Stephan Kreimer is a Master Dental Technician and director of Kreimer Dentallabor GmbH & Co. KG, a full-service dental lab specializing in digital workflows. More than 80% of their cases are received digitally and worked on by a team of 12 dental technicians in a space designed around the efficiency of digital workflows.

“Investing in high-quality hardware and materials has been incredibly beneficial for our dental lab. It's a smart investment that significantly boosts our efficiency and transforms our workflow. The impact has been nothing short of revolutionary."

Stephan Kreimer, MDT, Kreimer Dentallabor

Kreimer's lab is hugely productive — the team 3D prints an average of 300 dental models each month, about 60% of which are highly precise restorative models, as well as biocompatible appliances including occlusal splints, surgical guides, provisionals, and custom impression trays. To produce these, Kreimer Dentallabor has assembled a 3D printer fleet including the blazingly fast and accurate Form 4B 3D printer for biocompatible production of appliances, as well as the large-format Form 4BL for high-throughput production of models.

The intuitive workflows and ease of use of the Formlabs ecosystem enable higher efficiency, resulting in time savings and lower costs for the lab. At a time when skilled labor is hard to come by and expensive, investing in efficient, streamlined solutions is a game-changer.

To continue their high standard of care, increase efficiency, and save costs, Kreimer is always evaluating new technologies and materials in the dental 3D printing space. Kreimer put Fast Model Resin and Precision Model Resin through extensive testing before adopting them. He’s found that producing restorations on restorative models printed with Form 4BL and Precision Model Resin has not just saved time and costs, but eliminated patient appointments for dentists working with Kreimer Dentallabor.

