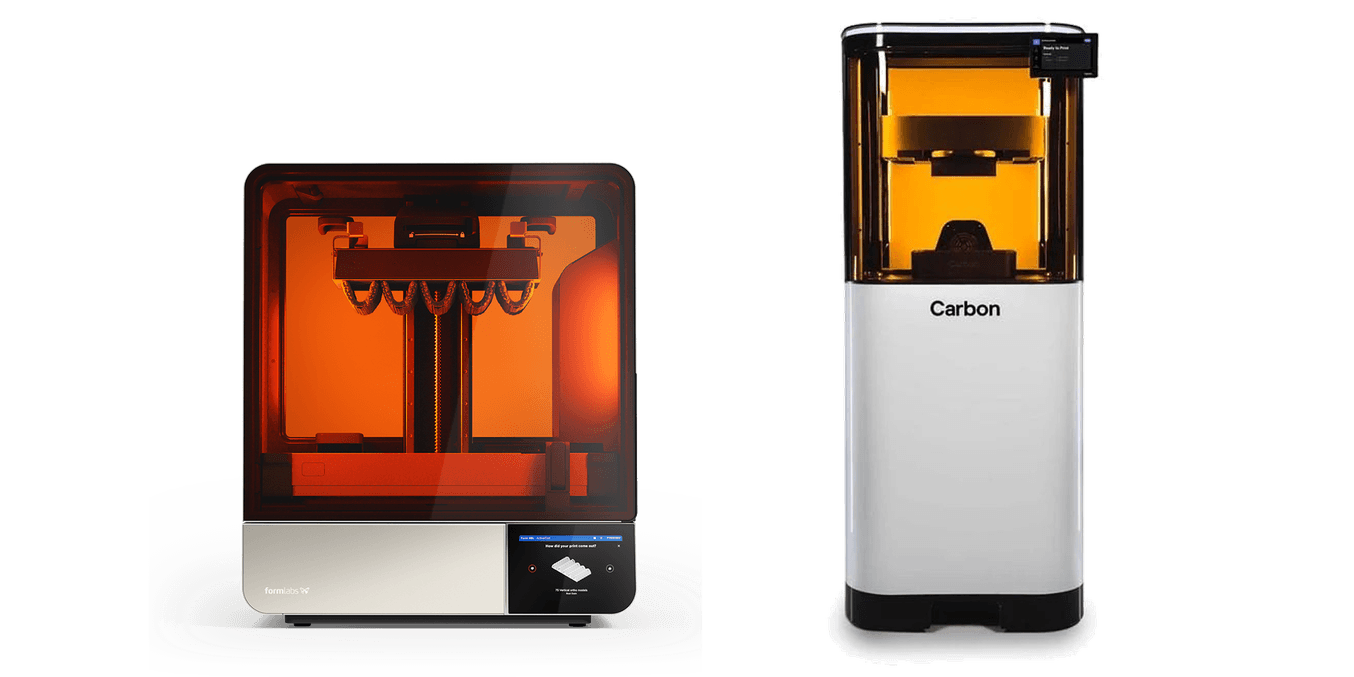

The Form 4BL Ecosystem

Complete Your 3D Printing Experience

Looking for a large-format dental 3D printer? Compare Formlabs Form 4BL with the Carbon M3 Max side by side.

Formlabs Form 4BL

Complete Cost

The $16,249 starting price includes all the essential tools required to start printing, access to the powerful PreForm software and online Dashboard, as well as Open Material Mode. The Form 4BL Complete package for $29,899 also includes custom-developed automated post-processing tools and a three-year premier dental service plan for a turnkey solution.

Buy from Formlabs via sales or the online store, or purchase through one of our distribution partners.

Materials

Supported Dental Applications & Materials

A wide range of applications on a single printer, validated, tested, and directly supported by Formlabs.

Open material mode is included, enabling freedom to print third-party resins.

Ease of Use

Simply insert a new cartridge and resin tank to change materials. Additional resin tanks may be purchased for $249 and include reusable lids for easy storage.

Resin Cost

Resins start at $79/L with discounts for 5 L containers for use with Resin Pumping System and additional discounts for bulk purchases.

Technology

Print Technology

LFD is a new generation of masked stereolithography (MSLA) 3D printing where reduced peel forces lead to incredible surface finish and unmatched accuracy. Formlabs Light Processing Unit (LPU) 4L is designed to deliver 600K - 1.9M layers of consistent print performance and takes only minutes to replace using a tool provided with the printer.

Light intensity

16 mW/cm² optical power intensity delivered to the cure plane.

