Growing patient demand for aligner treatment options has created a new class of orthodontic solutions. While digital orthodontics records have become standard, entering an in-office digital workflow can feel overwhelming due to the amount of software and hardware options on the market.

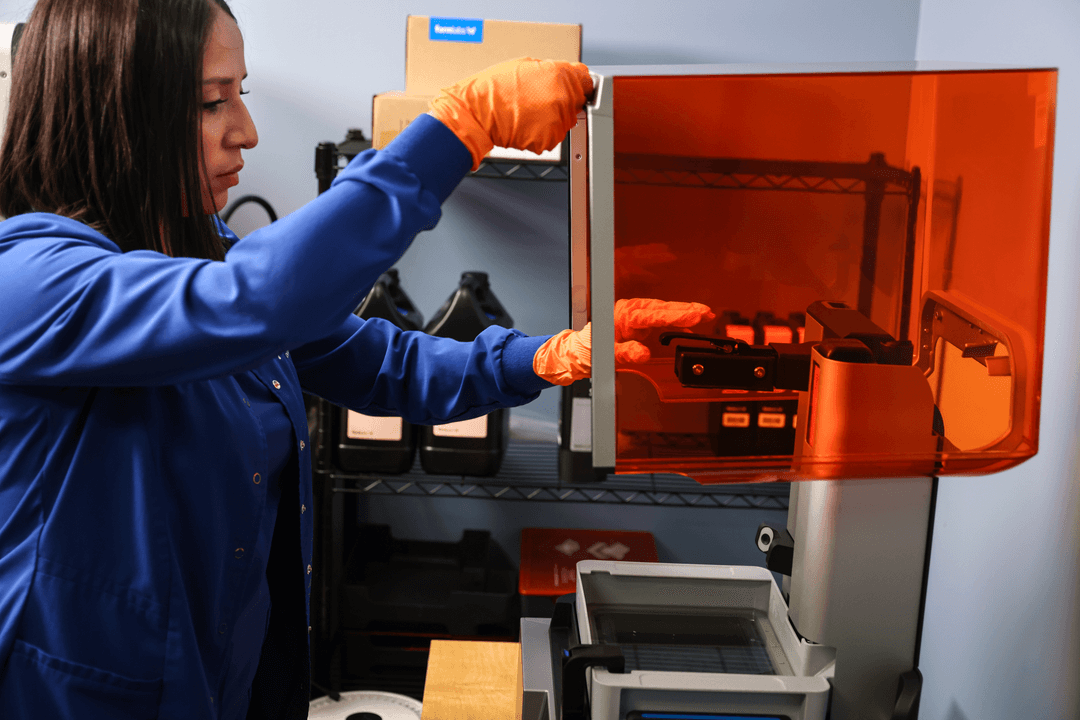

We sat down with Dr. Christopher Riolo and Cali Kaltschmidt to hear how they have been using Formlabs desktop printers in their orthodontic practice, and to see if they had any advice for others considering in-house aligner production.

Dr. Christipoher Riolo is an orthodontist in Seattle, running a completely digital practice which has incorporated 3D printing for five years. Cali Kaltschmidt, an orthodontist for seven years, the co-founded TheToothMovement. Both started printing with Formlabs machines, and it has changed the way they run their practices.

3D Printing for Orthodontists: Don’t Get Stuck in the Stone Age

In this webinar, Seattle based orthodontist Dr. Riolo of Riolo Orthodontics will introduce you to the different scanning, software, and printing technologies available in orthodontics. He will walk you through the in-house aligner workflow so you can seamlessly go from analog-to-digital.

Benefits of In-House Aligners

Dr. Christopher Riolo and Cali Kaltschmidt have been printing in-house aligners for years. When speaking with actual orthodontists, it becomes apparent how approachable the entire process is. Patients’ teeth are scanned, and free tools such as MeshMixer and PreForm are used to edit 3D files and prepare them for printing.

In their view, the core benefits of in-house aligner workflows are:

- Increase control over movement parameters.

-

More choices of aligner materials.

-

Wide choice of software platforms to set up treatment.

-

Control the production.

-

Cost savings.