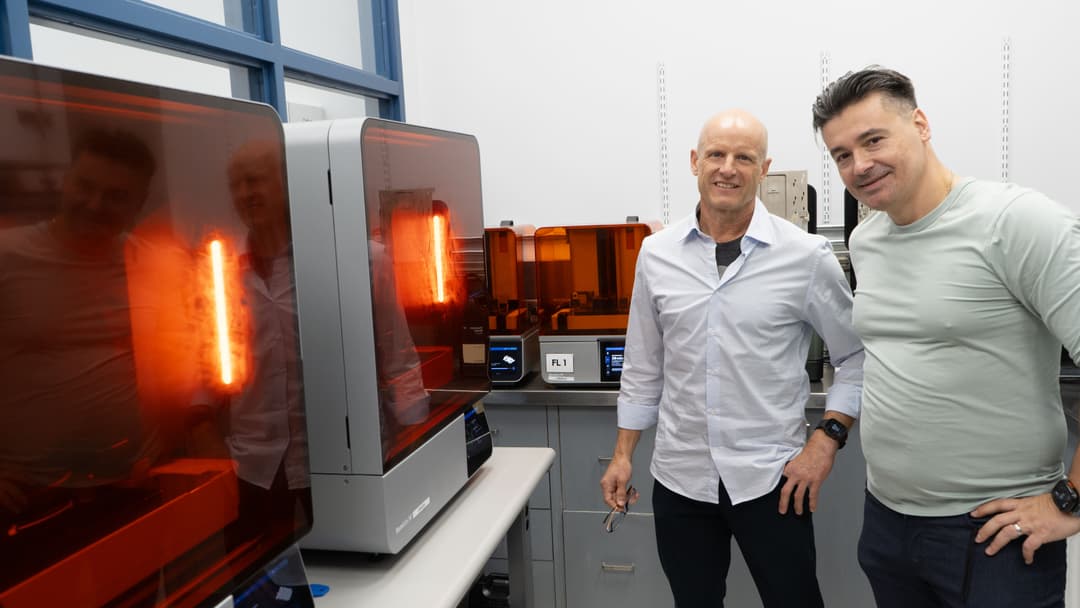

Assembling the Dental 3D Printer Fleet

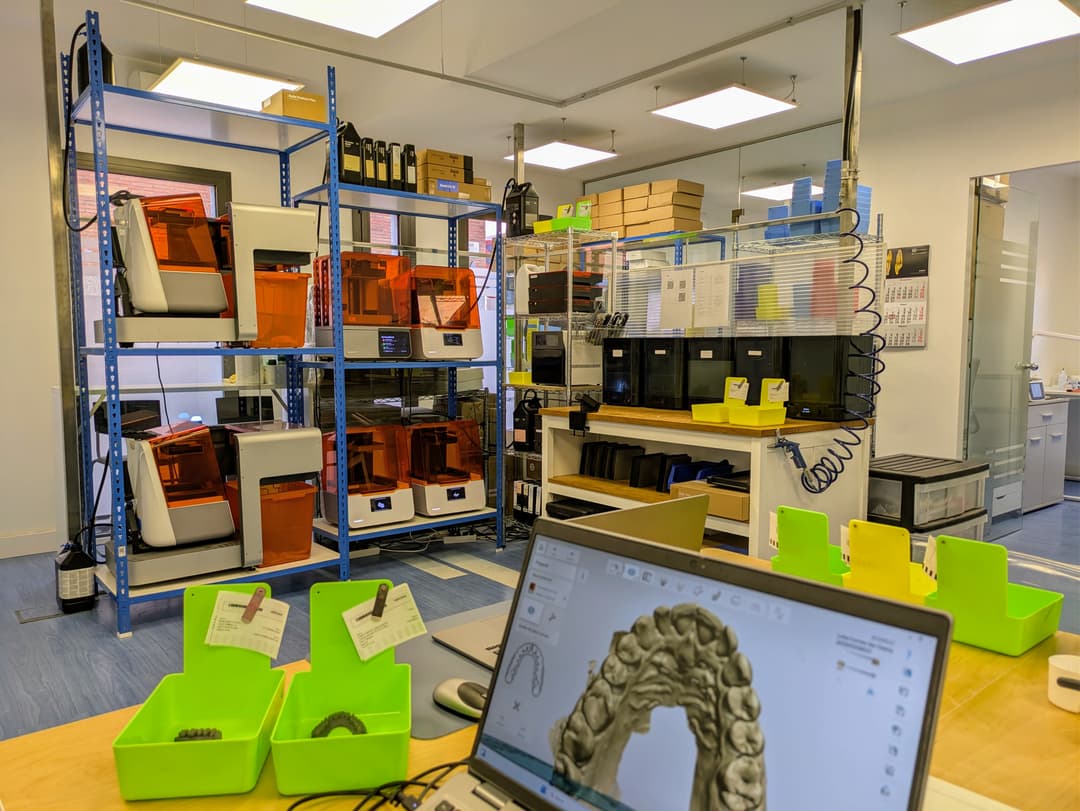

Kreimer Dentallabor’s space was designed for digital dentistry workflows, including a CAD/CAM area for designing, a dedicated room for CNC machining, and a dedicated room for 3D printing with eight 3D printers.

Form 4BL for large-format 3D printing is the most recent addition to Kreimer Dentallabor.

Kreimer’s Formlabs printers include three Form 3B+s, two Form 4Bs, a Form Auto, and Form 4BL.

Saving Time and Costs With Form 4B

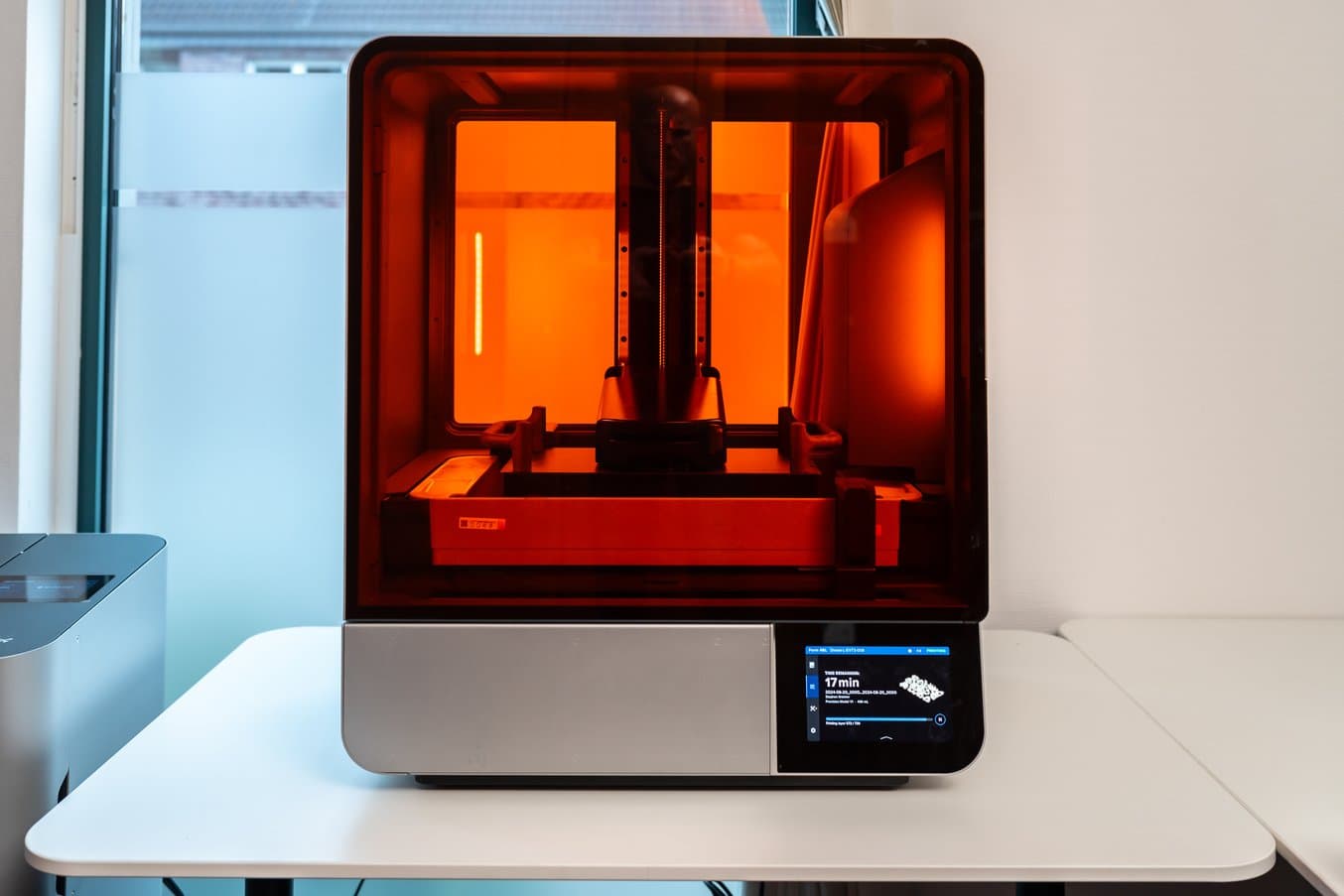

Form 4B was released in the spring of 2024, and Kreimer immediately put it to the test. "I've been waiting for years for Formlabs to update its technology to cure the entire build platform simultaneously, and now it's finally here."

