Formlabs Dental is pleased to announce that our digital denture solution is now available for the European market, empowering our community to continue to push the boundaries of prosthetic dentistry.

Long-Lasting, Affordable Dentures in Multiple Shades

Formlabs Denture Resins are CE-certified biocompatible materials for 3D printing dentures. With four semi-translucent pink base shades and six fully characterizable tooth shades, technicians can achieve lifelike gingiva with natural margins and truly patient-matched aesthetics. Use these resins to produce long-lasting, wear-resistant dentures at a fraction of the cost compared to traditional methods.

| DENTURE BASE | DENTURE TEETH | |

|---|---|---|

| Description | Use Denture Base Resin to 3D print biocompatible denture bases for long-term use in the mouth. | Use Denture Teeth Resin to 3D print biocompatible teeth for long-term use in the mouth. |

| Applications | Final denture base for 3D printed teeth Try-in dentures | Final denture teeth |

| Colors | DP (dark pink), LP (light pink), RP (red or reddish pink), OP (original pink) | A1, A2, A3, A3.5, B1, B2 (Classic VITA Shades) |

Benefits of the Digital Denture Workflow

"Digital Dentures with 3D printing opens the door to new treatment possibilities. This workflow has several advantages over the conventional workflow and is a great alternative to milling that is far more expensive."

—Stephan Kreimer, MDT

Switching from a traditional workflow to a digital workflow for denture production provides a number of key advantages:

Low-cost production: Affordable hardware allows labs to expand production without adding substantial overhead. Material costs around €8 per part for a complete denture compared to €40-50 using traditional denture cards and acrylic.

Accurate, consistent, high-quality results: A directly 3D printed prosthetic means fewer steps and less variability—a more consistent workflow for a quality end product every time.

Intuitive, adaptable tools: The digital workflow fits into your traditional processes today and will be much easier to teach to tomorrow’s digitally-savvy dental lab technicians.

Simplified, fast remakes: Digital denture designs are reusable, shareable, modifiable, and easy to reproduce with 3D printing.

Truly custom teeth: Unlike pre-manufactured denture cards, digital dentures are completely patient-specific.

"The ability to additively manufacture dentures in my practice is really exciting and it allows me to digitize even more procedures using my Formlabs ecosystem."

—Dr. Michael Braian, DDS, CDT, PhD, from Malmö, Sweden.

Techniques for Aesthetic Digital Dentures: 3D Printing Workflow and Characterization

In this webinar, Bernhard von Oppeln, MDT, Formlabs Dental Solutions Engineer will do an overview of the digital workflow for printing and producing dentures together with characterization techniques for optimal results.

The Digital Denture Workflow

1. Scan

Using a desktop laboratory scanner, scan the fully articulated poured model and wax-rim to collect patient anatomy.

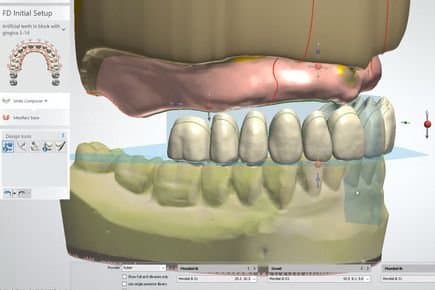

2. Design

Import the scan data into CAD software and design the denture digitally.

