The dental industry has been at the forefront of 3D printing innovation for the last decade and continues to find new ways of optimizing workflows in every dental application, from direct 3D printed dental splints and nightguards to dentures, models, and more. The following article summarizes a recent study that considers the angle at which splints are printed in relation to the build platform and the effect on fit and antagonist adaptation.

Study Background and Context

Occlusal splints are dental appliances used to address various dental conditions, including bruxism, temporomandibular disorders, and occlusal discrepancies. 3D printing has emerged as a fast, economical, and reliable method for fabricating occlusal splints with enhanced precision and customization.

Multiple design parameters influence the fit and function of a digitally designed occlusal splint application:

-

Splint offset to the dentition

-

Splint insertion axis

-

Anatomy of the patient's dentition

-

Extension of the splints outline over the widest area of the teeth (tooth equator)

-

Blockout threshold (distance from blocked-out areas to tooth equator)

-

Blockout angle (relative to the insertion axis)

-

Manually added retention areas

-

Antagonist adaptation (direct boolean subtraction of antagonist intersection)

-

Antagonist offset (additional positive or negative offset on antagonist adaptation)

With all these parameters in mind, digital design and 3D printing of occlusal splints yields a very predictable and reliable result.

However, optimizing the printing parameters and orientation is crucial to achieving optimal fit on dentition and antagonist adaption. This study aims to investigate the impact of printing orientation on the fit of occlusal splints, specifically evaluating dentition fit and occlusal antagonist contacts offset. Please check the application guide for more information.

Methodology

The study aimed to investigate the impact of printing orientation on the fit and adaptation of the splints. The parameter “antagonist adaption offset” in CAD software was set to 0.5 mm. Five occlusal splints were 3D printed at different angles (0°, 22.5°, 45°, 67.5°, and 90°) relative to the build platform.

Sample Size

A total of five occlusal splints were included in the study. Each splint was 3D printed at a different angle relative to the build platform, resulting in the following orientations: 0°, 22.5°, 45°, 67.5°, and 90°.

Printing Parameters

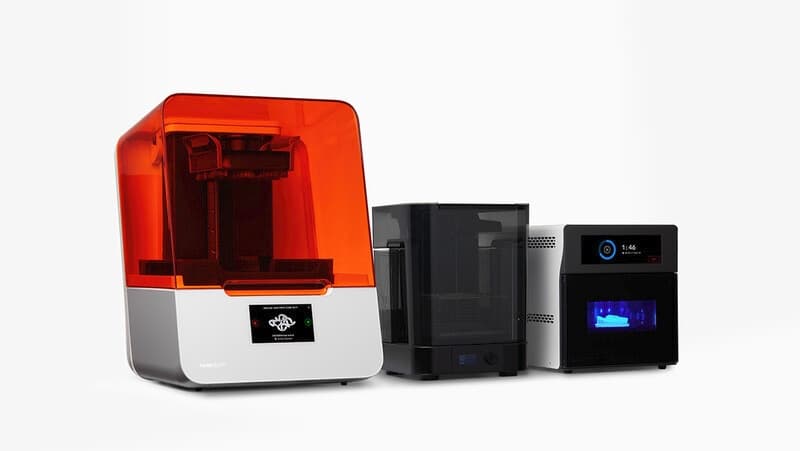

The printing process employed the Form 3B SLA printer and Formlabs Dental LT Clear V2 Resin. The printing parameters used for all splints were kept constant, including layer thickness, exposure time, and resin type.

Post-processing

The post-processing protocol followed the official recommendations, including the Form Wash and the Form Cure. All steps were executed to meet requirements for biocompatibility and to achieve optimal mechanical properties.

