3D Printing Permanent Crowns With the Form 3B

This application guide shows dental technicians and dentists how to 3D print monolithic full contour crowns and restorations for permanent use with Formlabs Permanent Crown Resin. Always consult the official instructions for use included in the packaging of the resin for the absolute requirements.

Table of Contents

3D Printing Temporary Crowns and Bridges with Formlabs SLA 3D Printers

Would you like to save this guide, print it, or share it with colleagues? Download it as a PDF.

Essentials

Needed From the Dentist

- A physical or digital impression of the patient's dentition

Required Hardware and Materials

Made by Formlabs:

- Form 3B+ SLA 3D Printer

- Form 3 Resin Tank V2 or higher

- Stainless Steel Build Platform

- Permanent Crown Resin

- Form Wash

- Form Cure

- Finishing kit or secondary wash station

Made by Third Parties:

- Desktop scanner (if physical impression or model)

- Low speed dental handpiece with cutting and finishing wheels

- Sandblaster

- Polishing or glazing equipment and materials

- Glass bead blasting material (BEGO Perlablast® recommended)

- Isopropyl alcohol (IPA) ≥99%

Required Software

Made by Formlabs:

- PreForm software (free) 3.10 or higher

- Firmware 1.8 or higher

Made by Third Parties:

- Dental design software or outsourcing to a dental design provider

Note

For full compliance and biocompatibility, Permanent Crown Resin requires a dedicated resin tank, Stainless Steel Build Platform, Form Wash, and Finish Kit, which should not be mixed with any other resins.

1. Scan

Dental design software requires a digital impression of the patient’s anatomy in order to design a dental prosthetic. To acquire this data, scan the patient directly with a 3D intraoral scanner or scan a physical impression or poured model with a desktop 3D scanner.

2. Design

2.1 Design the Appliance

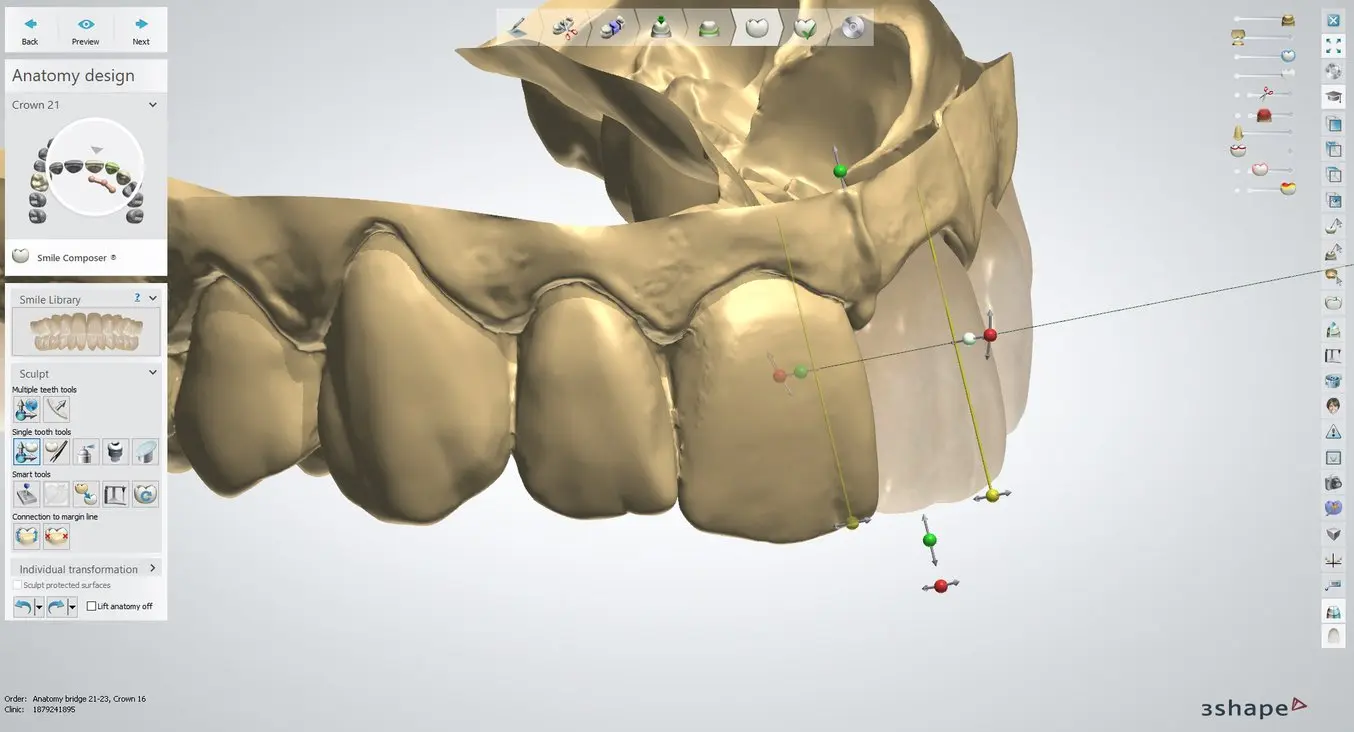

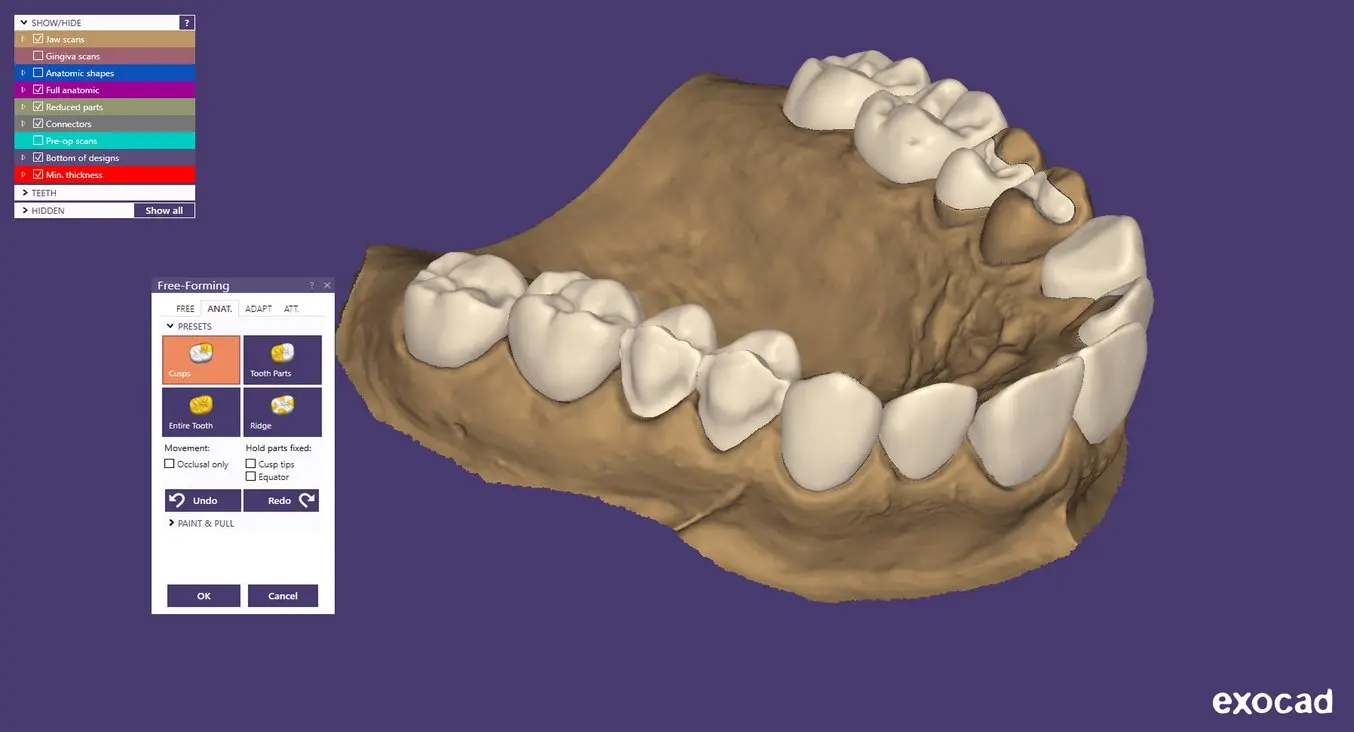

There are several dental software options for digitally designing dental crowns and restorations. In this application guide, we will be outlining parameters for 3Shape Dental System and ExoCAD.

There are also outsourced dental CAD providers where you can send a digitized impression for creating the design.

| General construction requirements | Recommended values | |||

|---|---|---|---|---|

| Minimum thickness (crowns, inlays, onlays, veneers) | 1.0 mm |

| 3Shape Settings | |||

|---|---|---|---|

| Cement Spaces | |||

| Cement gap | 0.02 mm | ||

| Extra cement gap | 0.07 mm | ||

| Distance from margin line | 1 mm | ||

| Overlay | |||

| Margin line offset | 0.15 mm | ||

| Drill compensation | Off |

Download the Formlabs Dental 3Shape materials library and watch our video to learn how to install 3Shape materials files.

