Digital Prosthodontics With 3D Printing: How Dr. Cacioppo Builds a Reliable 3D Printing Environment

Dr. Antonino Cacioppo is a digital dentistry expert who’s been 3D printing for almost a decade, and practicing digital dentistry since 2005. A dentist, private practitioner, and prosthodontist in Palermo, Italy, Dr. Cacioppo started out with a Form 2 3D printer, and currently uses 23 3D printers from different manufacturers, including all of Formlabs’ Form Series 3D printers for dental applications.

“You can be the best digital dentist in the world, but when you put your gloves on you need to be fast and you need technology that is easy. You don't need tons of parameters, you need the perfect ones for each resin, each application. And you need to know that you can trust your technology. Today I can say that I trust 100 percent Formlabs 3D printers. It's not the same with other 3D printers.”

Dr. Antonino Cacioppo, DDS, PhD, Prosthodontist

Each of Dr. Cacioppo’s printers is dedicated to a specific application based on his requirements for those applications and the parameters of the printers. The precision, accuracy, and reliability of Formlabs printers paired with the expansive material library have led Dr. Cacioppo to reserve Formlabs printers for biocompatible applications where high levels of precision and accuracy are needed. Printing surgical guides, occlusal splints, and both temporary and permanent restorations, Dr. Cacioppo is a 3D printing expert at the cutting edge of digital prosthodontics.

Product Demo: Form 4B Dental 3D Printer

Blazing speed meets unmatched accuracy in the next generation of dental 3D printing. Explore the latest innovations in our webinar.

Starting With Surgical Guides

Dr. Cacioppo is a Formlabs beta-tester and KOL who started designing dental appliances for 3D printing in 2007. As an early adopter of 3D printing, Dr. Cacioppo has first-hand experience with the history of 3D printers and resins for dental applications. In 2015, he brought printing in-house with Form 2, saying, “Previously, 3D printers were not accessible, both due to their dimensions and costs. I started with a few models and with surgical guides.”

