Across the world, businesses that have been shuttered to protect staff and customers from the COVID-19 pandemic are beginning to open their doors again. The dental industry has been particularly impacted by the pandemic, shutdowns, and the resulting economic recession. Returning to work also carries risk: dentists, dental hygienists, and patients face especially elevated risk of transmitting or contracting a respiratory disease.

Dental professionals across the industry are developing creative solutions that any practitioner with a 3D printer can implement. Read how digital technology can keep you and your staff safe in the “new normal.”

1. Fabricate PPE Onsite

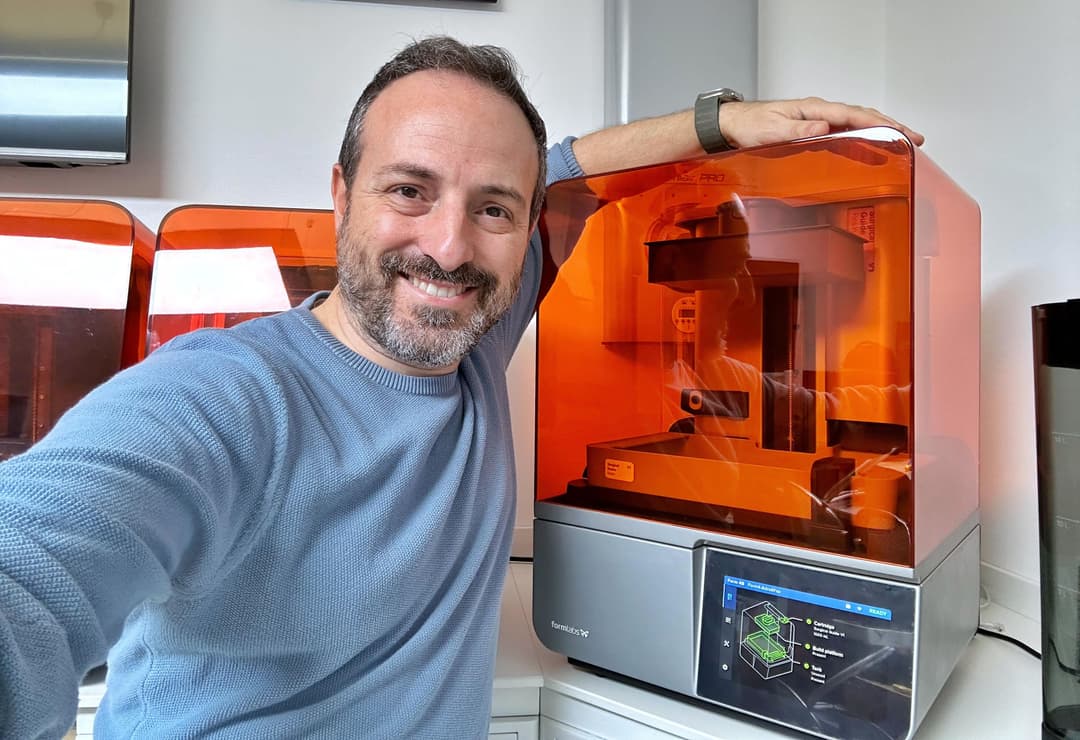

When Dr. Naren Rajan’s dental practice in New Jersey temporarily closed in March 2020, he brought his Form 2 3D printer to his family home, where he has been printing custom mask fitters for dental professionals across the country. He instructs the recipients to use Bellus3D’s free Face Mask Fitter software, which uses an iPhone or iPad to take a 3D scan of the face, to generate a custom-fit 3D file, which he then prints.

Once the mask fitters are in the hands of his staff and others, they can use them to improve peripheral seal on surgical masks, keeping dental professionals safe even when in close contact with patients.

At first, Dr. Rajan asked his social media network to donate Formlabs Grey Resin so he could provide the mask fitters for free. After using the donated resin to print hundreds of mask fitters, he switched to using Tough 2000 Resin, as he states it provides better mechanical properties for repeated use. Now he charges a nominal fee per mask fitter to cover print costs -- and labor, now that his practice is gradually reopening.