“Form 4B is truly a game changer for our entire production, because now we can produce parts two to five times faster than before. The surface, the small details, the edges, the fit—everything feels more precise. Overall, the printer's speed, efficient movements, added sensors and camera, and larger build platform are fantastic. With Formlabs’ ecosystem, our 3D print success rate is now close to 100%."

Stephan Kreimer, MDT, Kreimer Dentallabor

Beyond printing, workflow efficiencies increased as updates to the Form Wash (2nd Generation) enabled more powerful washes. Kreimer says, "I also love the improved washing capabilities of Form Wash. It has significantly more power, making it easier to clean parts. Additionally, since the materials are cured to a higher level with Form 4B, cleaning is even simpler. The entire post-processing workflow is better and faster now."

“Today, we had the first day of a new employee. He was designing a case, and while he was still calculating the milling file, the model had already finished printing."

Stephan Kreimer, MDT, Kreimer Dentallabor

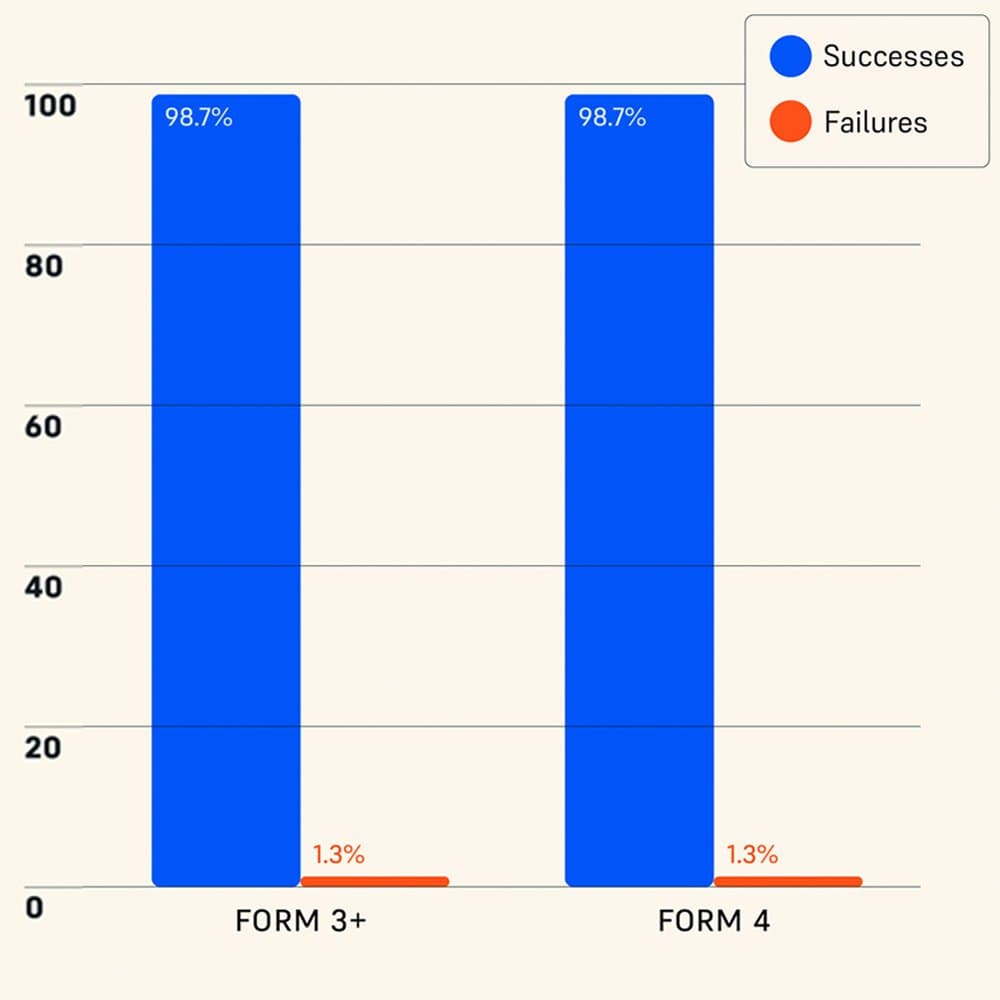

Independently Tested Reliability of Form 4 and Other Resin 3D Printers

Formlabs Form 4 was measured to have a 98.7% print success rate by an independent global leader in product testing. Read a complete description of the test methodology and see the results in our white paper.

Maximizing Throughput With Form 4BL

Form 4B enables Kreimer Dentallabor to print over 30 restorative models a day. However, printing that many models on the Form 4B build platform means that technicians have to go to the 3D printer room, remove models, wash them, and put in new build platforms a few times a day. This repetitive task takes technicians away from higher value tasks, and introduces a time to get distracted by conversations or other tasks.