| ExoCAD Settings | |||

|---|---|---|---|

| Gap | 0.05 mm | ||

| From margin | 1 mm | ||

| Additional spacing | 0.02 mm | ||

| Border | |||

| Horizontal | 0.15 mm | ||

| Undercuts Anticipate Milling | Off |

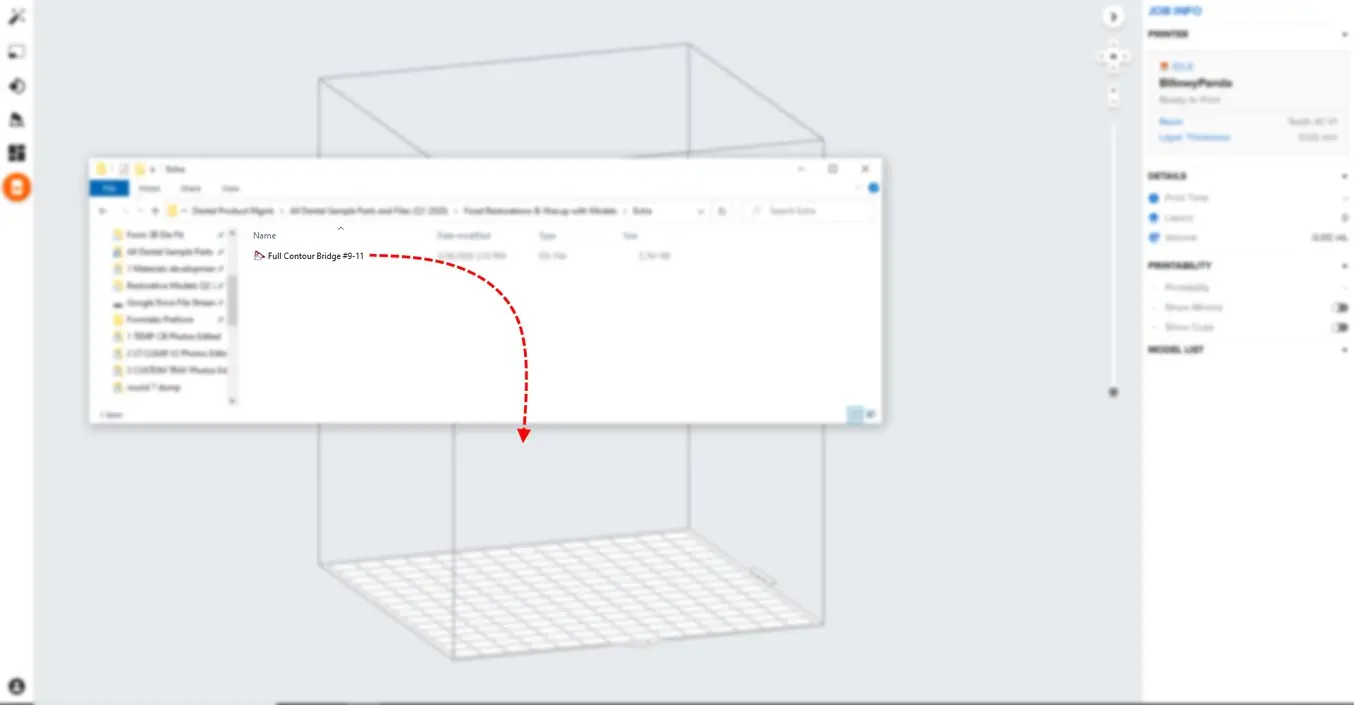

2.2 Export the STL File

Once the case has been designed to specification manufacturing can begin. The majority of dental design software generates a manufacturing file in .stl format. Locate the file and move it into the print preparation software, PreForm.

3. Print

Note

Use PreForm version 3.10 or higher and firmware 1.8 or higher.

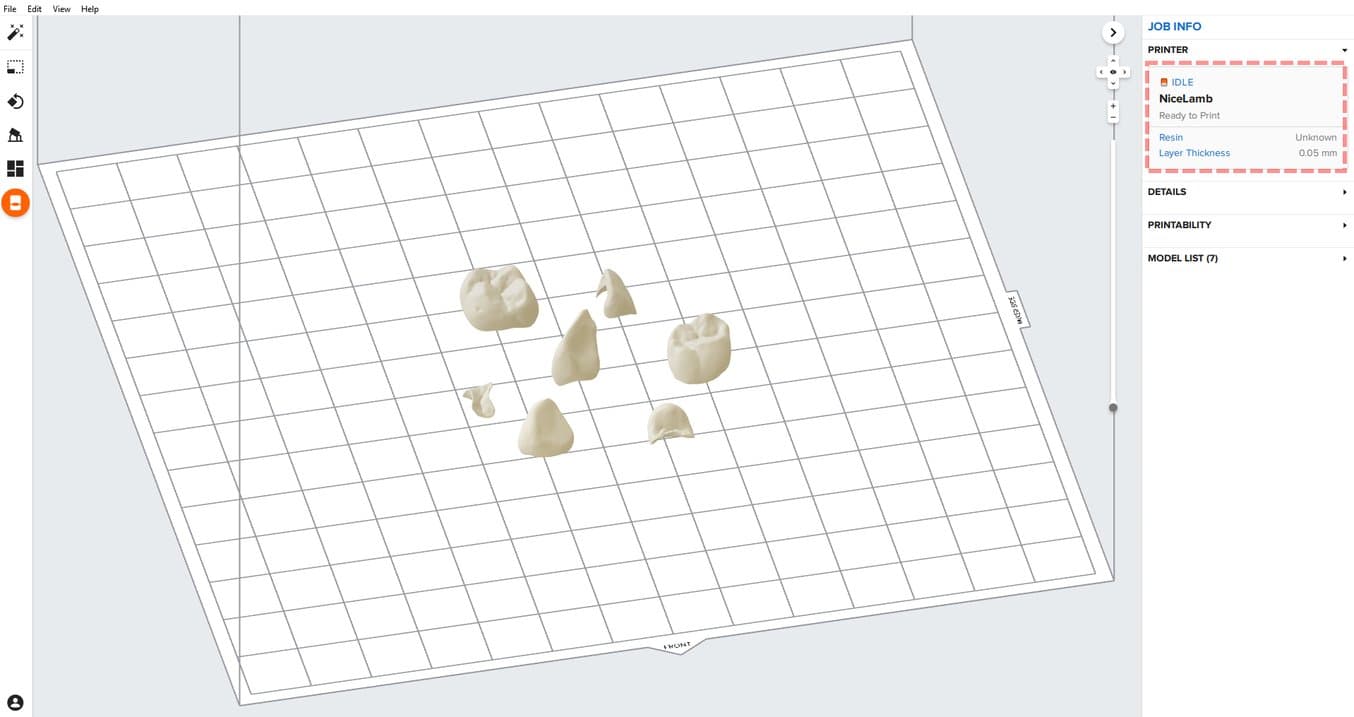

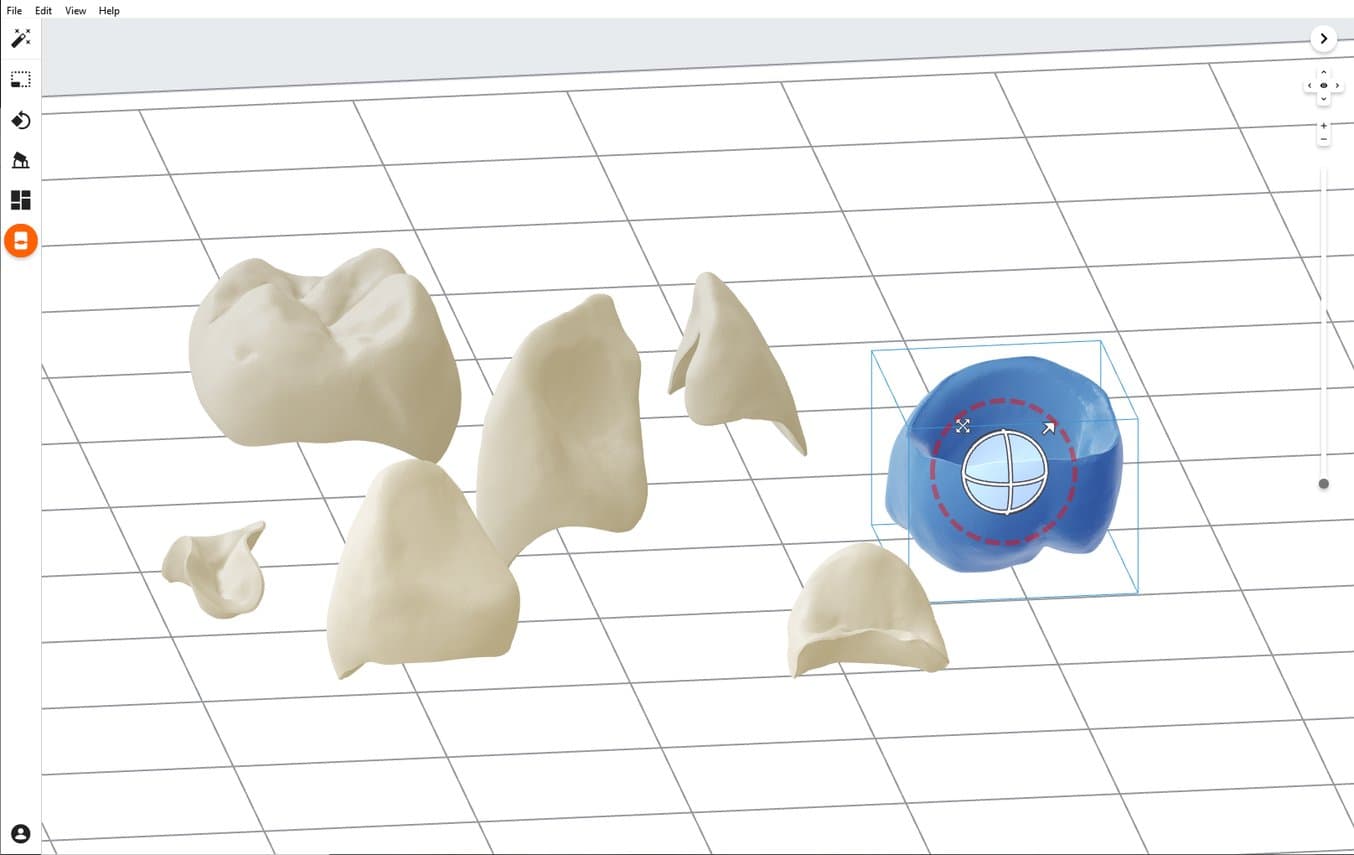

3.1 Import the File(s)

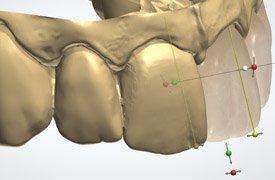

Import or open the design file(s) by dragging them into PreForm, or open them using the File menu to locate them on your computer or network.

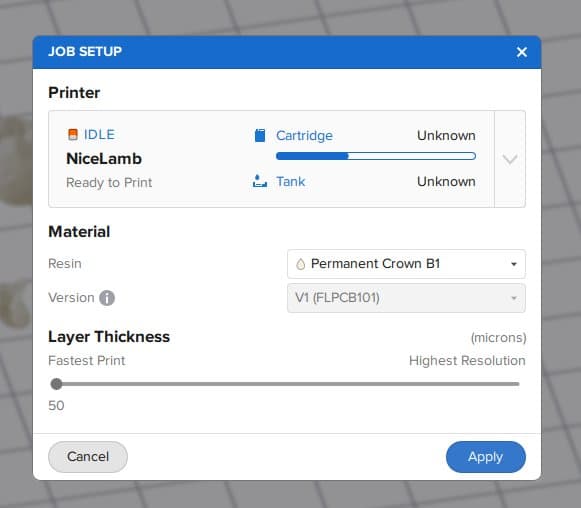

3.2 Material Selection

Select the material for printing by clicking the printer box in the Job Info menu on the right hand side.

Locate Permanent Crown in the material dropdown and select the appropriate shade (A2, A3, B1, C2).