Dr. Rajan was an early adopter of digital dentistry and lectures on the clinical benefits of digital workflows. In standard situations, when his Form 2 isn’t printing mask fitters, he uses it to print models and surgical guides.

“Those of us in the digital dentistry community were poised to be able to pivot our skills very quickly to start printing PPE,” said Dr. Rajan. “It’s really exciting and empowering to manufacture the things that I need right here.”

Formlabs has carefully curated a number of non-medical devices community-sourced parts that can help fight COVID-19, including the Bellus3D mask fitter. Get started printing today with designs from our Community Part Library.

2. Replace Lost or Broken Appliances Without a Visit

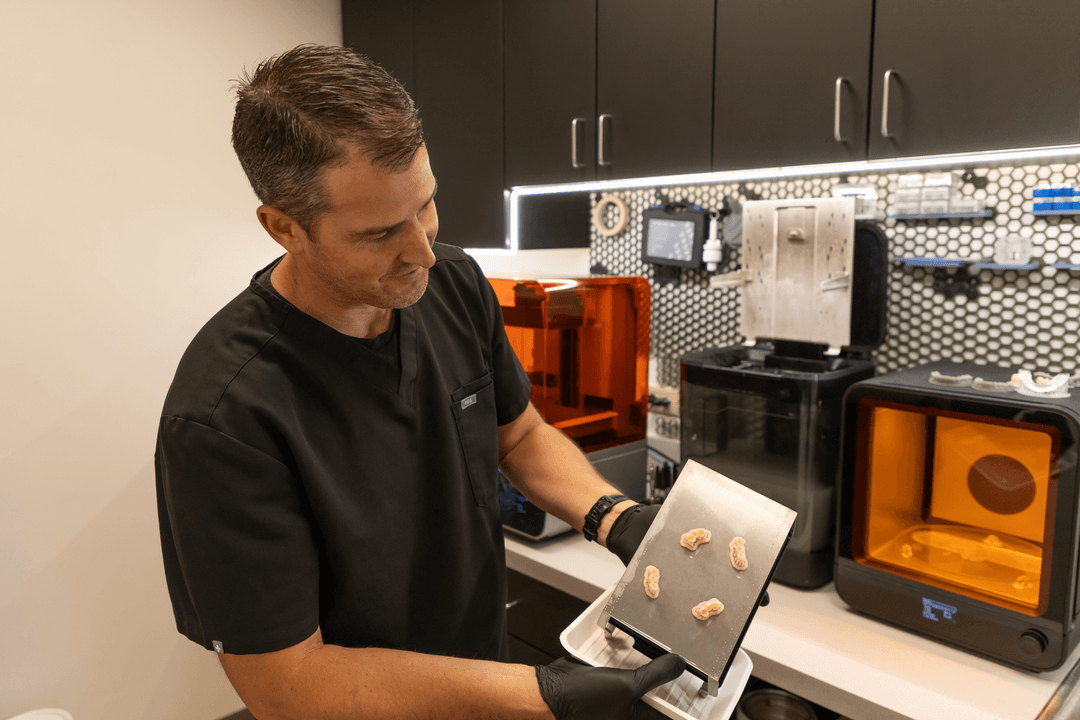

During a period when the state of Tennessee had restricted dental visits to emergency cases only, Dr. Jay Burton received a call from a patient who had lost his retainers. As he had his patient's case digitized with every step of the way registered, Dr. Burton and his team fabricated a new set of retainers without seeing the patient in person.

“We simply printed the models and fabricated the retainers. We then put them in the mail and he had them the next day,” said Dr. Burton. “Now, I don't have to worry about retreating a case while we can only see emergencies.”

For new appliances, the benefits of digital impressions and 3D printing still apply: in simple cases, patients can come for a simple fit check, reducing chairtime and potential disease transmission.

Learn to fabricate aligners and Essix retainers using 3D printed models.

