Model V3 Resin

Usage général

SLA

Détails fins

48 MPa

2,300 MPa

4.8 %

Sélectionner la série d'imprimantes et le volume de résine

| Bulk order quantity (L) | Discount % |

|---|---|

| 1 | 0% |

| 30 | 15% |

| 60 | 20% |

| 120 | 25% |

| 240 | 30% |

| 1,000 | 35% |

| 2,000 | 40% |

| 3,000 | 45% |

- Choisissez Precision Model Resin sur la série Form 4 pour une meilleure précision, une vitesse d'impression trois fois plus rapide et une esthétique améliorée.

Lisez notre guide d’application pour mieux connaître le processus numérique complet et les meilleures pratiques pour réaliser des modèles de restauration sur votre imprimante 3D Formlabs.

Model V3 Resin has been added to your cart.

Why Choose Model Resin?

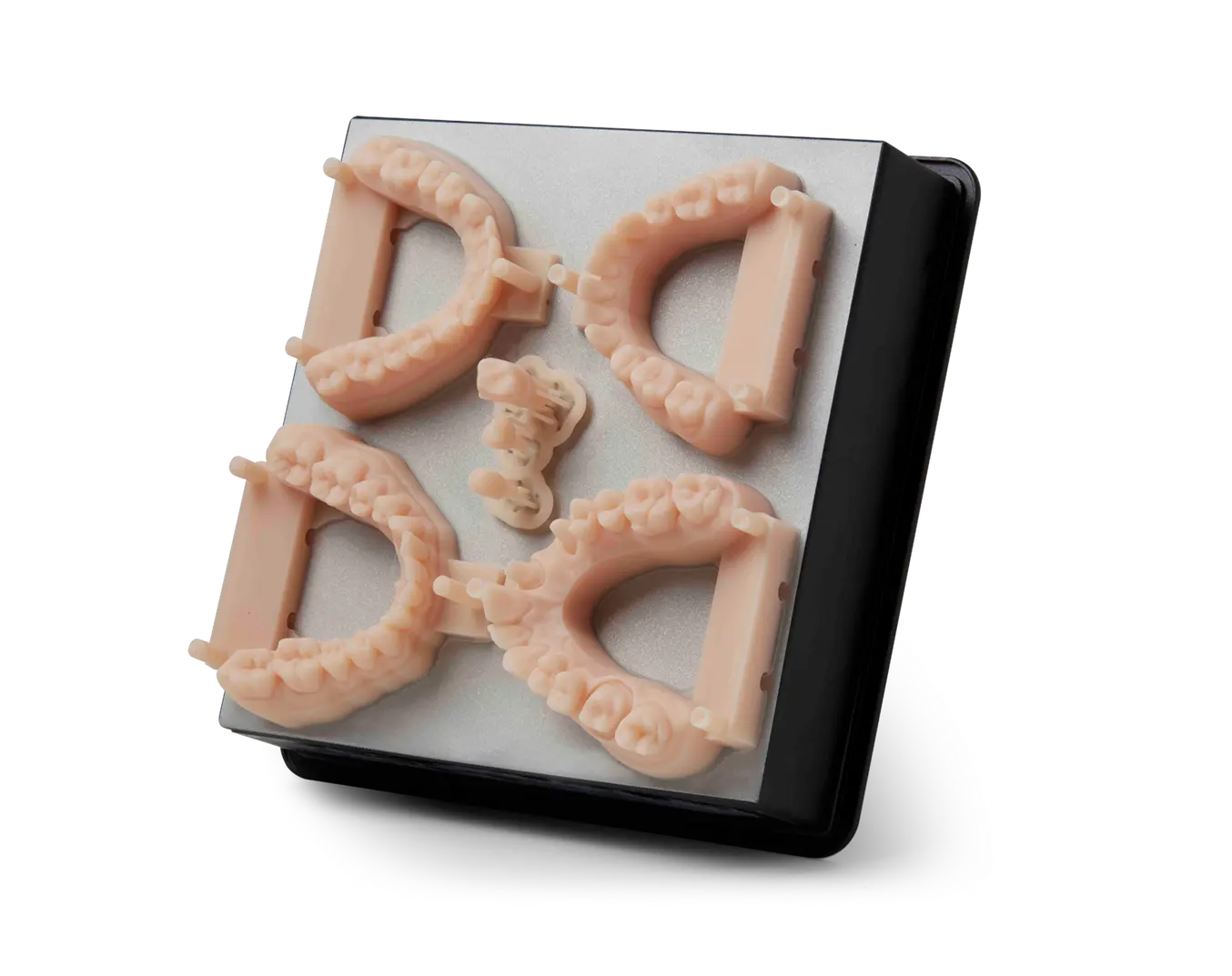

Model Resin enables dental professionals to print models in high volume, easily handle rush cases, and deliver highly-accurate custom fixed prosthetics and implants.

Fast

Produce models in high volume and easily handle rush cases.

Consistent and Reliable

Don’t spend time troubleshooting or redoing cases, get it right the first time.

Accurate

Deliver high-quality results with models you can rely on.

Biocompatibility

Provide the patient and clinician the peace of mind they deserve.

Applications

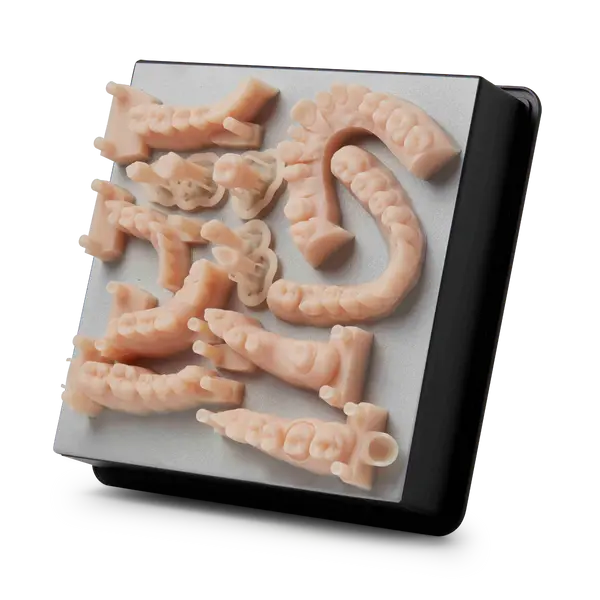

Formlabs 3D printers can quickly produce high-quality solid models, removable die models, and implant analog models with crisp margins and contacts.

Consider Model Resin for:

Material Properties*

Model Resin

Ultimate Tensile Strength

Tensile Modulus

Elongation

Flexural Modulus

Notched Izod

Heat Deflection Temp. @ 0.45 MPa

* Material properties may vary based on part geometry, print orientation, print settings, and temperature. Data for post-cured samples were measured on Type IV tensile bars printed on a Form 3 printer with 100 μm Model Resin settings, washed in a Form Wash for 10 minutes in ≥99% Isopropyl Alcohol, and post-cured at 60°C for 5 minutes in a Form Cure

Post-Processing

Form Wash Settings

10 min in IPA

When using a single wash bucket, residue from previously washed parts deposits on part surfaces. If washing darker-colored materials like Black Resin in the same wash bucket as lighter-colored materials like White Resin or Clear Resin, some color transfer may occur.

Form Cure Settings

5 min

60 °C

There is only one recommended post-curing time for Model Resin V3.