Effortlessly create parts for high volume dental applications. Print any resin with Open Material Mode.

Form4BL

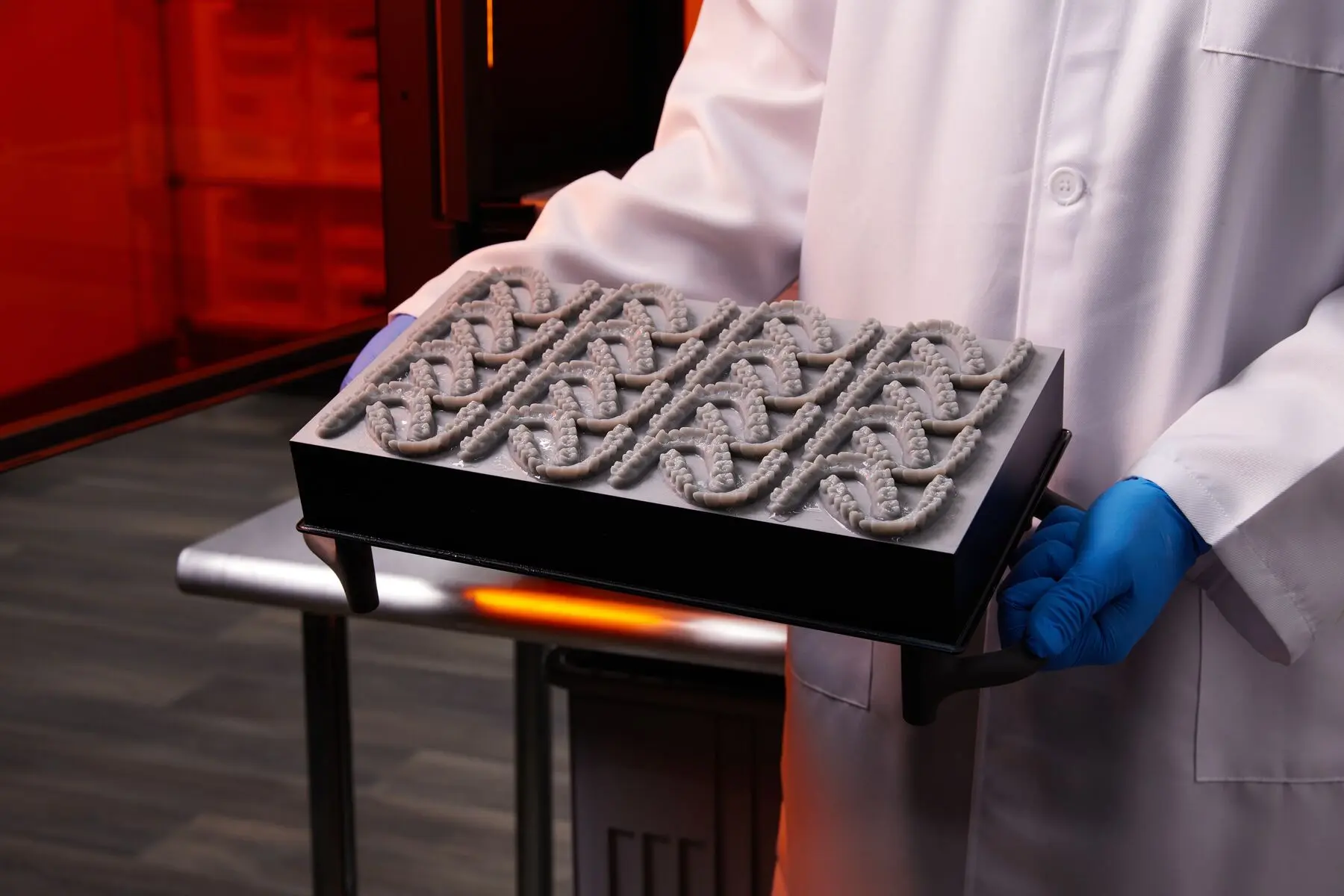

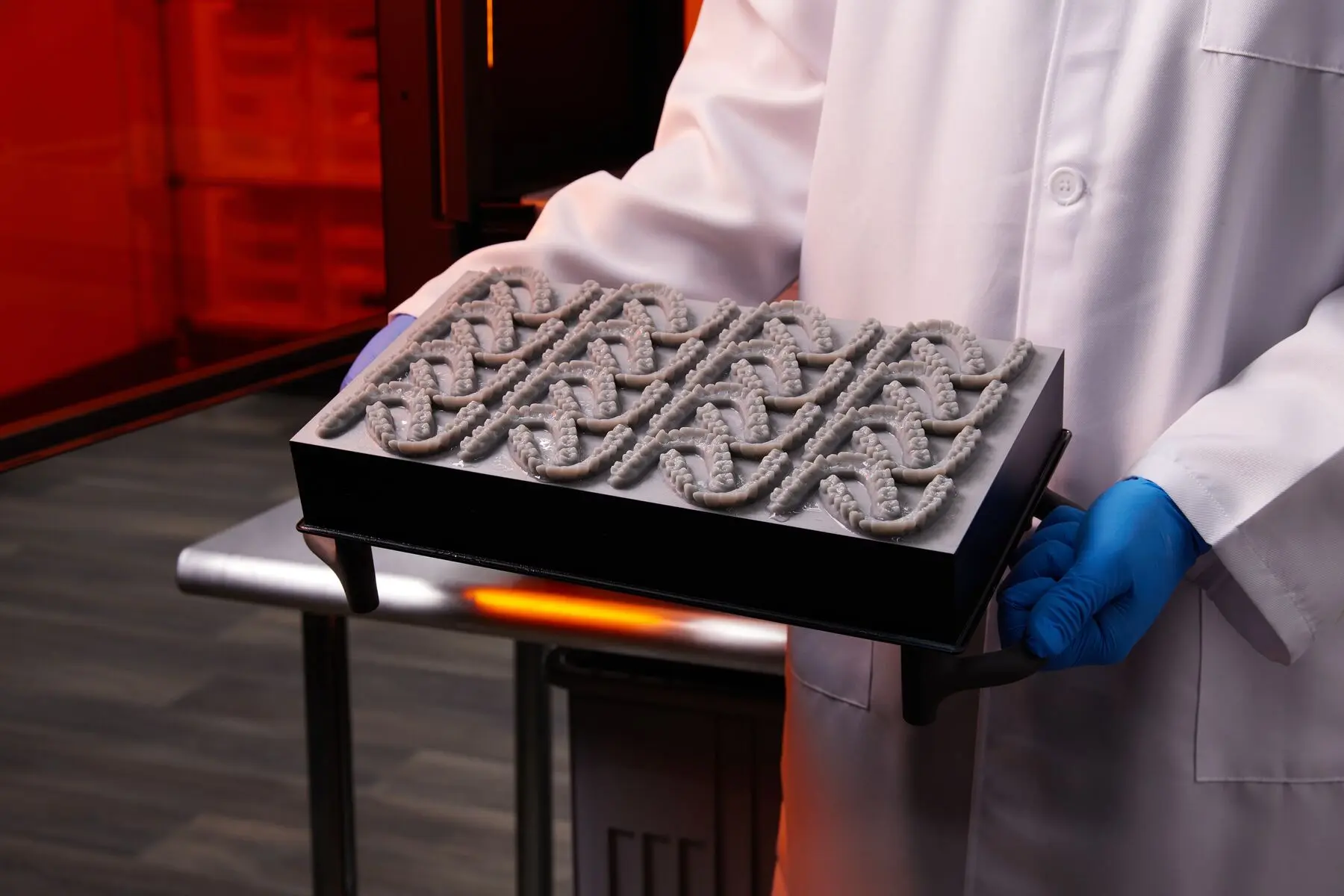

More parts per print with fewer interactions

32 models in 14 min*

Repeatable accuracy you can count on

Effortlessly create parts for high volume dental applications

Large format 3D printing that you can depend on

Easy, efficient operations optimized for large-scale production

Form4BL

Form4BL

More parts per print with fewer interactions

32 models in 14 min*

Repeatable accuracy you can count on

Effortlessly create parts for high volume dental applications

Large format 3D printing that you can depend on

Easy, efficient operations optimized for large-scale production

Form4BL

More throughput, fewer interactions.