3. Take Fewer Risky Manual Impressions

With the rising adoption of intraoral scanning and flexibility of data transmission with technology, digital impressions are becoming the new standard for both dental practitioners and laboratories. Digital data transfer is faster and less expensive -- and could be safer.

An article published in 2019 in the journal BioMed Research International found that manual impressions frequently transmit infectious microbes. On the other hand, with digital impressions, the potential biohazard is significantly lowered. In other words, digital-only data transfer, whether to an outside lab or an in-house technician, may reduce potential risk.

In addition to being less likely to transmit disease than manual impressions, digital impressions are faster, for reduced chair time, and more accurate, leading to precise clinical outcomes.

For practitioners who see this and choose to use digital impressions more frequently, 3D printing in-house is an easy next step in making the transition to digital workflows.

4. Spend Less Time on Equipment Maintenance

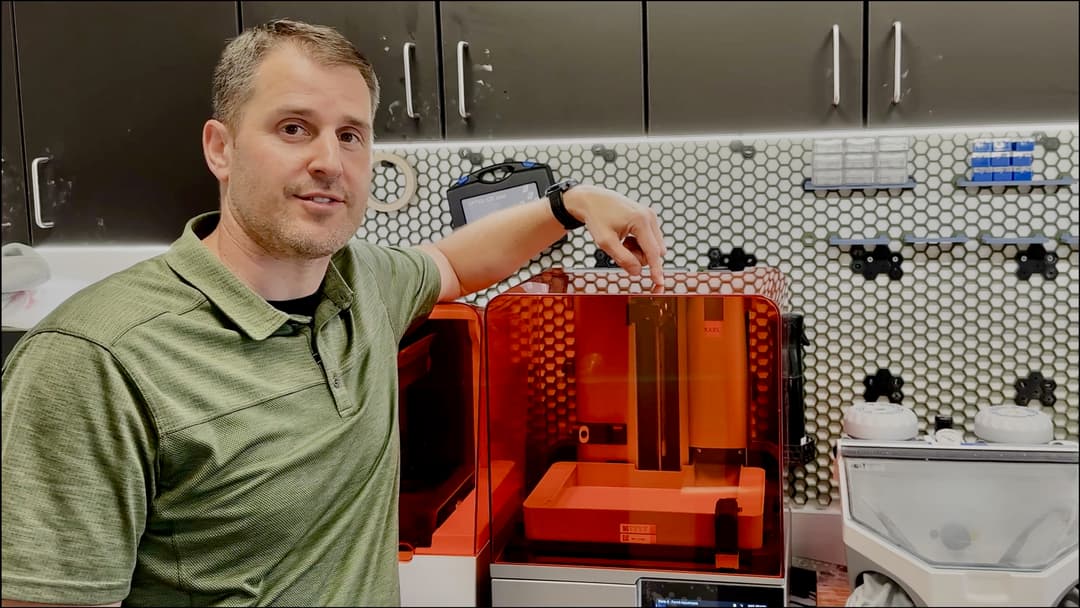

Desktop 3D printers require less maintenance than other computer-aided manufacturing (CAM) equipment. Milling machines and industrial 3D printers have a complex process to switch between materials, repairs can require a site visit from a technician, and software upgrades often come with an additional fee.

On the other hand, dental 3D printers like the Form 3B are reliable and require no routine maintenance beyond simple cleaning as you go. In the event that the printer does need service, most operations can be performed without specialized tools or skills. Being able to self-service equipment means fewer outside visitors need to come through a dental office, letting practitioners and staff focus on seeing patients and staying safe.

In addition, switching between materials takes just seconds and software updates are always free. Dr. Rick Ferguson has used several 3D printers in his practice and concluded that “the Form 3B is the easiest and most reliable 3D printer we have ever used.”

5. Optimize Your Time and Resources

In the midst of an economic downturn, businesses in all industries are worried about their bottom line. Dental offices, which typically have fewer than 10 employees, are no exception.

For practices that already have made the investment in an intraoral scanner, a desktop 3D printer is an easy way to bring production work in-house, saving money and delivery times on simple cases requiring models, surgical guides, occlusal guards, and even digital dentures.