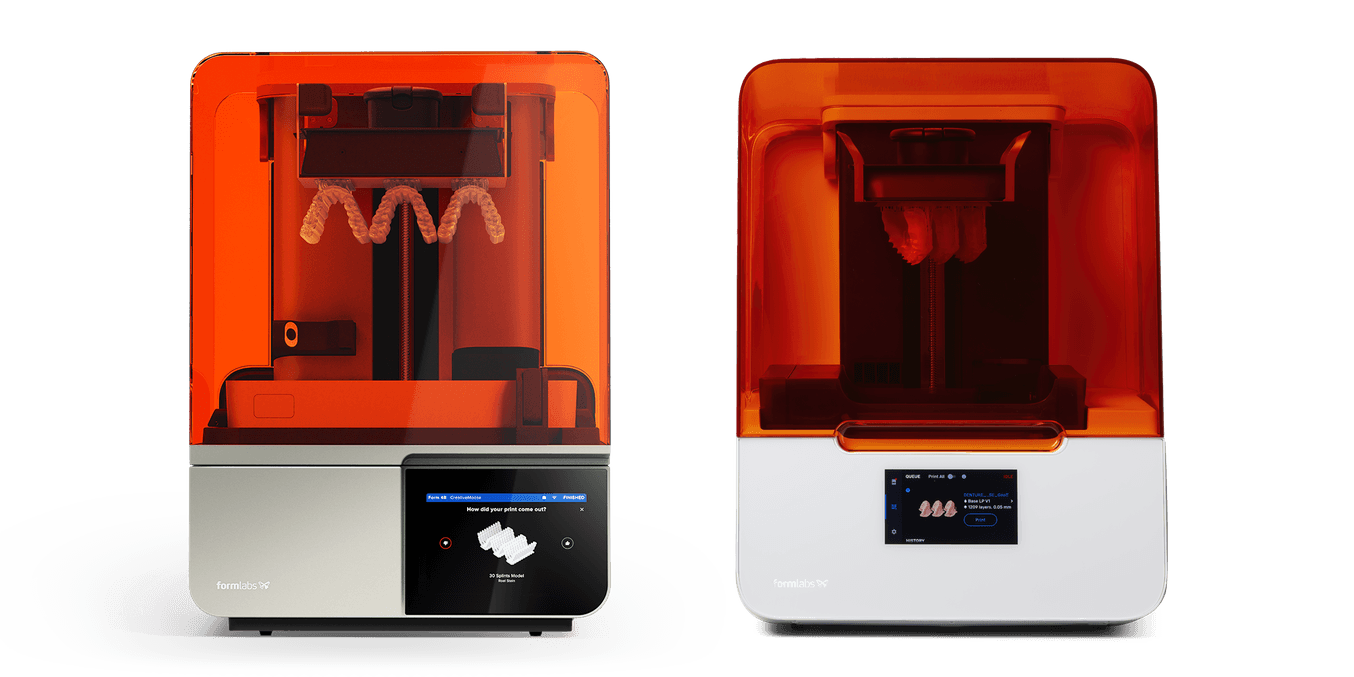

The Form 4B Ecosystem

Complete Your 3D Printing Experience

Discover how you can improve your productivity, print quality, and workflow, as well as reduce costs and lead time by upgrading to Form 4B from Form 3B or Form 3B+.

Improvement

form 4 vs. form 3

Speed improvements enable same-visit appliance delivery or more efficient production.

“I can print models in six minutes. That means this is approaching the point where models can be printed almost as fast as we can scan a patient."

Dr. Christopher Baer, DMD, Baer Dental

Read the Story

“We have found that we can eliminate appointments for patients because we can produce models so quickly on our Form 4B.”

Dr. Lisa Alvetro, DDS, Orthodontist at Alvetro Orthodontics

Read the Story

*Due to the larger print surface of Form 4B, more parts can be printed in one print job.

