How ArchForm and Formlabs 3D Printers Empowered an Orthodontist to Bring Clear Aligner Production 100% In House

Together, software and hardware are rapidly changing dental care. Easy-to-use software like ArchForm is enabling orthodontists to design and produce aligners in-office. Combining these workflows with next-generation dental 3D printers like the Form 3B+, dental professionals who are already offering aligners can now deliver aligners to their patients that have been produced chairside.

In this post, we will talk with Founder and CEO of ArchFrom, Andrew Martz, about the growth of ArchForm, and hear from Dr. Rooney of Rooney Orthodontics about deploying and scaling in-house aligner manufacturing with Formlabs Dental and ArchForm software.

You’ll learn how these two technologies are allowing dental professionals to work smarter, not harder, as well as:

- How continuous innovation by Formlabs and ArchForm are driving the digital revolution in dental care and helping address patient needs.

- What has made small, independent dental businesses like Rooney Orthodontics successful during the switch to in-house dental manufacturing.

- How Dr. Rooney has successfully scaled his dental practice.

In-House Clear Aligners; Scaling a Business With ArchForm and Formlabs Dental

Dr. Rooney has successfully launched and scaled his orthodontic office in Mahopac, NY, becoming a leading dental practitioner in his community by carefully investing in his practice and scaling with both ArchForm and the Form 3B from Formlabs Dental. Dr. Rooney has been able to grow a thriving small business while delivering exceptional clear aligners and dental care to his patients.

As his orthodontic practice began to grow, outsourcing his clear aligners became a consistent bottle neck due to the time it took to receive the aligners in the mail. Dr. Rooney told us, “my business philosophy was to provide high-quality appliances and treatment with the quickest turnaround times to fit into patient’s busy lifestyles. I began to become confident with Formlabs Dental and ArchForm when I started using them to make refinement aligners because I did not want to wait weeks for refinements aligners to be shipped to my office from major manufacturers. My results were fantastic due to the high quality of Archform software and Formlabs printers.” At the time, he was using well-known clear aligner manufacturers, and while happy with the quality of the aligners, Dr. Rooney saw a major opportunity to save on costs and time. He set an ambitious goal: to scale until 100% of his clear aligners were printed in-house.

