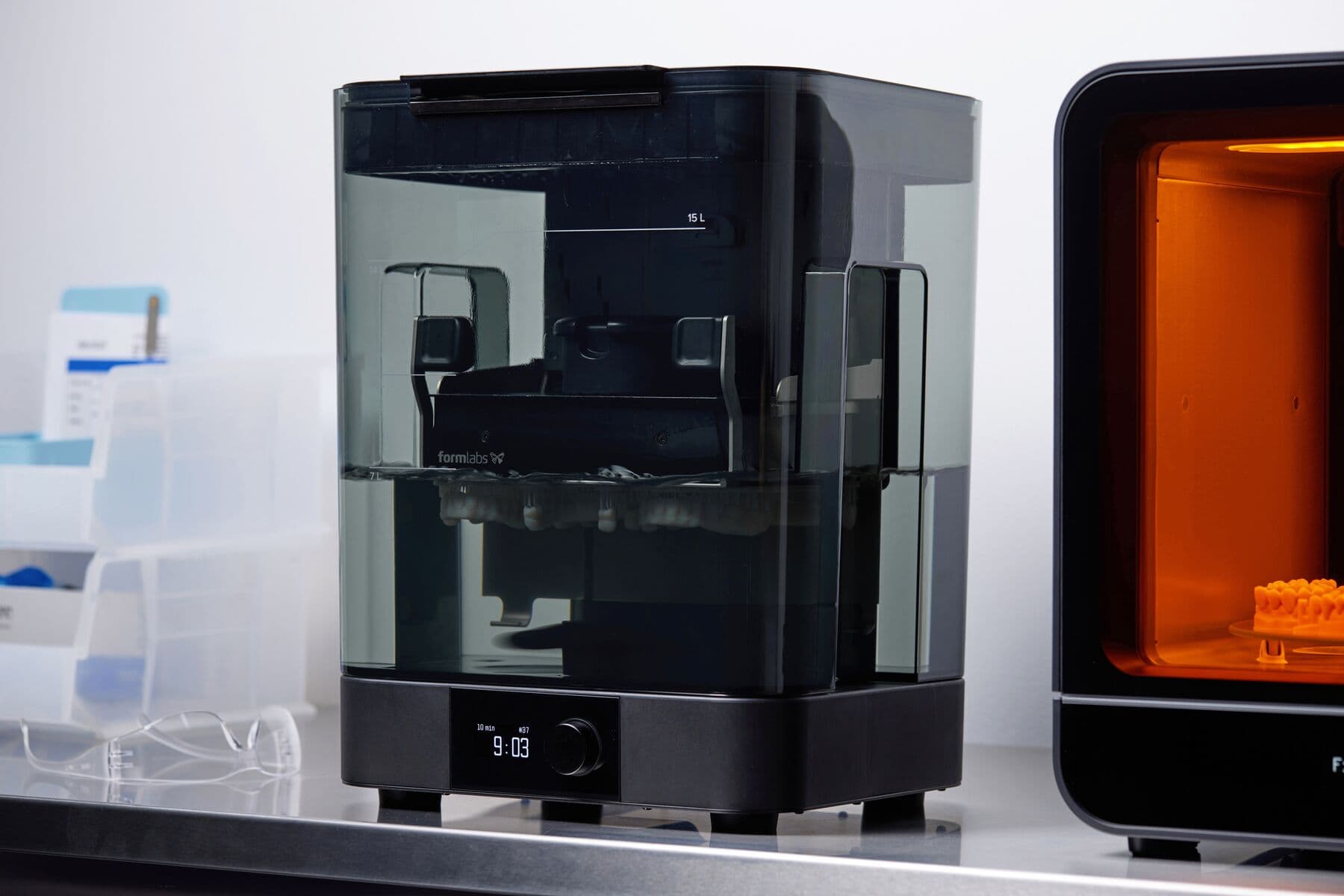

Effortless, Mess-Free Cleaning for Perfect Parts

Washing

How the Wash Works

Form Wash and Form Wash L provide thorough cleaning with powerful agitation to ensure residual resin is completely removed. After the preset wash cycle, the parts are automatically lifted from the bath to air dry.

Washing

Powerful Agitation

Let Form Wash auto-clean your parts faster with powerful agitation to clear every nook and cranny.

Washing

Adaptable to Build Platforms

Seamlessly switch between build platforms with adjustable platform mounts, configurable at various heights and widths.