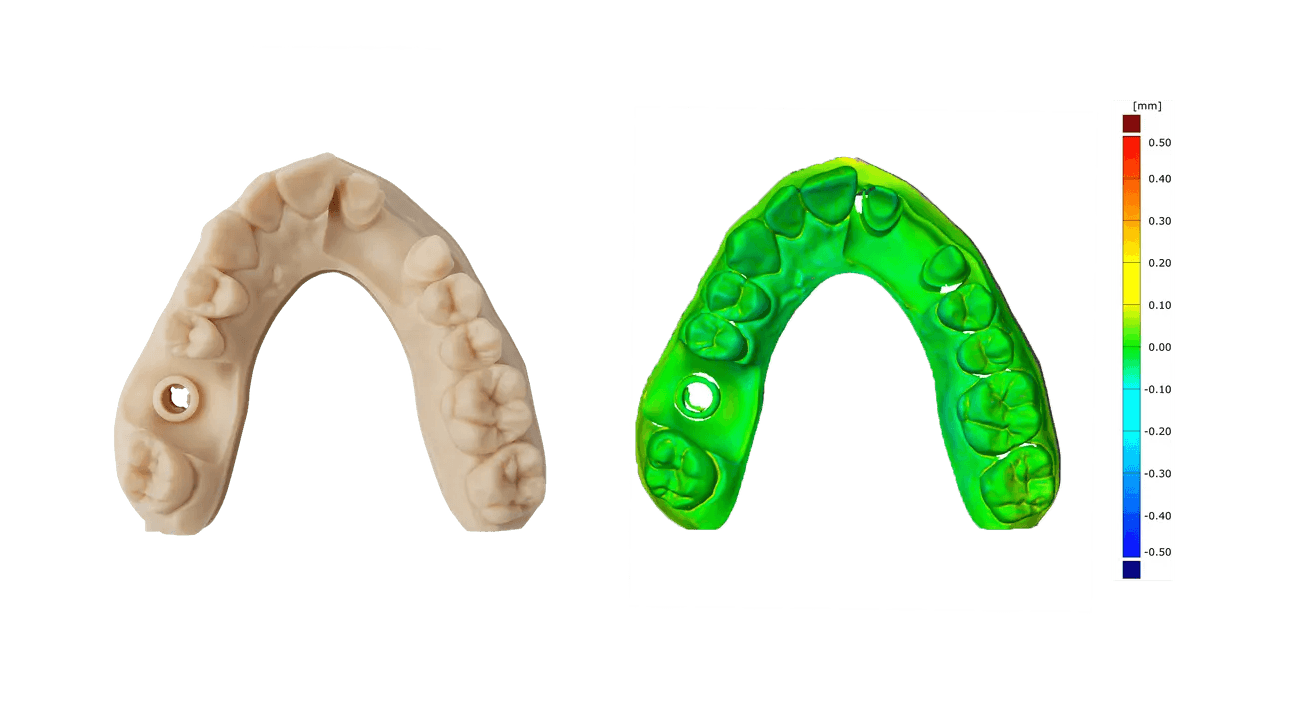

Matches your commitment to a perfect fit, every time.

“Consistent print quality with great surface accuracy makes this printer an excellent choice for dentistry. The surface comparison yielded some of the best results I have ever measured on a 3D printer.”

Stephan Kreimer, MDT, Kreimer Dentallabor

Read the Story

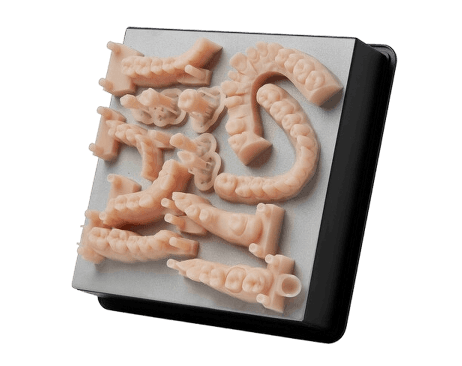

Faster print speed, increased accuracy, finer features, and improved aesthetics at a lower cost.

