With the release of two new materials, Permanent Crown Resin for direct-printed permanent restorations and Soft Tissue Starter Pack for gingiva masks, Formlabs Dental now has the most complete portfolio of materials for restorative dentistry of any 3D printer company.

Since launching the Form 3B, our dental desktop 3D printer, in November 2019, Formlabs has been busy: we introduced 5 proprietary formulations designed specifically for Formlabs stereolithography (SLA) printers, improving the workflows you depend on and expanding what your Formlabs 3D printer can do. We are committed to continuous expansion of our dental materials library into a wide range of indications on a single 3D printing platform.

Read on to learn what we’re adding to the arsenal of tools you can use to innovate in restorative dentistry.

3D Printing Comes to Restorative Dentistry

Restorative dentistry has already “gone digital.” Intraoral scanning and digital design (computer-aided design, or the CAD of CAD/CAM) have been readily adopted by dental professionals around the world. However, on the computer-aided manufacturing (CAM) side, digital milling of zirconia or lithium disilicate has been the preferred manufacturing method.

Historically, 3D printing permanent restorations were out of reach due to a lack of appropriate dental materials in the market that had the desired mechanical properties, accuracy and fit compared to milled or conventional materials. Increases in adoption and accessibility for 3D printing in dental over the last five years have opened the door to testing and validating cutting-edge indications.

The digital workflow for Permanent Crown Resin is developed in partnership with BEGO, a leading specialist in the field of prosthodontics and implant dentistry. BEGO has more than 20 years of experience in developing 3D printing materials for dental applications and is regarded as a specialist in all dental fabrication techniques.