3.3 Orientation

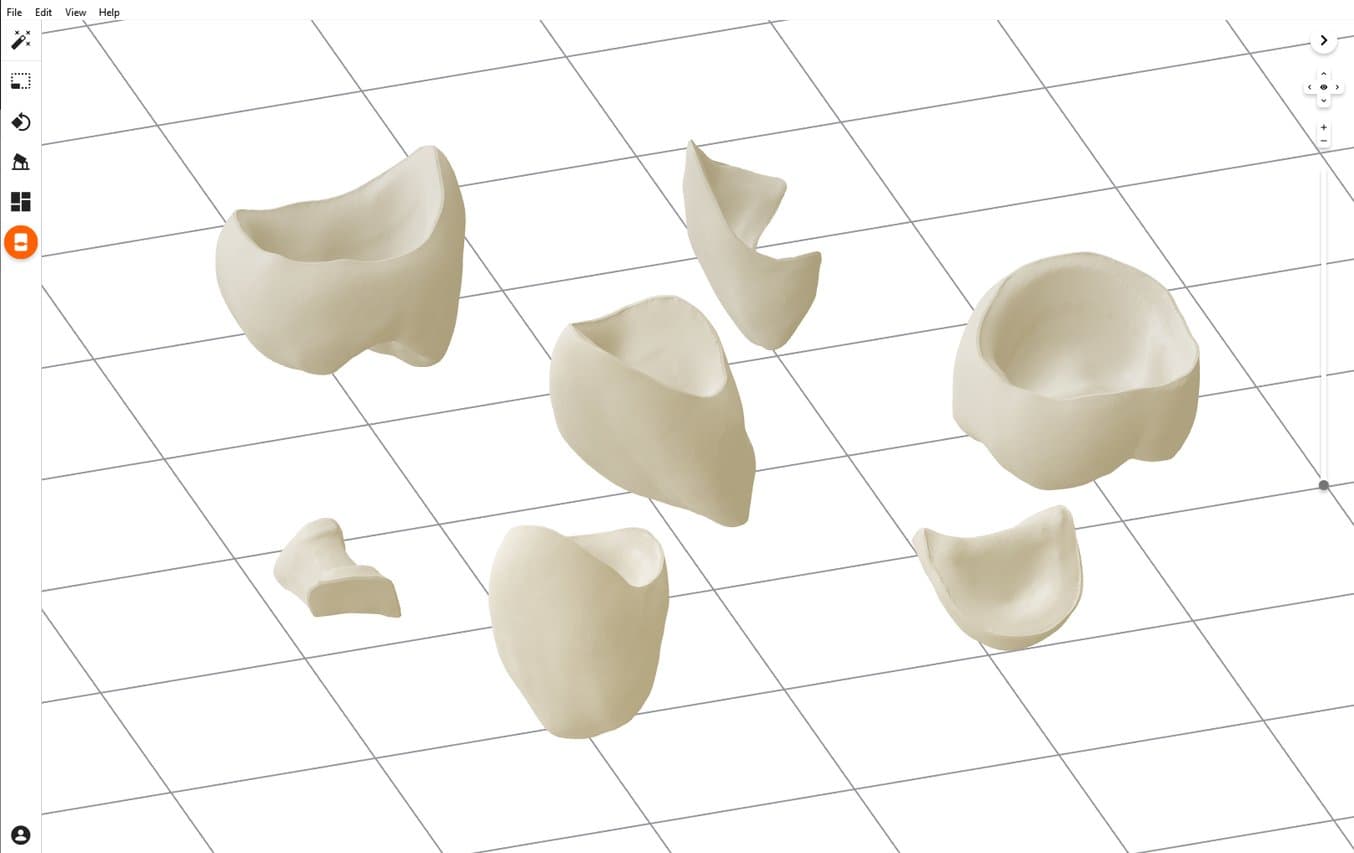

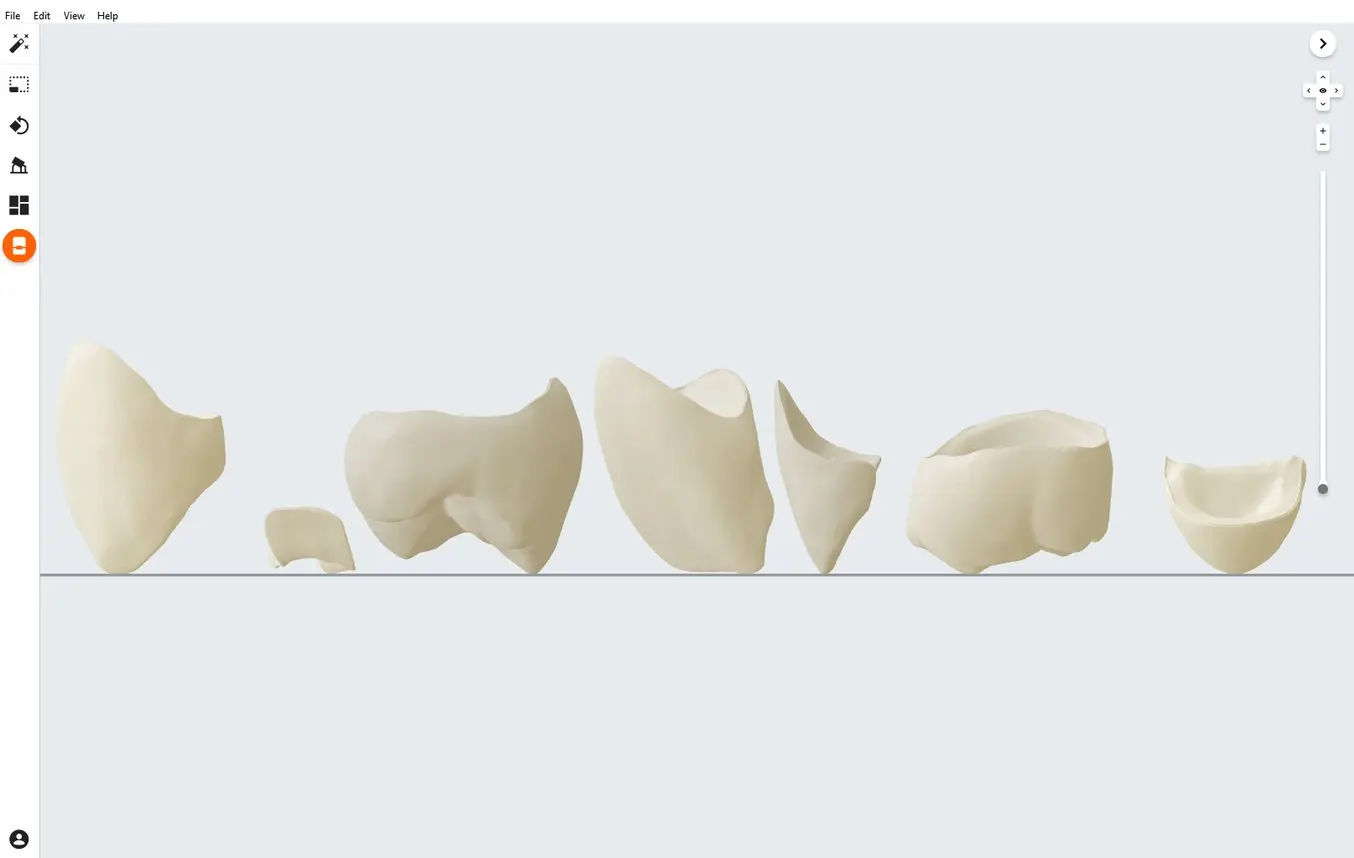

Proper part orientation is critical to ensure part accuracy and fitment.

Always position the restoration(s) horizontal to the build platform with the occlusal plane facing the build platform.

To rotate a restoration, click on the part and click and drag the sphere manipulator.

3.4 Generate Supports

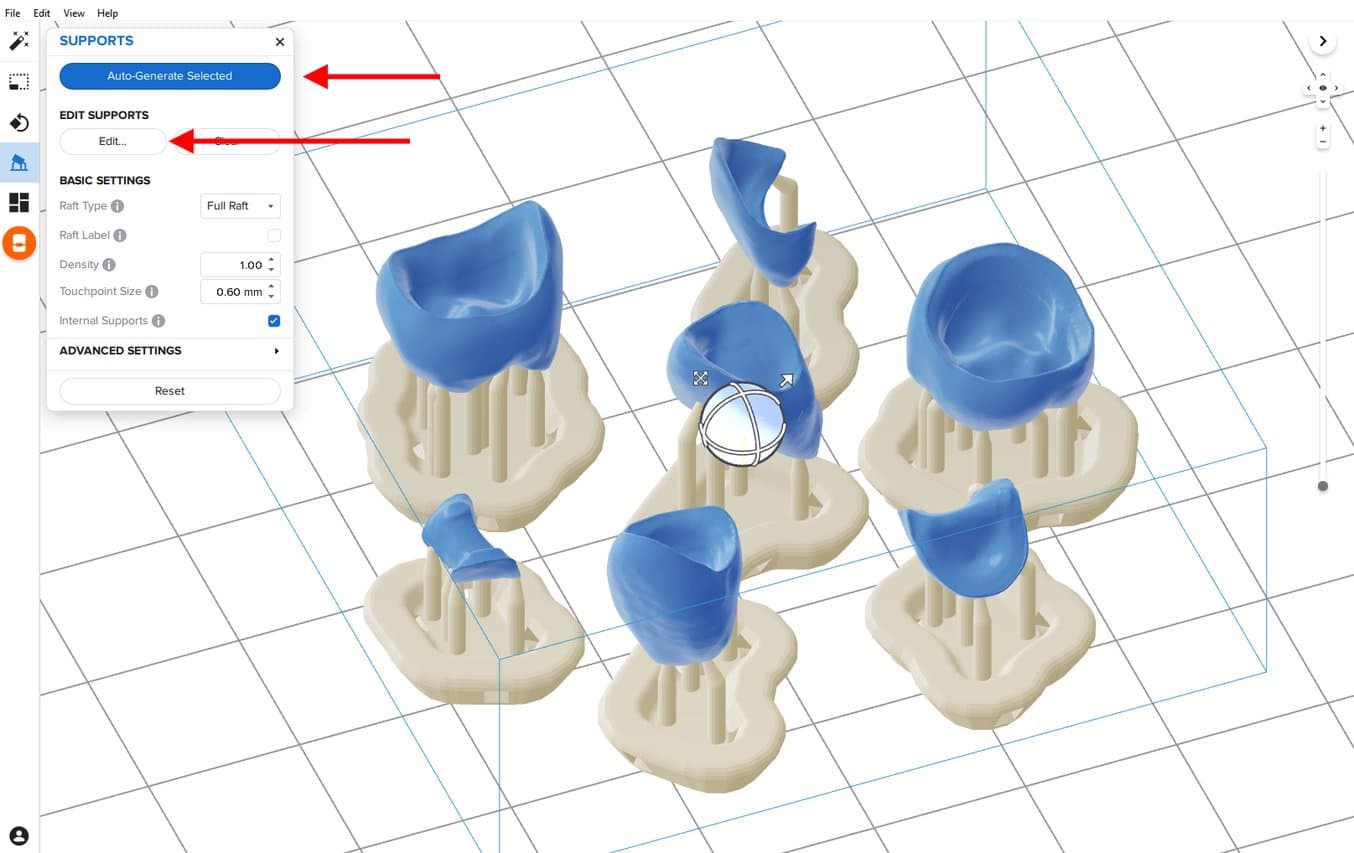

3.4.1 Automatic Support Generation

Open the Supports tool on the left side of PreForm and click the Auto-Generate Selected or Auto-Generate All button.

