Effortlessly create parts for any dental application. Print any resin with Open Material Mode.

Form4B

Form4B

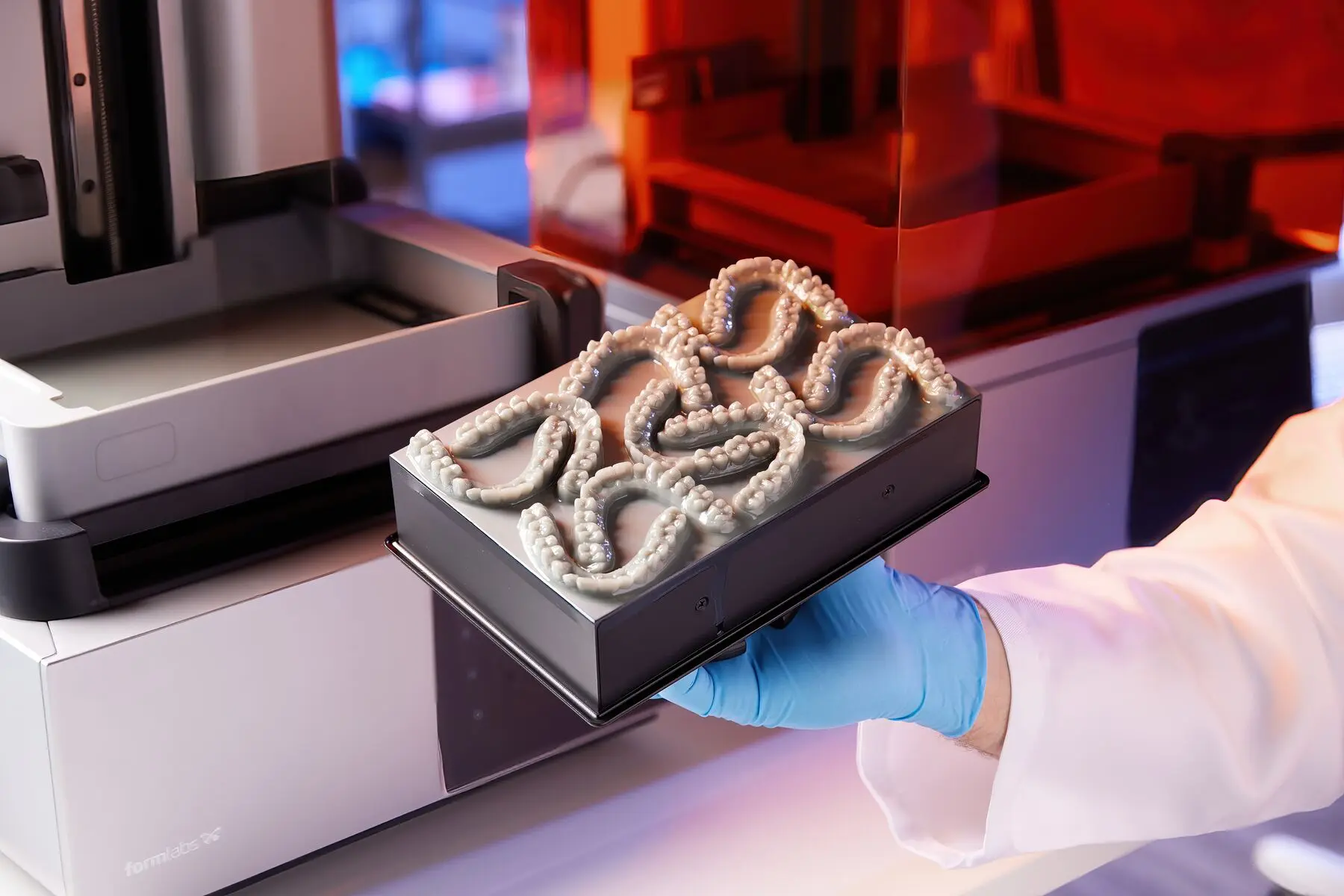

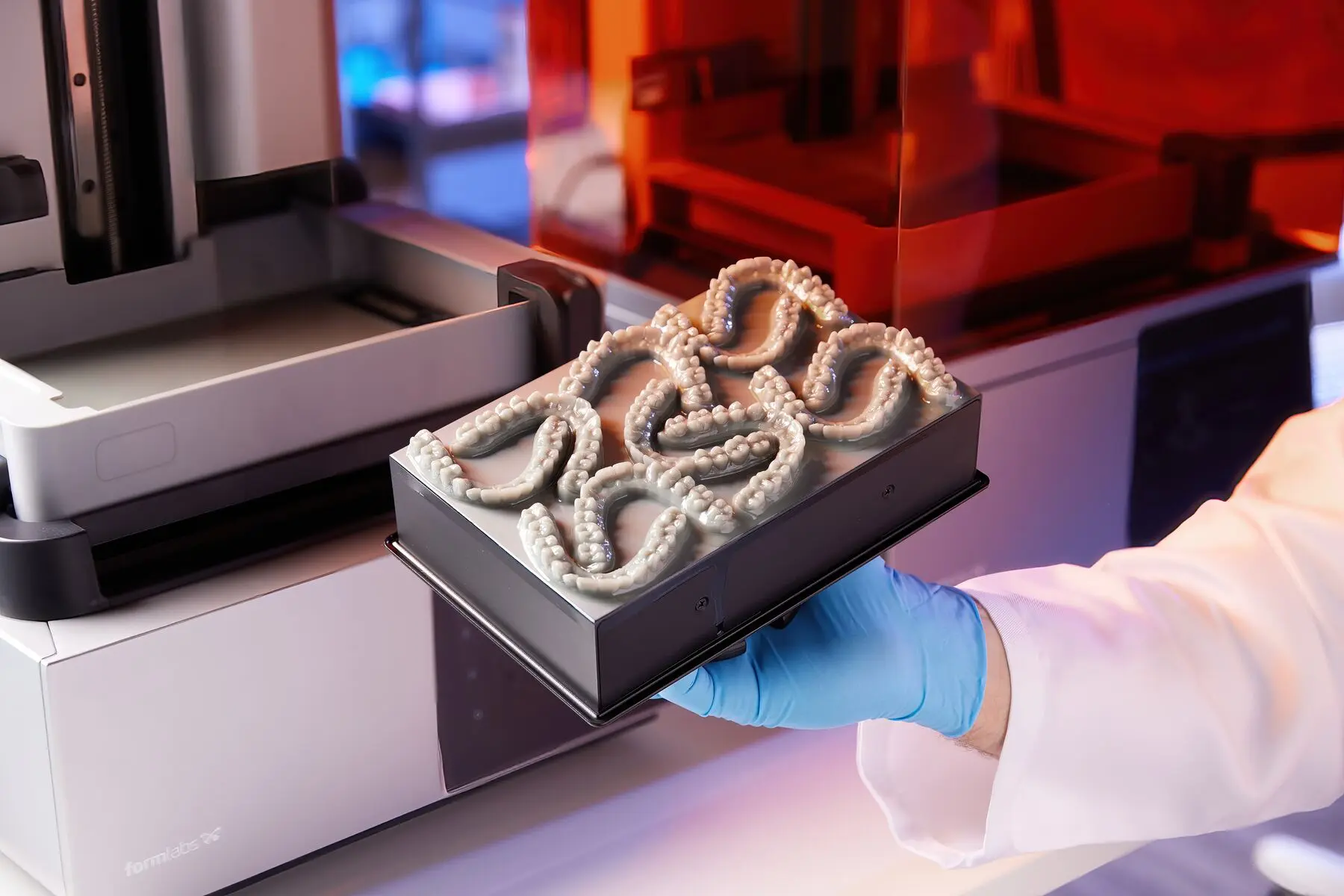

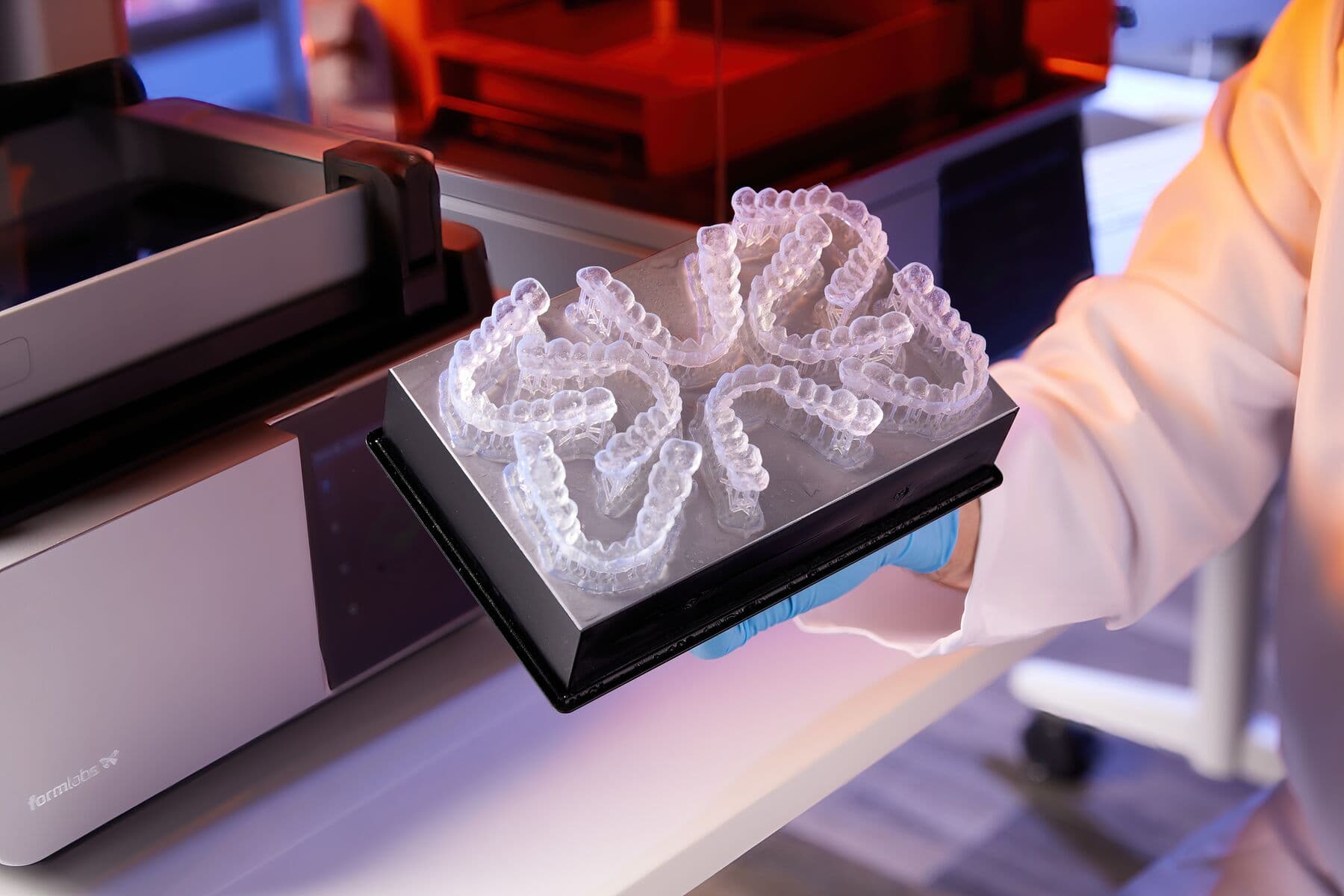