Antagonist Adaption Offset

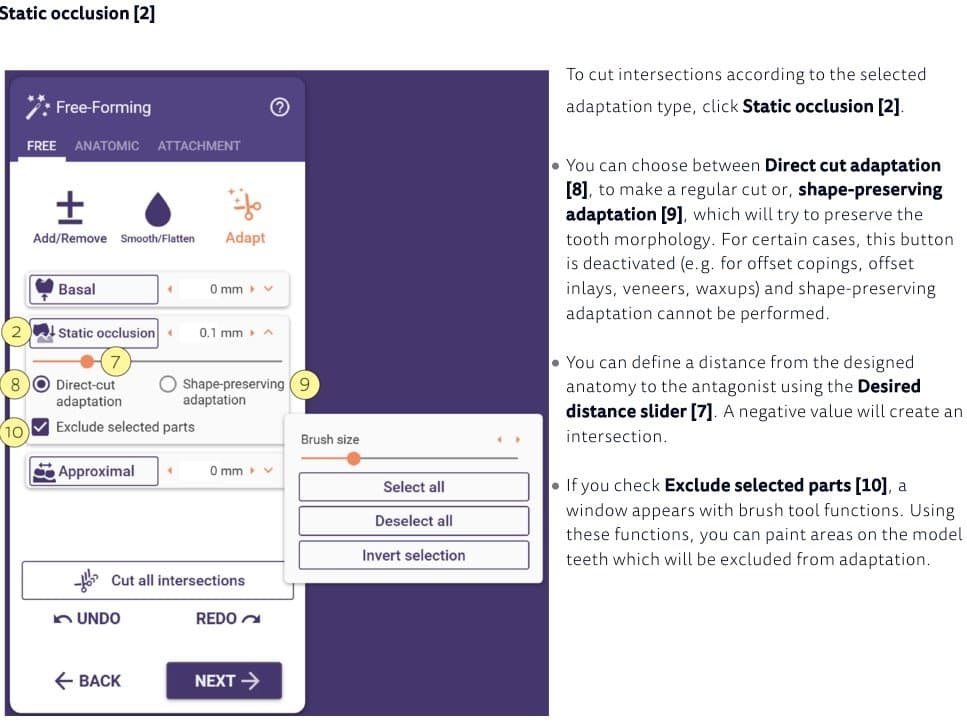

The parameter “antagonist adaption offset” in the CAD software was set to 0.5 mm for all splints. This parameter determines the offset distance between the occlusal antagonist contacts on the splint.

Screenshot from the exocad Wiki. The slider for occlusal offset is number 7. In the testing, this slider was set to 0.5 mm. A positive value means added distance and a negative value would result in an intersection. This offset can be applied to both dynamic and static occlusion adaptation. A similar parameter is available in 3Shape Splint Studio.

Evaluation Criteria

The fit on dentition and antagonist adaptation was evaluated as the primary criteria for assessing the splints’ performance. Dentition fit refers to how well the splint conforms to the patient’s teeth and dental arch, ensuring a comfortable and secure fit. Antagonist adaptation measures the contact between the splint and the occlusal antagonists, aiming for an optimal balance and distribution of forces during occlusion while preserving the exact vertical dimension provided by the construction bite.

Evaluation Process

For each printed splint, a detailed examination was conducted by a dental professional with expertise in occlusion and dental technology. The dentition fit and antagonist adaptation was manually assessed, measured, and photographed. To evaluate the fit on dentition, the raw printed splints with supports removed were directly assessed on printed dentition models. Before evaluation, the dentition models were articulated using a construction bite with a two-millimeter vertical dimension, that was also used during the design. This standardized procedure aimed to simulate the patient’s occlusion and ensure accurate splint fit assessment.

