The Digital Lab of the Future is Automated: How Kreimer Dentallabor Tripled Its Dental Model Production With Formlabs Automation Ecosystem

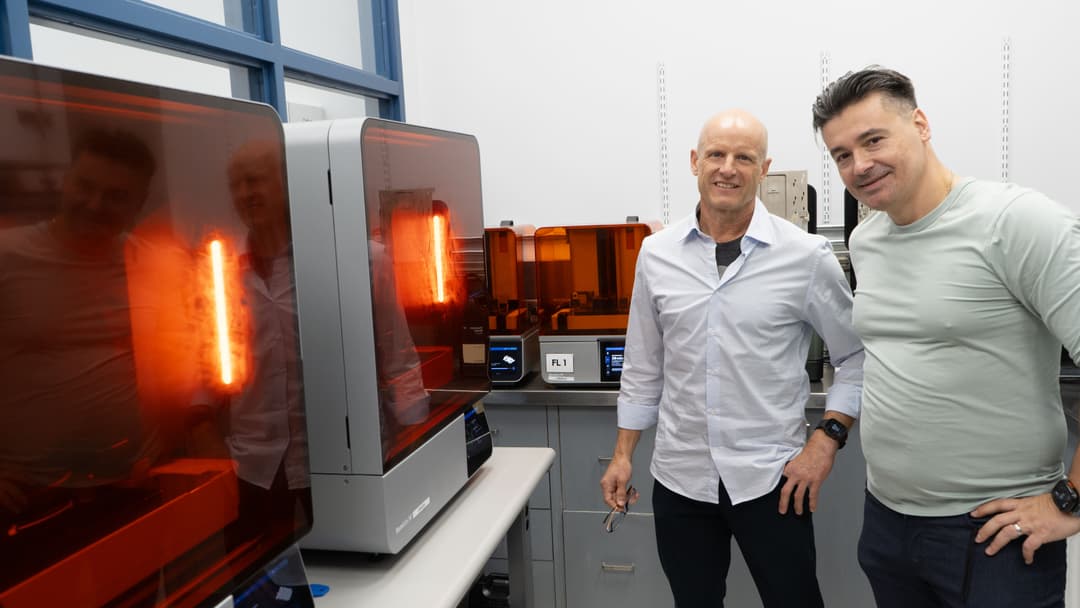

In 2017, Master Dental Technician Stephan Kreimer joined the family business as the managing director of Kreimer Dentallabor GmbH & Co. KG, a state-of-the-art dental lab based in Warendorf, Germany, about an hour northeast of Dortmund. Since his entry into the family business, Kreimer has focused on advancing digital dentistry and 3D printing to increase the lab’s productivity and streamline its workflow.

Despite the added efficiency, Kreimer was still affected by the shortage of skilled workers in Germany, and found it difficult to match the increased demand from dental practices for digital cases.

The solution for Kreimer’s lab is the Formlabs Dental Automation Ecosystem. By integrating Form Auto and Fleet Control into his lab’s workflow, he has tripled his team’s dental model production and expanded the number of dental indications possible.

Automation Ecosystem: Increase Productivity By 3x

Discover how the Automation Ecosystem enables seamless 24/7 dental part production to redefine throughput and productivity with a fully automated 3D printer fleet. During this webinar, our product experts will walk you through the Automation Ecosystem and answer questions during a live Q&A.