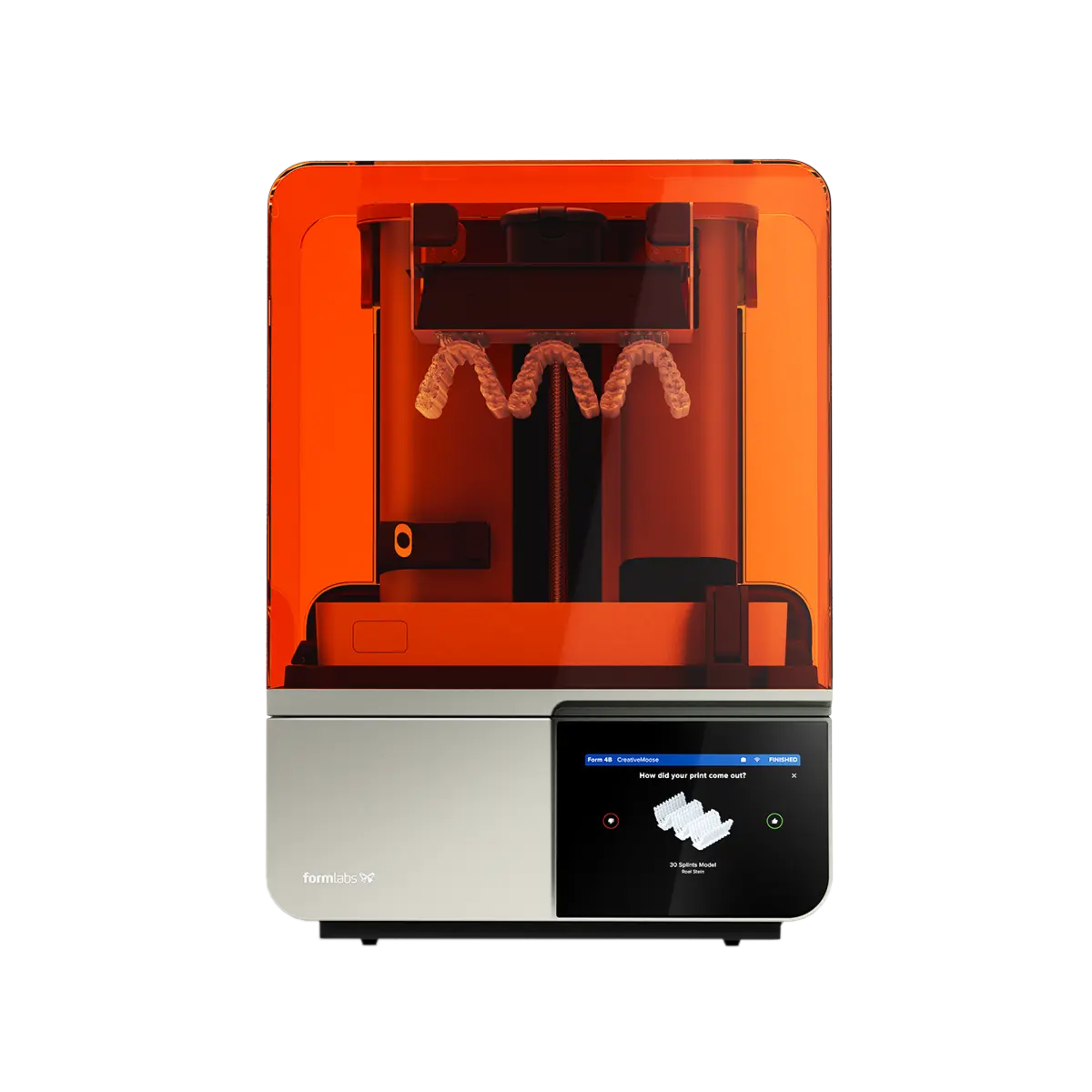

Unprecedented print speeds. Print 11 dental models in 9 minutes.