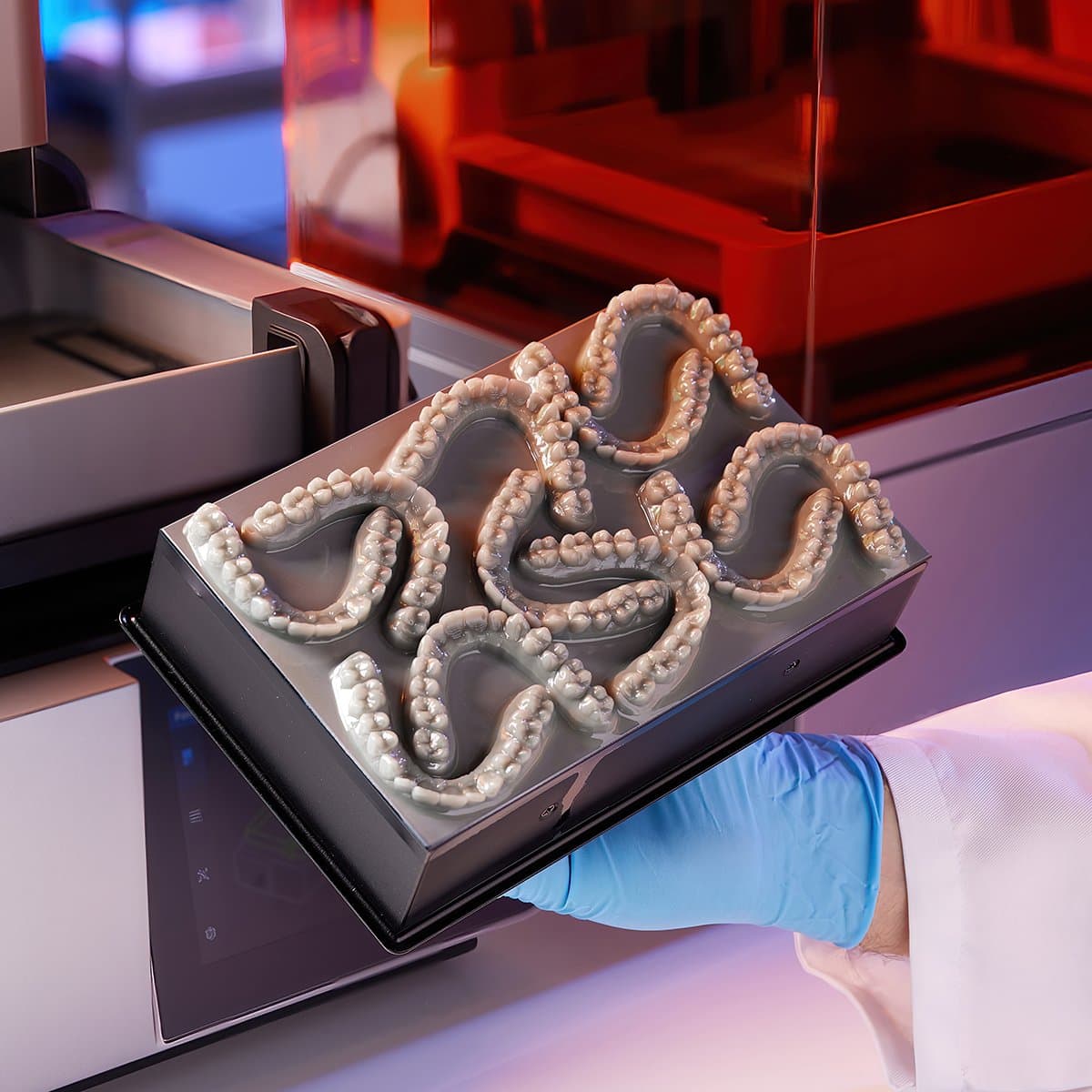

The Form 4BL build platform is 2.7x larger than that of Form 4B, enabling higher throughput.

Enter Form 4BL. With a 2.7x larger build platform surface than Form 4B, Form 4BL is Formlabs’ large-format dental 3D printer, built on the same technology as Form 4B for blazing fast printing and accurate and precise 3D printed models. Kriemer says, "I was very satisfied with the print quality of the Form 4B, and the Form 4BL delivers the same results. I scanned several models and used surface comparison software to compare them with the original dataset, and the results were similar to those from the Form 4B. Additionally, the fit of the implant analogs was also comparable."

"With the Form 4BL's build platform, which is three times larger, we can now produce three times more models with just one user intervention."

Stephan Kreimer, MDT, Kreimer Dentallabor

Adding Form 4BL to Kreimer’s printer fleet means the lab can fit three times as many models on one build platform. Now, rather than walk to the 3D printer room a few times a day, technicians can batch more models together, and post-process prints two to three times a day while achieving the same throughput.

Form Wash L, a large-format washing solution, enables washing an entire Form 4BL build platform at once, streamlining the post-processing workflow and freeing up technicians for higher-value tasks.

Kreimer says, "We are currently using the Form 4BL for all our model production and the Form 4Bs for biocompatible applications." Kreimer notes that assigning the printers this way "is a big advantage compared to the workflows we used before."

Invest in Efficiency

"When I compare our efficiency from 10 years ago, when we were working mostly with conventional methods, to now, where we are almost completely digital, the difference is astounding. Our employees are two or three times more efficient with this technology.”