15+ materials for dental applications, including biocompatible resins.

“We have a printer that is super fast, it has great resin options for every single indication in dentistry, and it comes at an affordable cost.”

Dr. Ahmad Al-Hassiny DMD, Institute of Digital Dentistry, IDD

Substantially lower operating costs thanks to cost-effective materials and long-lasting consumables.

If you handle 20 aligner treatment cases per month (20 models per case), you'll save $3000 per year.

Minimize upkeep costs and waste with long-lasting consumables.

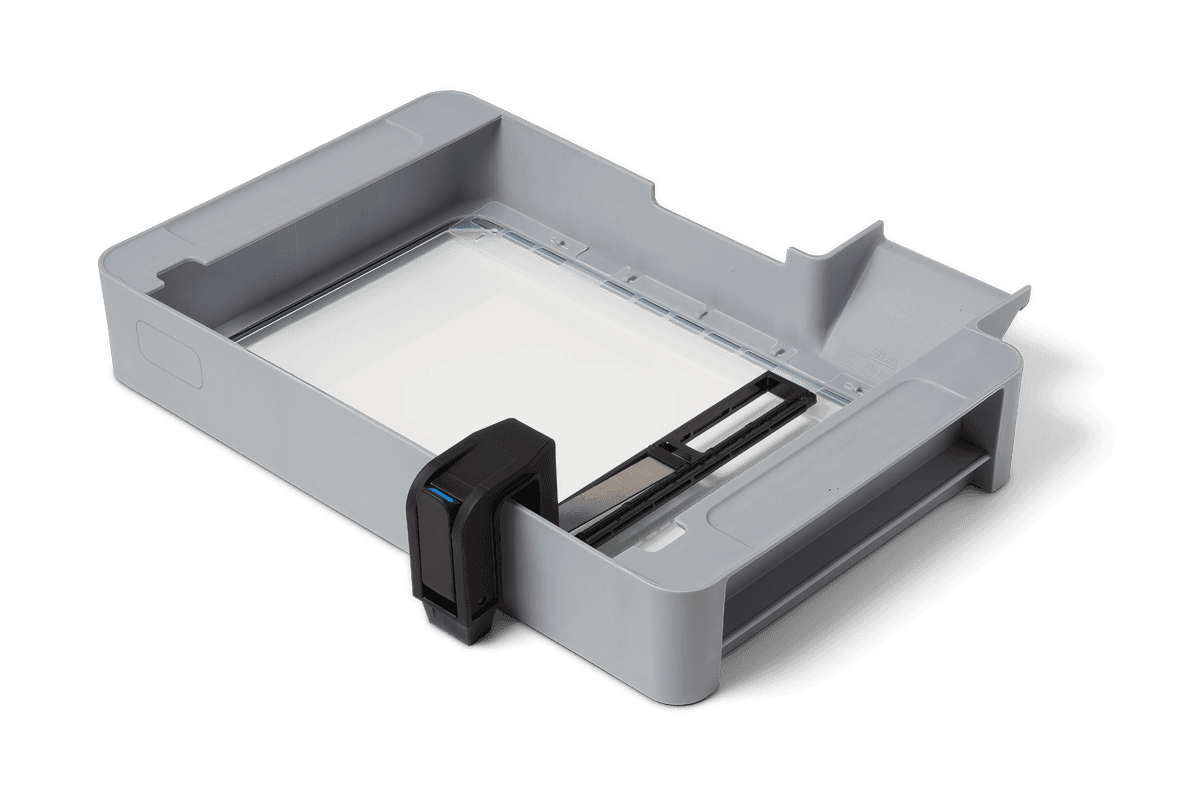

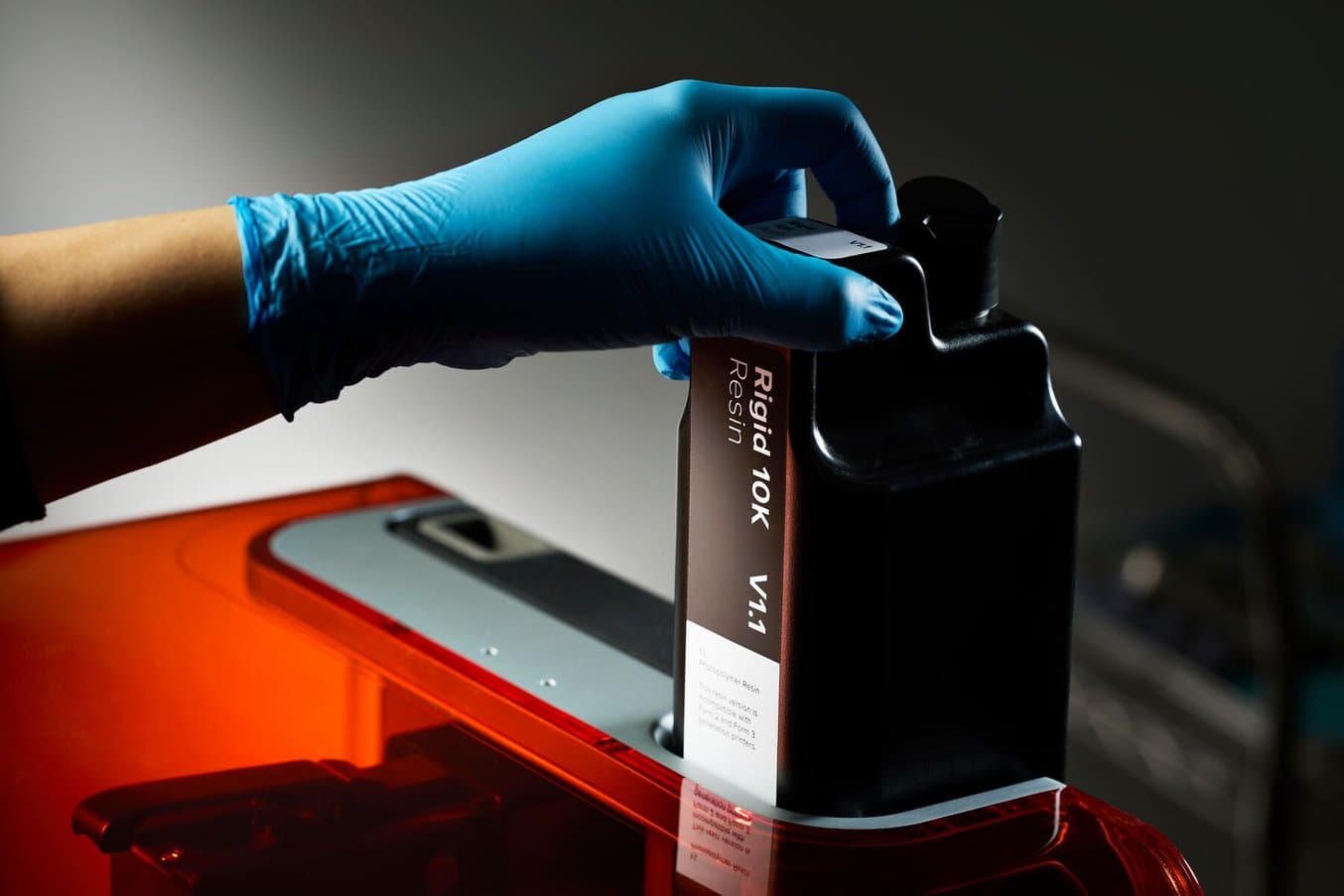

Our next-generation resin cartridge enables hassle-free, efficient, and fast automatic resin dispensing.

Access images and timelapses online to remotely monitor your prints.