- 9minForm 4B

44minBenchmark DLP*1h16minBenchmark LCD*1h32minForm 3B+*

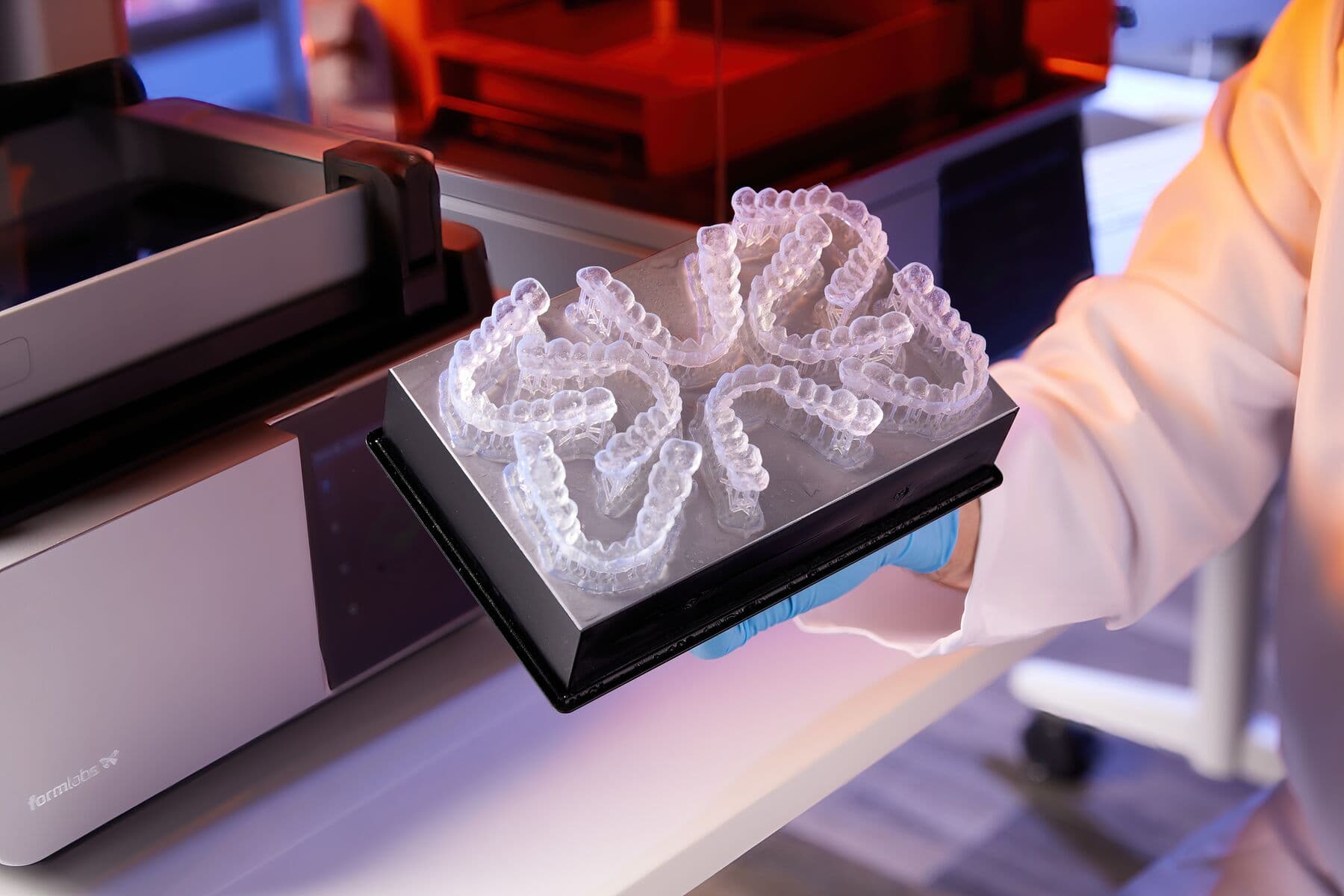

44minBenchmark DLP*1h16minBenchmark LCD*1h32minForm 3B+*11 Clear Aligner Models at 160 μm