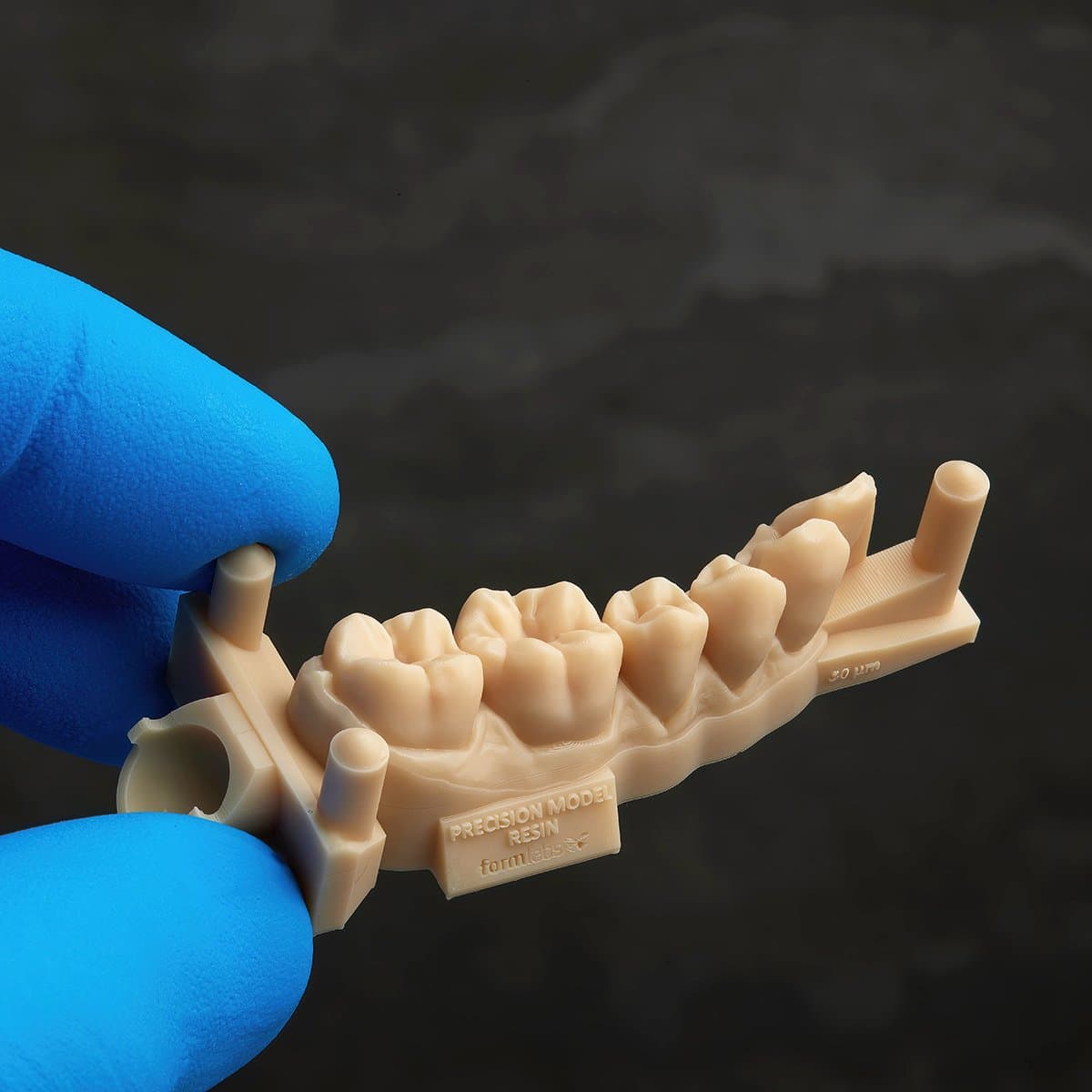

Models are the easiest application to print, but while surgical guides are also a good first application to bring in-house, they require highly precise printing to ensure the fastest, most successful procedures and outcomes for the patient. Most recently, Dr. Cacioppo has been printing on Form 4B with Surgical Guide Resin, a combination he says is “maybe the best I’ve ever used.”

“What is absolutely amazing with Form 4B is the accuracy of the printing. Because the perception is that the prints are near to zero deviation, zero error between the CAD file and the 3D print. And I can assure you that it is not a common experience with other printers. The fit with the sleeves, it's absolutely amazing.”