Print Speed

Up to 80 mm/h with Fast Model Resin, 24 mm/h on average across all materials. 32 clear aligner models in 14 minutes for up to 1000+ models within an 8-hour working day.

XY Resolution

Pretuned anti-aliasing for subpixel resolution resulting in superior fine and sharp feature performance.

Build Volume

35.3 x 19.6 x 35 cm

13.9 x 7.7 x 13.8 in

24.2 L

Software

Formlabs’ free PreForm Dental software is the golden standard when it comes to ease of use. Intuitive functionalities and presets for key indications such as models, splints, and surgical guides help users set up prints automatically, taking care of the orientation, support generation, and material selection in one click.

You can also use the online Dashboard to manage a fleet of printers, monitor prints, track materials and consumables, and work with your team.

Dental PreForm has settings for all Formlabs resins for easy, optimized printing.

Support

All Formlabs hardware comes with a one-year warranty and email support provided by a dedicated staff. Purchase a Dental Service Plan to extend your coverage further and gain access to additional benefits like hot-swap replacements, dedicated phone support, training, and more, so you can stay focused on growing your business.

Learn More About Formlabs Service Plans

Reliability

“With Formlabs’ ecosystem, our 3D print success rate is now close to 100%."

Stephan Kreimer, MDT, Kreimer Dentallabor

A new Release Texture and a durable Flexible Film Resin Tank minimize peel forces during printing. Plus, the built-in Resin Level Sensor and Z-Axis Force Sensor ensure consistency and performance.

In the event of an issue, error messages display QR codes that lead to support articles to get you back up and running as quickly as possible.