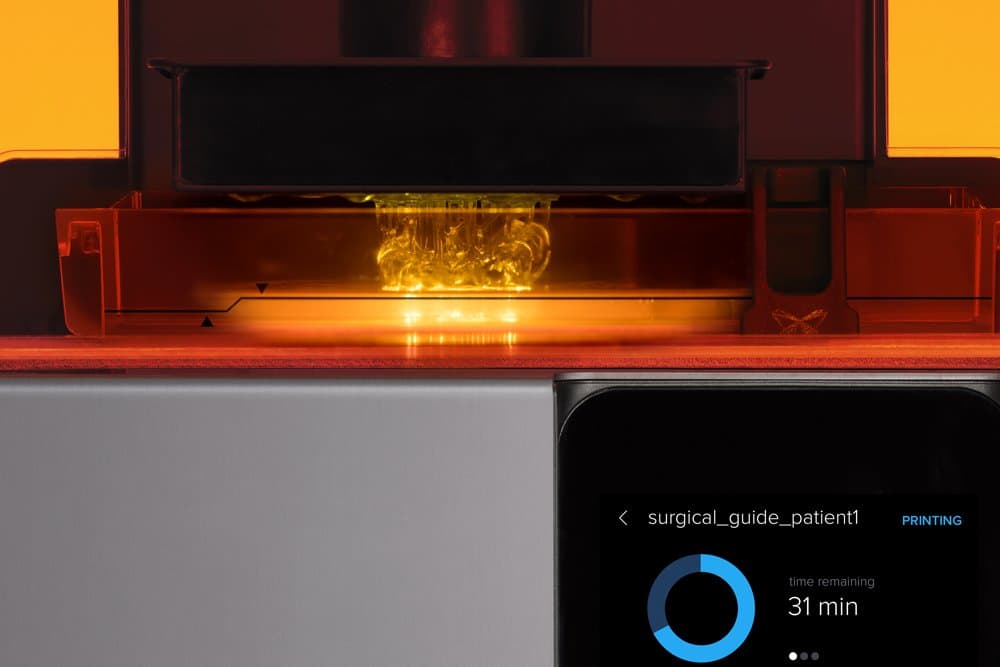

3. 3D Print

Bring the denture base and teeth designs into our nesting software, PreForm, for print preparation and easily send them to a Formlabs printer.

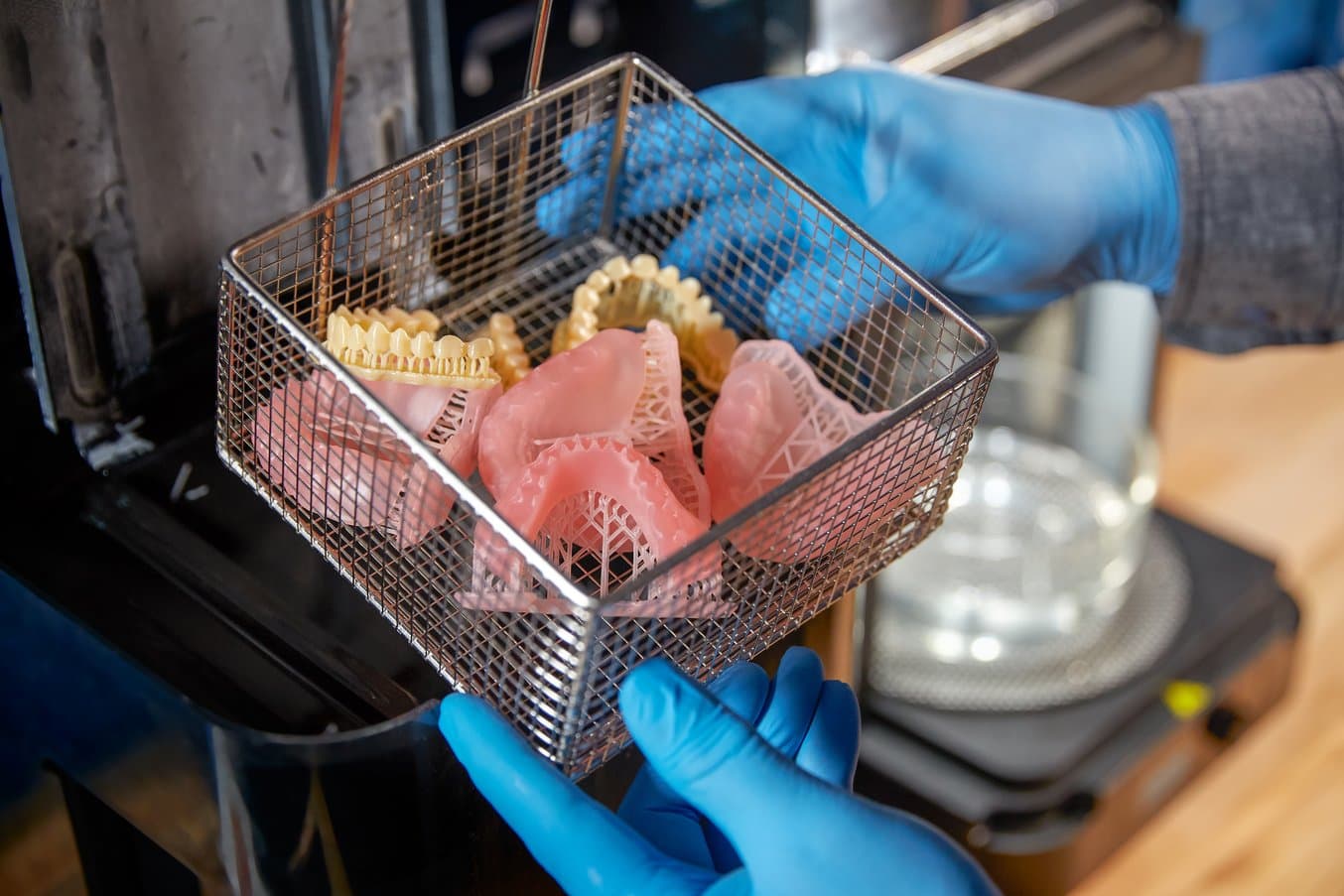

4. Prepare

Wash the printed parts using Form Wash and remove supports.