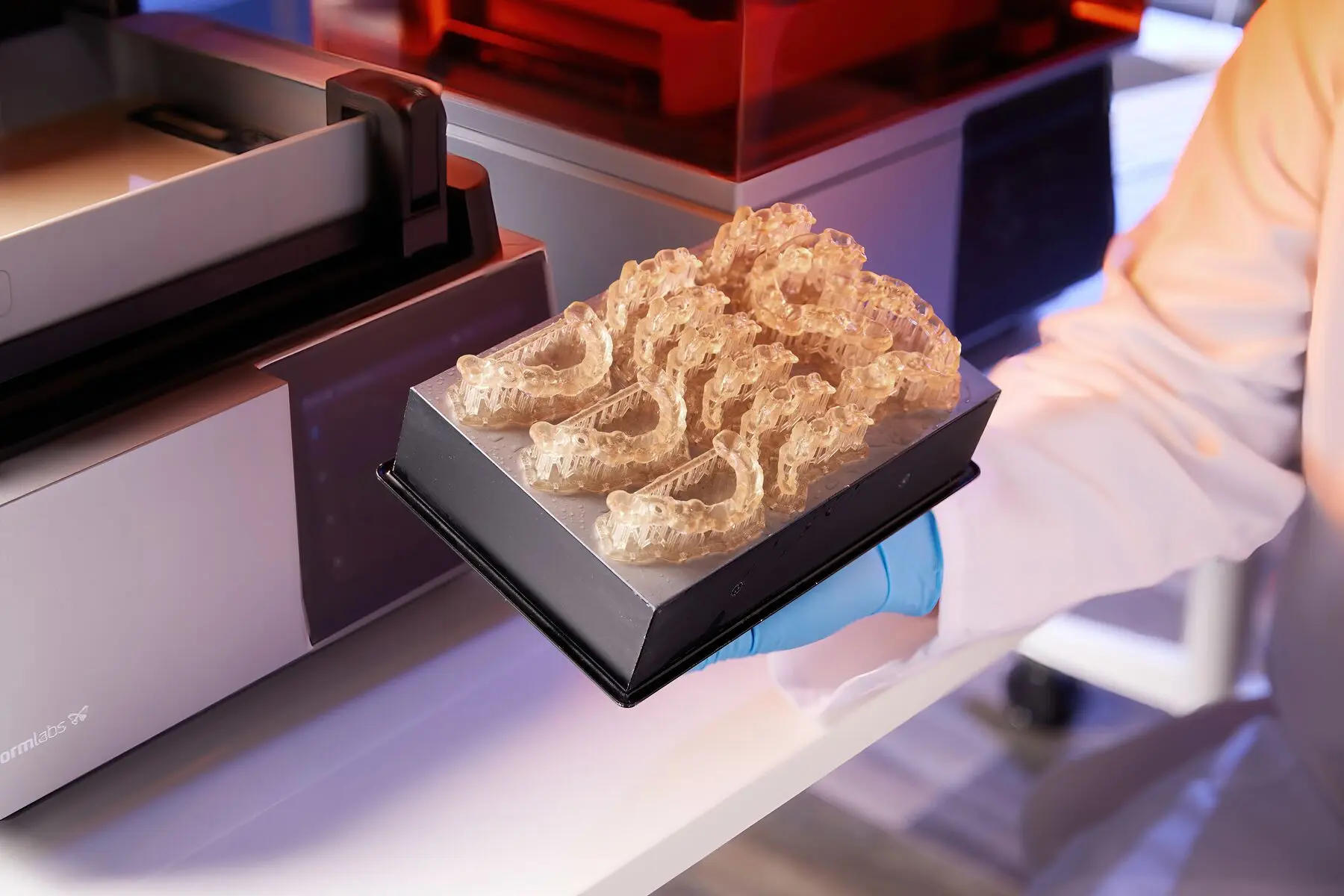

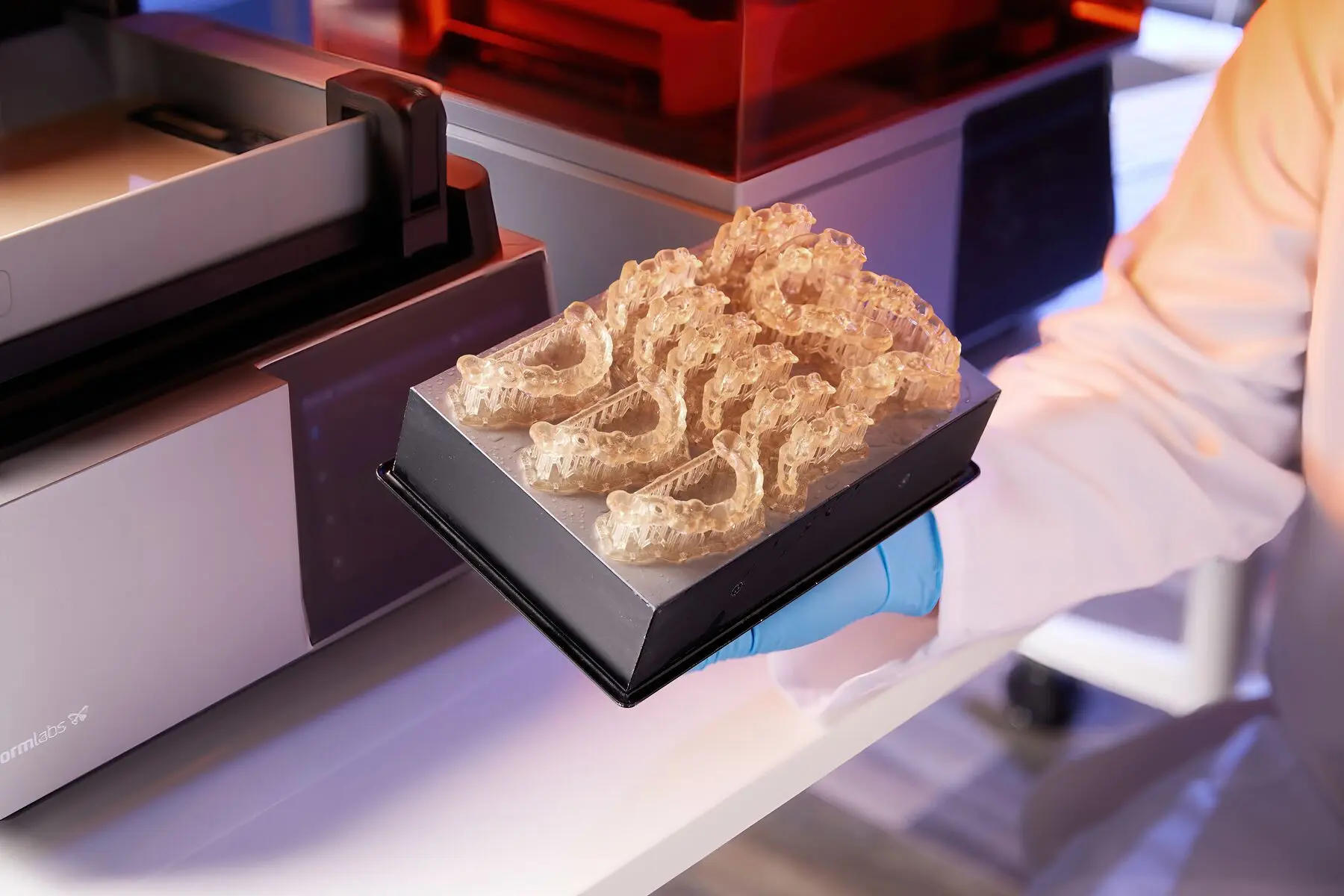

- 49minForm 4B

2h18minBenchmark DLP*3h30minBenchmark LCD*9h30minForm 3B+*

2h18minBenchmark DLP*3h30minBenchmark LCD*9h30minForm 3B+*8 Occlusal Splints at 100 μm

- 1h50minForm 4B

2h42minBenchmark DLP*3h6minBenchmark LCD*8h50minForm 3B+*

2h42minBenchmark DLP*3h6minBenchmark LCD*8h50minForm 3B+*10 Restorative Models at 50 μm

- 48minForm 4B

1h48minBenchmark DLP*2h38minBenchmark LCD*7h12minForm 3B+*

1h48minBenchmark DLP*2h38minBenchmark LCD*7h12minForm 3B+*12 Surgical Guides at 100 μm