Ecosystem

Additional Specs

Key Components of the Print Engine

Form 4B

Technology

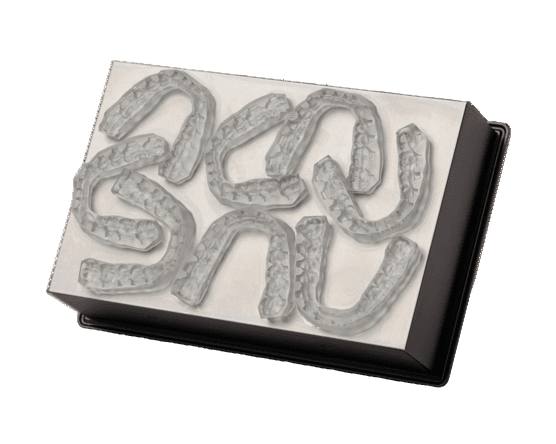

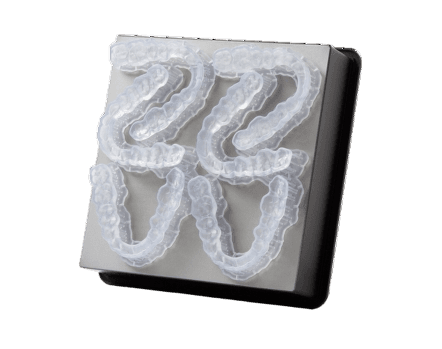

11 clear aligner models at 160 μm

8 occlusal splints at 100 μm

10 restorative models at 50 μm

20.0 × 12.5 × 21.0 cm

7.9 × 4.9 × 8.3 in

Restorative models with Precision Model Resin:

75,000+ layers with any Formlabs material.

Approximately 340 prints using clear aligner models (22 mm tall), any resin, and 100 µm layer height.

5-10x faster tank filling

63% less waste

30% less shelf space

2592 x 1944 resolution (5MP)

Remote monitoring, print history, and print timelapses

Can be easily disabled, covered, or removed

Test

form 4 vs. form 3

27.3 cm

10.7 in

1-30 mm features: ±0.15% (lower limit: ±0.02 mm)

31-80 mm features: ±0.2% (lower limit: ±0.06 mm)

81-150 mm features: ±0.3% (lower limit: ±0.15 mm)

Average: 40 mm/hour across all materials

Range: 15-100 mm/hour depending on the material

100 mm/hour

3.9 in/hour

18.3 kg

40.4 lb

40.7 × 47.8 × 84.4 cm

16.0 × 18.8 × 33.2 in

Form 3B/+

Technology

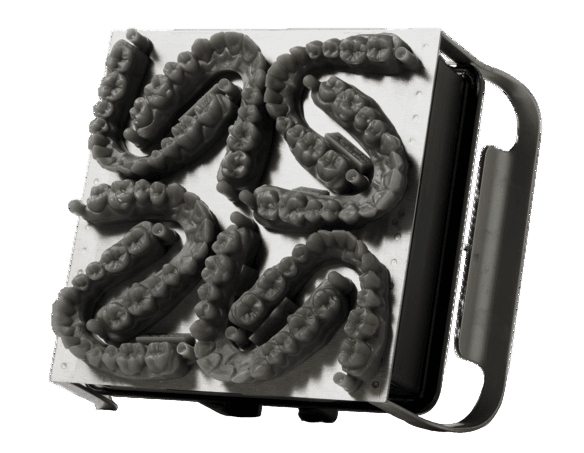

9 clear aligner models at 100 μm

7 occlusal splints at 100 μm

8 restorative models at 50 μm

14.5 × 14.5 × 19.3 cm

5.7 × 5.7 × 7.6 in

Restorative models with Model Resin V2:

250-800 hours of printing and/or 10-35 weeks exposed to resin, depending on the material.

Approximately 210 prints using Grey Resin V4 and average print time (3.7 hours).

