3D Printing Full Dentures With Formlabs 3D Printers

Making traditional dentures requires a lot of skill and experience, which can be scarce and valuable resources in today’s dental labs.

Formlabs Digital Dentures offer an easier and more affordable way to produce full dentures using 3D printing. With our Class II biocompatible Denture Base Resin and Premium Teeth Resin, you can reliably create accurate dentures.

While the steps to make a digital denture are different from the traditional lab process, the workflow for the dentist and patient stays very similar.

This application guide walks you through the key steps to go from a digital patient scan to a finished 3D printed denture using the Form 4B 3D printer and Formlabs post-processing tools.

For detailed instructions, please refer to the official Instructions for Use.

3D Printing Full Dentures With Formlabs 3D Printers

Making traditional dentures requires a lot of skill and experience, which can be scarce and valuable resources in today’s dental labs.

Formlabs Digital Dentures offer an easier and more affordable way to produce full dentures using 3D printing. With our Class II biocompatible Denture Base Resin and Premium Teeth Resin, you can reliably create accurate dentures.

While the steps to make a digital denture are different from the traditional lab process, the workflow for the dentist and patient stays very similar.

This application guide walks you through the key steps to go from a digital patient scan to a finished 3D printed denture using the Form 4B 3D printer and Formlabs post-processing tools.

For detailed instructions, please refer to the official Instructions for Use.

Essentials

Provided by the Dentist

-

A final functional impression of the mucous tissue of the jaws.

-

A bite rim with all necessary information, such as: lip line, midline, canine position, and occlusal plane.

-

Prescription with desired tooth shape, shade, and other clinical considerations.

Made by Formlabs

-

Resin Tank for each resin

-

Form 4 Mixer for each resin

Made by Third Parties

-

Desktop scanner

-

A heat-resistant, round glass container (approximately 1 liter or 4 cups) that fits inside the Form Cure

-

Glycerin

-

A dental handpiece and tools for acrylics

-

Handheld UV light cure unit

-

Optional:

-

Lathe for polishing

-

Steam cleaner

-

Ultrasonic bath

-

Silicone tongs

-

Pumice and polishing compound

-

Required Software

Made by Formlabs

-

Latest PreForm Dental software and printer firmware

Made by Third Parties

-

Denture design software

This may include:

|

Purchased CAD |

Pay-per-Case CAD |

Design Service |

|

|

|

1. Scan and Design

1.1 Scan

Digital denture design software requires a digitized model or an intraoral scan of the patient’s oral anatomy in order to design the removable prosthetic.

The best available method for creating a digital file for edentulous patients is to scan the fully articulated, poured, or printed model and wax rim with a desktop laboratory scanner.

To optimize the accuracy of the bite, use a desktop scanner that can scan the bite of the fully articulated model without unmounting it.

Alternatively, an intraoral digital impression can be used. This prevents any soft tissue compression during the impression, but makes it harder to identify lines between moveable and fixed soft tissue for a fully functional denture.