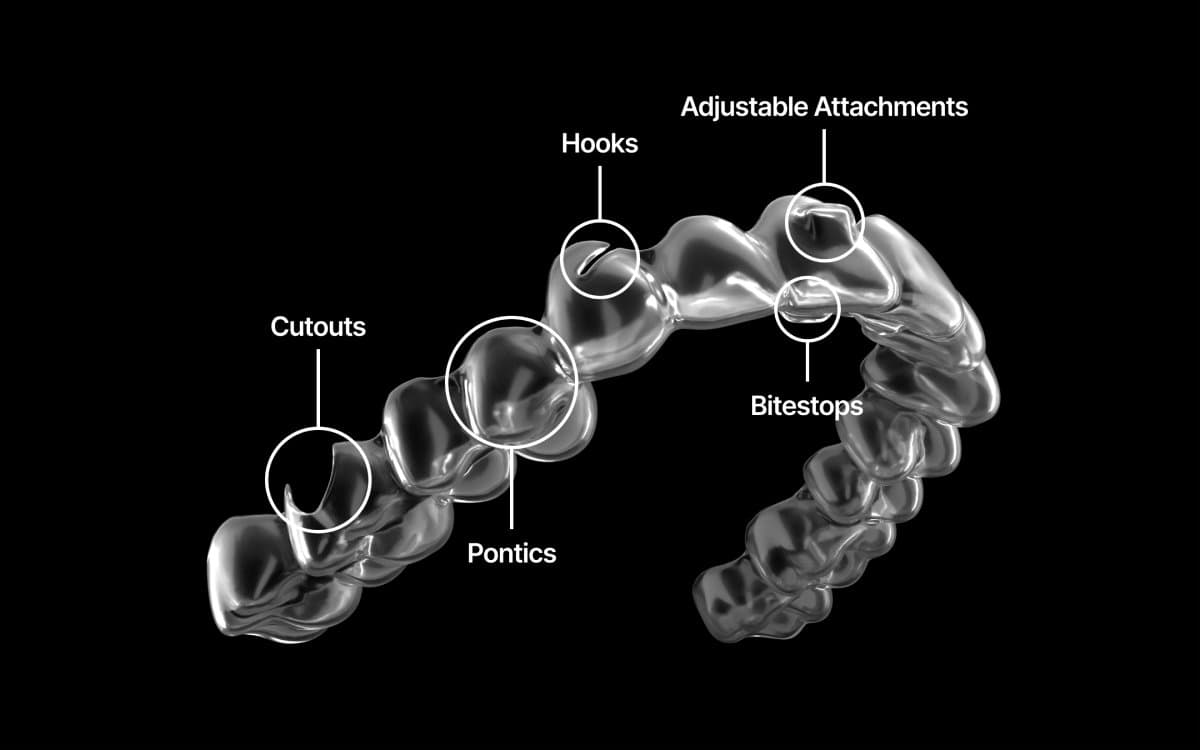

Preparing treatment designs using ArchForm is intuitive and easy to learn, a huge selling point for busy practitioners like Dr. Rooney. He told us , “what I like about ArchForm is I do not have to complete prescription forms and explain how I would like teeth moved, I just do it. The amount of time it takes me to set up a case on ArchForm is about the same amount of time it takes me to submit a case to a major manufacturer and adjust their initial setups. I personally move every tooth with ArchForm software and feel I understand and have more control of every aspect of treatment such as: which tooth movements will be successful, picking the correct attachments and which type of plastic should be chosen for the different tooth movements. New plastics are entering the orthodontic field with different characteristics. I enjoy learning about new materials and understanding how they can benefit my treatments. In addition, since my treatment setup is completed using ArchForm the files can be printed on Formlabs printers and the aligner manufacturing starts immediately. I can get aligners as fast as the same day if desired. I do not have to wait several weeks to receive the aligners.”

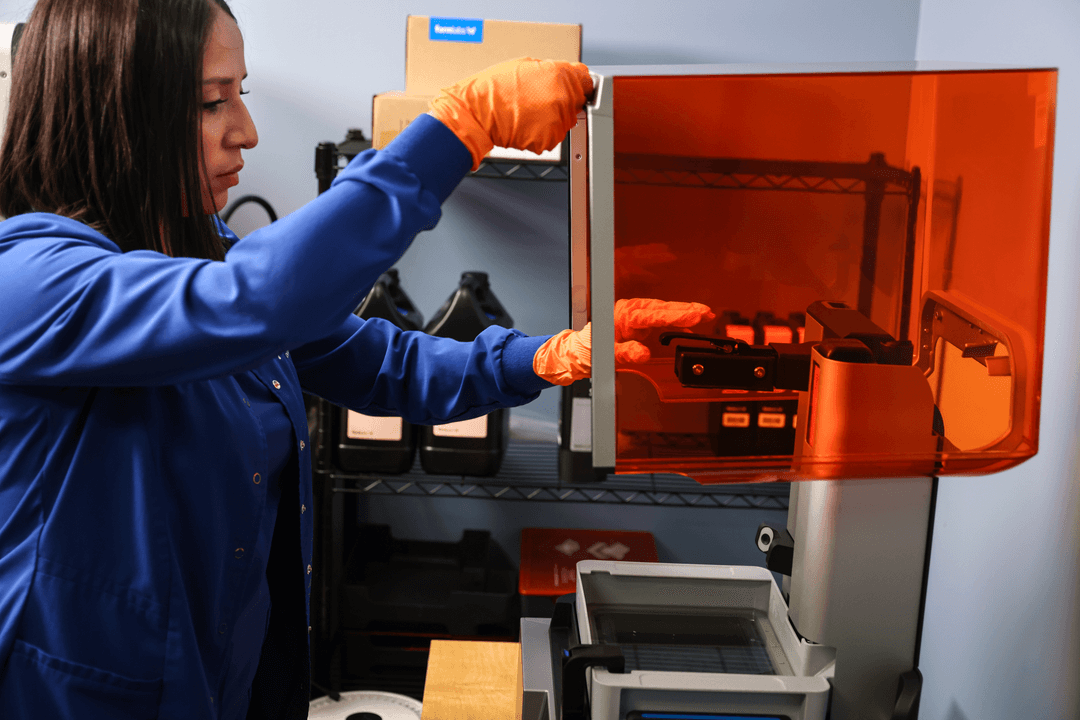

As Dr. Rooney began to scale his in-house printing capabilities, he realized that reliability of the Form 3B was just as important as end-part quality. He told us, “if the print quality is not ideal then the appliance will not be effective. Manufacturing aligners in office is like creating a custom manufacturing plant. If models need to be reprinted it will clog up the production line costing time and money. There are a lot of moving parts and every part in the manufacturing process of orthodontic appliances such as the software and printers need to be precise and reliable."

