Bring the Power and Flexibility of Clear Aligners to Your Business

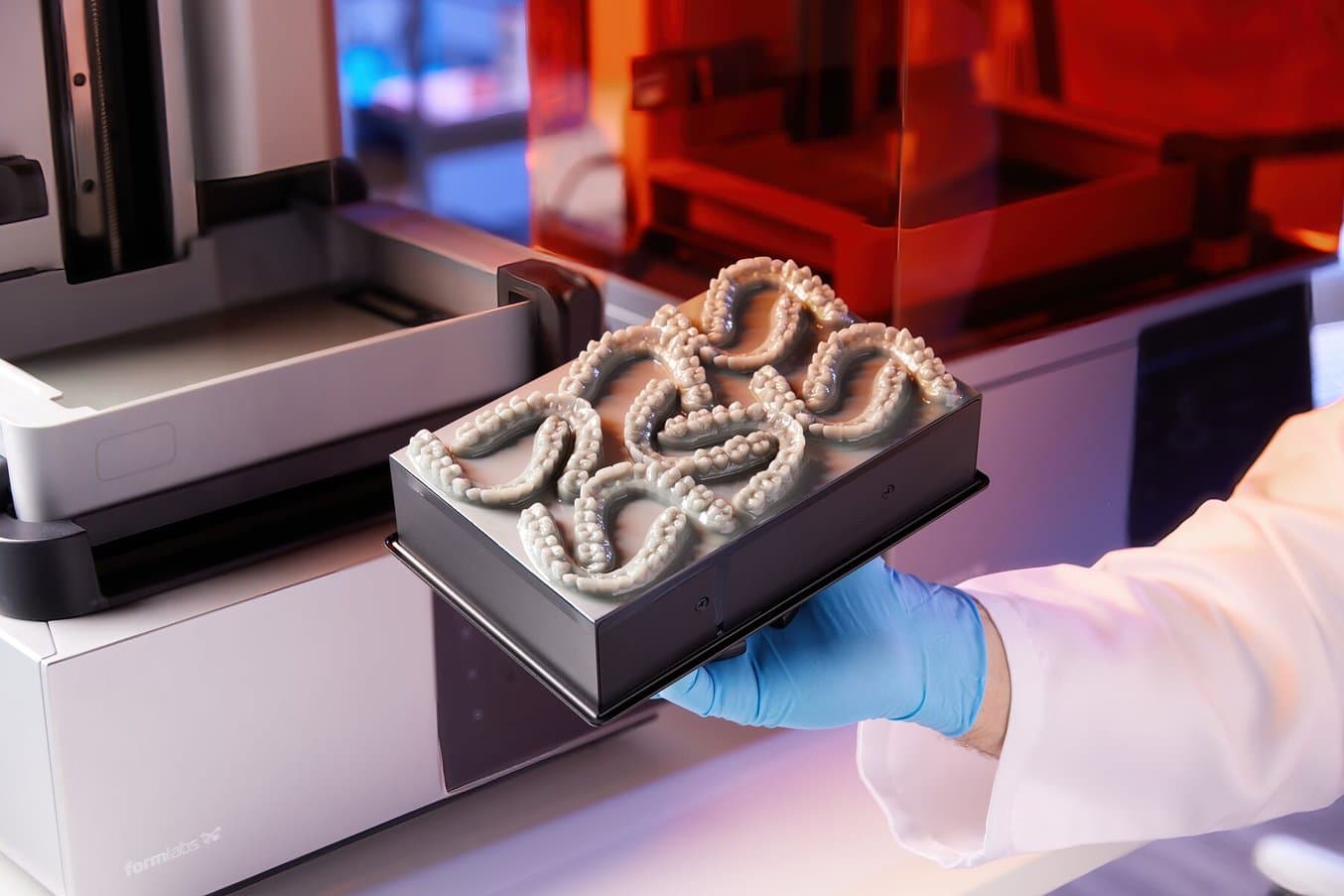

Clear aligners, made by thermoforming a thin sheet of plastic over a 3D printed model, transformed orthodontic care. Printing models gives you control over production, with easy workflows for efficiency and cost-savings.

Save Time and Money

Power In Your Hands

Same-Day Starts

Attain Positive ROI in Weeks

Print 11 models in nine minutes on Form 4B with Fast Model Resin for $1 per model. For high-throughput production with fewer interactions, print 32 aligner models on Form 4BL in 14 minutes (horizontal orientation) or 75 models in 106 minutes (vertical orientation) for $1 per model.

| Time from scan to treatment start | Cost for a comprehensive case* | |||

|---|---|---|---|---|

| Outsourced aligners | As much as 8 weeks | $1500-2000 | ||

| In-house aligners with Formlabs | As little as 1 hour | $300-400 | ||

| Savings per case | 8 weeks | $1100-1700 |

Independence, Flexibility, and Control

“The ability to 3D print has really allowed us to create our in-house aligner system, and that has allowed me to provide a service for patients. The effect on my practice has been amazing because people want aligners and so many people come here, particularly because we make them ourselves.”

Fast Printing: Scan to Aligner in Less Than an Hour

Easy, fast workflows enable true chairside delivery as well as serious throughput.

Scan

Design

Post-Process

Thermoform

“I can print models in under ten minutes. That means this is approaching the point where models can be printed almost as fast as we can scan a patient.”

Print With a Fully Validated System for an Easy Workflow

Our extensive validation and testing process makes sure your prints work every time: quick setup, no in-field calibration, and no messy resin handling.

Optimized settings and extensive validation makes it easy to print models in just nine minutes.

Learn With Formlabs Dental Resources

Virtual seminars, lectures from leading practitioners, and short, helpful videos help you start faster and get the most out of your 3D printer.