Evolution Towards the Automation Ecosystem

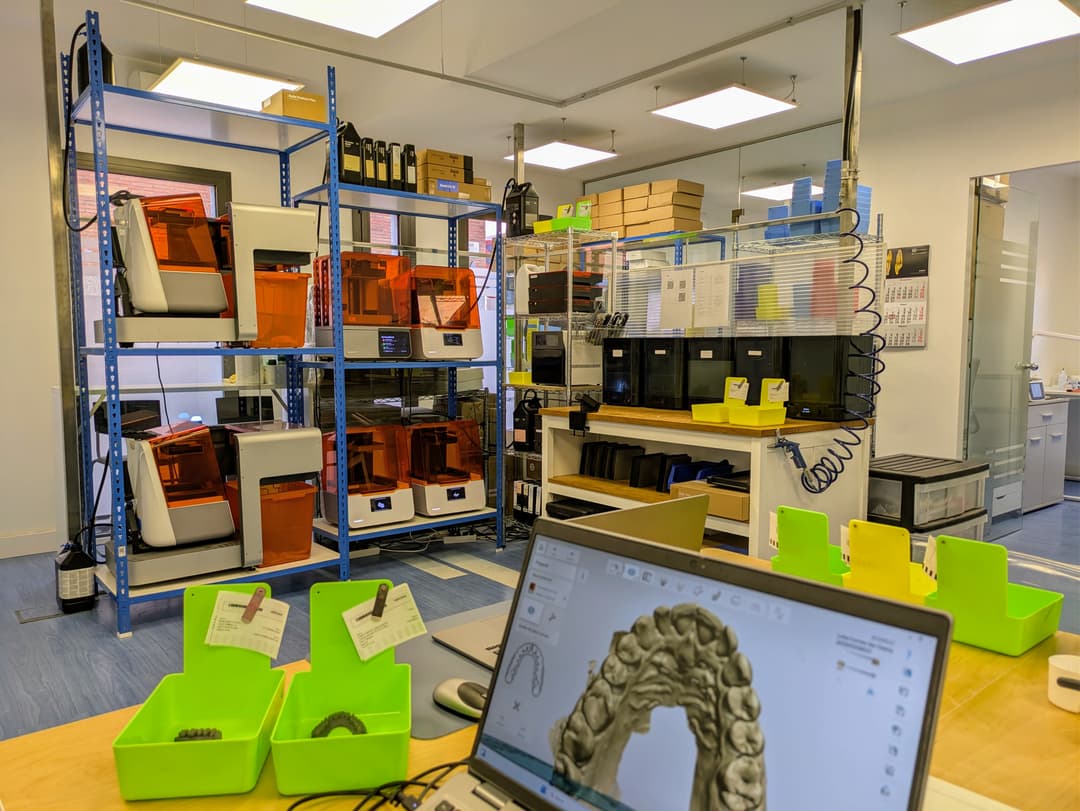

Adaptability and technological advances have always been top of mind for Stephan Kreimer. Since opening the lab, the Formlabs Dental 3D printers have been an essential part of propelling him ahead of his peers, who, for the most part, still heavily rely on analog workflows.

Kreimer’s team mainly works on digital cases, where 3D printed models of intraoral scans are essential. Compared to a traditional process, this streamlined digital workflow saves time, personnel, and production costs, while preserving the highest precision, accuracy, and reliability.

The quality of digitally produced appliances made such an impression on Kreimer’s network of dental practices that orders started increasing, and the lab began to struggle to keep up with the demand. Kreimer was unable to match that demand solely by increasing headcount, and he realized he would have to improve the productivity of the processes instead.

As 3D printers are the focal point of Kreimer’s productions, he realized that the greatest potential for further improvements lay in the reduction of manual interactions with them. The necessity of entering the 3D printing room to manually remove finished parts was taking valuable working time away from his team.

Automating simple steps like part removal could have outsized impacts on their productivity, and increase the number of cases they could handle each week. “There is a growing need for automation in this process to enhance productivity and minimize the hands-on time required from our employees,” Stephan Kreimer says.