-

Ability to coordinate hybrid treatment.

Dr. Riolo elaborated on all of these benefits. For example, when talking about aligner materials, he highlighted the range of materials available when printing in-house. Dr. Riolo recommended using Essiz A+ for attachment templates due to its low price point; you can use any material for attachment templates, so using cheaper materials makes the most sense. In-house workflows give orthodontists total control over what they use and when, meaning each practice can tailor production to what the practitioner or client prefers.

“I haven’t used Invisalign in two years”

Dr. Christopher Riolo

Dr. Riolo and Cali Kaltschmidt also discussed how they set up their Formlabs printers in the office, and reviewed the multitude of benefits 3D printing has on aligner production, which included reducing lab fees by 90%:

| Five In-House Aligners | Five Invisalign Aligners |

|---|---|

| $25-50 | $500 |

| Ten In-House Aligners | Ten Invisalign Aligners |

| $100 | $900 |

From Analog to Digital

Dr. Christopher Riolo and Cali Kaltschmidt reviewed seven considerations when getting ready to implement digital workflows. Dr. Riolo stressed that the printer is not the focal point of the process. The best printer is one that disappears into the background of your daily work.

Seven key considerations when switching to a digital workflow in orthodontics:

-

Different material requirements

-

Different systems employed by the staff

-

Additional software

-

Additional hardware/equipment

-

Training demands

-

Opportunities to add value to the care you offer your patients

-

Opportunities to streamline and improve office systems

Dr. Riolo elaborated on each of these considerations. For example, when thinking about staffing, he has gone through different systems to make sure staff are not skipping steps in the digital workflow. This could be using online software or giant whiteboards. At his practice, every staff member is trained on scanning, editing STL files, and printing. Even if your practice employs a single technician that is a digital workflows expert, there needs to be a tailored system in place to make sure every step in the process is followed.

Speed is King?

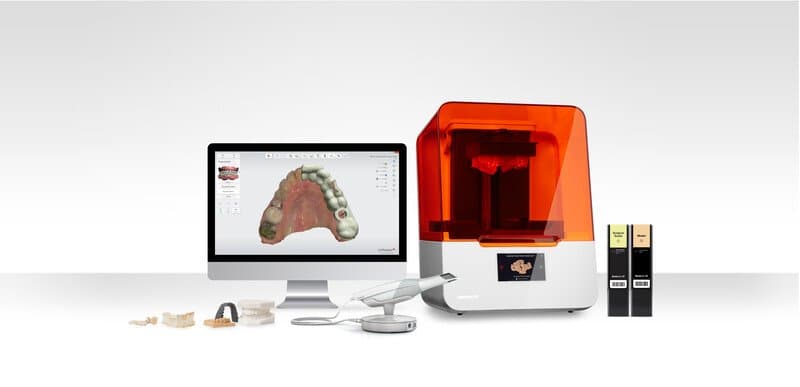

Dr. Riolo believes speed shouldn’t be one of the major metrics to consider when shopping for a printer, whether creating aligners or other dental applications. It’s easy to focus on how fast a machine can print a set of aligners, but resin availability and FDA approved materials are far more important. These are the two things Dr. Riolo has seen vary from printer to printer, and he recommended investigating further before making a purchase for your practice.

The Form 3B was created with both of these concerns in mind. The Form 3B is an advanced desktop 3D printer optimized for biocompatible materials. Feedback from the Form 2, such as the importance of resin availability and FDA approval, were central to the design process of the Form 3B.

Support is another key factor to consider over print speed when committing your practice to a 3D printer. When Dr. Riolo first bought his Formlabs machine, he joked that the company didn’t know what a dentist was. Now the company has a team of over 30 dentist-focused employees offering how-to guides, phone support, free webinars and more. Ultimately this means one thing: it’s never been easier to get your practice up and running with in-house aligners. As Dr. Riolo says, “the time has arrived, it’s just not difficult anymore”.

Watch the Full Free Webinar Now

We had a great time talking to both Dr. Christopher Riolo and Cali Kaltschmidt. You can listen to the entire conversation for free to learn about different scanning, software, and printing technologies available in orthodontics, and to hear the entire Q&A segment.