Results

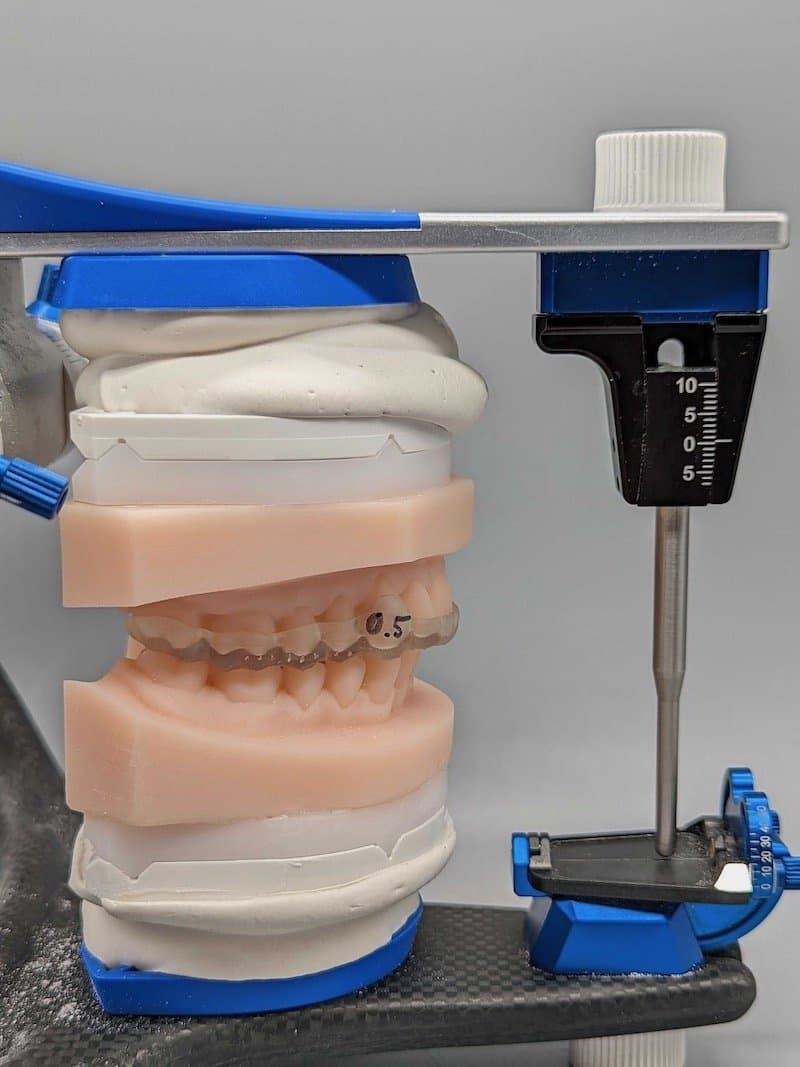

The result of the raw splint without manual correction was printed at 22.5° and designed with an occlusal antagonist impression offset of 0.5 mm. The articulator pin is very close to 0 mm. Designed with exocad.

Result of the raw splint without manual correction printed at 22.5°, designed with no occlusal offset. Notice the articulator pin position at ~2.8 mm. Designed with exocad.

The results showed that the splint printed at 0° had the best fit on dentition, while the 90° angle resulted in the worst fit. The splint printed at 22.5° exhibited the best antagonist adaptation and good dentition fit. These findings provide valuable insights for optimizing the printing orientation and parameter settings for 3D-printed occlusal splints.

The results of the study are presented as follows:

-

Fit on dentition: The splint printed at 0° demonstrated the best fit on dentition among all the tested orientations. It exhibited optimal conformity to the dental arch, ensuring secure and comfortable positioning. The splint printed at a 90° angle showed the least favorable fit on dentition, with a noticeable increase in retention.

-

Antagonist adaptation: The splint printed at a 22.5° angle exhibited the best antagonist adaptation. It displayed a balanced and harmonious contact pattern with the occlusal antagonists. The splint printed at this orientation preserved the vertical dimension as used during the design.

-

Optimal print orientation: Along with its favorable antagonist adaptation, the splint printed at a 22.5° angle also showcased a good dentition fit. It provided satisfactory retention of the patient’s dentition while ensuring the desired antagonist relation.

Discussion

The findings of this study highlight the significance of printing orientation in achieving optimal fit on dentition and antagonist adaptation in 3D printed occlusal splints with the Form 3B/3B+. The splint printed at a 0° angle demonstrated superior conformity to the dental arch, indicating the importance of aligning the printing direction parallel to the occlusal plane. Conversely, the splint printed at a 90° angle exhibited the least favorable fit. This is due to the energy of the laser bleeding into adjacent layers, which affects the accuracy of specific geometries like the inter-proximal septa when printing at a steeper angle.

The splint printed at a 22.5° angle emerged as the most successful in terms of both antagonist adaptation and dentition fit. This suggests that a slight inclination from the parallel orientation may facilitate better occlusal contacts and vertical dimension accuracy.

The parameter “antagonist adaption offset” set to 0.5 mm in CAD software played a significant role in achieving the desired occlusal contacts. Adjusting this parameter can offer a degree of customization to achieve the optimal balance between fit on dentition and vertical dimension accuracy.

Conclusion

This study investigated the influence of printing orientation on fit on dentition and occlusal antagonist contacts offset in 3D-printed occlusal splints. The splint printed at a 0° angle demonstrated the best fit on dentition, while the 90° angle resulted in the least favorable fit. The splint printed at a 22.5° angle showcased the best antagonist adaptation and acceptable dentition fit. These findings emphasize the importance of considering printing orientation and antagonist adaption offset parameters in CAD when fabricating occlusal splints.

Optimizing the printing parameters and orientation can significantly enhance the performance and clinical outcomes of 3D-printed occlusal splints. Further research and technological advancements in additive manufacturing are essential to refine the fabrication process and enable customized solutions for patients with varying dental needs.

To learn more about designing and 3D printing splints and occlusal guides, download the application guide.