3.4.2 Manual Support Editing

If an automatically generated support point is not in an ideal location, move it by clicking the Edit… button in the Supports menu.

Manually move and edit support touchpoints from any marginal edges (common on inlays and onlays).

Always properly support the parts of the anatomy closest to the build platform.

PreForm will indicate in red which areas might require additional support.

Confirm under the Job Info menu bar on the right side of the screen that Printability shows a green thumbs-up.

3.5 Printing Layout

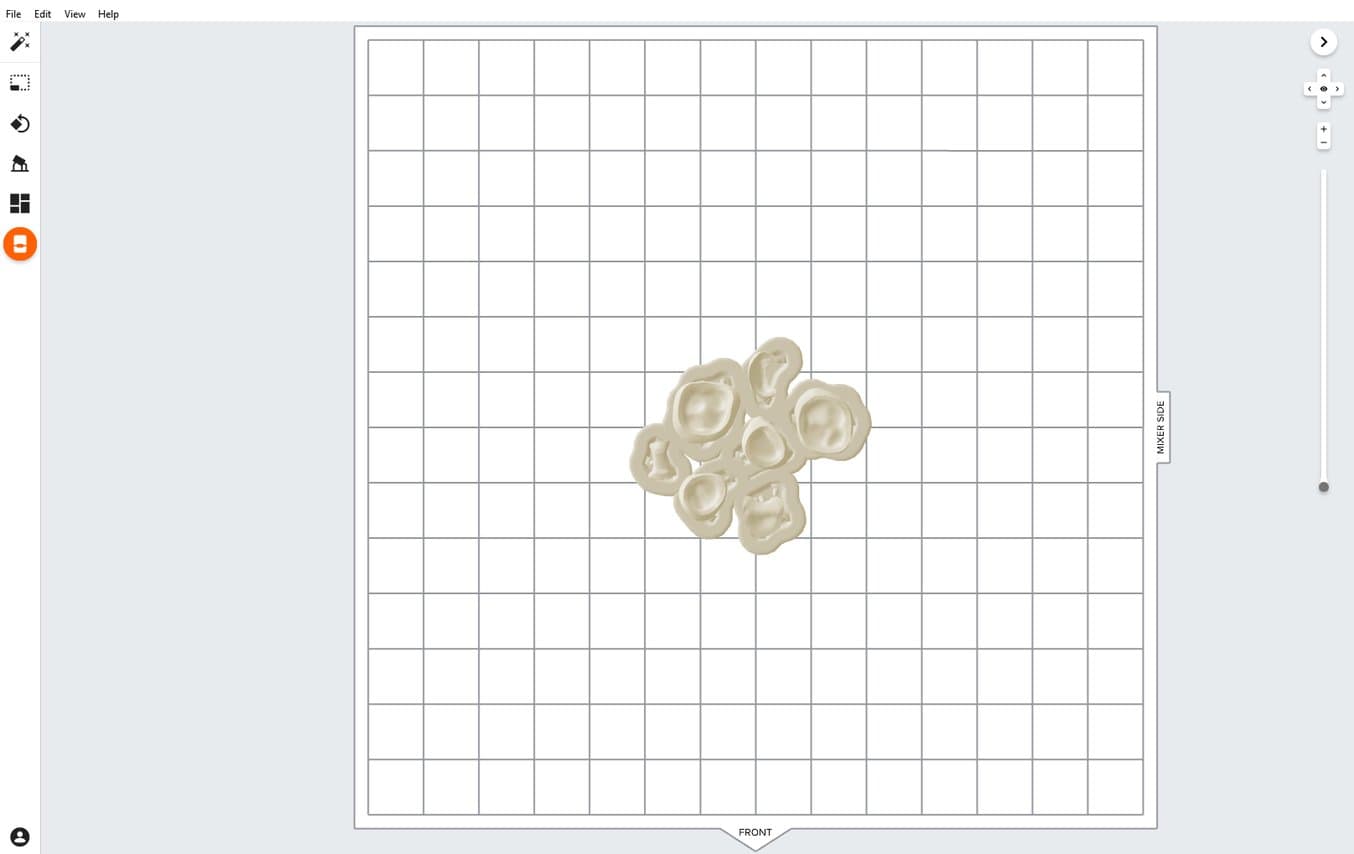

Standard Printing

For most jobs it is best to place parts toward the middle of the build platform.

Tip: When printing multiple cases, overlapping rafts can optimize the use of the build volume and save material.

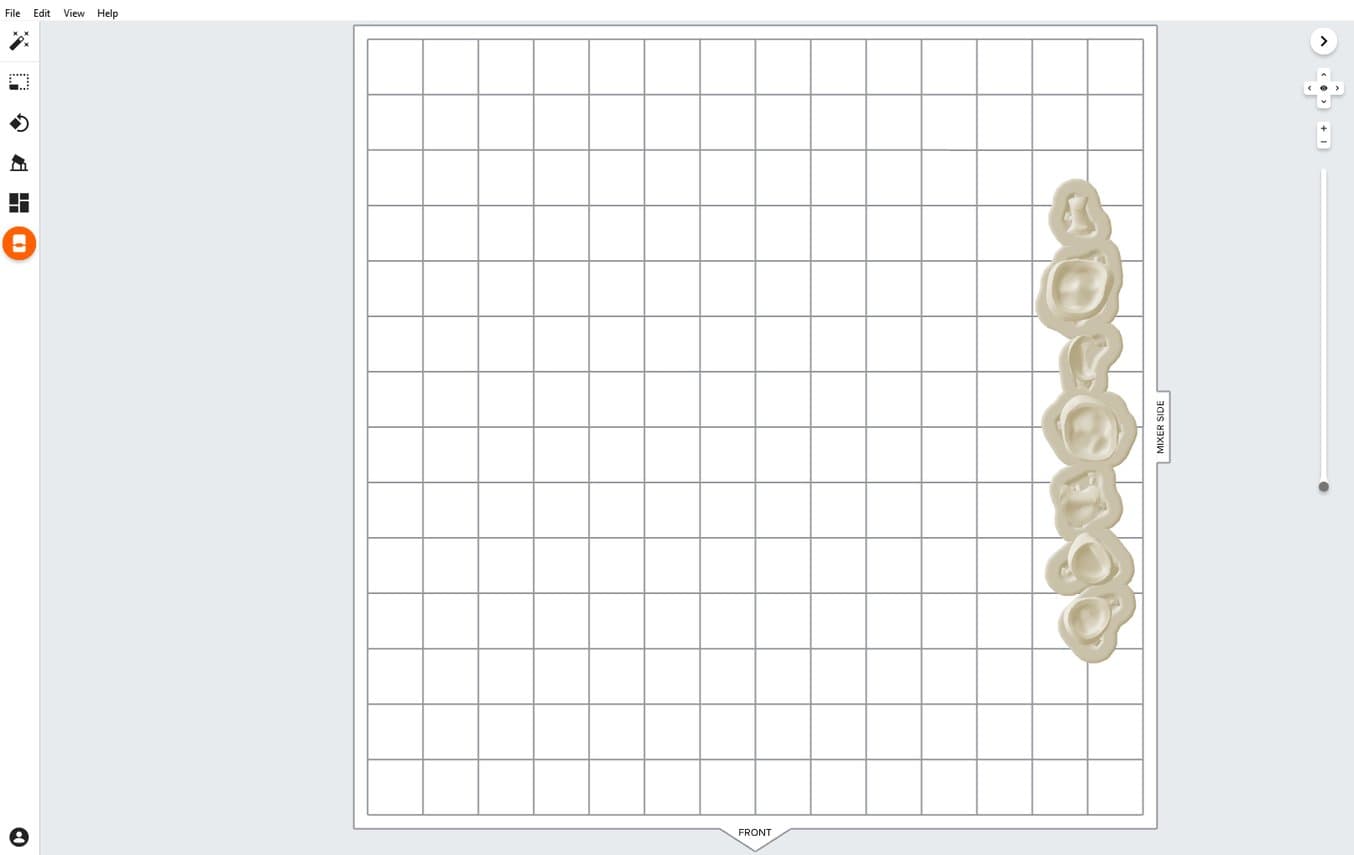

Fastest Printing on the Form 3B

If the fastest print time is needed, move the parts toward the mixer side of the build platform indicated in PreForm.