Typical Dimensional Tolerances

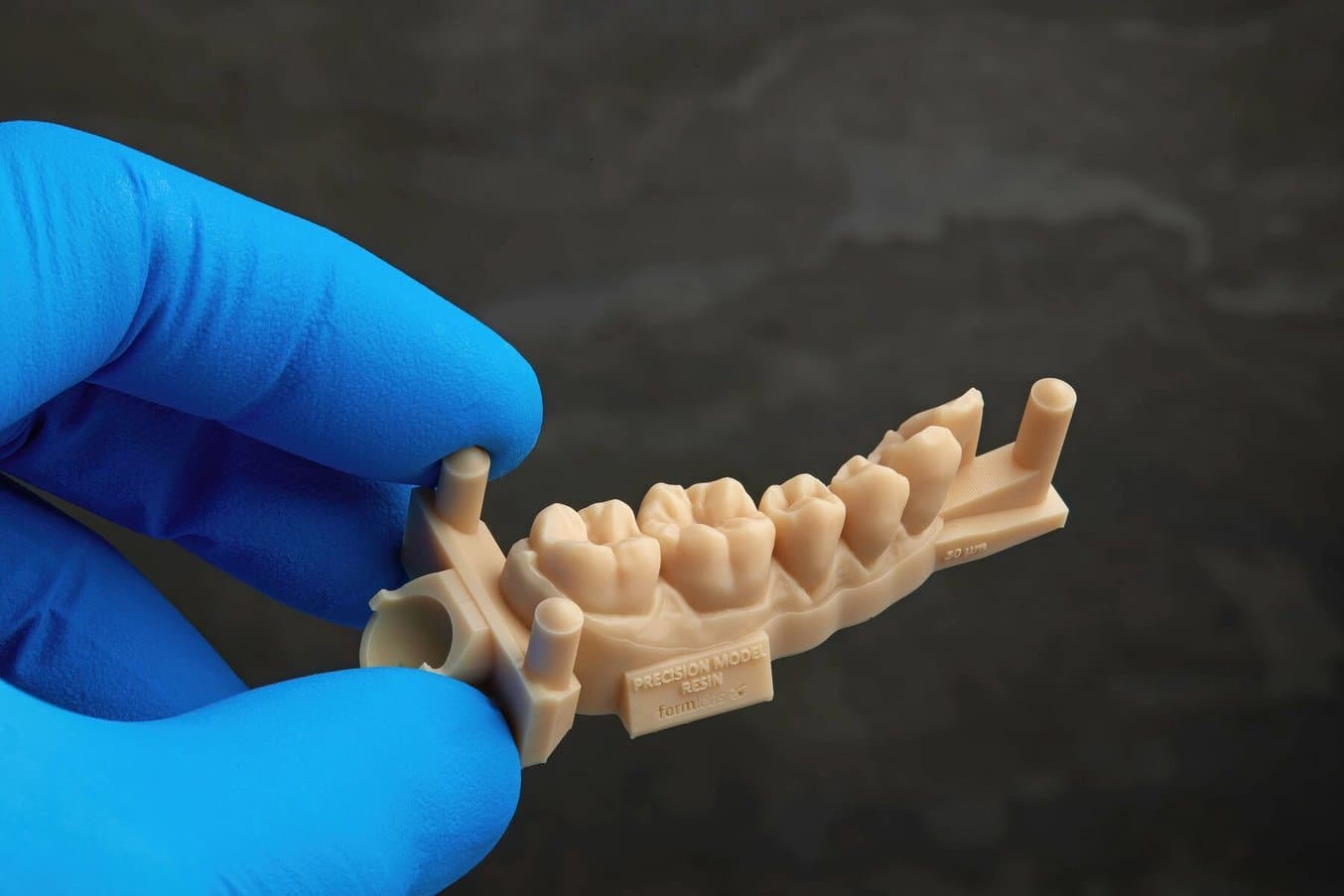

Restorative models (Precision Model Resin at 50 µm layer height)

Clear aligner models for thermoforming (Fast Model Resin at 160 µm layer height)

Ease of Use

Resin Dispensing

Pre-tuned support settings with light touch supports are available for every material to facilitate support removal.

Automated washing and post-curing solutions designed for Form 4L and with validated settings for each Formlabs material.

Part Removal

Quick, easy, and tool-free with Build Platform Flex. Prevents part breakage and potential injuries while removing parts.

Consistent printing and a wider variety of material options, including highly-filled materials. Debris detection.

15 minutes until your first print.

Company

Formlabs brought SLA 3D printing to the desktop in 2011 and SLS printing to the benchtop in 2021, and has become the market leader in both technologies, selling more than 130,000 printers. Form 4B is a 4th generation product, powered by a proven technology that has been used to print over 15 million dental parts.

Carbon M3 Max

Complete Cost

Carbon 3D printers are only available as a subscription, meaning you do not own the printer outright and it must be returned at the end of the subscription. Support is included in the subscription price.

Pricing is not transparent and customers must contact Carbon to receive a quote.

*Price is to the best of our knowledge and may vary.

Reliability

Supported Dental Applications & Materials

A range of application with certified third-party materials.

Only certified third-party materials are available.

Ease of Use

Each Carbon lease includes one tank and additional tanks cost $4,000-$6,000 a year. If using one printer for multiple materials, change out can take time for cleaning.

Resin Cost

To receive the highest resin discount on Carbon's DPR 10, a user must take shipment on 208 L (55 gal) drums that require a pump costing $4,000.

Materials

Print Technology

Carbon’s digital light projection (DLP) 3D printers project a sequence of UV images through oxygen-permeable optics to cure resin into solid parts.

Light intensity

N/A

Print Speed

Carbon is vague about print speed and throughput, but based on the best available information, we estimate that the M3 Max can produce around 400-450 models per day. Even their largest printer, the L1, can only produce 640–800 clear aligner models per day, achieving a lower throughput than a single Form 4BL.

XY Resolution

Lower resolution, resulting in inferior details and surface finish.

Company

30.7 x 16.3 x 30.5 mm

12.1 x 6.4 x 12 in

15.3 L

Build Volume

Carbon’s Automatic Operation (AO) suite software offers file preparation and part nesting.

Software

Integrated service package includes customer support and preventative maintenance.

Cost of Ownership

Typical Dimensional Tolerances

Restorative models

Clear aligner models for thermoforming

Ease of Use

Resin Dispensing

The Carbon Smart Part Washer can be used to wash parts, though the build platform for M3 Max does not fit in the wash and parts must be removed prior to washing. Post-curing solutions are necessary but are not available from Carbon.

Part Removal

Tools required to remove parts. Risk of part breakage or injury while removing parts. Not compatible with flexible build plates.

Manual mixing is required periodically. The lack of resin mixer limits material options. Debris detection.

Carbon used to require that they install their printers, but Carbon M3 and M3 Max are now installed by users over the course of hours.

Technology

Founded in 2013, Carbon previewed their first printer in 2015, and has since gone on to develop a line of professional resin printers combining proprietary hardware, software, and service. Unlike other companies, Carbon 3D printers are only available as subscriptions, rather than purchasing the printer outright.

Do you have more questions about the differences between these solutions?

With 75+ support and service staff and 150+ engineers, Formlabs backs its products with the strongest team in 3D printing.

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your lab or practice.

Speed at scale. Produce 32 models in 14 minutes*.

Repeatable accuracy you can count on.

The Form 4BL Ecosystem

Complete Your 3D Printing Experience