- 37minForm 4B

1h46minBenchmark DLP*3h42minBenchmark LCD*5h37minForm 3B+*

1h46minBenchmark DLP*3h42minBenchmark LCD*5h37minForm 3B+*9 All-on-X at 100 μm

- 25minForm 4B

44minBenchmark DLP*54minBenchmark LCD*1h13minForm 3B+*

44minBenchmark DLP*54minBenchmark LCD*1h13minForm 3B+*5 Restorations at 100 μm

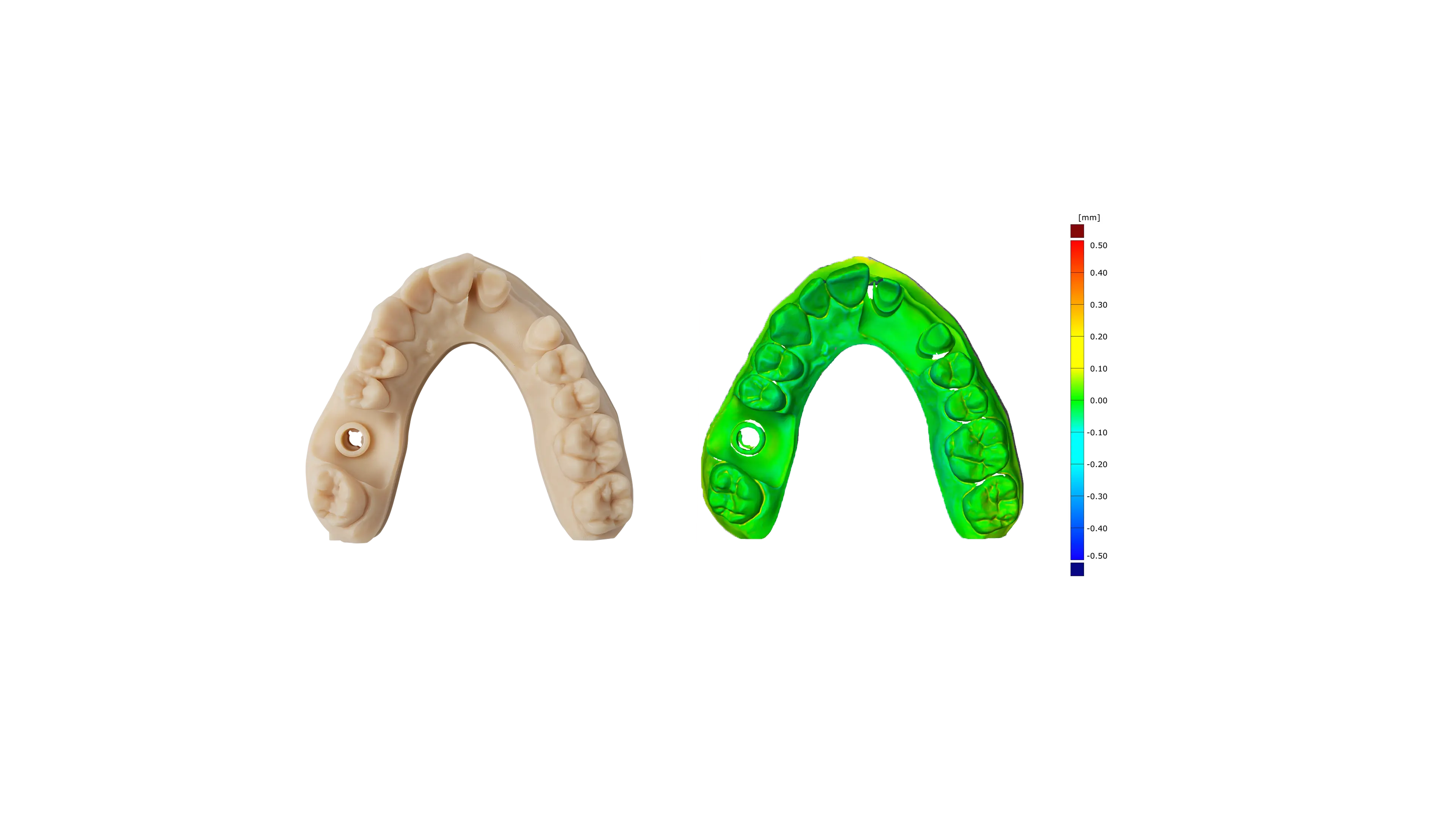

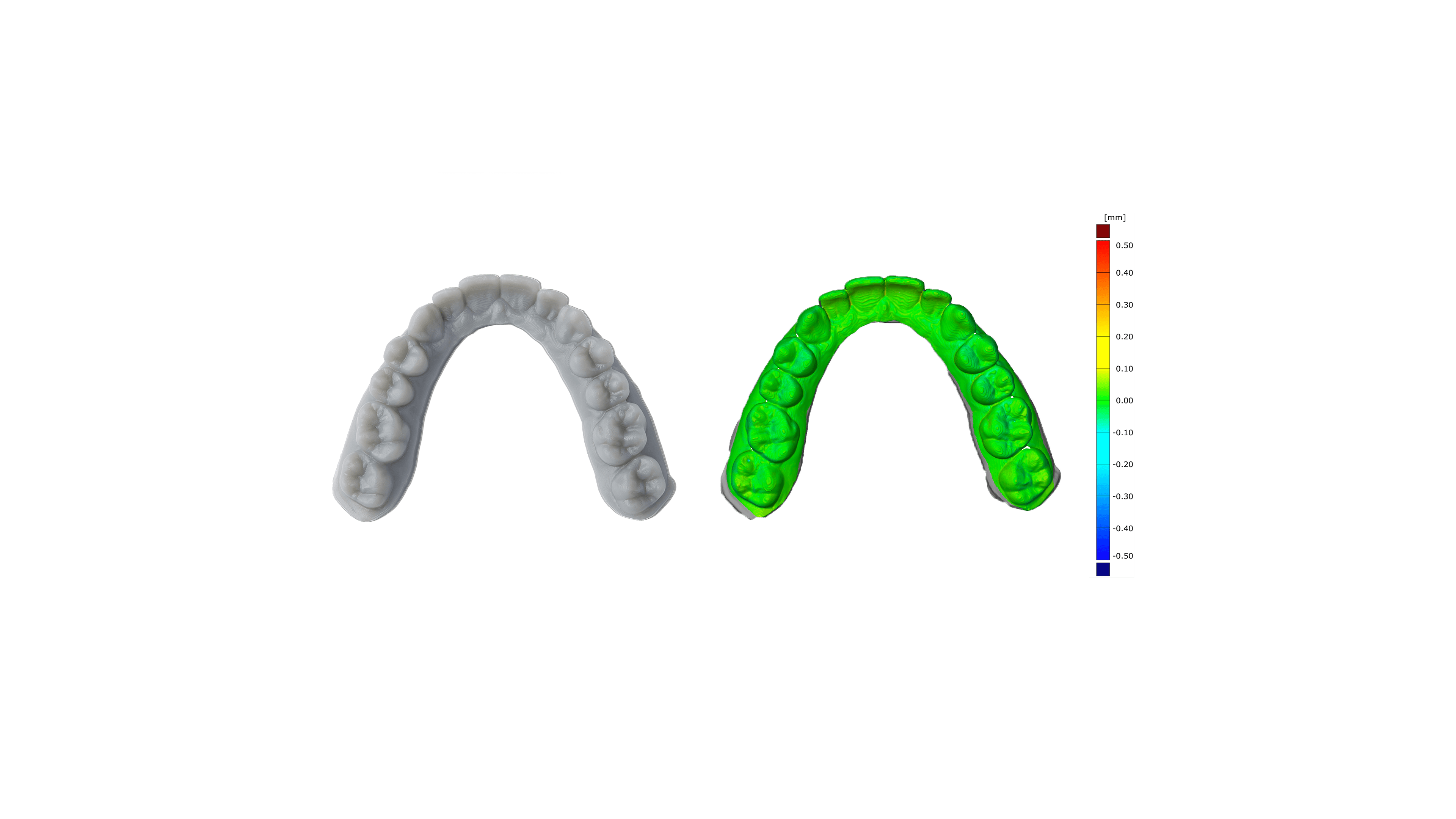

Unrivaled accuracy that matches your commitment to a perfect fit, every time.