Fit up to 32 flat or 75 vertical dental models in one print.Speed at scale. Produce 32 models in 14 minutes*.

- 14minForm 4BL

1h27minBenchmark DLP**2h3minBenchmark LCD**1h21minForm 3BL

1h27minBenchmark DLP**2h3minBenchmark LCD**1h21minForm 3BL32 Clear Aligner Models at 160 μm

- 2h10minForm 4BL

10h12minBenchmark DLP**11h18minBenchmark LCD**18h14minForm 3BL

10h12minBenchmark DLP**11h18minBenchmark LCD**18h14minForm 3BL80 Occlusal Splints at 100 μm

- 2h48minForm 4BL

6h18minBenchmark DLP**6h15minBenchmark LCD**9h25minForm 3BL

6h18minBenchmark DLP**6h15minBenchmark LCD**9h25minForm 3BL28 Restorative Models at 50 μm

- 1h40minForm 4BL

7h42minBenchmark DLP**9h24minBenchmark LCD**6h15minForm 3BL

7h42minBenchmark DLP**9h24minBenchmark LCD**6h15minForm 3BL60 Clear Aligner Models at 100µm

- 2h10minForm 4BL

7h57minBenchmark DLP**9h39minBenchmark LCD**6h59minForm 3BL

7h57minBenchmark DLP**9h39minBenchmark LCD**6h59minForm 3BL75 Clear Aligner Models at 100µm

*Print time based on clear aligner models printed with Fast Model Resin at 160µm

**Printers with smaller build platforms might take 3 builds to achieve the same throughput as Form 4BL. In these cases, we summed up the print times of these builds.