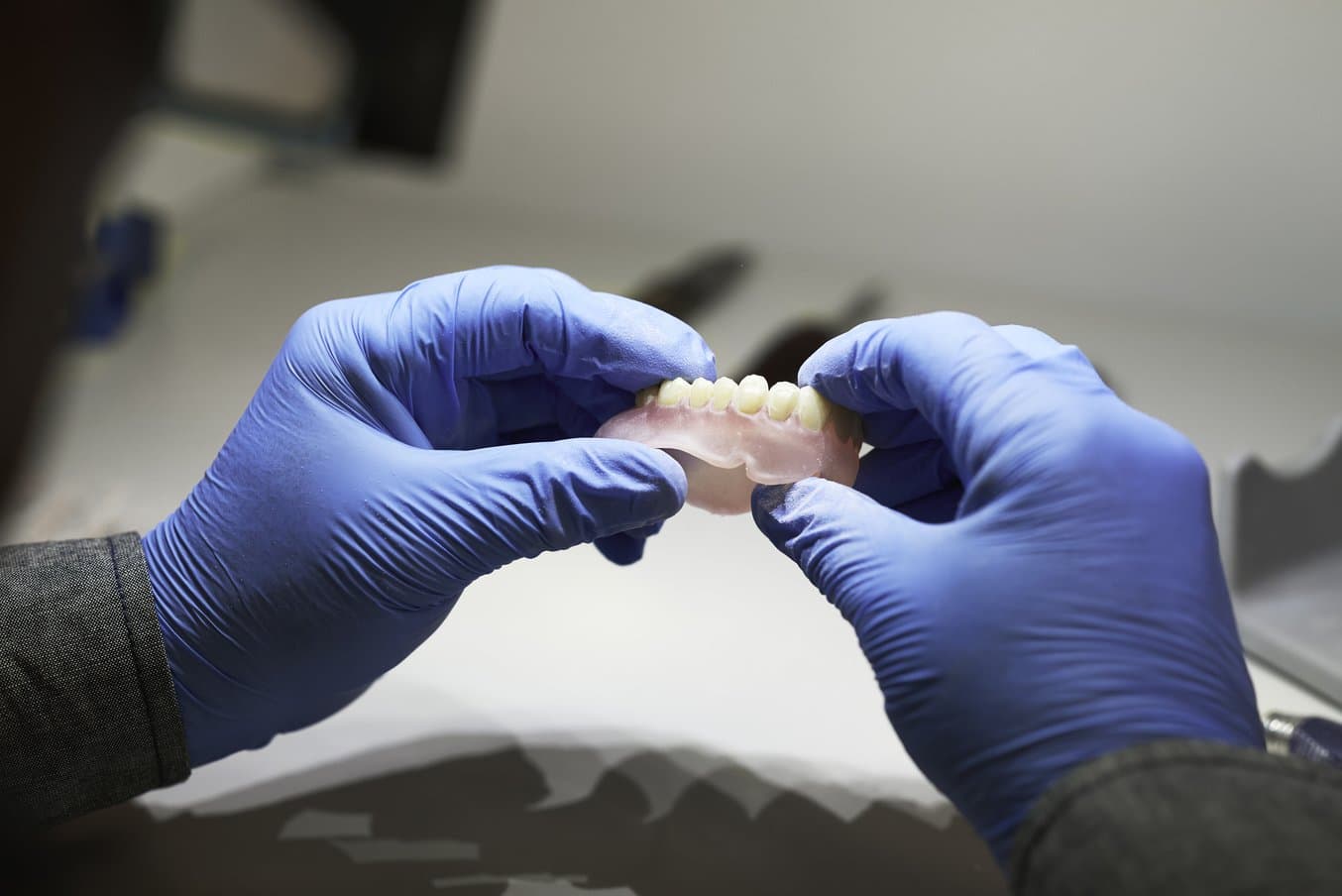

5. Assemble

Insert the teeth into the denture base, tack them together, and post-cure the denture in Form Cure to bond the parts together.

6. Finish

Polish at low speeds with pumice and at high speeds using hi-shine polish compound before the final quality control.

Get Started With Digital Dentures

Ready to get started? Order digital denture resins now via our online store.

Do you have any questions about the materials or the workflow? Get in touch with the Formlabs Dental team or our dental partners.