Adapting to the Ecosystem — Seamless Integration With Existing Workflows

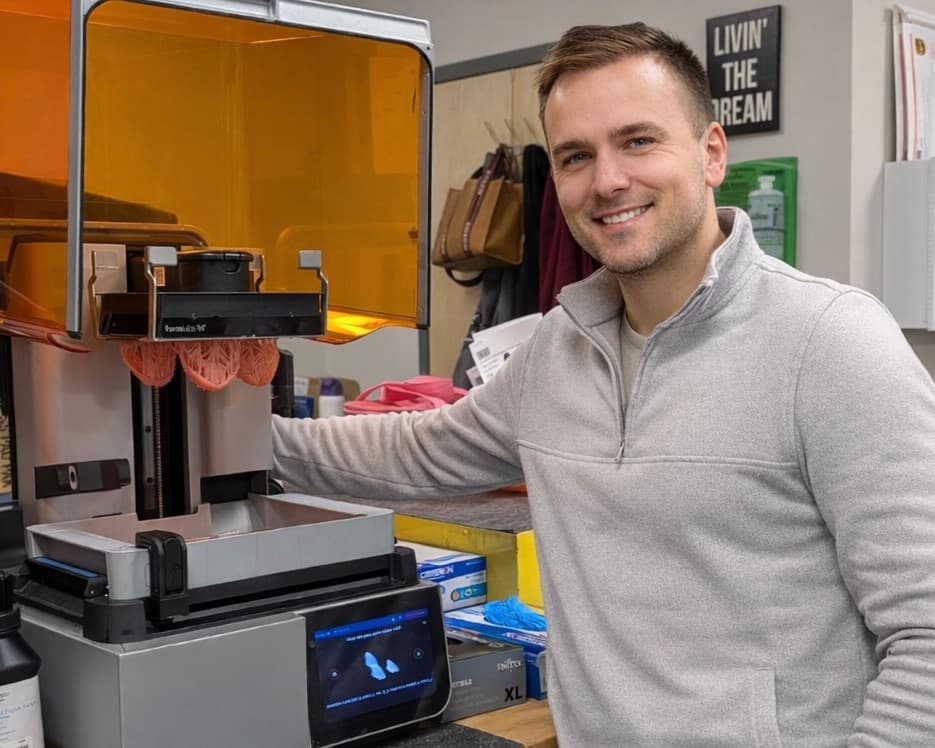

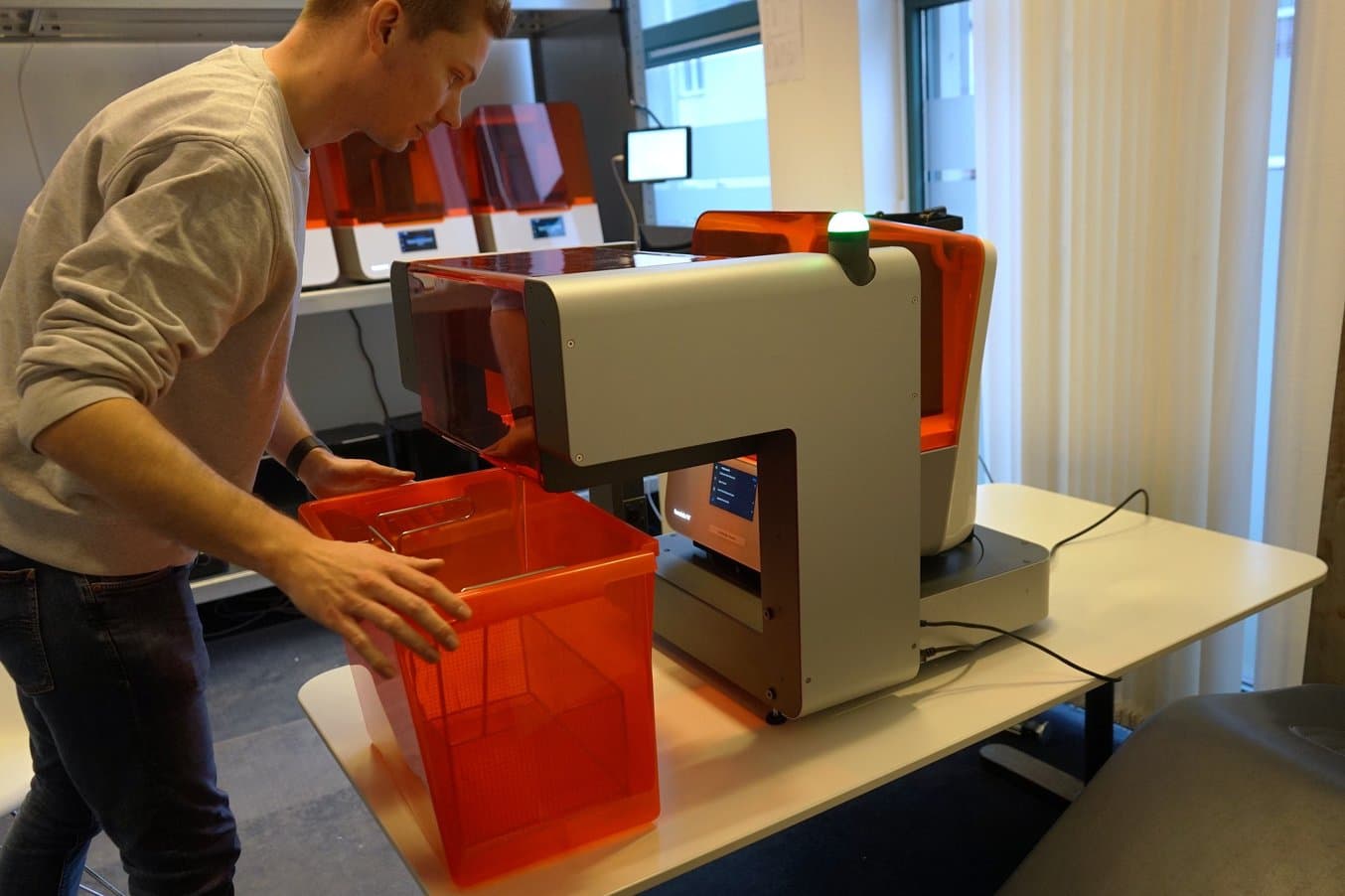

Integrating the Automation Ecosystem into the lab’s existing workflow went smoothly — the Form Auto and Fleet Control are designed as a plug-and-play solution for printer fleets of any size. On the hardware side, Form Auto is easily installed as an add-on to any Form 3+ or Form 3B+ stereolithography (SLA) 3D printer that leverages the Quick Release Technology of the Build Platform 2.