Dr. Antonino Cacioppo, DDS, PhD, Prosthodontist

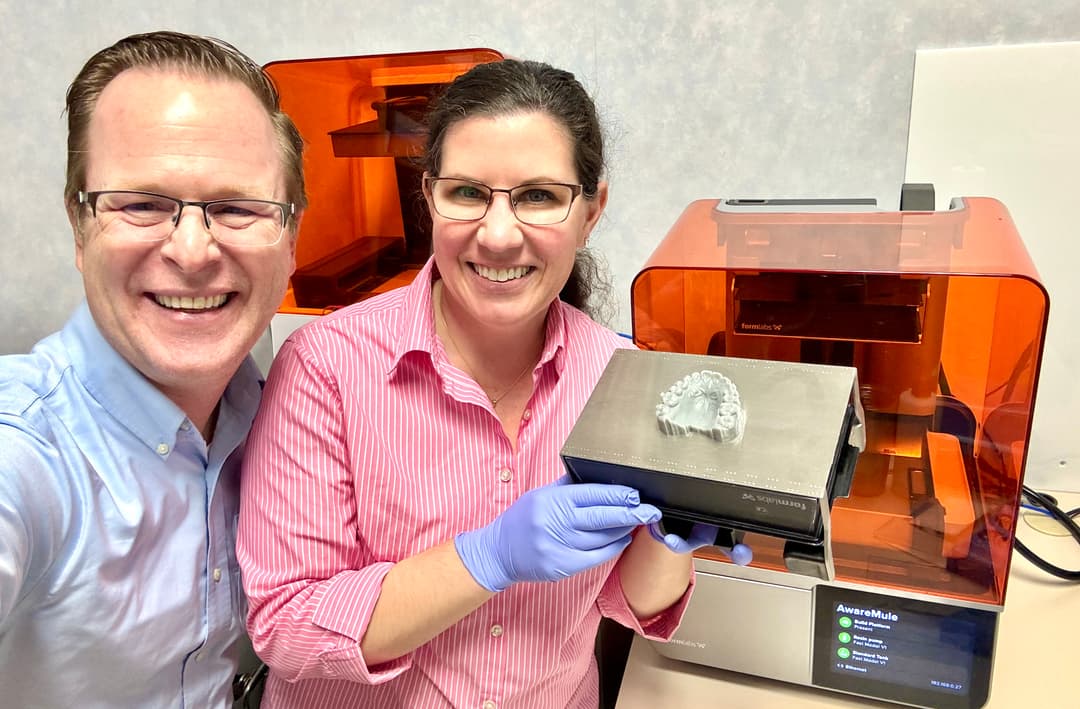

Dr. Cacioppo has found that surgical guides printed with Surgical Guide Resin on Form 4B offer exceptional clarity out of the printer.

Dr. Cacioppo found that the precision of Surgical Guide Resin printed on Form 4B means sleeves fit perfectly on the first try.

Using Surgical Guide Resin on Form 4B, Dr. Cacioppo noted that he could not see the layers, and that the transparency and hardness were even more noticeable compared to parts printed on Form 3B+. The sleeves, too, fit perfectly on the first try.

“What is important to me is the finishing, I feel that I don't need to finish my piece. This was my first reaction with the first printed surgical guide with Form 4B.”

Dr. Antonino Cacioppo, DDS, PhD, Prosthodontist

Not needing to finish prints saves valuable workflow time, translating to less labor, cost-savings, and the difference between multiple appointments and same-day procedures. The benefits go beyond these savings, making for less chairtime, more precise surgery, and a better patient experience.

“In the future, I think that guided surgery will be the secret for all implantology, thanks to the speed and accuracy of 3D printing in-house.”

Dr. Antonino Cacioppo, DDS, PhD, Prosthodontist

3D Printing & Guided Implant Surgery

Join Dr. Ahmad Al-Hassiny, BDS (HONS), Director of Institute of Digital Dentistry, to learn the digital workflow, how to design and print pilot drill guides with Form 3B+ and Surgical Guide Resin, and the clinical performance in real cases.

Reliable and Easy to Use for Maximum Efficiency

“3D printing is not easy, but if you want it to be easy, you need to trust your 3D printing partner. My main partner is Formlabs, because they make it comfortable and easy to print.”

Dr. Antonino Cacioppo, DDS, PhD, Prosthodontist

“Time-saving is absolutely important,” says Dr. Cacioppo. In his office, where multiple printers are working every day and all staff are involved in 3D printing, streamlined, efficient workflows are key.

Unreliability in dental 3D printing means repeat prints, wasting time and costs. Tricky workflows take more time and are more likely to result in errors. Inaccuracies mean remakes, wasting time, material, and potentially lengthening treatment timelines. This is why having a printer, settings, materials, workflows, and support you can rely on is key.

“100 percent of us, not only the digitally engaged dentists like me, are able to use Formlabs 3D printers. They are for the newbies and for experienced dentists. It's not a coincidence that my first 3D printer nine years ago was from Formlabs and my newest one is from Formlabs.”

Dr. Antonino Cacioppo, DDS, PhD, Prosthodontist

But it’s not just about workflows: the final dental appliance must meet the exacting standards of dental professionals. When evaluating a new printer, Dr. Cacioppo puts it through a thorough testing regime to check accuracy, reliability, precision, and material quality.

Form 4 Series printers print with 95% of the surface within 50 μm of the CAD model, and 99% of the surface within 100 μm of the CAD model, for sleeves that fit in surgical guides, restorations with titanium bases, and appliances that fit every time.