ArchForm works exceptionally well with Formlabs Dental printers, coming with custom pre-printing settings to optimize build platform packing on both the Form 3B and Form 3BL. Ease of use, from scan to printer, is essential for busy practitioners like Dr. Rooney. He told us, “the software itself is simple to work with. I'm seeing success with it. I'm seeing my appliances fit properly and my cases treat out nicely.”

Over time, using ArchFrom and printing his own files became second nature, and the transition to fully in-house aligner production was complete. Not wanting to totally close the door on outsourcing, Dr. Rooney recently re-evaluated his journey into in-house aligner manufacturing and compared it to his previous business structure of using large manufactures and said: “When I make aligners in house in my opinion I produce a higher quality product because I personally move every tooth with ArchFrom, I print models at a very high print quality with Formlabs printers and can choose what plastic I would like to use and can have the aligners custom trimmed to my preference, the turn around time to receive the appliances is much faster and most of the time I decrease my business expenses.”

When it comes to investing in any new software or hardware, ROI is always top of mind for Dr. Rooney. He told us that, “my rule of thumb is I always have to make a profit because I'm running a business. I do not run at a loss. I bought one printer at a time when I started and then when I achieved my desired ROI and would then buy another printer. I figured out what my profit margin was and realized that it was a fast return on investment for the Form 3B. I always keep track of a bunch of different metrics to see how we are doing, and I think it's helped my practice.”

Product Demo: Form 3B+ Dental 3D Printer

Watch our product demo for a walkthrough of our new LFS dental 3D printer from a Formlabs expert.

He entered the in-house production practice model with some trepidation but the benefits have become apparent. Dr. Rooney’s has the ability to manufacture aligners, retainers, nightguards and mouthguards. “The ability to manufacture retainers quickly for patients that lost or broke their retainers is beneficial. Often patients come home from college and say they need a new retainer and will only be home for 1 or 2 days. I can actually have a new retainer ready for them the same day or the next day.” Providing this wonderful service can increase revenue.

Investing in the Future: Continuous Dental Innovation

When it comes to growing his dental practice business, Dr. Rooney wants software and hardware that is going to evolve and improve over time, delivering increased productivity and quality. This was a similar trend he sees in both ArchForm and Formlabs; both companies continuously roll out software updates and materials. This means he is more comfortable investing in these platforms, knowing they are future proof and will continue to keep up with his needs.

When Dr. Rooney first started with 3D printing, he tried a Form 2 printer. At the time, his experience was mixed when using it to 3D print models for aligner fabrication, saying, “I was frustrated at one point. I was having a lot of print failures and other reliability issues.”

As his practice grew, Dr. Rooney decided to invest in the Form 3B, and noticed a significant improvement in print quality and reliability. He told us that, “When I bought the Form 3B, the consistency was so much better. So I was happy with it. To me, speed of 3D printed models wasn’t the main factor, it was the quality of the printed model. If the printed model quality is not perfect and an appliance is made using it then I waste my time not only in the manufacturing area but also the time I spend attempting to deliver an appliance that does not fit to a patient. Patients have busy lives and are not pleased to come back to the office for a new appliance. With the Form 3B especially, I was getting very high-quality prints on it, so I was very happy with it. The fact Formlabs is not being complacent is important. That's why I stuck with Formlabs Dental.” Dr. Rooney also mentioned recent products such as the Build Platform 2 and new resins as signs Formlabs Dental is listening to practitioner’s needs.

On the software side, Dr. Rooney has been impressed with the updates he has seen from ArchForm, saying that, “they are making advancements with the software. I see them getting better and better quickly. I see that they are progressing. That is why I am sticking with ArchForm. I am committed to doing everything myself, and ArchForm allows me to do that.” In addition, ArchForm's dashboard has made monitoring patients' cases very easy.

ArchForm: Empowering Orthodontists With Easy-to-Use Software

When Dr. Rooney told us that he is “committed to doing everything myself, and ArchForm allows me to do this”, it's exactly the type of comment Martz wants to hear. When he set out to create ArchForm he wanted to nail two key pain points: easy integration with 3D printers such as Formlabs Dental, and a dentist-friendly pricing model. The market, he felt, was ready for in-house aligners.