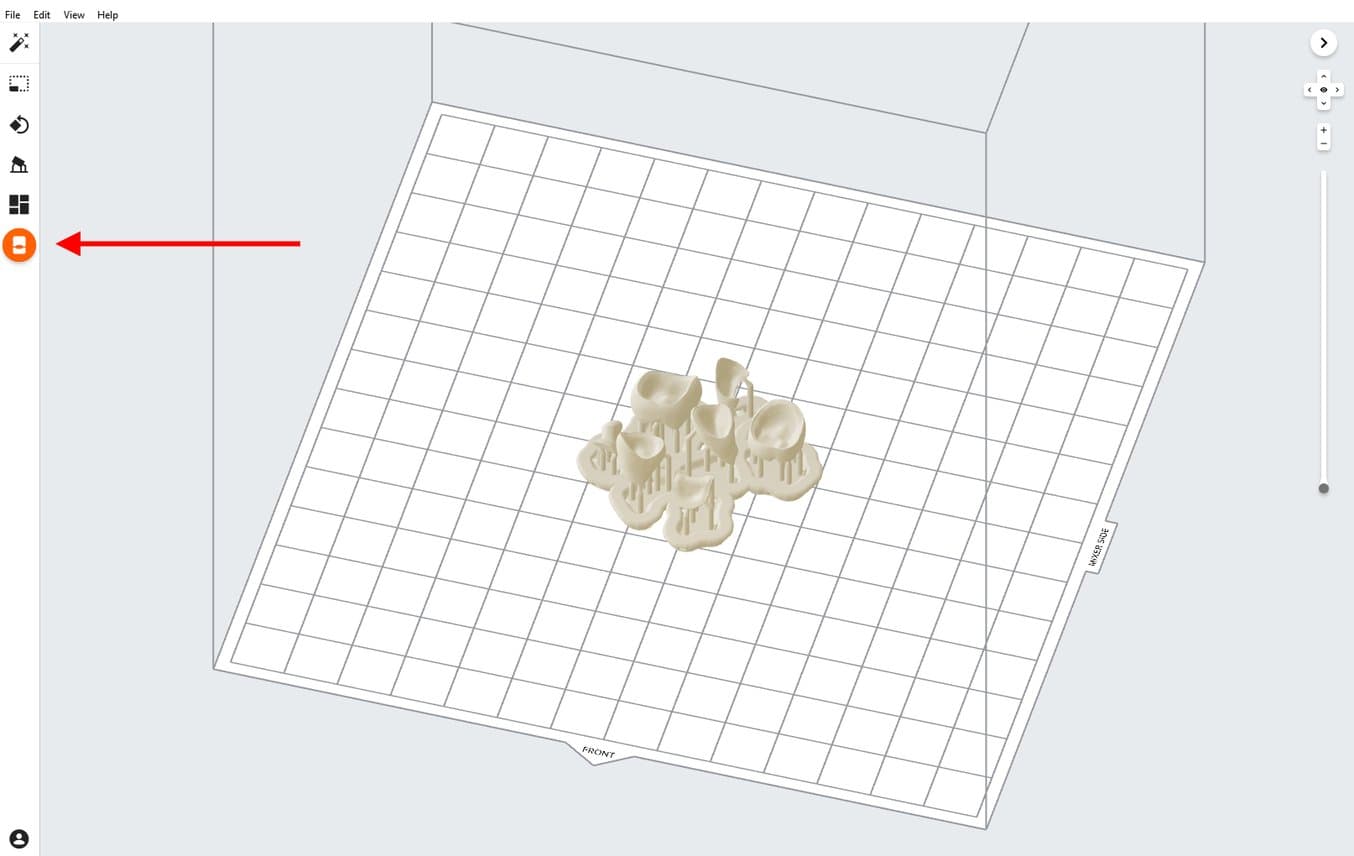

3.6 Transferring Job to the Printer

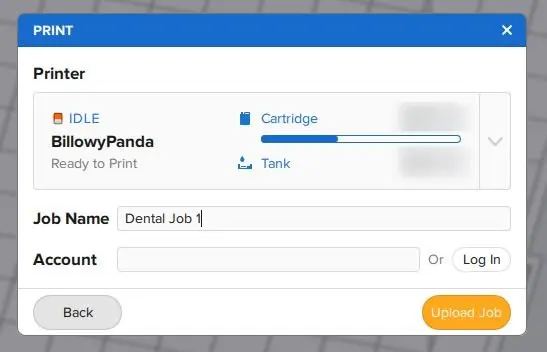

Send the job to the printer by clicking the orange printer icon on the left.

The Print dialog box will open to select the printer.

Click the orange Upload Job button to begin the transfer of the job to the printer.

3.7 Set Up the Printer

Shake the Permanent Crown Resin cartridge and then insert the cartridge, a Stainless Steel Build Platform, and a compatible resin tank into the Form 3B printer.

- Begin printing by selecting the print job from the printer’s touch screen

- Follow any prompts or dialogs shown on the printer screen

- The printer will automatically complete the print

Note

To ensure the correct build platform is being used. Permanent Crown Resin has only been validated for use with the Stainless Steel Build Platform. Deviating from recommended instructions may adversely affect performance, biocompatibility, and aesthetics of the printed prosthetics. The Stainless Steel Build Platform includes a white ST or CB mark laser-etched next to the Formlabs logo on the build platform handle and has stainless steel from the print surface to the top lip.

Attention

For full compliance and biocompatibility, Permanent Crown Resin requires a dedicated resin tank and Stainless Steel Build Platform. Only use the Form Wash with other Formlabs biocompatible resins, such as Surgical Guide Resin.

4. Post-Processing

Always use gloves when handling uncured resin and parts.

4.1 Part Removal

Remove printed parts from the build platform by wedging the part removal or scraping tool under the part raft and rotating the tool.

4.2 Washing

Precautions

- When washing the printed part with solvent, it should be in a properly ventilated environment with proper protective masks and gloves.

- Expired or unused Permanent Crown Resin shall be disposed of in accordance with local regulations.

- IPA shall be disposed of in accordance with local regulations.

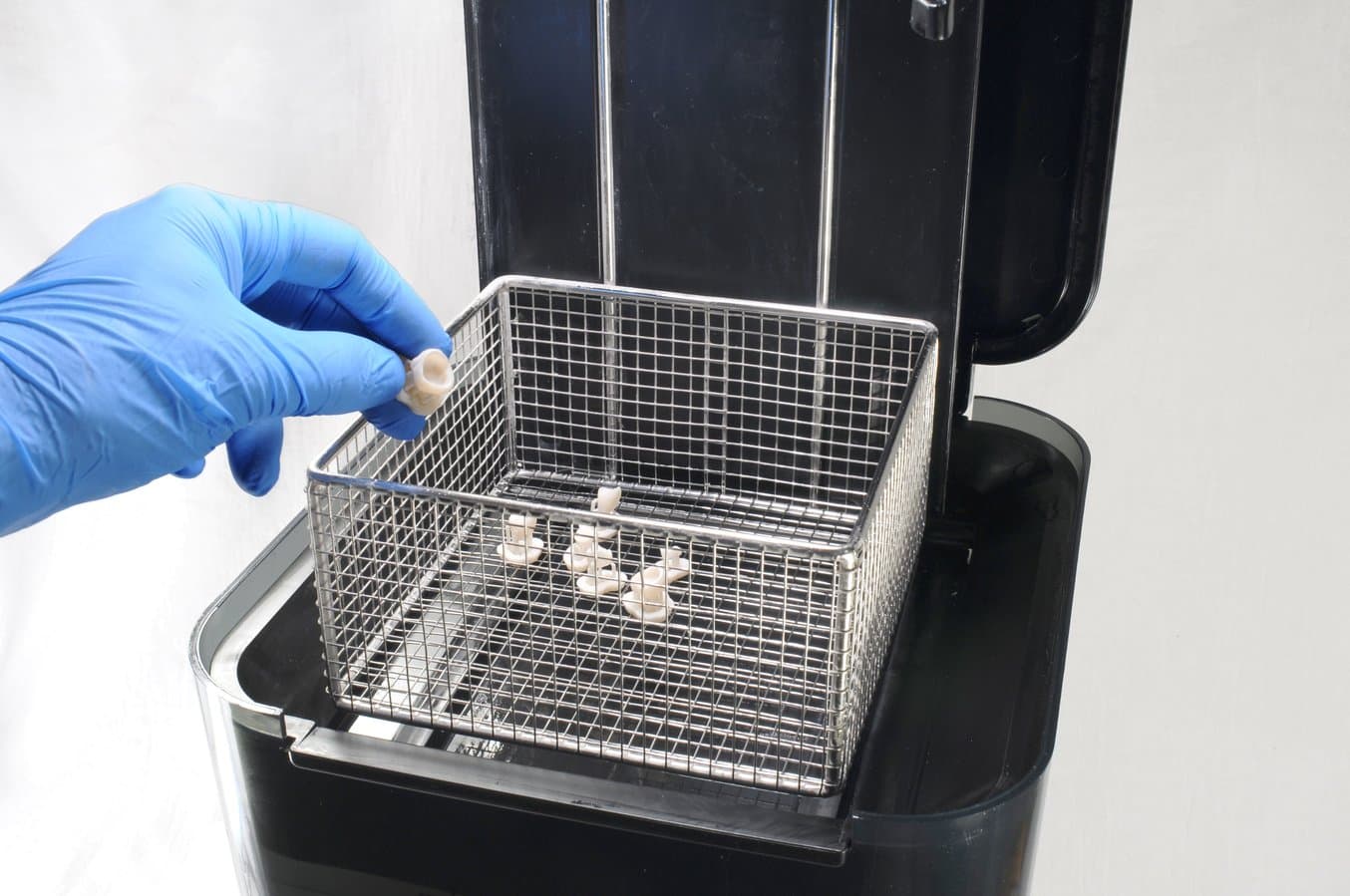

Place printed parts in a Form Wash or Form Wash L filled with isopropyl alcohol (IPA, ≥99%) and wash them for the time established in the IFU.

Make sure the parts are fully submerged in IPA when washing.

Exceeding wash duration may affect dimensional accuracy and performance of printed parts over time.

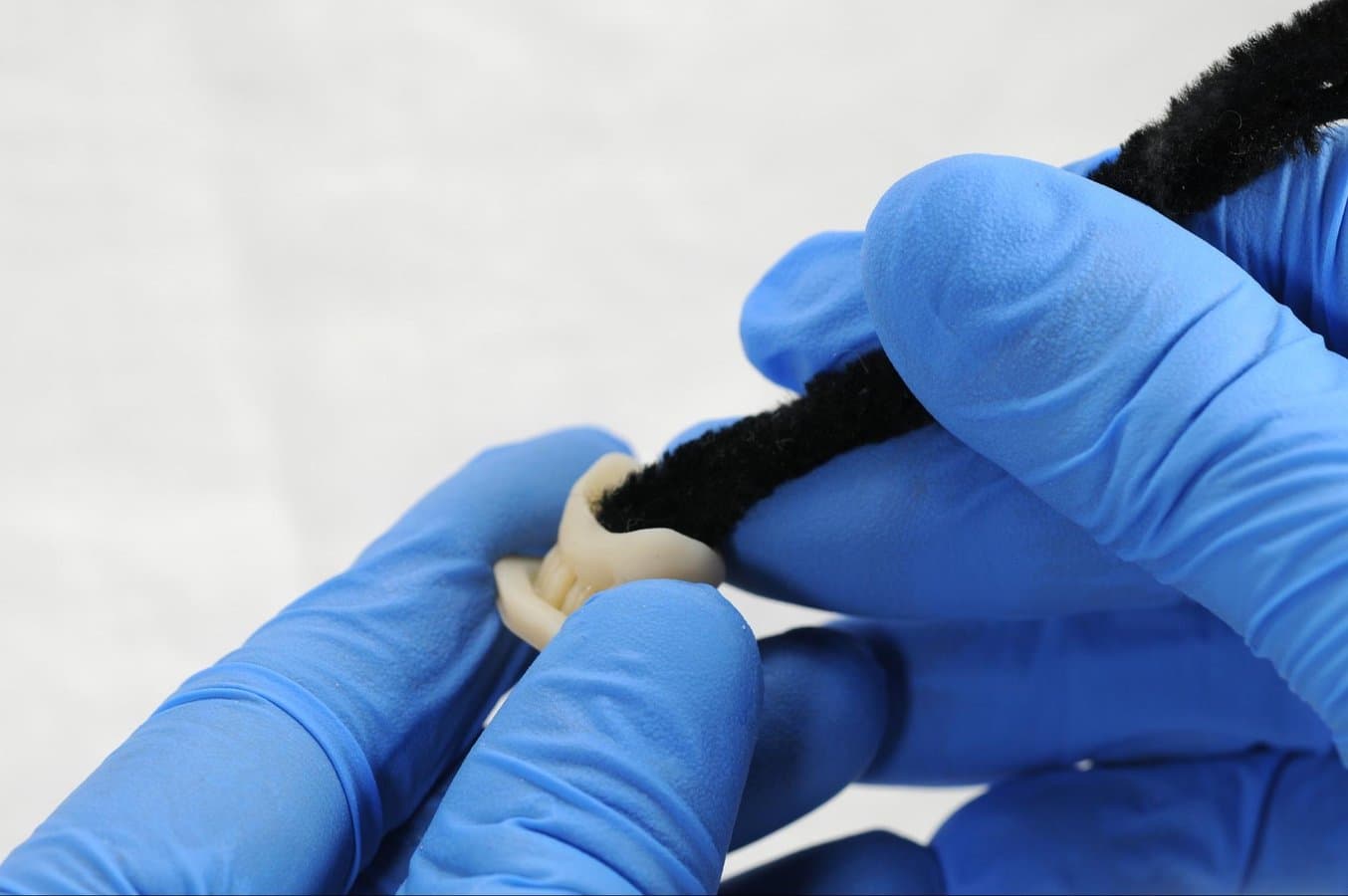

Use a brush or pipe cleaner to remove excess resin and reduce the amount of post-processing required later.