Original resin cartridge

No camera

Test

form 4 vs. form 3

22.4 cm

8.8 in

Not measured

Average: 11 mm/hour across all materials

Range: 4-17 mm/hour depending on the material

31 mm/hour

1.2 in/hour

17.5 kg

38.5 lbs

40.5 × 53 × 78 cm

15.9 × 20.9 × 30.7 in

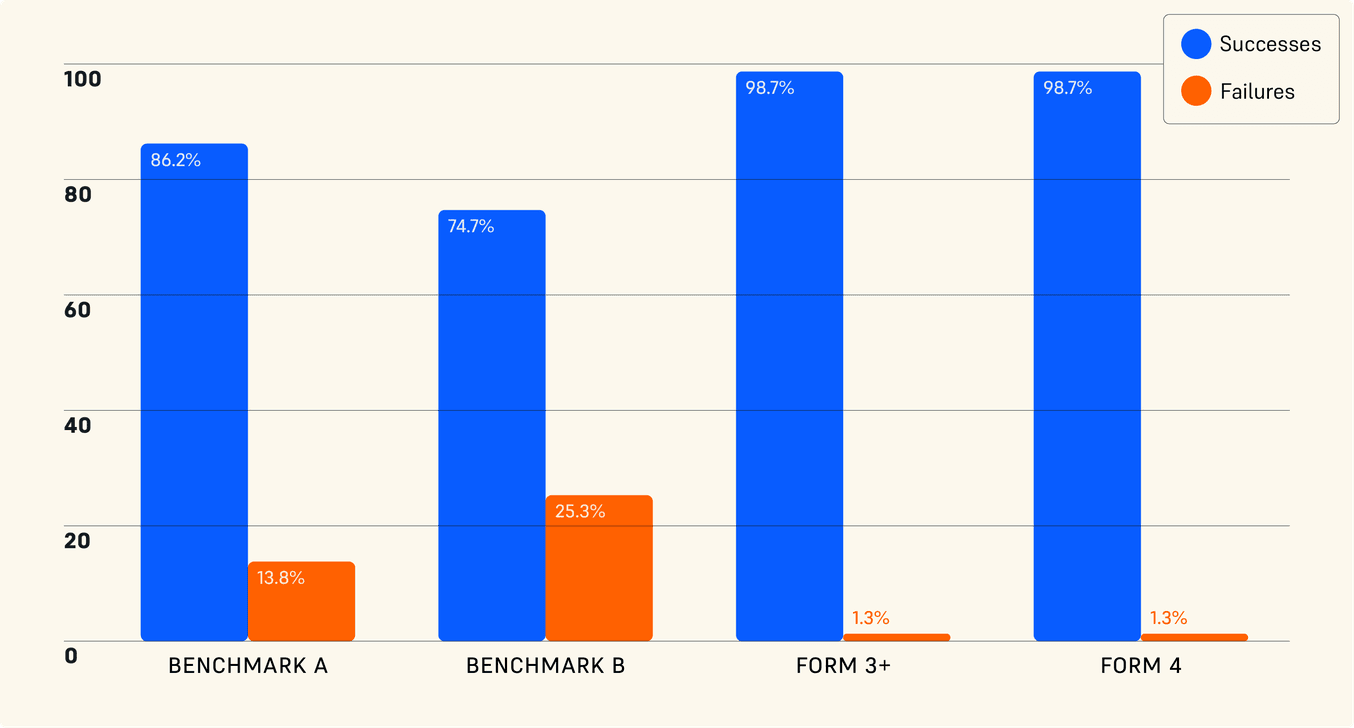

Form 4B achieved stellar results in a series of comprehensive performance tests conducted by an independent third-party lab to evaluate the success rate and repeatability of parts produced on different SLA 3D printers.

“We get all the things we love about Formlabs — and we get that competitive speed. If I had two to three Form 4Bs, I could double our production.”

The Form 4B Ecosystem

Complete Your 3D Printing Experience