Stephan Kreimer, MDT, Kreimer Dentallabor

When Kreimer received Form 4BL, he delegated the set-up of the printer to a team member. “It was running in 15 minutes. It’s as easy as Form 4B — everyone can do it in 15 minutes.”

"Digital technology helps us onboard new employees faster, allowing them to achieve a high level of quality much quicker than before."

Stephan Kreimer, MDT, Kreimer Dentallabor

Good dental technicians can be hard to find and their labor is expensive, but leveraging the optimal tools and materials quickly pays off. Digital dentistry workflows are faster and more efficient, and the intuitive workflows of Formlabs 3D printers make it easy to onboard and train.

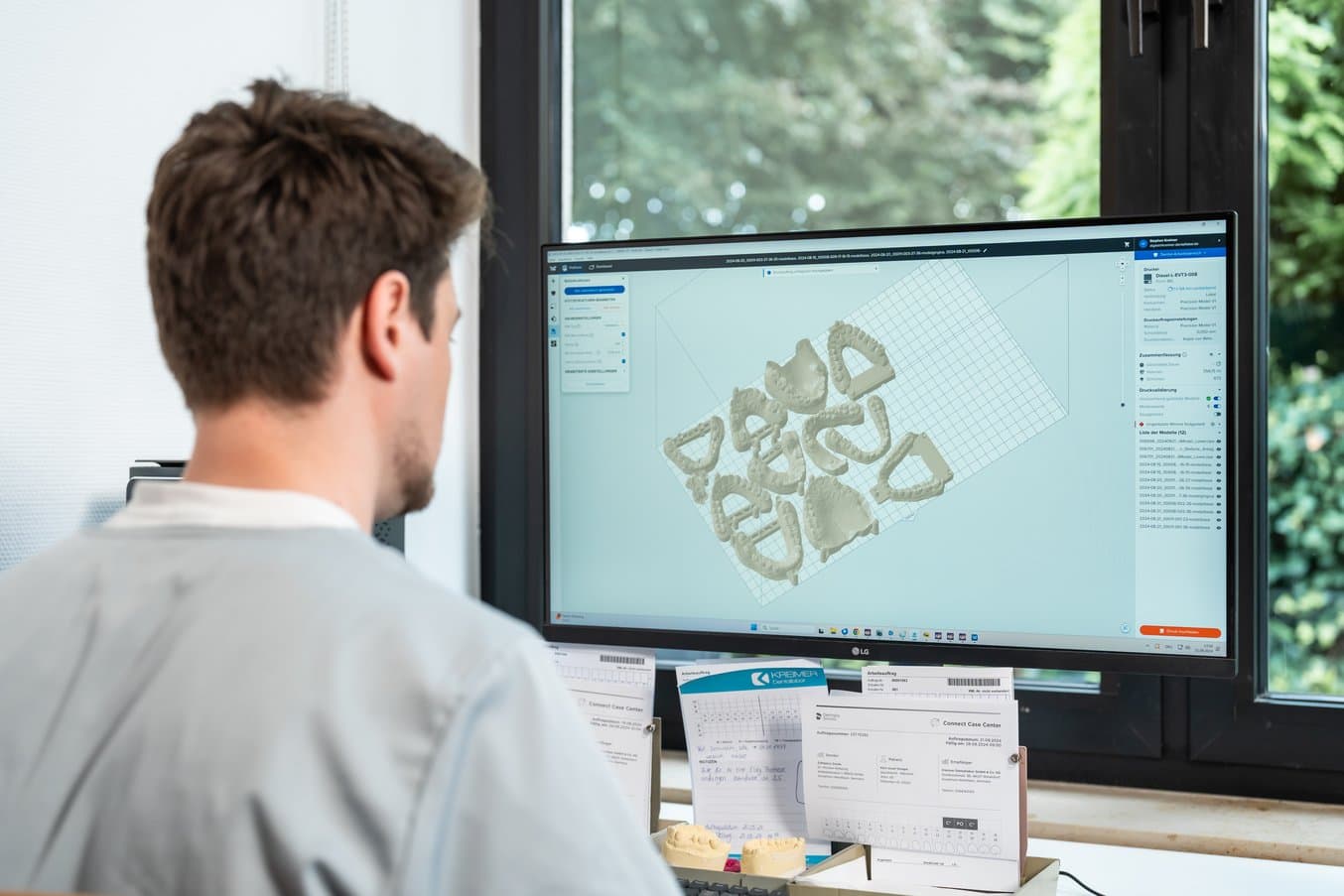

A dental technician lays out restorative models on a build platform in PreForm, Formlabs’ print preparation software.

Reliability ensures fewer remakes, for appliances that fit the first time. Fine details and smooth finishes decrease the time spent finishing appliances. For example, occlusal splints printed with Dental LT Comfort Resin take minimal time to polish.

Formlabs printers all feature the same intuitive workflows, so team members can seamlessly shift from Form 3B+ to Form 4B to Form 4BL, enabling labs to grow production without increasing demands on staff or overhead costs. Ultimately, Kreimer finds that "It’s worth investing to save labor time, as it allows the team to complete more work, which leads to increased revenue. The real profit comes from the case, not just the models. By spending less time on post-processing and printing, the team has more time to focus on producing high-quality dental appliances."