4.3 Drying

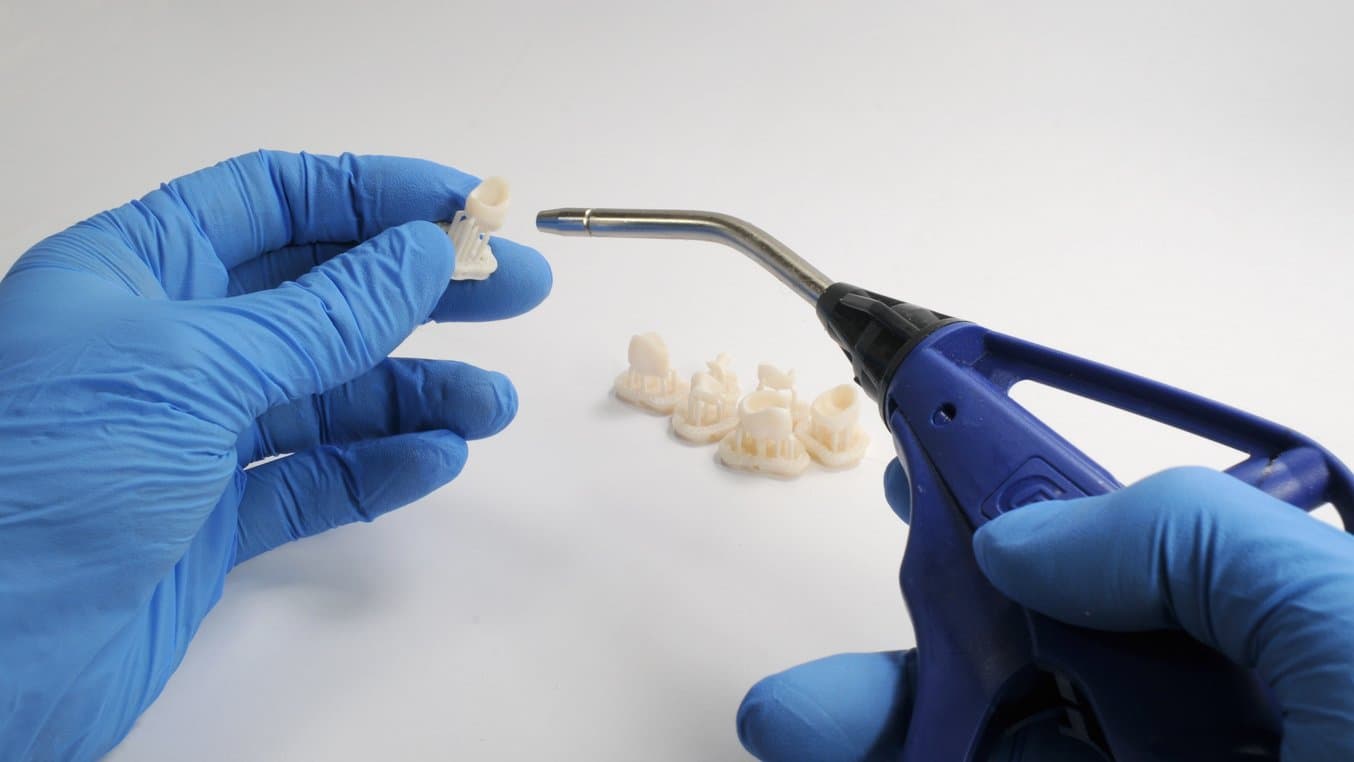

Compressed air can be used to help dry parts and allow for rapid inspection of unwashed resin.

Leave parts to air dry for at least 30 minutes in a well-ventilated area.

The dried parts will have a white, powdery coating on the print surfaces.

If any wet, uncured resin is still present after drying, use a squeeze bottle with fresh IPA to remove uncured resin and then air dry the parts again.

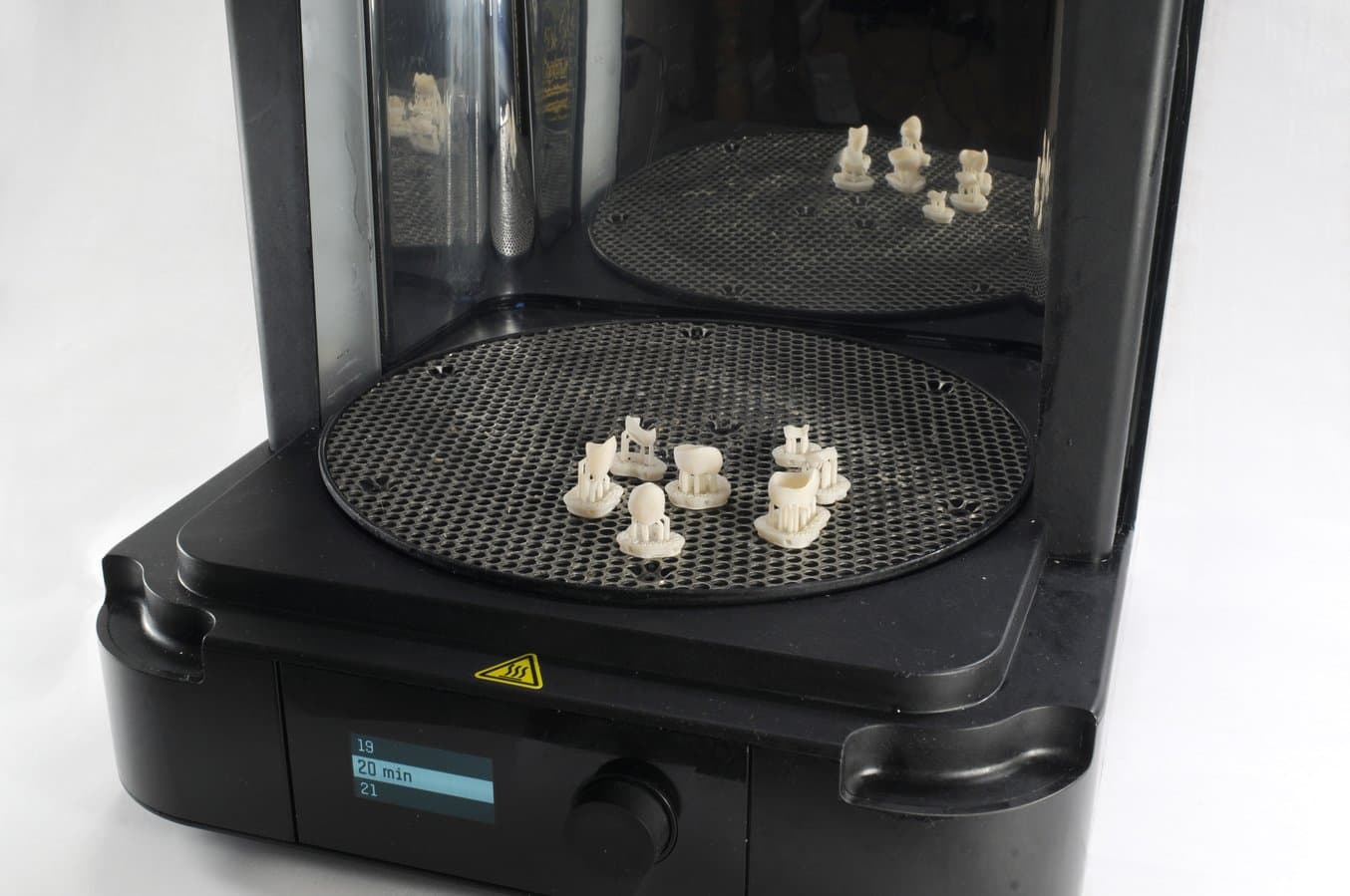

4.4 Post-Curing and Support Removal

To maintain dimensional accuracy and biocompatibility, post-curing must be done in two steps.

4.4.1 Post-Curing Step One

With the raft and supports still intact, place printed parts in the cure unit with the raft side down.

Post-cure the parts in a Form Cure, Form Cure L, or Fast Cure using settings established in the IFU.