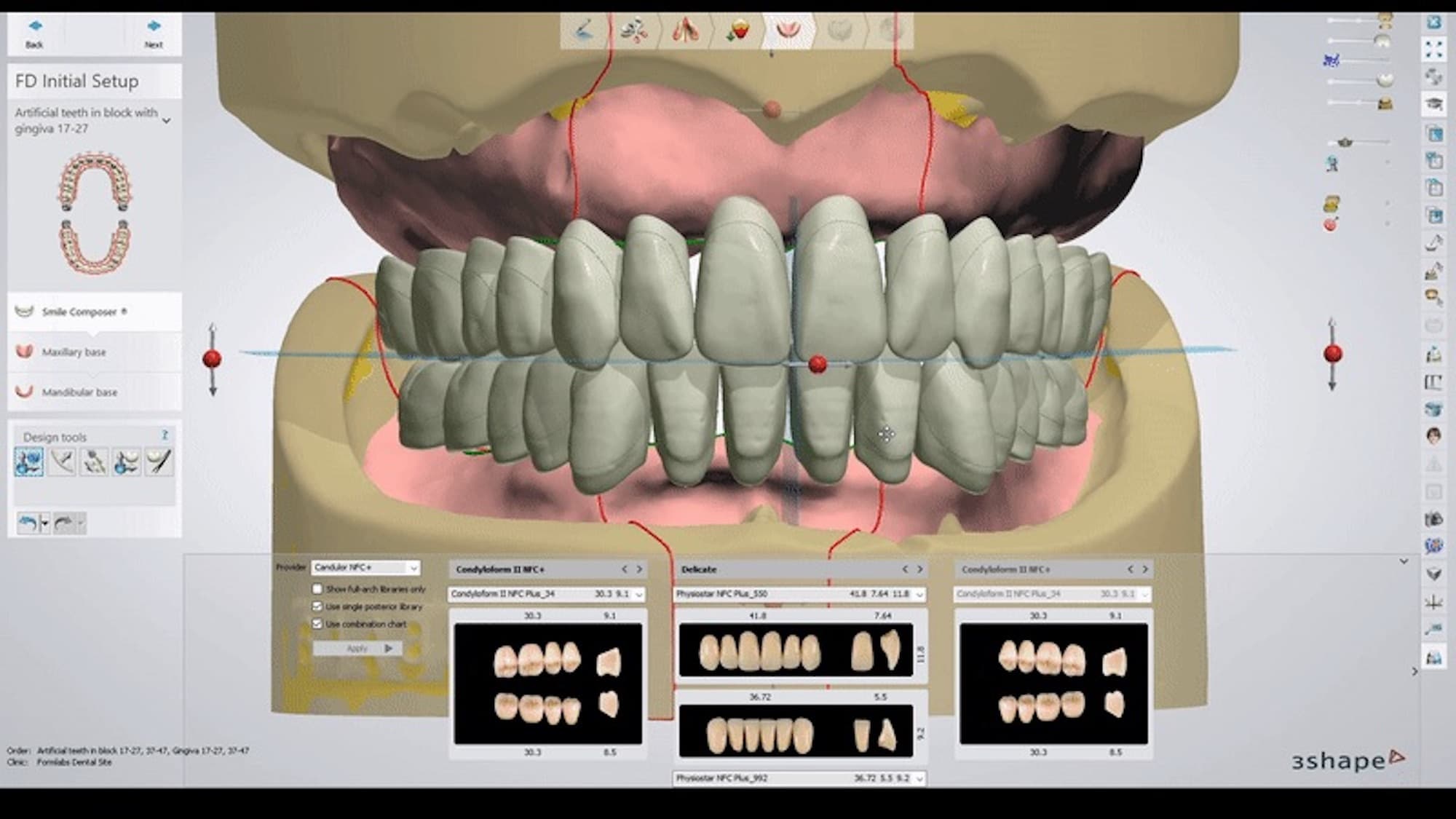

1.2 Design

Denture Design Software

Adjust your workflow according to the software you use.

Install the material libraries provided by Formlabs:

> Download our 3Shape materials library (DME).

> Install the exocad materials library using exocad dentalshare.

Use the following tips while designing the denture.

General design recommendations:

-

Base thickness: > 2.0 mm (add a 0.1–0.2 mm buffer for polishing). A thicker base ensures a stronger 3D printed denture.

-

Vertical non-load-bearing walls can be reduced to as thin as 1.0 mm if needed

-

It’s recommended to disable drill compensation, as it isn’t relevant for 3D printing and can negatively affect the fit of the denture base.

-

Formlabs libraries include a predefined coupling setting. If you’re using software other than exocad or 3Shape, set the offset between the base and teeth to 0.1 mm or less to ensure a proper gluing gap.

-

Denture Base Resin is more translucent than traditional acrylics, so it’s best to use tooth libraries without roots, with only short root portions, or trim the root in CAD if the software allows. This helps maintain a natural-looking result.

If you wish to use pre-manufactured teeth, consider selecting options designed for digital workflows such as VITA VIONIC VIGO, Dentsply Sirona IPN 3D, or Kulzwe Artic Digital. These teeth feature a significantly reduced root portion, which enhances aesthetics when used with our semi-translucent base material and minimizes the need for basal adjustments.

2. STL File Output

Denture teeth or CAD libraries are an important part of the digital denture process. Library compatibility varies by software. For example, some open libraries restrict output, while other libraries generate the denture teeth splinted, but not individually.