Versatility With Formlabs’ Dental Resins

Kreimer extensively tests resins from multiple manufacturers to find the optimal resin for each application, selecting specific Formlabs resins only after thorough testing and evaluation.

Form 4B Series printers print 15+ dental-specific resins, including biocompatible resins designed and manufactured within our robust Quality Management System that is ISO 13485 and EU MDR-compliant. Of these, Kreimer uses Dental LT Comfort Resin for the production of occlusal splints, Surgical Guide Resin for guides, BEGO™ VarseoSmile® TriniQ® Resin for restorations, and more, as each is highly precise and accurate, providing appliances that fit every time.

With BEGO™ VarseoSmile® TriniQ® Resin it’s possible to print both temporary and permanent restorations.

Exceptionally clear occlusal splints printed on Form 4B in Dental LT Comfort Resin.

With the release of Form 4B, Formlabs material scientists took advantage of the advanced hardware to develop two new, industry-leading materials for dental applications: Precision Model Resin and Fast Model Resin. Kreimer put both to a rigorous test, printing models to scan and check for accuracy and precision.

Formlabs Dental Materials Overview: Discover What You Can Print With the Form 4B

This webinar will guide you through the various benefits and applications enabled by Form 4B, including its existing biocompatible materials and newly developed formulations for model production such as Fast Model Resin and Precision Model Resin.

Putting Precision Model Resin to the Test

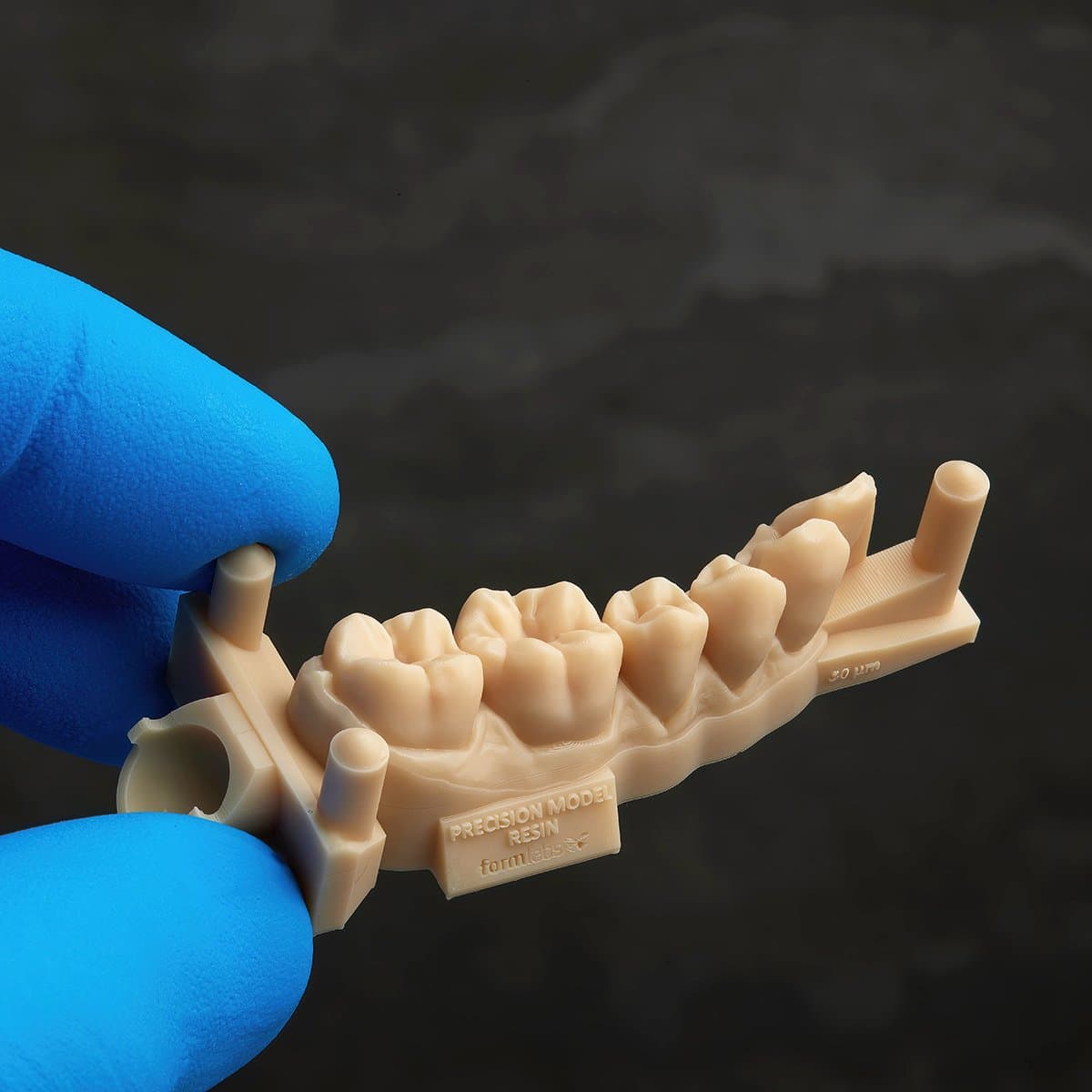

Resins for restorative models must be highly precise and accurate. Kreimer says, "For all restorative models, such as crowns, bridges, and implant cases where precision is essential, you need a material that is highly accurate. For instance, when printing implant models with analogs or models with removable dies, the fit must be perfect, with no need for adaptation."