4.4.2 Support Removal

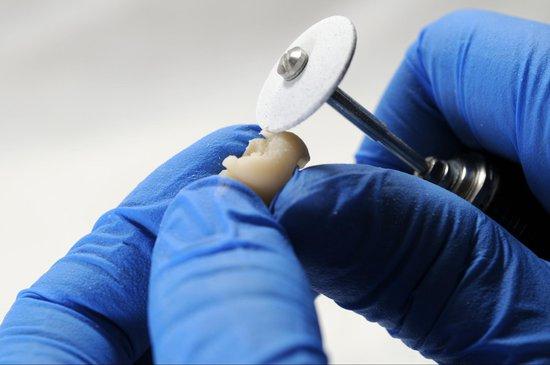

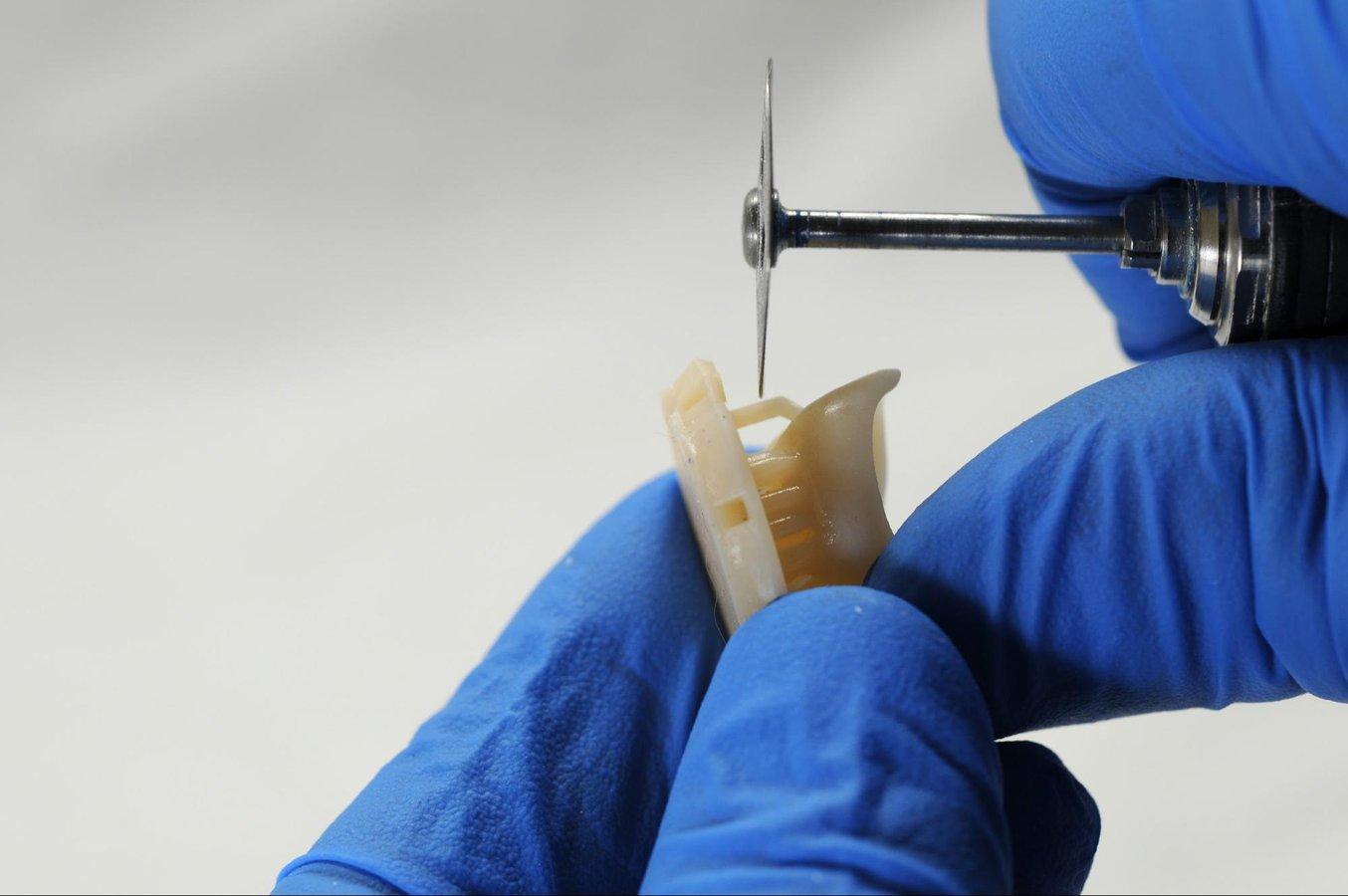

Remove parts from Form Cure and use a handpiece with a cutting disc to separate supports and the raft from printed parts.

Note

Do not use trimmers or clipping tools to remove the support structures. This can leave divots in the surface of the part.

Carefully sandblast the printed part surfaces to remove the white, powdery coating using a sandblaster with glass bead blasting material, such as Perlablast® Micro (REF 46092/54302) sandblasting medium, at a maximum blasting pressure of 1.5 bar.

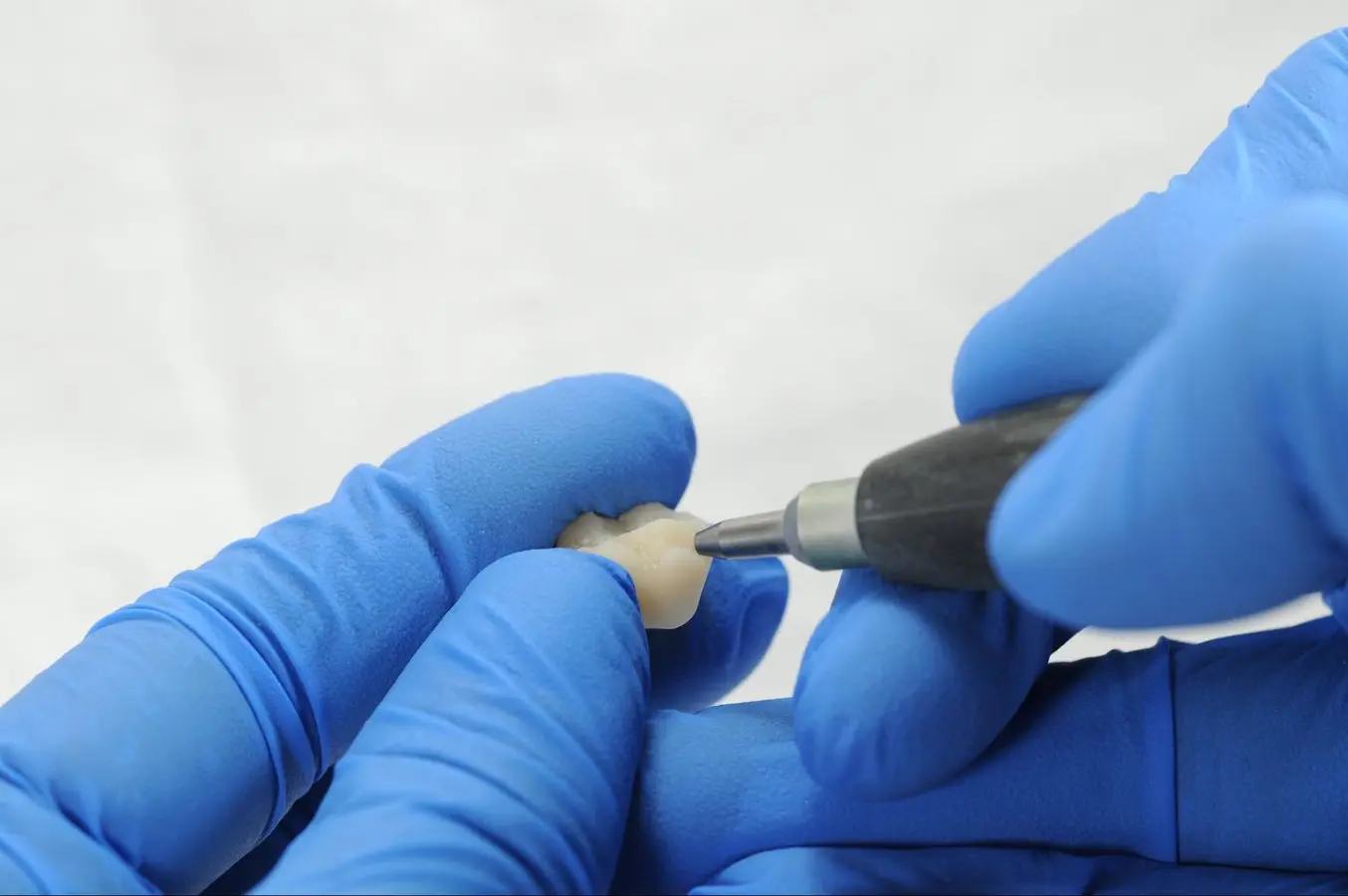

Check printed part fit and finish, and contour parts as needed using a dental handpiece and carbide rotary burs.

4.4.3 Post-Curing Step Two

Place finished parts in the cure unit with the occlusal plane facing upwards. Post-cure the parts again using settings established in the IFU.

For best results and full compliance, printed parts must be post cured twice as recommended.

Any deviations from this protocol, may lead to unsatisfactory fit and affect biocompatibility.

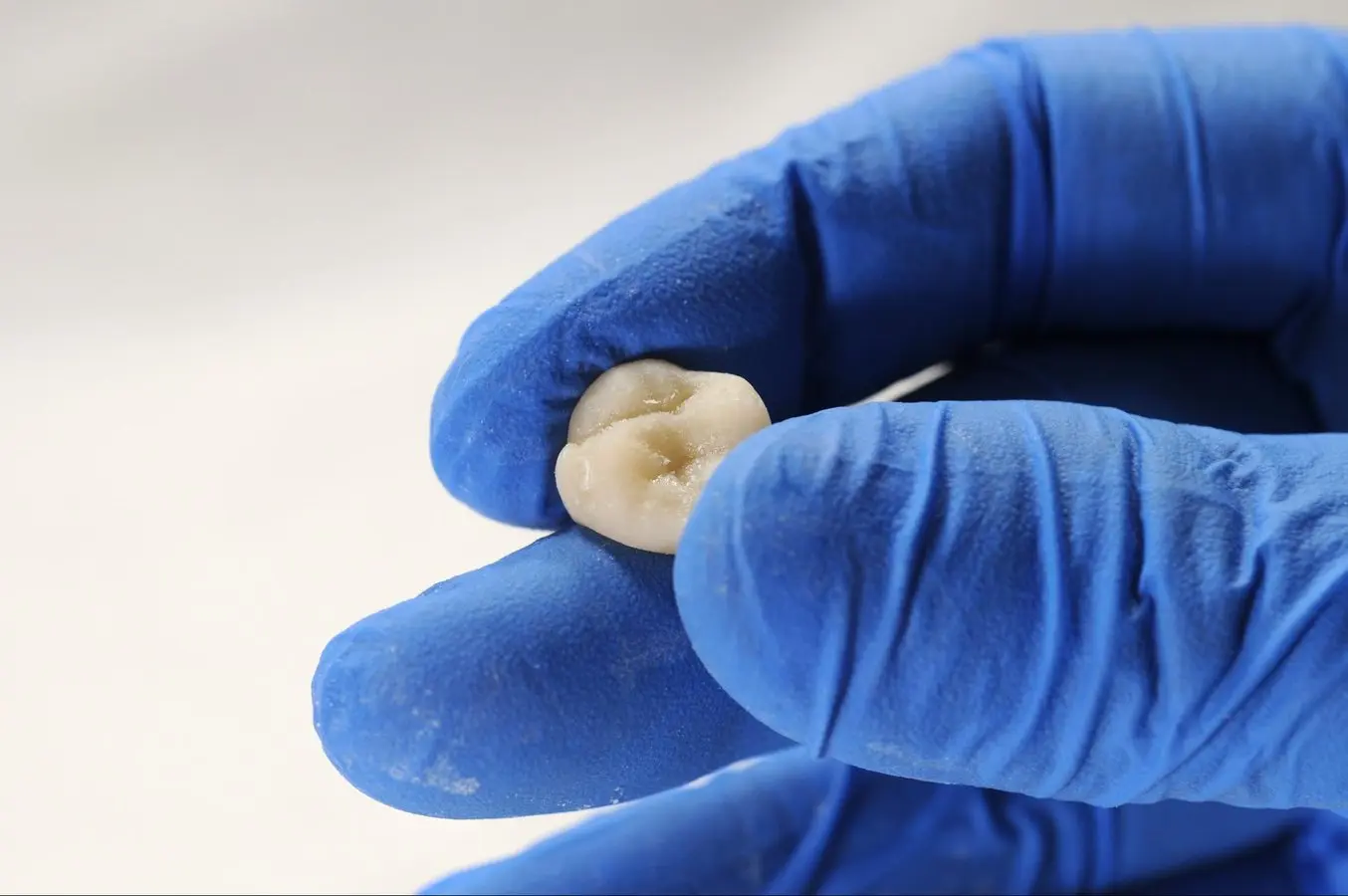

Inspect the restoration. Discard and reprint it if any cracks or damage are detected.