Washing

Flexible Solvent Volume

Tailor the solvent volume to the size and quantity of your parts. Use lower solvent quantities for smaller parts and builds to increase resource efficiency.

Washing

Compatible With Variety of Solvents

Our recommendation is to use IPA for the best cleaning experience. Alternative solvents such as TPM and Formlabs Resin Washing Solution are also compatible with Form Wash.

Optimal Accuracy in Record Time

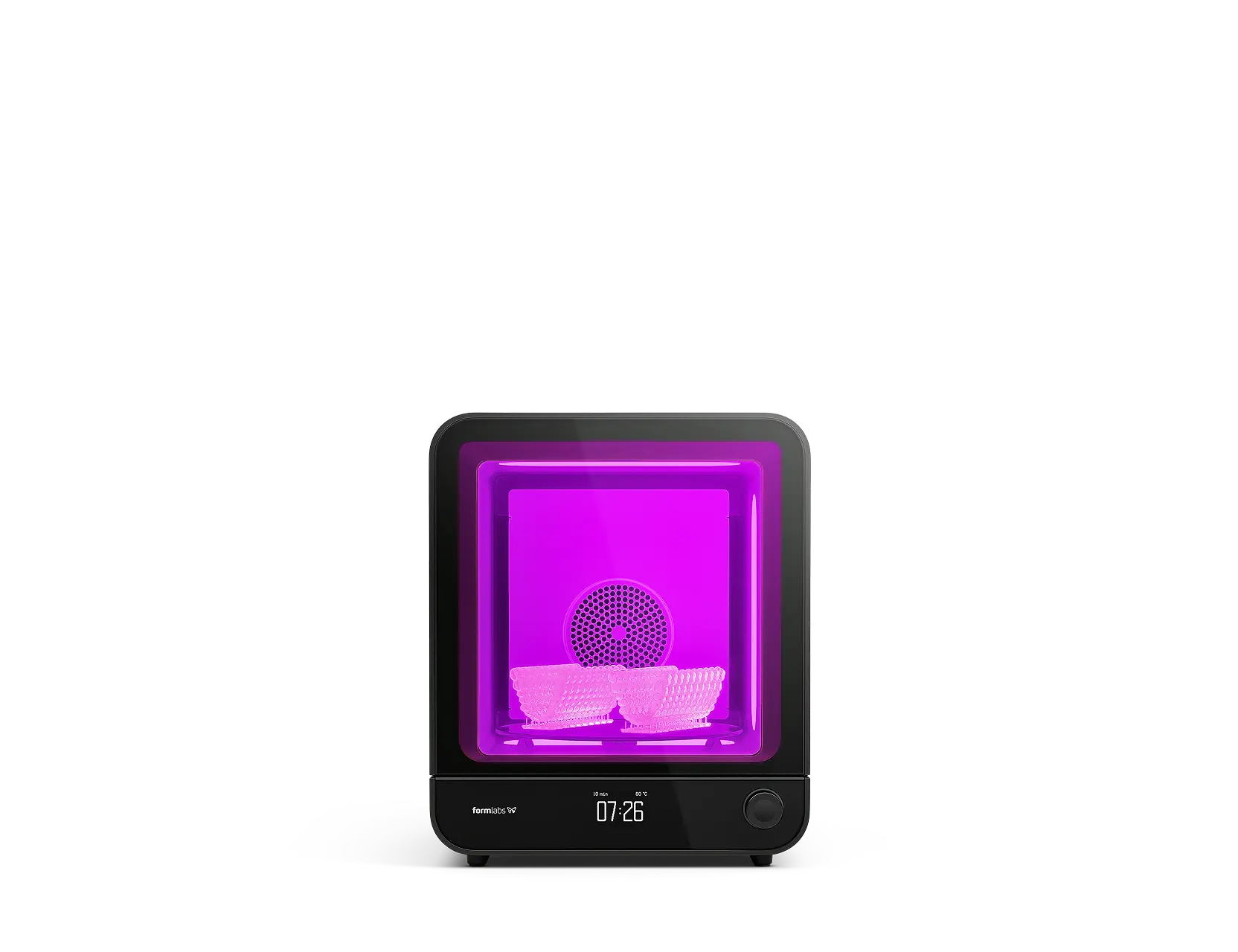

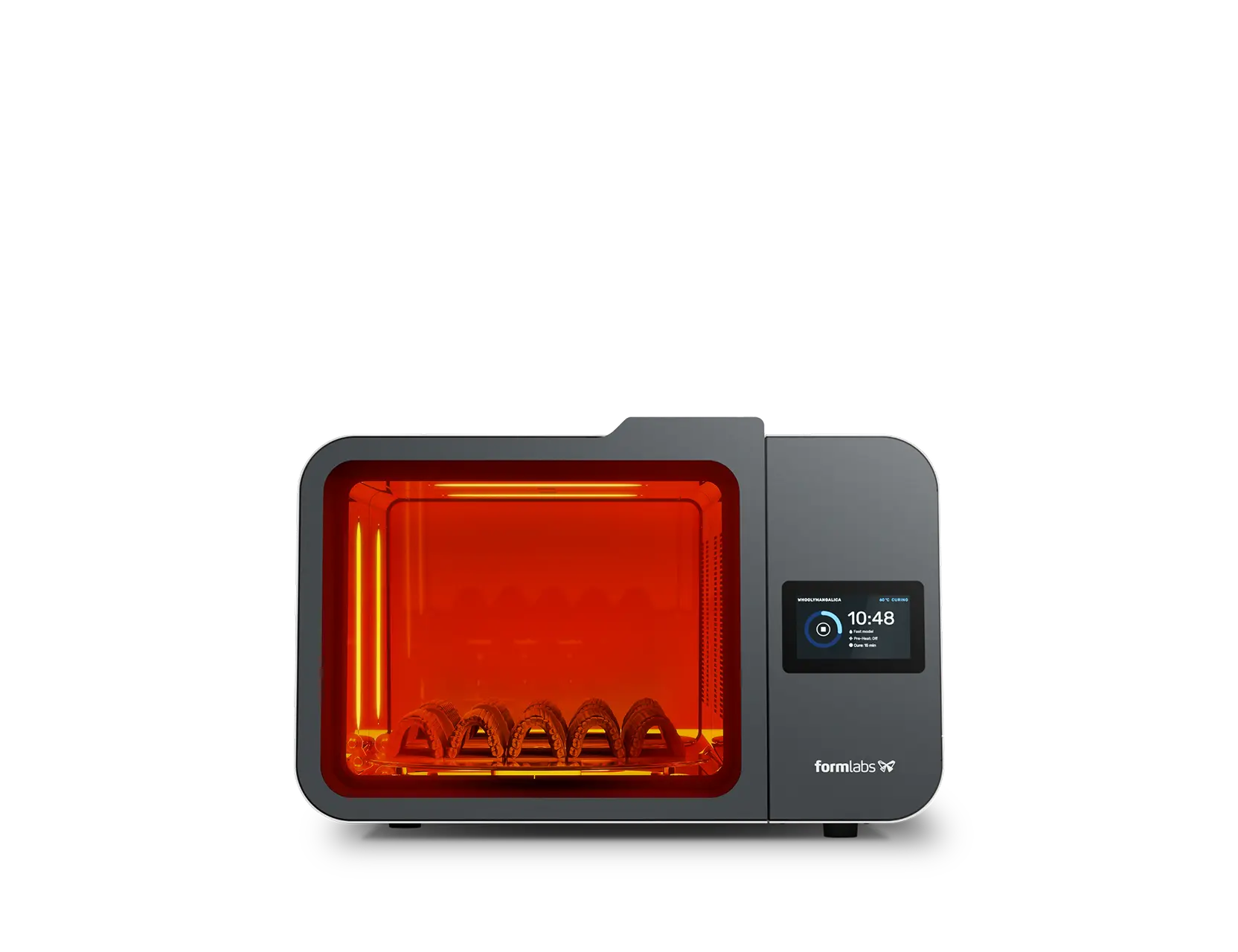

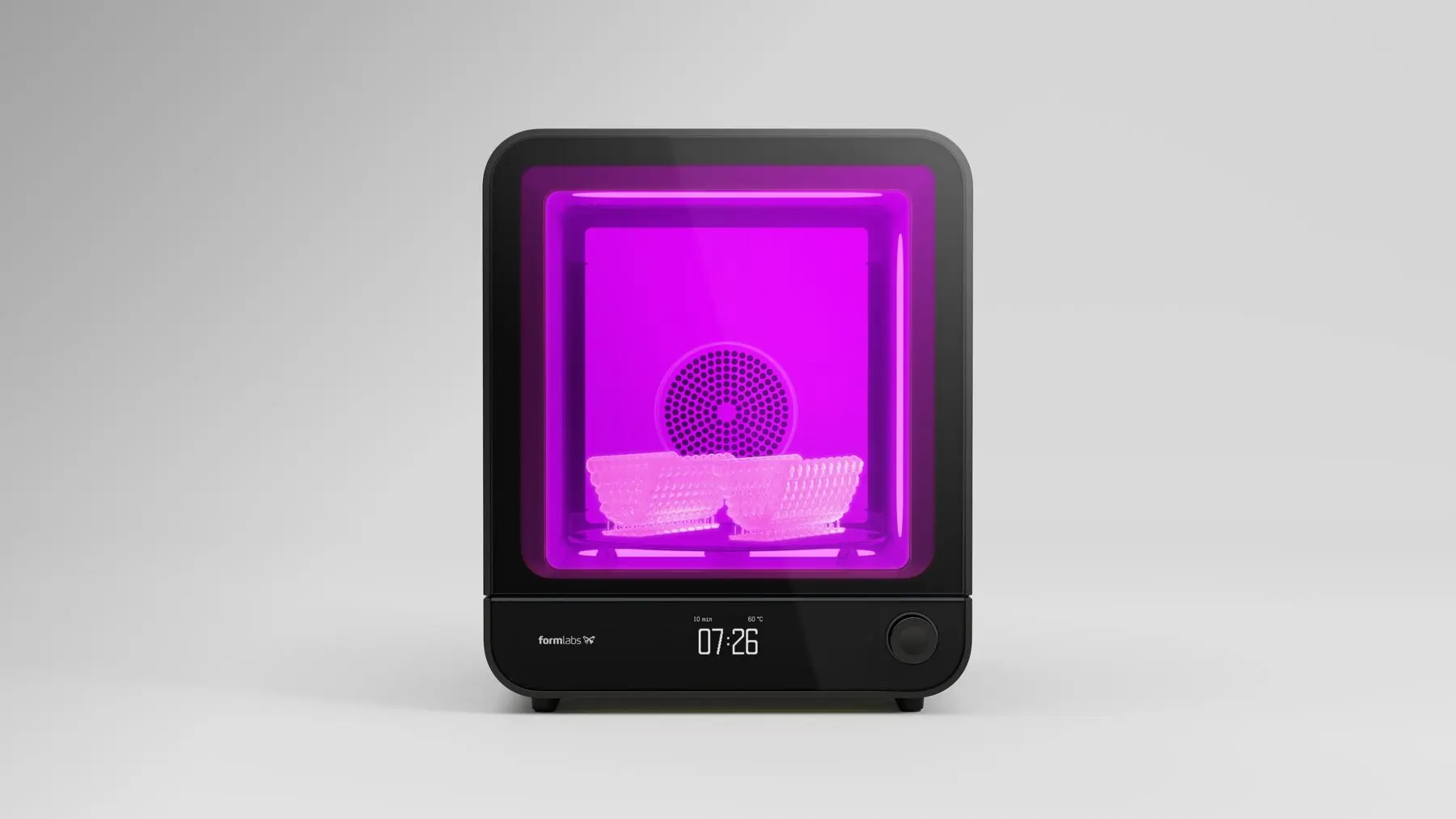

Curing

How the Cure Works

Form Cure and Form Cure L use powerful LEDs, convective heating, and validated presets to achieve optimal mechanical properties with speed and precision.

Curing

Why Post-Curing Matters

Post-curing improves your part on a molecular level. 405 nm light initiates a reaction that cross-links the individual polymers, creating an interconnected, isotropic, and 100% dense final part.

-Safer biocompatible workflow

-Higher accuracy

-Stronger appliances

-Higher surface hardness

Curing

Blazing Fast Curing, Nearly Instant Heat Up

Cure any Formlabs dental material in 10 minutes or less.

Curing

Consistent, Validated Results

Pre-programmed and validated cure settings let you safely cure biocompatible resins, without guesswork.

Curing

Cure 15 Models per Minute

One cure unit serves multiple continuous Form 4B printers. Technicians no longer need to walk away from the unit due to the rapid curing of dental models.

Curing

Easier Than Ever

Sleek new design with an easy to clean glass turntable, eliminating the need to flip parts midway through the curing cycle. The side-opening provides convenient access within a compact footprint, while the high clearance allows for effortless part placement and removal.

Set It and Forget It

To Unlock Peak Performance

Choose your Ecosystem

For Form 4B and Form 4BL

Form 4B Package

Form 4BL Package

* Based on a five minute wash, a quick dry using compressed air, and a one minute cure for model resins.