Additionally, Kreimer says, “The model resin should be visually comfortable. Opacity is preferable to translucency for this type of model, as it is easier on the eyes during extended periods of work and makes it easier to see margins and small details.” Precision Model Resin has matte aesthetics and a gypsum-like appearance to better distinguish margin lines and fine details.

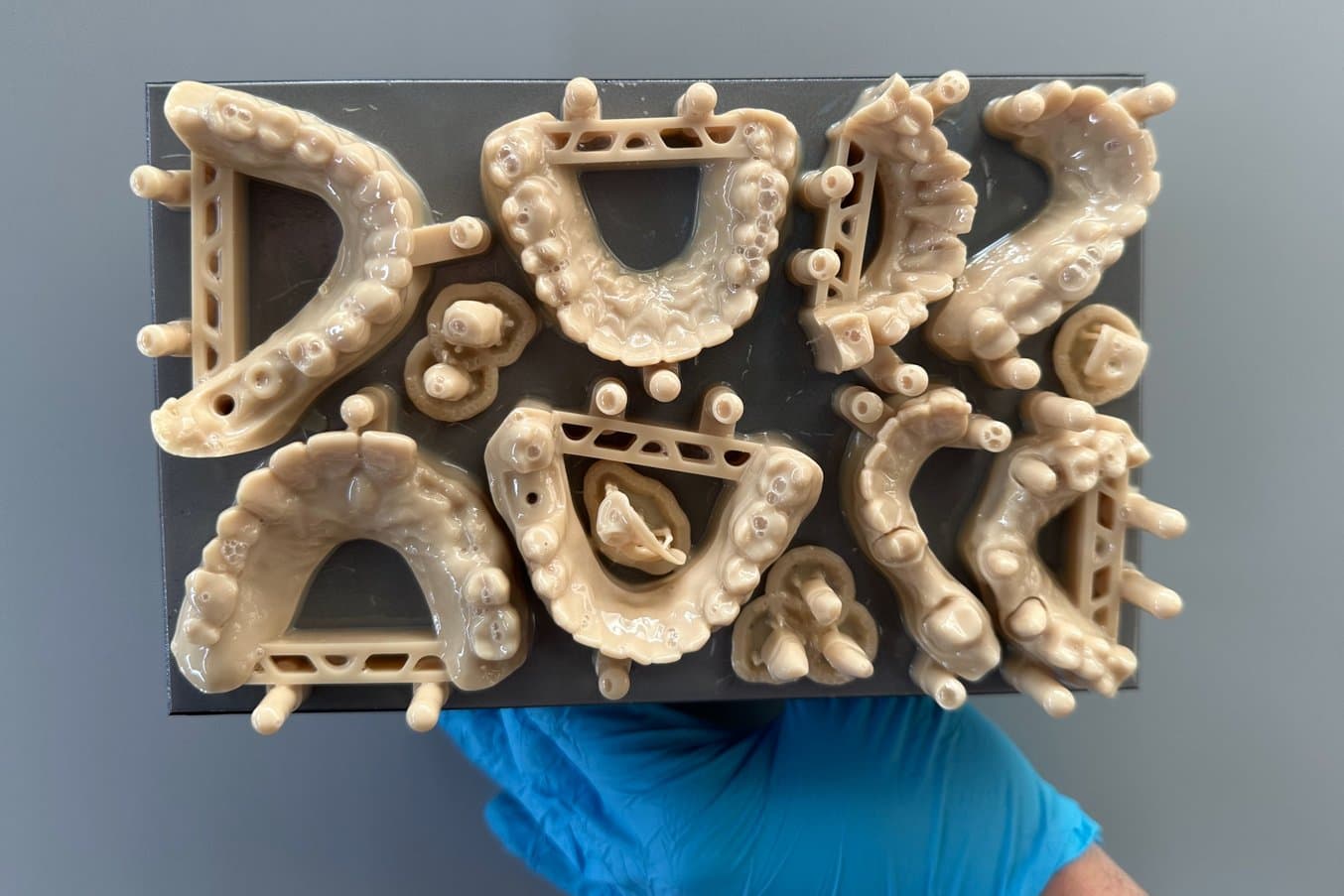

Kreimer’s test prints include a full build platform of models and implant analogs printed with Precision Model Resin on Form 4B.

Kreimer thoroughly tested Precision Model Resin, starting with test blocks to evaluate the printing of fine details and to assess geometric accuracy. Additionally, he prints test models and analyzes the printed and post-processed models against the original STL dataset. Finally, he creates test bodies for implant analogs to examine the fit and reproducibility.

With these tests showing good results, Kreimer moved on to his usual material evaluation, printing and post-processing typical patient cases which he then scans with a highly precise dental desktop scanner. He then uses software like GOM Inspect, to compare datasets. Kreimer says, “I perform these tests on at least 10 models to evaluate how the material behaves with different geometries. This test is crucial to ensure I can trust the workflow for our patient cases." Kreimer looks for models that are as close as possible to the STL file. The closer the print is to the original model, the more accurate the fit of the final appliance is for the patient.