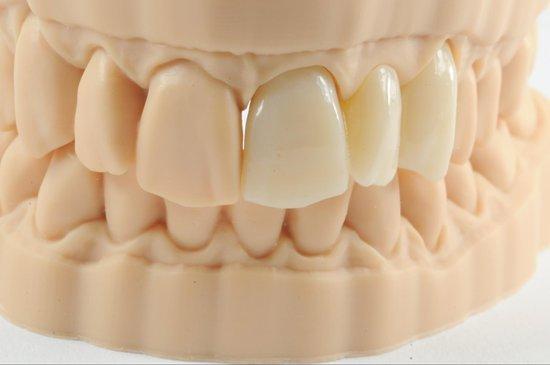

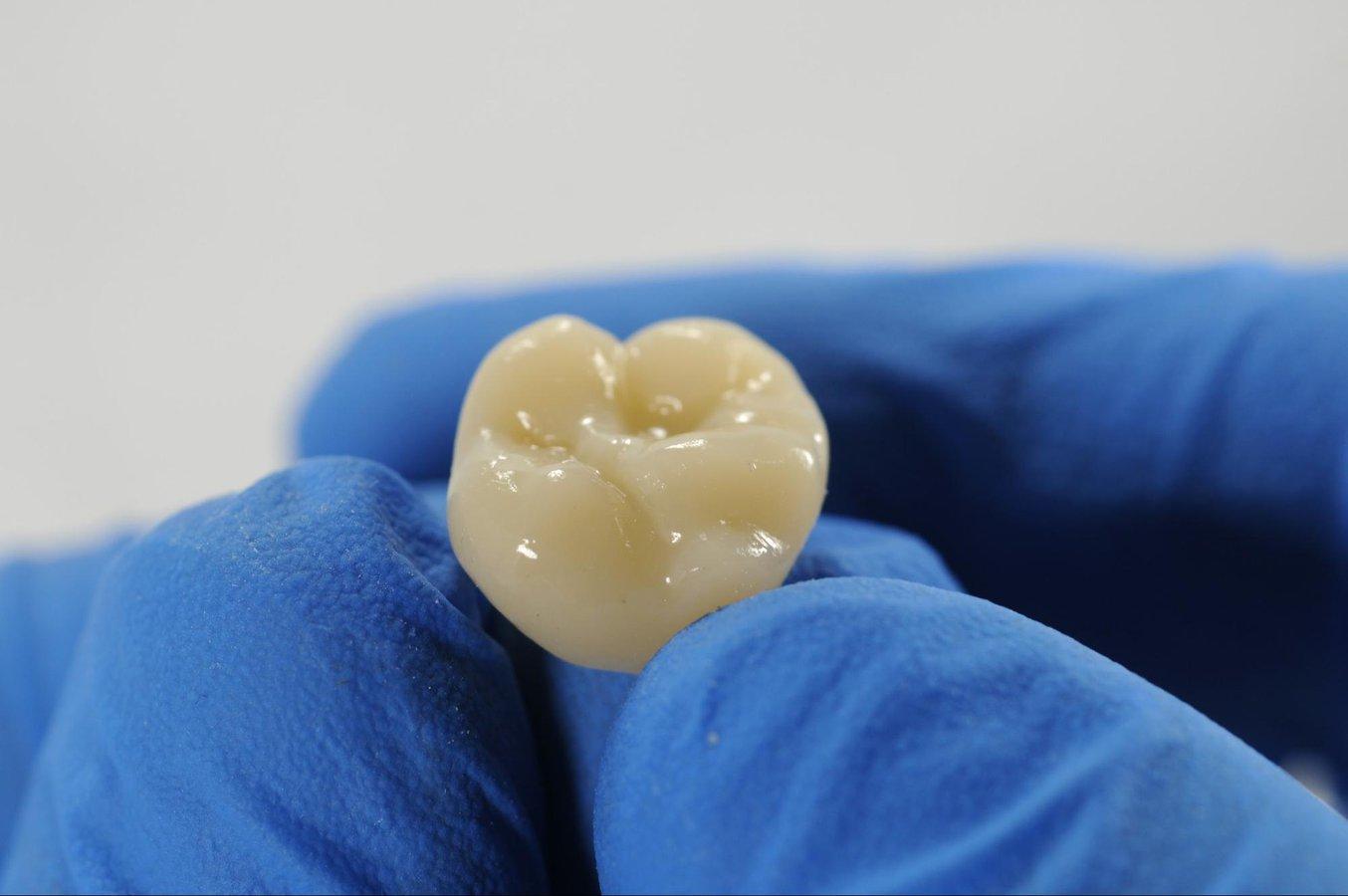

4.5 Finishing and Polishing

Post-cured parts must be polished using pumice stone and polishing compound prior to use.

If rough marks are left behind after support removal, use a carbide or other rotary before polishing surfaces to improve patient comfort.

A high gloss shine can be achieved with traditional polishing tools and materials used for acrylics and composites.

Note: Robinson brushes and rubberized spiral wheels are ideal for polishing occlusal anatomy. Refert Opal-L works very well as a polishing material.

Avoid overheating the parts during polishing.

Inspect the restoration again. Discard and reprint it if any cracks or damage are detected.

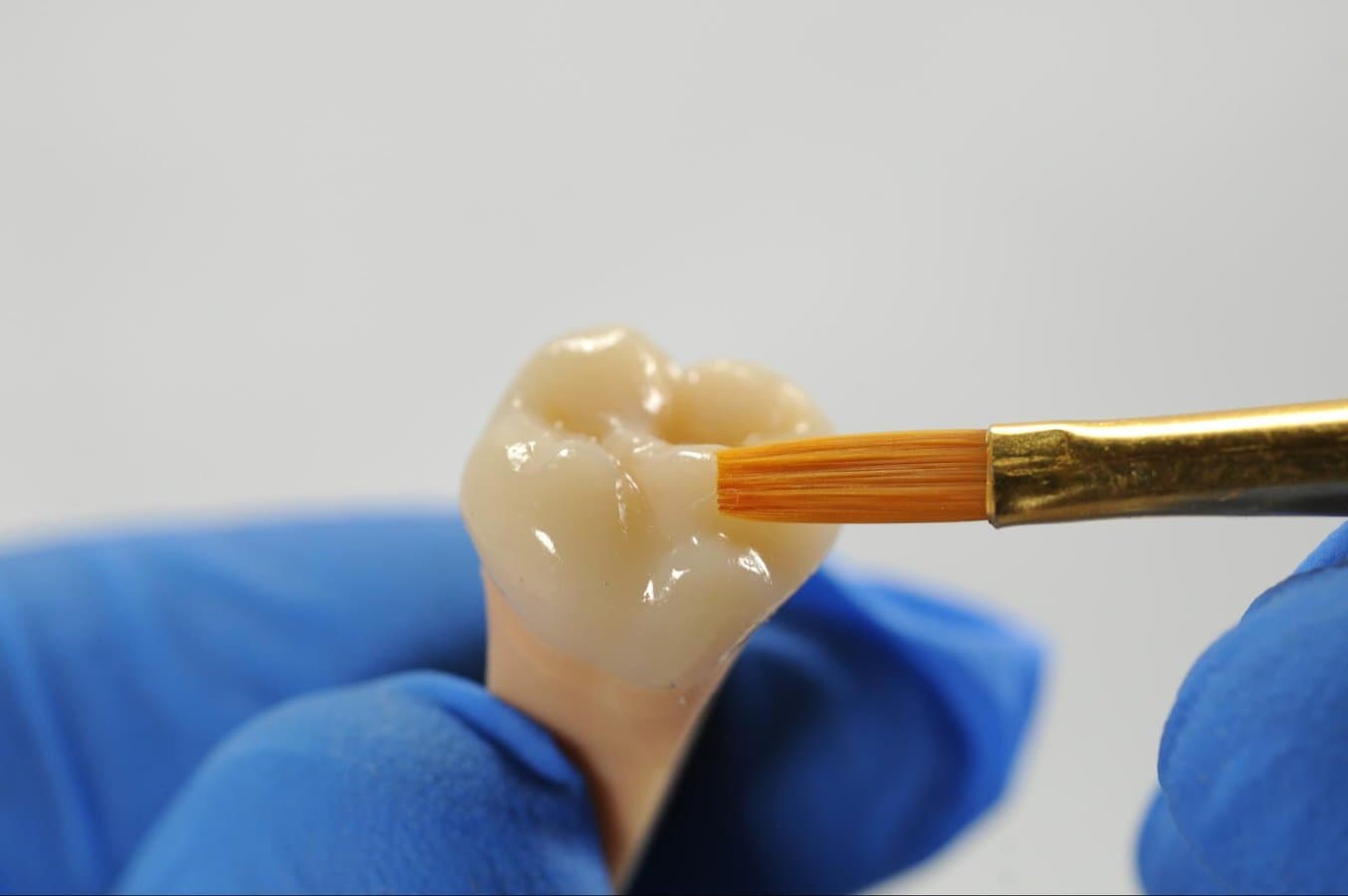

Light-cured glaze and characterization can be also used like GC OPTIGLAZE™.

Follow the instructions from the material manufacturer.

5. Delivery and Treatment

Follow the instructions for use provided by the luting agent manufacturer.

Restorations can undergo high-gloss polishing with composite polishers commonly used in dental practice. The finished permanent restoration can be cemented using self-adhesive cements (e. g. Relex Unicem*, 3M Espe) or composite cement with primer (e. g. Variolink Esthetic DC* and Monobond Plus*, Ivoclar Vivadent).

Note

If the subsequent definitive restoration is to be attached using methacrylate-based composite cement, the use of eugenol-free temporary cements is recommended. Observe the instructions for use of the luting agent.