3Shape

> Open the Download Center in the 3Shape Dental Manager Control Panel to download new libraries. See 3Shape’s documentation for details.

Exocad

> Install teeth libraries following the instructions for exocad dentalshare.

Denture teeth library availability and outputs will likely change as the industry evolves. Follow your digital denture design software provider’s guidelines for the most up-to-date information.

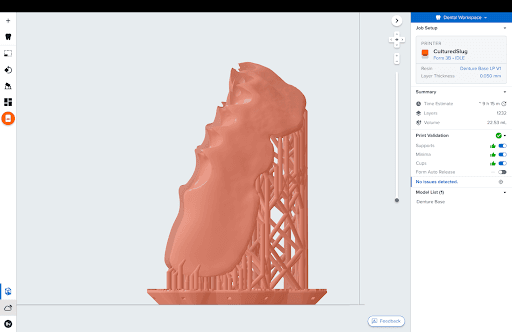

3. Prepare for Printing

3.1 Import Files Into PreForm

Once you export the STL files from the denture design software, import the files into PreForm Dental to prepare them for printing.

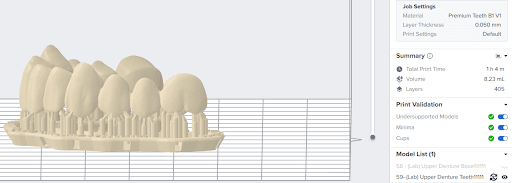

Select the material for printing: Premium Teeth or Denture Base Resin.

For the best results, use the latest version of PreForm and printer firmware.

You need to manually set up your files in the PreForm Dental Workspace. To change your workspace, go to View in the Menu and select Choose Workspace.

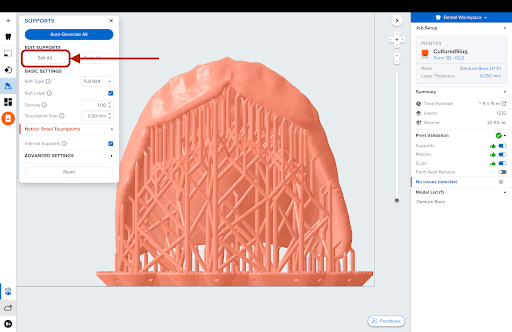

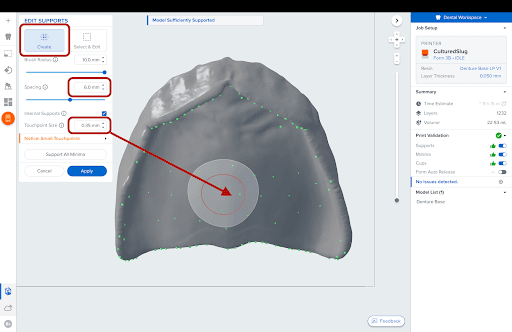

3.2 Orientation and Supports

Tip

When adding or editing supports, click the Printability button and enable Show Minima to identify unsupported features that could impact the print.

Notice

Proper part orientation is critical to ensure accuracy and reduce post-processing after printing.

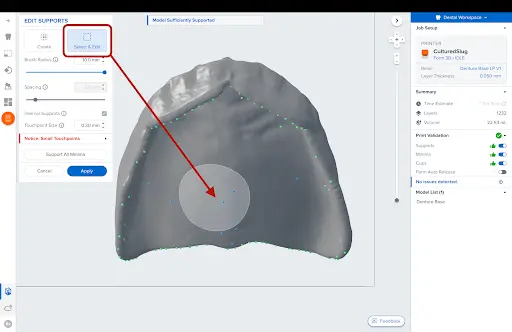

Denture Base

Orientation:

Orient the denture base parts almost vertical, at an angle of approximately 80° to the build platform. The anterior buccal part can face towards or away from the build platform. We recommend placing the supports on the intaglio face of the denture base.

After auto-generating supports for the denture, click on Edit All for modifications.

Concentrate support touchpoints around the perimeter of the denture. Support removal from these areas is less laborious and leaves critical detailed areas support-free.