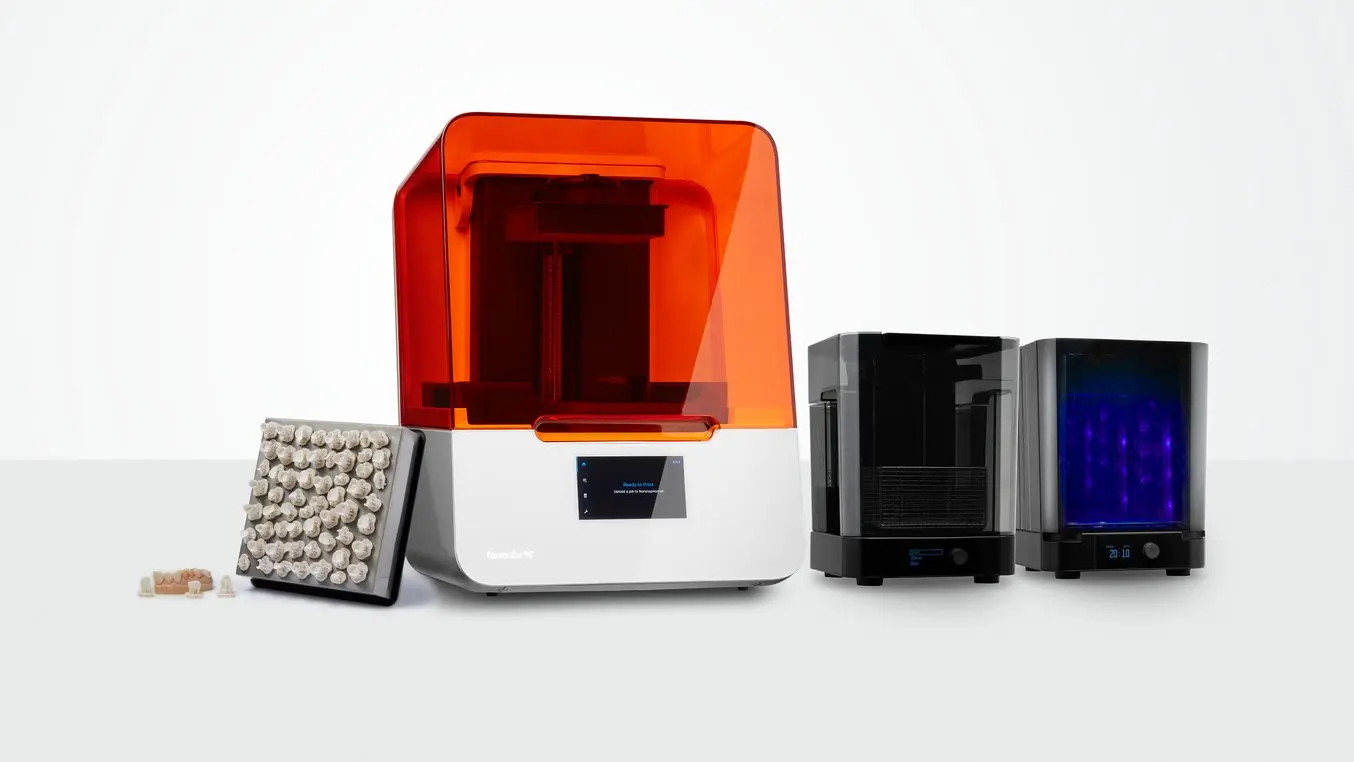

With the Form 3B and the entire surrounding ecosystem (including Form Wash and Form Cure, which simplify post-processing of 3D printed parts), it’s possible to achieve the necessary level of dimensional accuracy required for such high-precision products in a rigorously validated, intuitive workflow and at an accessible price point.

Interested in 3D printed temporary restorations? The Form 3B can do that, too.

3D Printed Permanent Restorations, Tested to the Highest Standards

Permanent Crown Resin is a tooth-colored, ceramic-filled resin, indicated for the direct printing of permanent single crowns, inlays, onlays, and veneers.

This cutting-edge resin produces high strength, long term restorations with an accurate and precise fit. Low water absorption and a smooth finish ensure restorations made from Permanent Crown Resin have a low tendency to age, discolor, or accumulate plaque.

Finished and unfinished single unit restorations printed in Permanent Crown Resin, on model printed in Model Resin.

Since 3D printed permanent restorations are new to the market, each printer manufacturer can decide how much safety testing to perform. Formlabs has rigorously tested every stage of the workflow to ensure patient safety is preserved at each step. The Form 3B-specific workflow (documented in the Instructions For Use) has even been independently reviewed by the Notified body to validate the entire printer ecosystem for third party and health agency (FDA) audits. This extra validation is one of the benefits of working with a Formlabs workflow that has been validated from start to finish.

Note: Permanent Crown Resin is compatible only with the Form 3B.

Printing With Permanent Crown Resin

Parts printed in Permanent Crown Resin can be contoured, polished, and glazed with common dental tools, and does not require sintering. Learn more in our step-by-step application guide.

Permanent Crown Resin: Product Demo

In this webinar, learn about the new material and digital workflow developed in partnership with BEGO from Georgio Haddad, Dental Strategic Partnerships Manager at Formlabs, and Dr. Elisa Praderi, Clinical Protocols & KOL Manager at Formlabs.

Reliable, Accurate Soft Tissue Models

Implant models printed in Model Resin, with gingiva masks printed in light, medium, and dark pink Soft Tissue Resin.

Soft Tissue Starter Pack, which includes Flexible 80A Resin and pigments for mixing Soft Tissue Resin in custom colors, allows laboratories to make gingiva masks and other soft tissue models on a Formlabs printer.

-

Minimize chairside adjustment time with accurate planning for restorations with proper tissue impingement.

-

Confidently check implant prosthetics by adding removable soft tissue components to your model production.

Mixing Soft Tissue Resin With the Soft Tissue Starter Pack

The Soft Tissue Starter Pack includes Flexible 80A Resin for use as a base with three Color Pigments in Magenta, Yellow, and White, so you can customize the shade of your model. We’ve validated three recipes in dark, medium, and light pink for consistent printing. Just measure out the pigments, mix into the Flexible 80A Resin base cartridge, print your model, and post-process.

The Soft Tissue Starter Pack includes Flexible 80A Resin as a flexible base, as well as three Color Pigments in Magenta, Yellow, and White.

Read more about how to mix Soft Tissue Resin for printing gingiva mask models in our application guide.

The Best 3D Printer for Restorative Dentistry

With the addition of these two new materials, the Form 3B cements its position as the most versatile 3D printer for restorative dentistry, in both dental offices and laboratories.