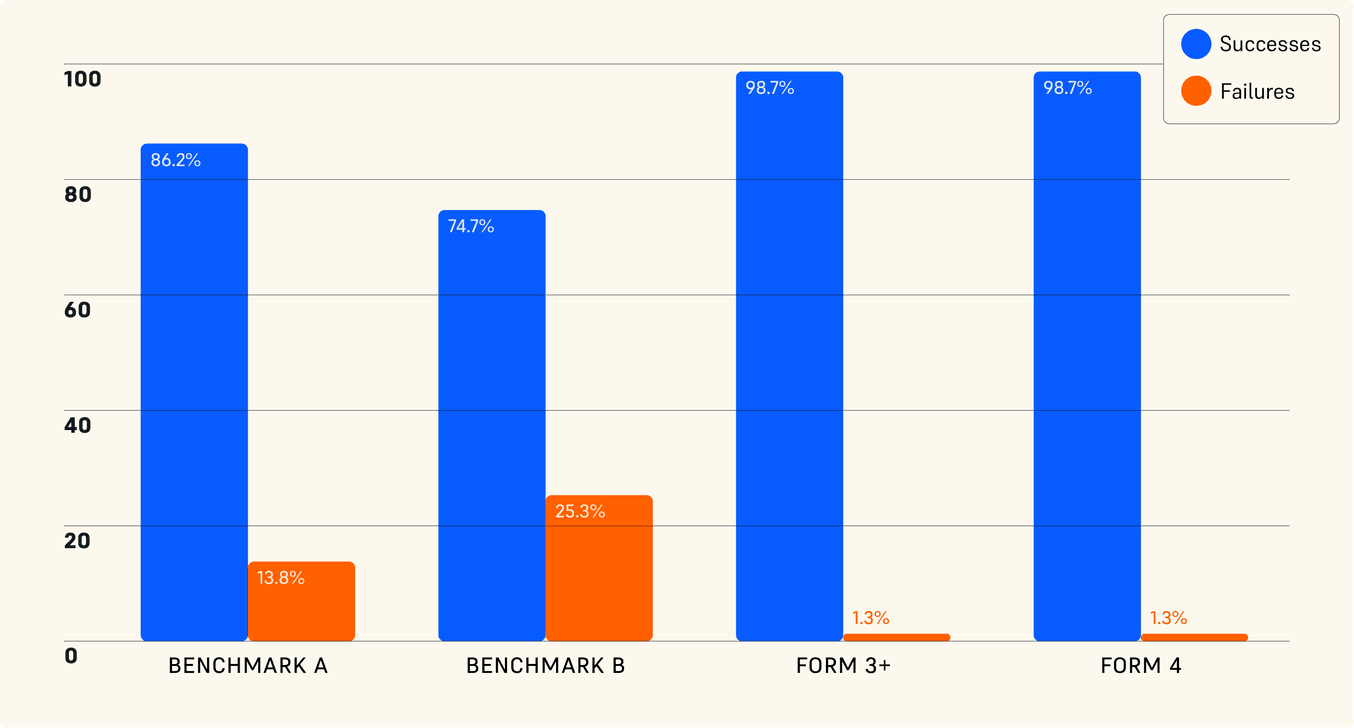

Independently Tested Reliability of Form 4 and Other Resin 3D Printers

Formlabs Form 4 was measured to have a 98.7% print success rate by an independent global leader in product testing. Read a complete description of the test methodology and see the results in our white paper.

Biocompatible, Validated Materials for Easy Printing and Predictable Outcomes

The requirements of MDR in Europe mean 3D printing biocompatible parts is carefully regulated, and Dr. Cacioppo prints all of his biocompatible resins in one room — all on Formlabs printers: his original Form 2, three Form 3B 3D printers, one Form 3B+, and one Form 4B. He uses these Formlabs printers for surgical guides, temporary restorations, long-term or permanent crowns, bridges, and occlusal splints.

The clarity of occlusal splints printed with Dental LT Comfort Resin means minimal polishing is needed.

Of these printers, two are for occlusal splints: one prints Dental LT Clear Resin (V2) for rigid splints, and one Dental LT Comfort, for flexible splints. Another printer is dedicated to printing surgical guides with Surgical Guide Resin, and Form 4B prints restorations with Premium Teeth Resin and BEGO™ VarseoSmileⓇ TriniQⓇ Resin.