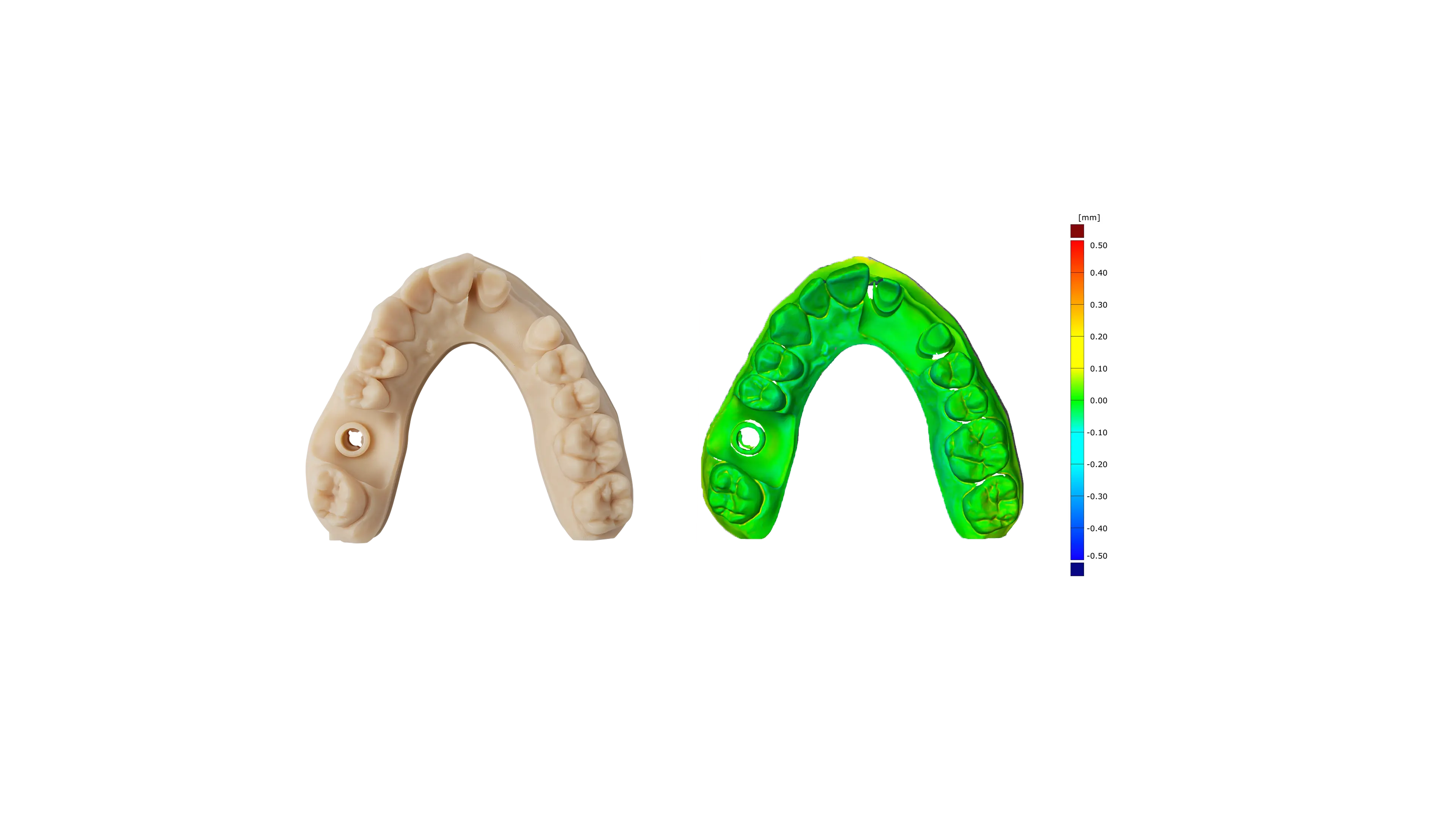

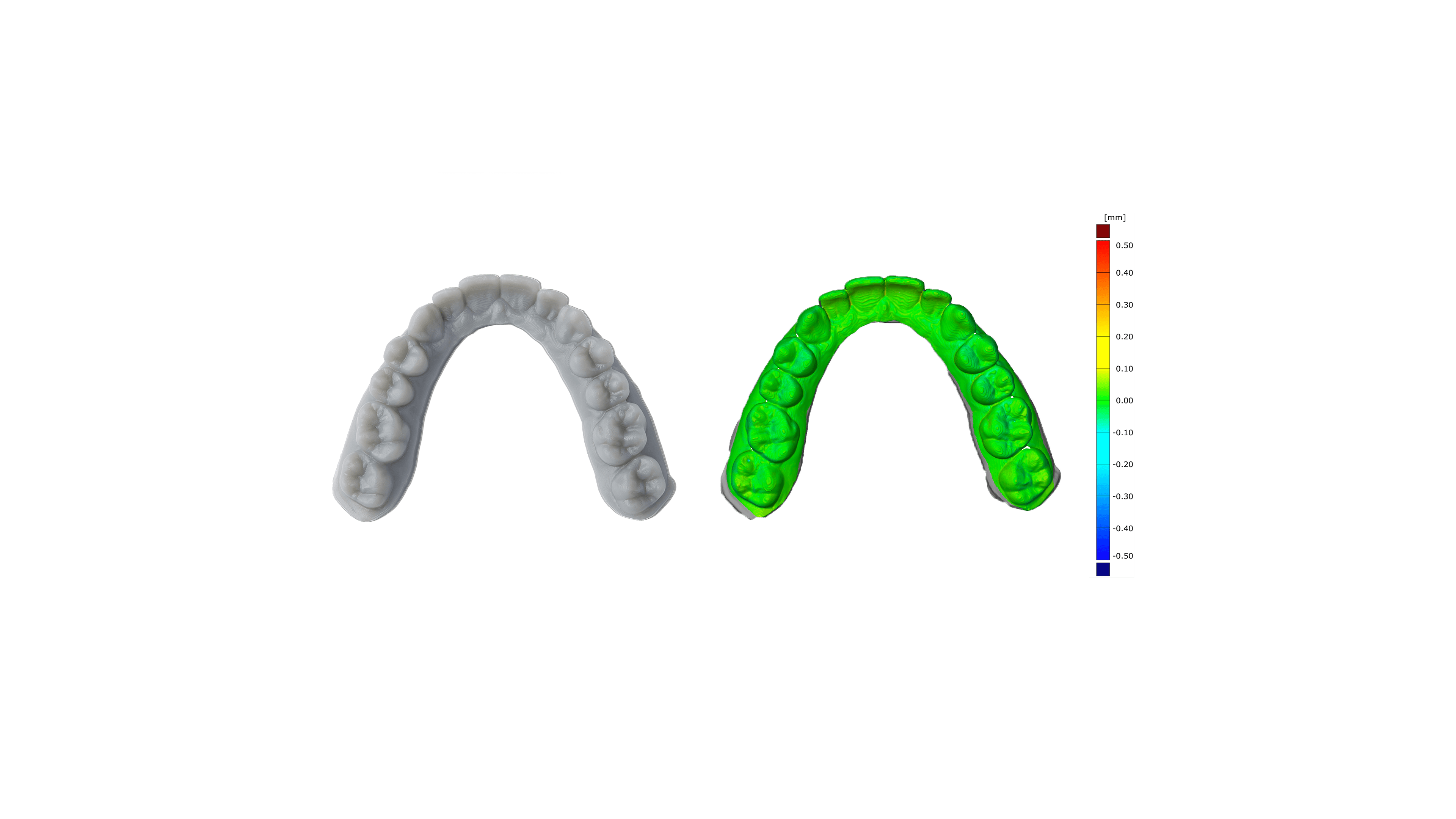

Repeatable accuracy you can count on.

Consistently Accurate

Repeatable accuracy across prints on a single printer, and across printers.

Smoothest Surfaces

Lower peel forces, light touch supports, and 46 µm pixel size with pre-tuned anti-aliasing.

Sharpest Details

Highly collimated light and 46 µm pixel size with pre-tuned anti-aliasing for subpixel resolution.

95% OF THE SURFACE WITHIN 50 μm OF THE CAD MODEL. 99% OF THE SURFACE WITHIN 100 μm OF THE CAD MODEL.

95% OF THE SURFACE WITHIN 50 μm OF THE CAD MODEL. 99% OF THE SURFACE WITHIN 100 μm OF THE CAD MODEL.Consistently Accurate

Repeatable accuracy across prints on a single printer, and across printers.

Smoothest Surfaces

Lower peel forces, light touch supports, and 46 µm pixel size with pre-tuned anti-aliasing.

Sharpest Details

Highly collimated light and 46 µm pixel size with pre-tuned anti-aliasing for subpixel resolution.

Precision Model Resin50 μm 95% OF THE SURFACE WITHIN 100 μm OF THE CAD MODEL.

95% OF THE SURFACE WITHIN 100 μm OF THE CAD MODEL.Consistently Accurate

Repeatable accuracy across prints on a single printer, and across printers.

Smoothest Surfaces

Lower peel forces, light touch supports, and 46 µm pixel size with pre-tuned anti-aliasing.

Sharpest Details

Highly collimated light and 46 µm pixel size with pre-tuned anti-aliasing for subpixel resolution.