For an upper jaw base, particularly the palate area, which is commonly very thin, adding additional supports can improve the fit of the appliance. Begin by removing any auto-generated supports in this specific area.

Add small additional supports over the widest part of the palate for better fit. Remove support touchpoints from the teeth sockets or cervical margin if possible to reduce post-processing.

Denture Teeth

Orientation:

Position the tooth arch at approximately a 0-25° angle to the build platform. The occlusal surface of the teeth can face towards or away from the build platform, depending on preference in finishing the part.

Supports:

To generate supports automatically, click Generate, then select Edit from the Supports menu. Manually replace any supports that appear in undesired areas — especially if they interfere with anatomical features or increase post-processing complexity.

4. Print

Thoroughly shake the resin cartridge before use. Prepare the 3D printer by inserting a resin tank, resin cartridge, and build platform into the printer. Send the job to the printer from PreForm, and start the print.

Notice

For full compliance and biocompatibility, Formlabs Denture Base Resin and Premium Teeth Resin each require a dedicated resin tank, build platform, and Finish Kit or Form Wash.

5. Post-Processing

Always use gloves when handling uncured resins and parts.

See the instructions for post-processing in our Instructions for Use (refer to the links for Premium Teeth Resin and Denture Base Resin).

5.1 Washing

If you use the Form 4 Flex Build Platform, use the release handles to remove the printed parts. Alternatively, you can wash parts directly on the build platform in the Form Wash.

To remove uncured or excess resin, refer to the instructions in the IFU or Manufacturing Guide.

Important

To prevent cross-contamination, do not use the same wash as for non-biocompatible resins.

Washing times for Formlabs resins can be conveniently found on this page.

After washing, allow the parts to air dry for 30 min, or use compressed air to remove alcohol from the parts’ surfaces and air dry for 15 min.

5.2 Support Removal

Once the parts have been washed and dried, remove the raft and supports from the base and teeth. To save time, consider using a low-speed dental handpiece, cutting disc, and a universal silicone polisher wheel.

This step may also be completed after curing.

5.3 Curing

5.3.1 Denture Base Resin

Denture Base Resin must be cured in Glycerin for 15 min at 80 °C in Form Cure (2nd Generation). For Form Cure (1st Generation) or the Fast Cure, please consult the IFU.

To maintain biocompatibility, post-cure the assembled denture while submerged in glycerin. We recommend the use of a heat-resistant round glass container (approximately one liter or four cups) that fits inside the Form Cure.

5.3.2 Premium Teeth Resin

Please consult the IFU and Manufacturing Guide for Premium Teeth Resin. You can also check out the application guide for 3D printing temporary applications using Premium Teeth Resin.

6. Assembly

Warning

After post-curing, the glycerin and denture are hot. Use heat-resistant silicone tongs to remove the denture from the curing chamber. To prevent burns, do not touch the metal turntable or container.

Wash away the glycerine with water until it is no longer slippery or slick to the touch. Blow dry or allow it to air dry.

Insert the teeth into the denture base to test the fit. If anything inhibits seating, trim the teeth and the base as needed using a hand tool.

Once your tooth arch fits without obstructions in the sockets on the printed base, the two parts can be assembled.

To securely attach the denture base to the teeth, we recommend using a dental-grade, self-polymerizing, gap-filling bonder for optimal results. While Formlabs has tested the Ivoclar Ivotion Bond Kit, any similar product designed for bonding PMMA to composite materials will be effective. Self-curing bonding systems are preferred over UV-curing options to prevent additional UV light exposure to the printed parts. Please follow the manufacturers’ instructions for use.

7. Finishing

Once assembled, 3D printed dentures can be pre-polished and polished using traditional methods. For optimal efficiency, if available, we suggest utilizing a lathe with medium-fine pumice and a high-gloss acrylic polishing compound. Avoid the "candy-coating" technique as it may compromise the biocompatibility of the final appliance. While traditional polishing offers the best finish, a dental-grade light-curing varnish, such as Kulzer Palaseal© or GC Optiglaze©, can be used as an alternative.

After confirming the desired outcome, cleanse the denture in an ultrasonic bath using mild soap and rinse thoroughly. Your denture is then ready for delivery.

Congratulations! You have successfully created a beautiful and natural-looking denture for your patient.