Formlabs resins for biocompatible dental applications are manufactured at our FDA-registered facility in Ohio. These materials are designed and manufactured within our robust Quality Management System that is ISO 13485 and EU MDR certified. A dedicated team of operators and quality assurance professionals make the resins inside a certified ISO Class 8 clean room. All of our Medical Device Resins are appropriately registered with the FDA and CE-marked according to the EU MDR.

These strict quality standards are important for Dr. Cacioppo, even more so since Formlabs’ resins are validated on Formlabs printers, giving him peace of mind, and making it easy to press print knowing the printer settings don’t require any troubleshooting or adjustment.

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part printed on the Form 4B to your office.

An Introduction to Regulatory Compliance in Dental 3D Printing

Implementing 3D printing workflows in your lab or practice can be a game changer for your business. Understanding the basics of regulatory compliance can help inform your decisions and what is best for your business. Regulation depends on geography; in this paper, we examine regulations in the United States of America and the European Union.

Permanent Restorations: BEGO™ VarseoSmileⓇ TriniQⓇ Resin & the Role of Dental Labs

Though Dr. Cacioppo has a fleet of 3D printers, he doesn’t produce all appliances in-house; the dental lab is still an important partner. Occlusal splints, surgical guides, and temporary restorations are all produced in-house, but about 40% of permanent restorations are still produced in a dental lab. Restorations made from zirconia, which requires advanced skills to mill, and final ceramic structures, which Dr. Cacioppo calls a dental art, are sent to the dental lab, to be manufactured by specialists.

Dr. Cacioppo sees prosthodontists being more and more involved in 3D printing, managing all design and production of temporary restorations in-house, with highly specialized final restorations being produced by the dental lab. This gives prosthodontists full control and quicker turnaround on temporary restorations, for faster delivery which impacts patient care, while letting the dental lab specialists produce high-quality permanent restorations.

With new dental materials becoming available indicated for permanent and temporary restorations, clinicians are slowly starting to 3D print these parts in-house for some of their cases. Dr. Cacioppo has been printing crowns, onlays, anterior bridges, and posterior three-unit bridges with BEGO™ VarseoSmileⓇ TriniQⓇ Resin. Based on his use thus far, Dr. Cacioppo says it’s, “perfect for posterior implant crowns, for inlays, onlays, and overlays, and very good for long-lasting provisionals.” Additionally, he found the interaction with the cement agent to be advantageous.