"The surface accuracy of Precision Model Resin is among the best I have measured in any model resin. The entire surface is nearly identical to the original dataset, and the print quality is consistently excellent."

Stephan Kreimer, MDT, Kreimer Dentallabor

Internal testing at Formlabs shows that parts printed with Precision Model Resin have 99% of the surface within 100 μm of the CAD model and 95% of the surface within 50 μm of the CAD model when printed at 50 μm layer heights.

Precision Model Resin and Form 4B: Guide to Making the Most Accurate Restorative Dental Models

The Formlabs Form 4B Masked Stereolithography (MLSA) 3D printer is a game-changer for printing restorative dental models. It features fast printing speeds, reliability, and consistently precise outputs. This article is a guide on how to easily make functional and accurate restorative dental models on Form 4B with Precision Model Resin.

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part printed on the Form 4B to your office.

Decreasing Chairtime for Dentists

At Kreimer Dentallabor, technicians start and finish cases on restorative models printed with Precision Model Resin.

The majority of the dentists Kreimer works with follow a digital workflow. Kreimer states, “Our dentists appreciate working with us not only for our expertise in digital technology but also because it saves them a lot of chairside time."

"We can start and finish even large cases on the Precision Model Resin printed model, which is precise enough that the fit on the model matches the fit in the mouth, eliminating the need for corrections. I believe that’s the biggest advantage dentists see in working with us. The entire workflow is efficient and well-controlled, saving a lot of chairside time and patient sessions."

Stephan Kreimer, MDT, Kreimer Dentallabor

Kreimer provides an example of a telescopic crown case. In a conventional dental lab using traditional methods, it's common for the patient to have four to five sessions with the dentist for impressions, bite registrations, a try-in, and a final insertion.

With an intraoral scan, Kreimer obtains more precise information than with a physical impression alone. Additionally, Kreimer notes, “The 3D printing materials, like Precision Model Resin, have become much more precise and accurate than the materials we used before. We can now complete about 80% of even the very large cases, like full arch cases, with one scan and two to three sessions. This helps save sessions for both the patients and the dentist. As a lab, we benefit from fewer intermediate steps, allowing us more time between sessions to focus on aesthetics."

With intraoral scans, fully digital workflows, and highly precise printing materials, it’s possible to produce an accurate appliance that fits the first time, cutting out appointments and saving valuable time for dentists, patients, and the lab.

An Introduction to Regulatory Compliance in Dental 3D Printing

Implementing 3D printing workflows in your lab or practice can be a game changer for your business. Understanding the basics of regulatory compliance can help inform your decisions and what is best for your business. Regulation depends on geography; in this paper, we examine regulations in the United States of America and the European Union.

Optimizing With the Best Resin for Each Application

Kreimer Dentallabor, like most dental labs, prints models for various applications. At first, Kreimer says, "I thought Precision Model Resin would be my only dental model material, but when I saw the printing speed and surface quality of Fast Model Resin, I was impressed. It still looks quite good for a dental model. I love using it for applications like splint models, aligner models, or provisionals — any models that don't require 100% precision and where speed is important."

"I see the advantage of using both Precision Model Resin and Fast Model Resin simultaneously. Sometimes you need very precise models, and other times you need fast models that don't have to be 100% accurate."

Stephan Kreimer, MDT, Kreimer Dentallabor

Print 10 restorative models in Precision Model Resin at 50 μm in one hour and 50 minutes with Form 4B.

Print 11 models for thermoforming in Fast Model Resin at 160 μm in just nine minutes.

For models where precision is not the most important feature, printing Fast Model Resin at a thicker layer height therefore saves significant time on what is already a fast print job. As Kreimer says, "My workflow would be much less efficient if I only used Precision Model Resin because Fast Model Resin allows me to produce a higher volume of cases each day. For cases requiring high precision, I can still rely on Precision Model Resin."

Selecting a resin based on the requirements of a particular application enables true optimization and efficiency. Kreimer also says, "You don't need a lot of materials as long as you have the two that meet your specific needs." In this case, Precision Model Resin for precise, accurate models, and Fast Model Resin for models that require slightly less precision and blazing fast print speeds.

Accuracy Requirements of 3D Printed Models in Dentistry

This document aims to establish a comprehensive understanding of the dimensional accuracy requirements of models used in dentistry, assessing what researchers have determined to be clinically acceptable, and what constitutes an adapted gold standard in the context of our current 3D printing technology’s capabilities and limitations.

A Complete Dental Ecosystem

"The entire ecosystem is crucial for scaling your business. I have the PreForm software, a range of printers, washers, the curing unit, and materials — all working seamlessly together. Adding another application is simple and efficient."

Stephan Kreimer, MDT, Kreimer Dentallabor

Working with the Formlabs ecosystem streamlines Kreimer’s processes, and empowers the production of consistently accurate, high-quality appliances. Form 4B and Form 4BL have been game-changers for the lab, speeding up production, increasing model precision, and, with Form 4BL, providing a more efficient way to meet the lab’s throughput demands.

Ultimately, Kreimer says, “I hope we can reach 100% adoption of intraoral scanning so that every case can go through this workflow. This way, I’m confident we can deliver the best results for our clinicians and their patients.”

To learn more about Form 4B, watch our webinar. To find the Formlabs Dental solution that’s best for your business, talk to a dental expert today.