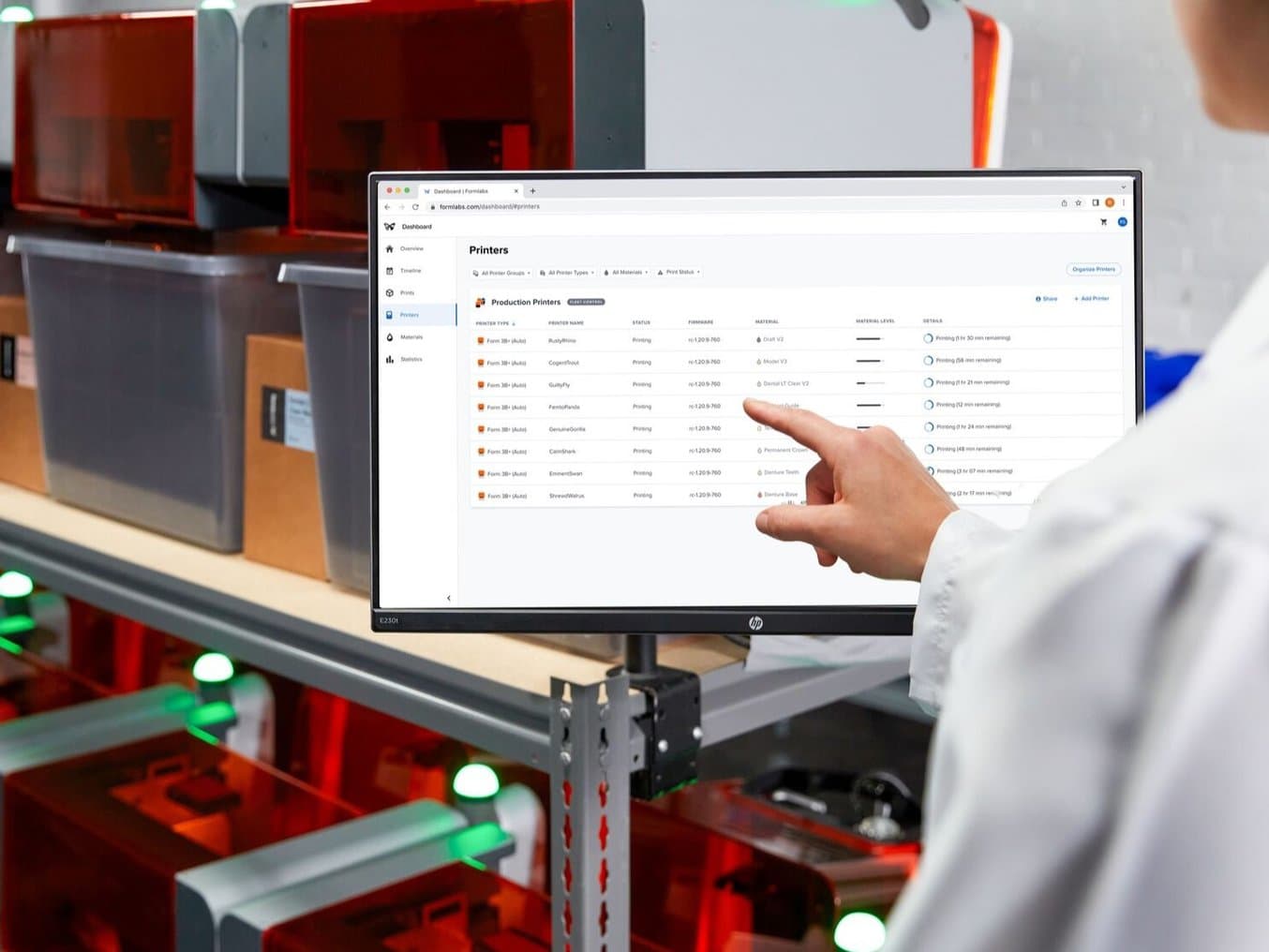

An extra step that improved oversight and streamlined production was the addition of a tablet that tracked all the print jobs through Dashboard, making it easy for every lab member to quickly check in on the printers’ progress.

The Form Auto is conceptualized as a seamless add-on for Formlabs SLA printers.

Whenever changes regarding working procedures and environment are introduced it is necessary for the whole team to get on board with these changes. But thanks to the seamless integration of the Formlabs Dental Automation Ecosystem into a lab that was already using Formlabs Dental solutions, adapting to it was effortless.

Since Form Auto and Fleet Control are more or less self-explanatory, the transition process was absolutely smooth.

Stephan Kreimer, MDT & CEO, Kreimer Dentallabor GmbH & Co. KG

Letting the Automation Ecosystem Do the Work

Not only did the transition towards the Automation Ecosystem go smoothly, but most importantly, it has helped Kreimer optimize the daily workflows of the lab.

Fleet Control — Starting Prints Automatically

Thanks to Fleet Control, handling the multi-printer fleet has never been easier for Kreimer. Fleet Control activates additional features within Dashboard and PreForm to leverage automation and optimize workflow for advanced fleet management. Thanks to this automatic distribution, Kreimer has reduced manual work related to printing as well as the downtimes of the printers.

"Fleet Control is truly impressive, as it eliminates the need for manual printer selection and starts prints automatically. Consequently, we have substantially minimized our interactions with the printers and eliminated the need to deliberate over printer assignments for each job," Kreimer says.