Dr. Rooney said the pricing structure Martz set up enabled him to try ArchForm for the first time, saying that, “what got me into Archform at first was their price structure. With other software programs, you sign up for subscription upfront. With ArchForm, I was able to start with just one case and scale as my practice grew. Especially when I was looking to use it for the first time. It did not make sense to me to sign up for a subscription about something that at the time I knew nothing about. A benefit of ArchForm at this time is they offer subscriptions that fit into the size of my practice and I can have them help me with any area of aligner fabrication if my lab gets backed up."

ArchForm can detect open intraoral scans and caps them, using machine-learning for accurate tooth segmentation and offers numbered aligners and automated attachments, enabling orthodontists to streamline the process of aligning teeth at an affordable cost. Critically, Martz had used 3D printers for years before making ArchForm, which he helped him create the ArchForm software, saying that “the early experience we had with Formlabs helped me design the software.”

Building a 3D Printing Dental Fleet

Archfrom can print high-quality clearer aligners for its customers.

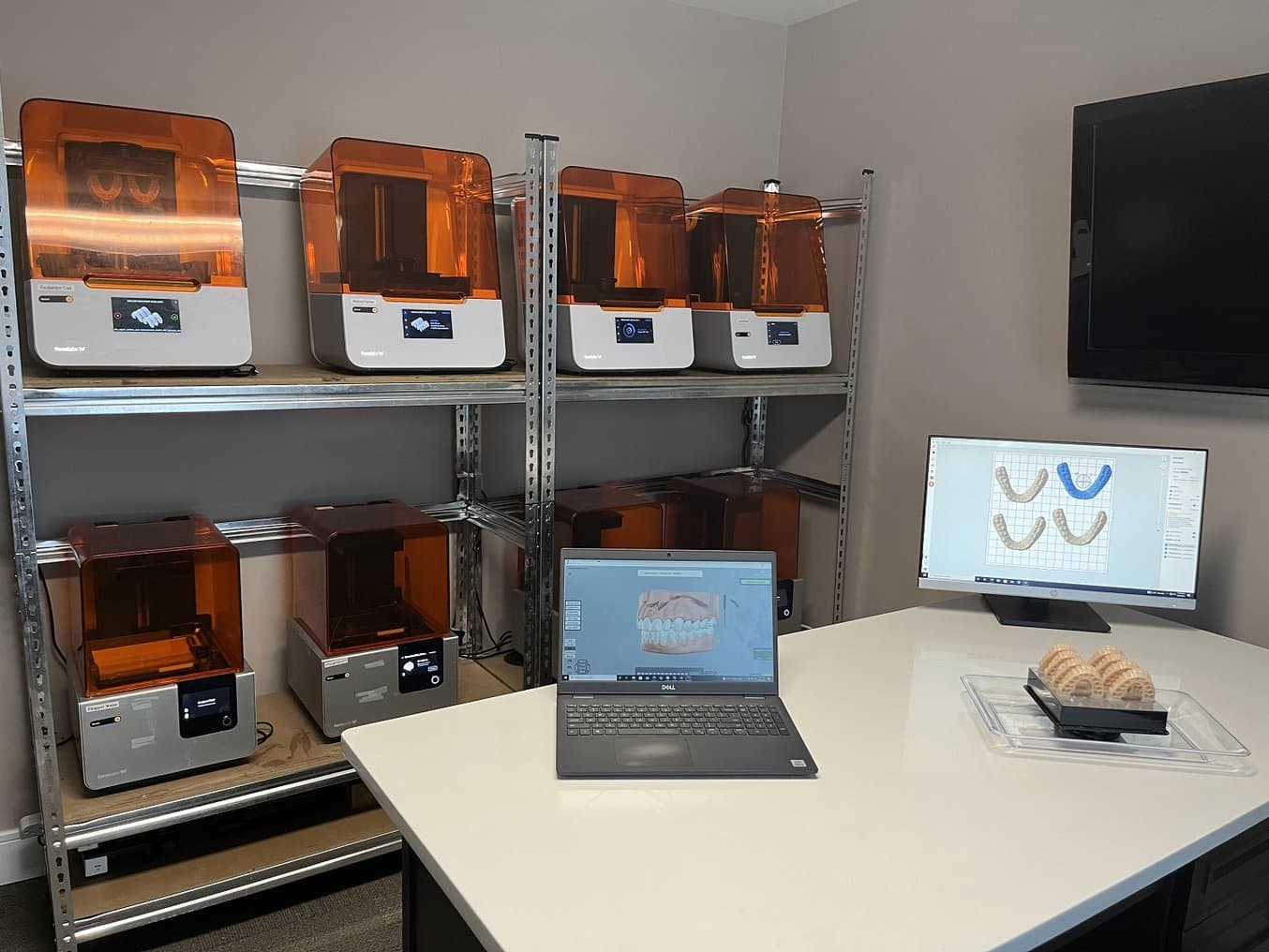

As ArchForm gained adoption, Martz realized there was another opportunity: to create a 3D printing hub so that ArchForm users could outsource prints to him directly from the software. This allows practitioners to get started with ArchForm software, and then eventually scale their own printing fleet to bring production in-house. It also helps small labs that don’t have the on-site space for 3D printers, but still wish to use ArchForm due to its friendly pricing structure.

To achieve this, Martz invested in a major manufacturing fleet of Formlabs Dental printers, such as the Form 3B and Form 3BL. This includes a full suite of Form Washes and Form Cures, saying, “we are using Formlabs all the way through. And it’s been really easy.”

At first, Martz was hesitant to invest in his own 3D printing fleet, but the orders have been rolling in. “The advantage of the Form 3BL is that we can print an entire case in one print, and that helps with organization,” he told us. Martz continued, saying, “we are printing 24/7, using the queuing system, priming the printers, so the printers are continuously providing output for us.” Martz shifted his aligner production to Draft Resin solely due to the printing speed and accuracy of the models, telling us that “everything we do centers on how many dental models we can print per day.”

