Drive Case Acceptance With Comfortable Occlusal Splints and Guards

Occlusal splints, night guards, and mouthguards are devices that provide protection for teeth for patients who are suffering from parafunctional activities, bruxism, or are diagnosed with temporomandibular joint disorders (TMD).

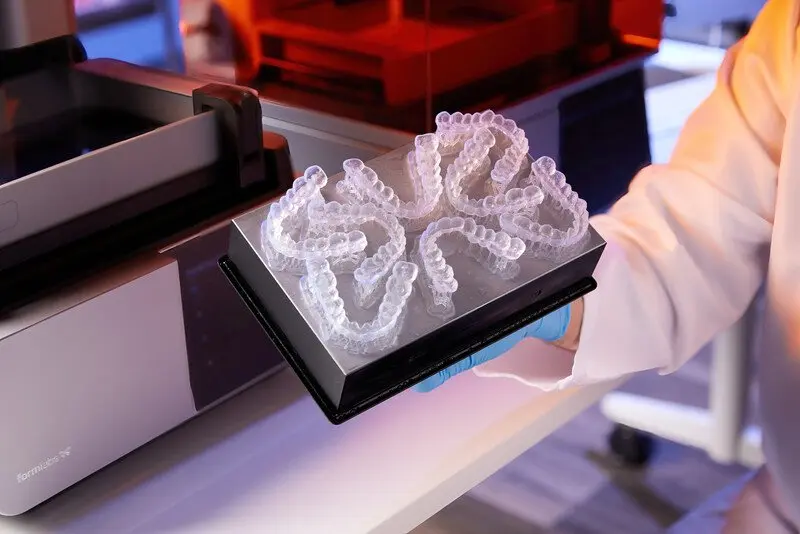

3D print occlusal splints in-house to save money and time, increase case acceptance, and simplify your workflow.

Fast, Easy Production

Save Time and Money

Improve Patient Outcomes

Attain Positive ROI in Weeks

Print eight occlusal splints in 54 minutes on Form 4B, or 24 in 79 min on Form 4BL at a cost of $3-4 per appliance.

LT Comfort Resin and LT Clear Resin provide options for printing more flexible or more rigid splints, so you can select the optimal material for every case.

| Time from scan to treatment start | Cost for a comprehensive case* | |||

|---|---|---|---|---|

| Outsourced occlusal splint | As much as 2 weeks | $80-150 | ||

| In-house occlusal splint with Formlabs | As little as 1 hour | $3-4 | ||

| Savings per case | 2 weeks | $76-147 |

Easy to Start, Easy to Scale

The workflow to 3D print splints and night guards is fast and flexible enough for both true chairside delivery and series production.

Scan

Design

Post-Process

"I have been using KeySplint Soft for years, but when I had the opportunity to beta-test the new dental splint material called Dental LT Comfort from Formlabs Dental, I was amazed. The material's pre-polished appearance and exceptional translucency right after printing significantly reduced post-processing time. Furthermore, I was impressed by its fracture resistance and flexibility, which ensure optimal comfort, making it the perfect choice for dental splints."

Print With a Fully Validated System for an Easy Workflow

Our extensive validation and testing process makes sure your prints work every time: quick setup, no in-field calibration, and no messy resin handling.

Dental LT Clear Resin for Hard Splints

A stiff, highly durable, and fracture-resistant material that polishes to high optical transparency and resists discoloration over time.

Dental LT Comfort Resin for Flexible Splints

A flexible and durable material for optimally comfortable long-term splints, occlusal guards, and bleaching trays that is easily polished to high optical transparency.

Learn With Formlabs Dental Resources

Virtual seminars, lectures from leading practitioners, and short, helpful videos help you start faster and get the most out of your 3D printer.