Kreimer's Form Auto is currently used to automate the printing of dental models, which constitute the bulk of the lab’s print jobs, on a single Form 3B+. But with Fleet Control, the Automation Ecosystem benefits the whole printing fleet and portfolio of tasks of his lab. “Despite having only one Form Auto, we also use Fleet Control for all other printers, as this equates to software-side automation for indications with lower volumes,” Kreimer says.

Managing 3D Printer Fleets

In this white paper, learn how you can manage multiple printers with the right organizational systems.

Form Auto – Non-Stop Production

Form Auto detaches printed parts from the Build Platform 2 thanks to its Quick Release Technology, then immediately prepares the printer for the next print job. For Kreimer’s lab, this led to a drastic reduction in hands-on labor time. Before adding Form Auto, lab employees had to stop what they were doing every time a print finished. Now the printing process is fully automated and prints are collected in big batches, so that post-processing tasks can be consolidated into one block of working time.

"Since we started working with Form Auto, we have been able to seamlessly send our print jobs to Fleet Control throughout the day, eliminating the need to enter the 3D printing room at all. All models are printed automatically, enabling us to empty the container just once a day and process all the models in a single batch," Stephan Kreimer says.

The Form Auto has helped Kreimer’s lab increase production without adding headcount and has even created more time for higher-value tasks.

Before the Form Auto, if no one was working, production stopped. Now, the lab produces models around the clock, seven days a week, ensuring that production doesn’t stop when the team leaves for the day.

We can now maximize productivity by utilizing the full 48 hours of Saturday and Sunday, enabling us to initiate dozens of print jobs during the weekend or conveniently from home office.

Stephan Kreimer, MDT & CEO, Kreimer Dentallabor GmbH & Co. KG

Setting up the Form Auto with the Form 3B+ was very easy for Stephan Kreimer.

Survival of the Fittest – The Evolution So Far and Future Steps

By integrating the Automation Ecosystem, Stephan Kreimer has been able to tackle the challenge of handling increasing demands without hiring more employees. The team is now printing non-stop with drastically reduced manual interactions, so they have more time to spend on other tasks. Thanks to this rise in productivity his dental lab tripled its output of dental models and is handling more customer jobs per year, which ultimately leads to higher profits.

What I love the most about the Automation Ecosystem is the simplicity of Form Auto combined with Fleet Control, resulting in a remarkable boost in efficiency thanks to the automated printing process. Thanks to this automation, our employees have been able to free up valuable time, enabling them to focus on handling an increased number of incoming jobs from our customers. With the same user interaction, we can now triple our weekly dental model production.

Stephan Kreimer, MDT & CEO, Kreimer Dentallabor GmbH & Co. KG

Calculating ROI for the Formlabs Automation Ecosystem

In this whitepaper, we’ll walk through three manufacturing scenarios to explain cost per part and return on investment (ROI) calculations.

Future Evolution

Adapting to innovations like 3D printing, intraoral scanning, and the recent Formlabs Automation Ecosystem has given Kreimer’s lab a significant competitive advantage. Due to the efficiency of Form Auto, he is planning on acquiring extra units to automate existing printers for additional indications. “If a specific indication exceeds the capacity of a single printer during the week, the addition of another Form Auto will be implemented to automate this indication as well,” Kreimer says.

Moreover, the already automated model production can be optimized even further by leveraging the advantages of the new Resin Pumping System as well as post-processing in large batches with Form Wash L & Form Cure L.

The utilization of Form Wash L and Form Cure L proves to be remarkable in enabling the simultaneous post-processing of multiple models.

Stephan Kreimer, MDT & CEO, Kreimer Dentallabor GmbH & Co. KG

With the addition of the Formlabs Automation Ecosystem, plus the post-processing capacity of Form Wash L and Form Cure L, it’s possible to further streamline workflows, increasing the efficiency of labs and enabling staff to focus on higher-value tasks.