There were other key reasons he invested in Formlabs Dental for his print production setup: accuracy and reliability. He told us his favorite feature about Formlabs printers is, “the laser self calibrates after every print. No one talks about that, it’s not advertised, and it’s one of the biggest things Formlabs has figured out compared to other printers.” Furthermore, with dozens of printers running 24/7, Formlabs has made it easy for Martz to track each individual model. He told us, “when you’re printing at the scale we are, using the Formlabs Dashboard and having API access to the printers has been huge. We pull a list of every single model that was printed, so if we forgot to load some models into PreForm, we can call that out and know we forgot to print it.”

Martz heavily relies on this fleet of Form 3B printers, and often prefers to spread his print load out over multiple machines, saying that, “the Form 3Bs in particular have been very reliable.”

Best of all, the investment has paid off. ArchForm is better able to serve its clients and expand access to its dental software, and the printer investment had a positive financial ROI. “The printers pay for themselves in three months. We paid for the hardware very quickly, and it helped with redundancy”, said Martz.

Martz said the key to his success has been innovation, “We stay close to our doctors, and we roll out continuous updates. We’re not a giant company, we can move fast. Our main selling point is definitely ease of use. Other software in this space has a huge learning curve, and we want you to learn how to use ArchForm in a few hours. We’re constantly adding in new features, and reducing costs while giving orthodontists a lot more clinical control.”

Standing Out From the Crowd

Digital preparation of the scanned model for printing.

Dr. Rooney now has years of experience under his belt not only as an orthodontist and business owner, but also as a manufacturer of his own aligners, retainers, nightguards, mouthguards and dental models. This gives him a unique perspective—from scanning to printing to placing the appliances in a patient’s mouth—of the full digital dental workflow. He said, “the advantage I have is I actually appreciate the quality of an appliance when I insert it in their mouth and ask a patient how they feel. Patients say, ‘This is awesome,’ or ‘It is not awesome.’ The ability to be on all sides of that and seeing things follow through is priceless.”

He continued, “I am committed to providing my patients with high-quality treatment that uses the best technology and materials available. I will also be respectful of my patient’s busy lives and their desire to improve their smiles safely and without any unnecessary delays in treatment time.”

With Formlabs Dental and ArchForm, Dr. Rooney is able to leverage new technology to offer his own unique, personal touch for each and every patient.

Dr. Rooney is excited for Straight2You Orthodontic Lab (Rooney Orthodontics) to start accepting cases from other offices starting in the Fall of 2022.