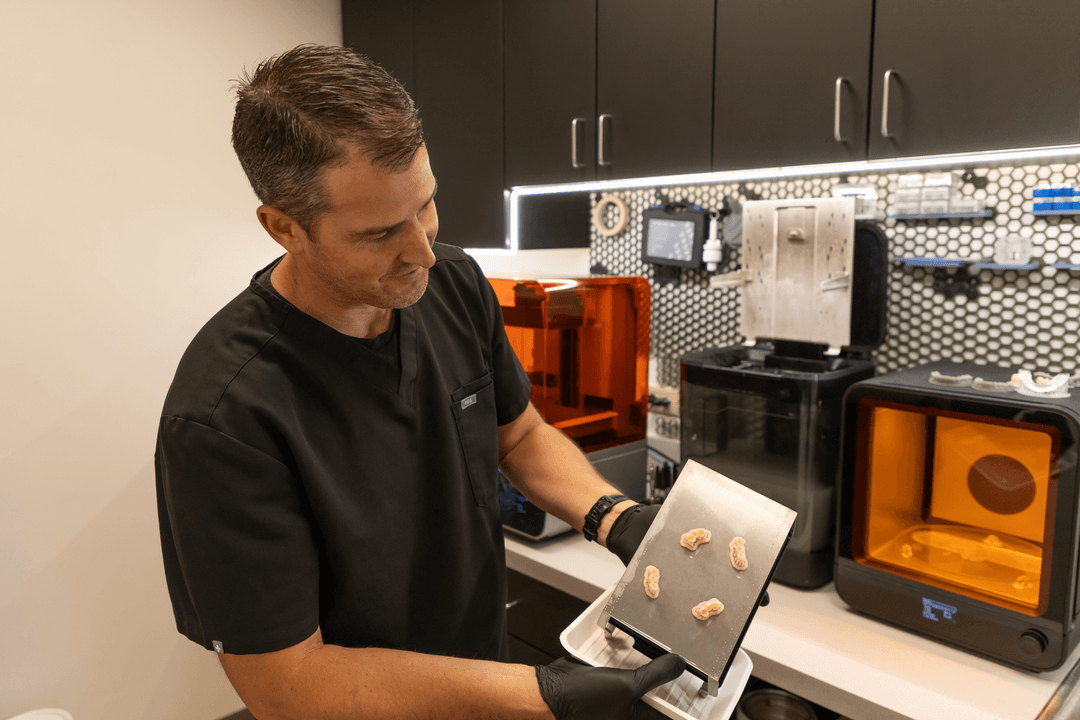

Dr. Cacioppo found that the surface of BEGO™ VarseoSmileⓇ TriniQⓇ Resin is of good quality after washing and curing, minimizing finishing time.

BEGO™ VarseoSmileⓇ TriniQⓇ Resin is a versatile ceramic-filled biocompatible material, indicated for temporary and permanent single units (crowns, inlays, onlays, and veneers) and bridges, and denture teeth.

“I will suggest all my 3D printing digital colleagues try BEGO™ VarseoSmileⓇ TriniQⓇ Resin as soon as possible. A very good weapon in our arsenal.”

Dr. Antonino Cacioppo, DDS, PhD, Prosthodontist

Dr. Cacioppo appreciates that restorations printed with BEGO™ VarseoSmileⓇ TriniQⓇ Resin are radiopaque, making them clinically visible on X-rays. However, in accordance with ISO standards, its radiopacity is below the specified threshold.

BEGO™ VarseoSmile® TriniQ® Compendium

This compendium compiles BEGO™’s comprehensive testing on BEGO™ VarseoSmile® TriniQ® Resin including a 10-year chewing simulation, biocompatibility testing, case documentation, bond strength, preparation guidelines, and more.

Control of Your 3D Printer Fleet: Formlabs Dashboard

“3D printing in the dental office, it's not possible if you own just one 3D printer,” says Dr. Cacioppo. While it’s easy to do material changeovers on Formlabs 3D printers, offices that are printing multiple applications a day will find it easier to have dedicated printers for each resin.

“It's not related to the printer,” says Dr. Cacioppo. “But when, every day, you’re printing occlusal splints, temporaries, models, and surgical guides, your dental office needs more than one printer.”

“There is the world of dental 3D printing and then there is Formlabs. When you have multiple 3D printers — and this is the future for dental — you need a good way to manage all those 3D printers. And there is nothing close to the Dashboard and the ecosystem from Formlabs.”

Dr. Antonino Cacioppo, DDS, PhD, Prosthodontist

Dr. Cacioppo relies on Dashboard to monitor and manage printers. “I love Dashboard because my secretary and my assistant know the printing time and if everything is okay. Lots of times I am out of my office for courses or congresses. If I want to print something, I can print even if I’m outside of my office.” Everyone on staff can track prints, get notifications about print status, and start jobs from anywhere. Dashboard also tracks material usage for seamless reordering.

Good for Patients & Practitioners

“The speed of new 3D printers is a good thing — it’s a good future for the patients. For example, prosthodontists could have the ability to have three different shapes of the same tooth of the same patient, and you can try one after another for an aesthetic visualization.”

Dr. Antonino Cacioppo, DDS, PhD, Prosthodontist

The technology powering Formlabs Dental 3D printers makes printing easy and intuitive while empowering the production of a full range of appliances and restorations.

Explore Form 4B to learn more or talk to a dental specialist to see how Formlabs Dental can help you produce quality dental appliances and restorations.