Fast Model Resin160 μm

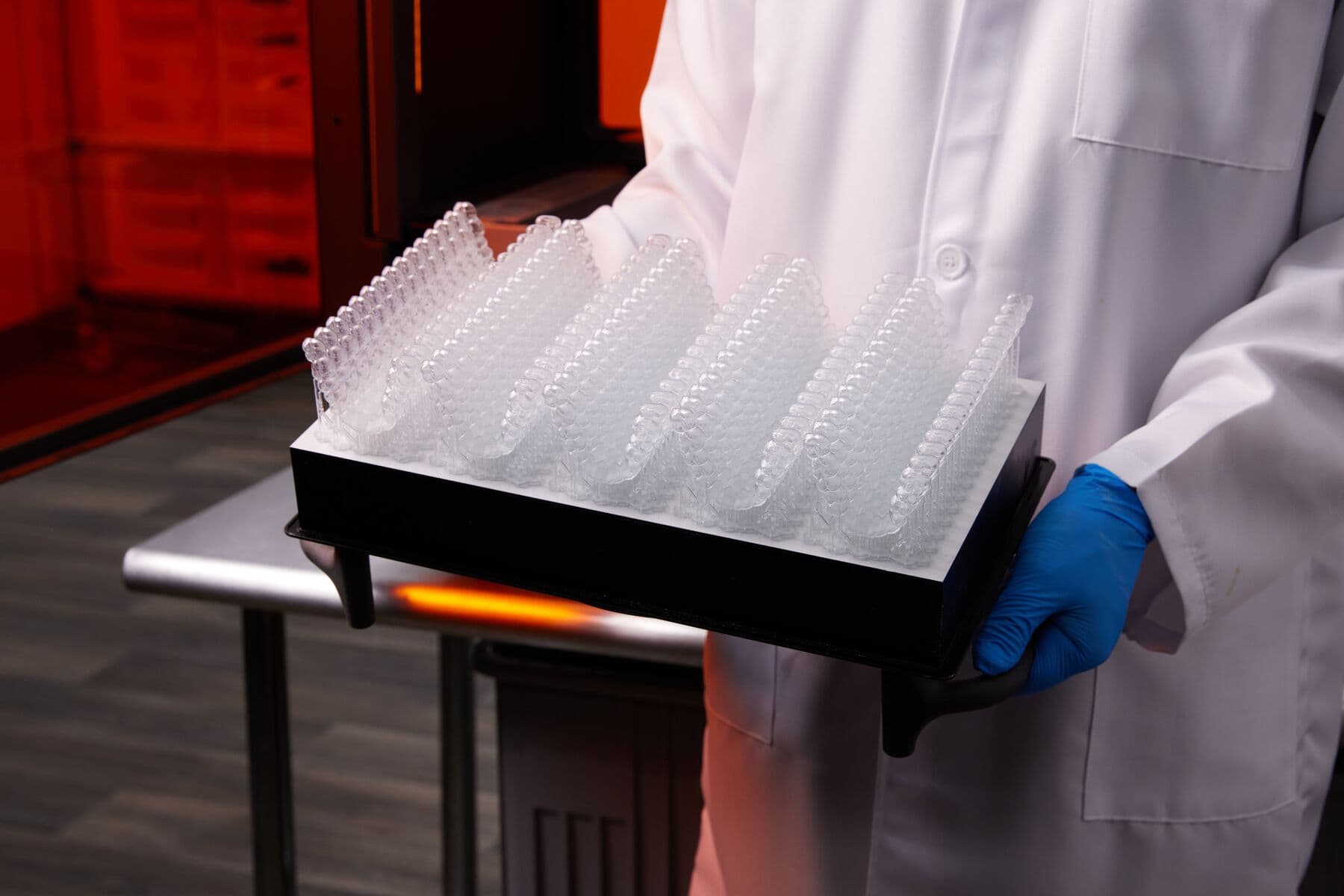

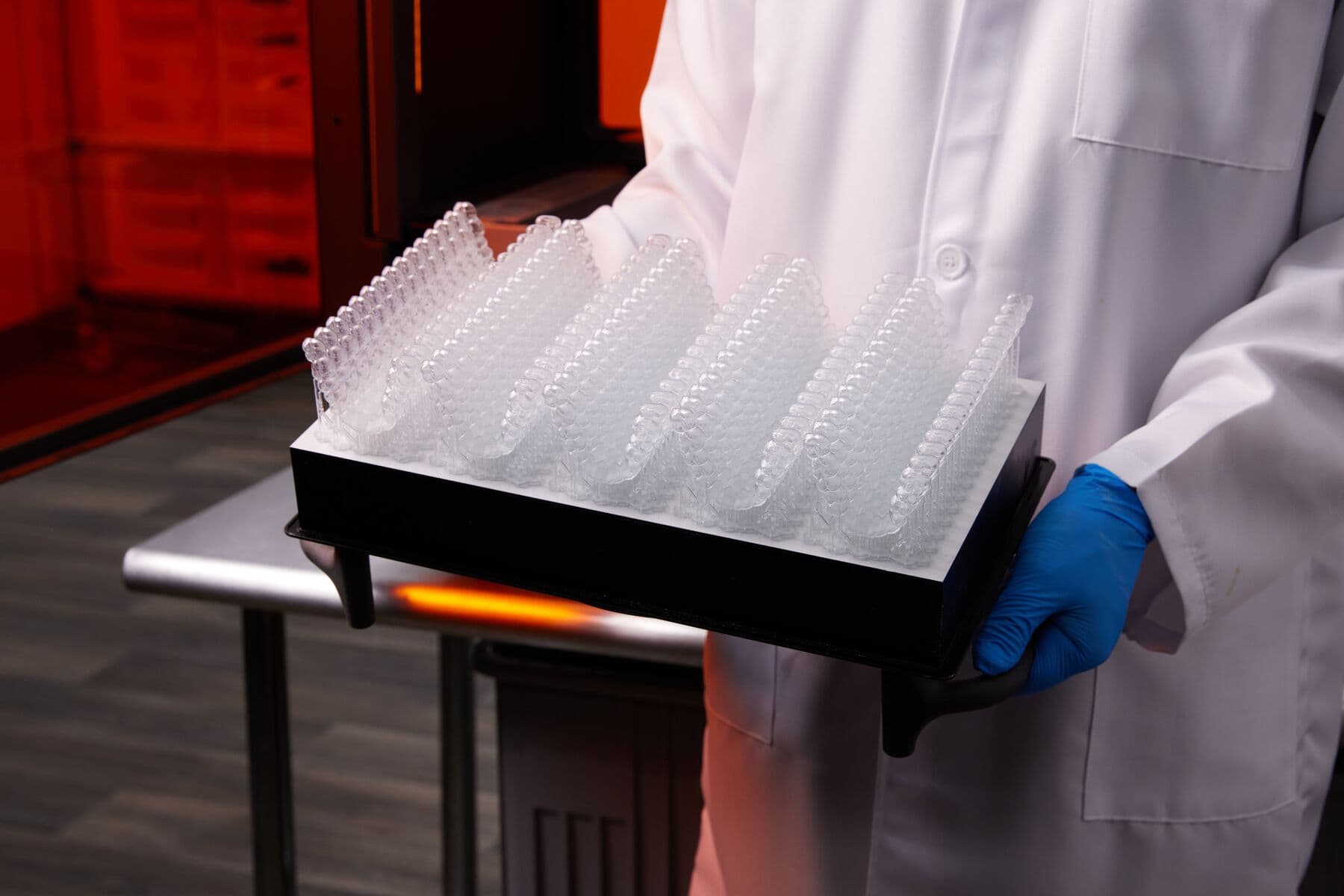

Maximum uptime and yield. Large format 3D printing you can depend on.

Formlabs optimization engineers put hundreds of printed parts to the test to ensure each material performs to the most reliable standards, right out of the box.

Maximum uptime and yield. Large format 3D printing you can depend on.

Formlabs optimization engineers put hundreds of printed parts to the test to ensure each material performs to the most reliable standards, right out of the box.

Streamlined for large-scale production. Easy onboarding, efficient operations, and fewer touchpoints.

So intuitive that anyone can learn to print in 15 minutes.

- 1

Import your model and prepare your print.

- Automatic print setup based on indication

- Convert scans to 3D printable models with Scan to Model

- Seamless integration with scanners and CAD software

- Advanced support generation and manual editing

- 2

Load a material and click print.

- Validated print settings

- No-mess cartridges and tanks

- Automatic and fast resin dispensing

- 3

Remove, wash, cure.

- Quick release part removal*

- Automatic part cleaning

- Precision post-curing for peak material properties

- *Build Platform Flex L is not yet available. Coming soon.

- 4

Finish your part.

- Light touch supports for quick, clean support removal

Low Force Display (LFD)™

The Power Behind Form 4BLLow Force Display (LFD)™

The Power Behind Form 4BLKreimer Dentallabor

“We are currently using the Form 4BL for all our model production, and the Form 4Bs for biocompatible applications. With the Form 4BL's build platform, which is around three times larger, we can now produce three times more models with a single user intervention.”

Stephan Kreimer,

MDT, Kreimer Dentallabor

Aurora DTC

“Compared to some of the more expensive printers we use in our lab, the Form 4BL stands out for its efficiency. We can fit two to three times more models on its build platform, all with a similar print duration and exceptional reliability and accuracy. The result? Our throughput has doubled, even tripled, which has been a game-changer for us!"

Milos Markovic,

Director of Cad-Cam and Implantology, Aurora DTC

The Form 4BL Ecosystem

Complete Your 3D Printing Experience

Form 4BL