Consistently Accurate

Across the build platform

Smoothest Surfaces

Lower peel forces, light touch supports, and 50 µm pixel size with pre-tuned anti-aliasing

Sharpest Details

Highly collimated light and 50 µm pixel size with pre-tuned anti-aliasing for subpixel resolution

95% OF THE SURFACE WITHIN 50 μm OF THE CAD MODEL. 99% OF THE SURFACE WITHIN 100 μm OF THE CAD MODEL.

95% OF THE SURFACE WITHIN 50 μm OF THE CAD MODEL. 99% OF THE SURFACE WITHIN 100 μm OF THE CAD MODEL.Consistently Accurate

Across the build platform

Smoothest Surfaces

Lower peel forces, light touch supports, and 50 µm pixel size with pre-tuned anti-aliasing

Sharpest Details

Highly collimated light and 50 µm pixel size with pre-tuned anti-aliasing for subpixel resolution

Precision Model Resin50 μm 95% OF THE SURFACE WITHIN 100 μm OF THE CAD MODEL.

95% OF THE SURFACE WITHIN 100 μm OF THE CAD MODEL.Consistently Accurate

Across the build platform

Smoothest Surfaces

Lower peel forces, light touch supports, and 50 µm pixel size with pre-tuned anti-aliasing

Sharpest Details

Highly collimated light and 50 µm pixel size with pre-tuned anti-aliasing for subpixel resolution

Fast Model Resin160 μm

“We have found that we can eliminate appointments for patients because we can produce models so quickly on our Form 4B.”

Dr. Lisa Alvetro,

DDS, Orthodontist at Alvetro Orthodontics

“Form 4B is truly a game changer for our entire production, because now we can produce parts two to five times faster than before. The surface, the small details, the edges, the fit—everything feels more precise. Overall, the printer's speed, efficient movements, added sensors and camera, and larger build platform are fantastic. With Formlabs’ ecosystem, our 3D print success rate is now close to 100%."

Stephan Kreimer,

MDT, Kreimer Dentallabor

“Form 4B is a no-brainer, especially if you're looking at trying to implement a high-quality 3D printer in your practice for the first time. It's definitely an affordable printer and it's going to save you money in the long run versus a traditional analog process.”

Dr. Christopher Baer,

DMD, Baer Dental

“The validated Formlabs ecosystem makes 3D printing scalability easier in our lab. All our technicians, even those with no prior experience with similar technologies, have successfully adopted its use, efficiently integrating digital technology.”

Alan Alves,

Director, Smileep

“What is absolutely amazing with Form 4B is the accuracy of the printing. Because the perception is that the prints are near to zero deviation, zero error between the CAD file and the 3D print. And I can assure you that it is not a common experience with other printers. The fit with the sleeves, it's absolutely amazing.”

Dr. Antonino Cacioppo,

DDS, PhD, Prosthodontist

“The team and I have been blown away by the Precision Model Resin and the speed at which it prints. My metal department has to screw implant screws into models we make and the threads often do not hold. This issue is non-existent in the new model material. If I had two to three Form 4Bs, I could double our production”

Shawn Simpson,

CAD/CAM Technician, Hybridge Implants

The intuitive workflow that transformed digital dentistry. Now up to 5x faster.

- 1

Import your model and prepare your print.

- Automatic print setup based on indication

- Convert scan files to 3D printable models with Scan to Model

- Seamless integration with scanners and CAD software

- 2

Load a material and click print.

- Validated print settings

- No-hassle cartridge and tanks

- Automatic resin dispensing

- 3

Remove, wash, cure.

- Quick release part removal

- Automatic part cleaning

- Fast post-curing with peak material properties

- 4

Finish your part.

- Light touch supports for quick, clean support removal

Low Force Display™ (LFD)

The Power Behind Form 4BLow Force Display™ (LFD)

The Power Behind Form 4BUnmatched reliability. Stop coming back to failed prints.

Form 4B was measured to have a 98.7% print success rate by an independent global leader in product testing. Read a complete description of the test methodology and see the results in our white paper.

Unmatched reliability. Stop coming back to failed prints.

Form 4B was measured to have a 98.7% print success rate by an independent global leader in product testing. Read a complete description of the test methodology and see the results in our white paper.

Get started immediately

with our best-in-class 3D printing resources.

Dental Service Plan (DSP)

Premium 3D printing support, made for dental. Includes personalized onboarding, unlimited access to dental experts, replacement parts, and hot swaps.

Formlabs Dental Academy

Your Learning Hub for Digital Dentistry. Master any workflow with our in-depth library of tutorials,guides,

and more.

Speed That Scales

Powered by the same groundbreaking LFD technology, Form 4BL can print more than 100 models per hour with up to 3x fewer interactions than Form 4B, so you can increase efficiency and reduce labor costs.

The Form 4B Ecosystem

Complete Your 3D Printing Experience

Form 4B