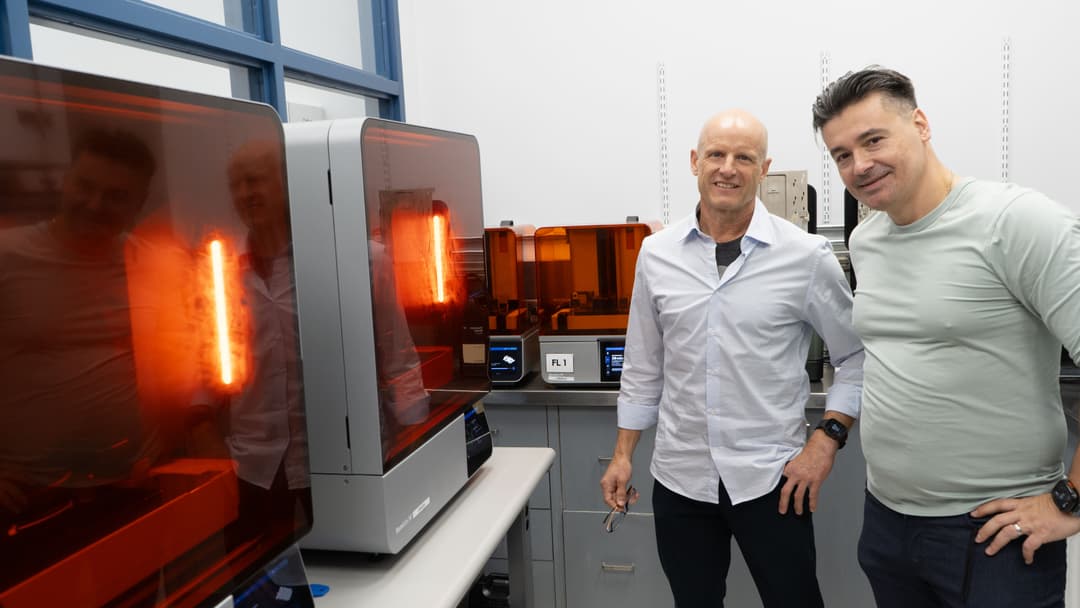

“Smileep is a digital-native laboratory. From the beginning, we have never followed the traditional model; instead, we have embraced high-performance 3D printing technologies and CAD/CAM tools. This has allowed us to maintain maximum precision in our products and optimal operational efficiency, supported by the industrial engineering expertise of our founding team.”

Alan Alves, Director, Smileep

Smileep is a full-service dental laboratory specializing in digital workflows for dental prosthetics and clear aligners. The Barcelona-based lab has a unique background: before 3D printing dental appliances and models, the company founders carried out numerous 3D printing projects across a variety of industries, including 3D printing adapters for Decathlon Snorkel Masks that converted them to emergency PPE during COVID-19 shortages.

Coming from an industrial engineering and 3D printing background, Smileep is dedicated to digital workflows. Over 98% of their orders are received through intraoral scanners, and they handle over 400 cases per month for more than 250 dental clinics in Spain and Portugal. By focusing on digital technology, Smileep can fulfill the demands of all of Iberia, which would not be possible with traditional workflows.

“From the beginning, as a dental laboratory, we have offered our clients the option to digitize their impressions and plaster models if they did not have an intraoral scanner, allowing us to provide them with our digital services. However, due to our digital focus, we have attracted clients with intraoral scanners from the start.”

Alan Alves, Director, Smileep

Smileep began with two Formlabs Form 2 3D printers in 2021, scaled up with Form 3B, and has since adopted Form 4B. They now have eight printers and a team of five dental technicians and two commercial support workers. With the surface finish, cost per part, validated workflows, and scalability of Form 4B, they expect to double their size in 2025.

Product Demo: Form 4B Dental 3D Printer

Blazing speed meets unmatched accuracy in the next generation of dental 3D printing. Explore the latest innovations in our webinar.

60-80% Higher Productivity For Technicians

“We estimate that the productivity of a technician in a dental laboratory using 3D printing is 60-80% higher than in a traditional laboratory, and even more for specific products.”

Alan Alves, Director, Smileep

Smileep found that adopting Form 3B led to significant improvement in precision and productivity over traditional workflows. Form 4B propelled this, enabling Smileep to deliver superior quality with fewer printers. Adding Form 4B to their robust processes and skilled technicians, Smileep has increased their potential print production capacity, giving them the capacity to significantly grow their production.

Lab Production With the Formlabs Dental Ecosystem

| Appliance or model | Quantity per month with 3D printing | Monthly printing capacity with Form 4B |

|---|---|---|

| Occlusal splints | >200 | >1,700 |

| Temporary crowns and bridges | >60 | >2,100 |

| Permanent inlay restorations | >10 | >2,800 |

| Prosthesis models | >200 | >960 |

| Orthodontic models for clear aligners | >300 | >12,900 |

| Surgical guides | >5 | > 2,640 |

Form 4B and Premium Teeth Resin can be used to 3D print life-like temporary full-arch implant-supported restorations (All-on-X).

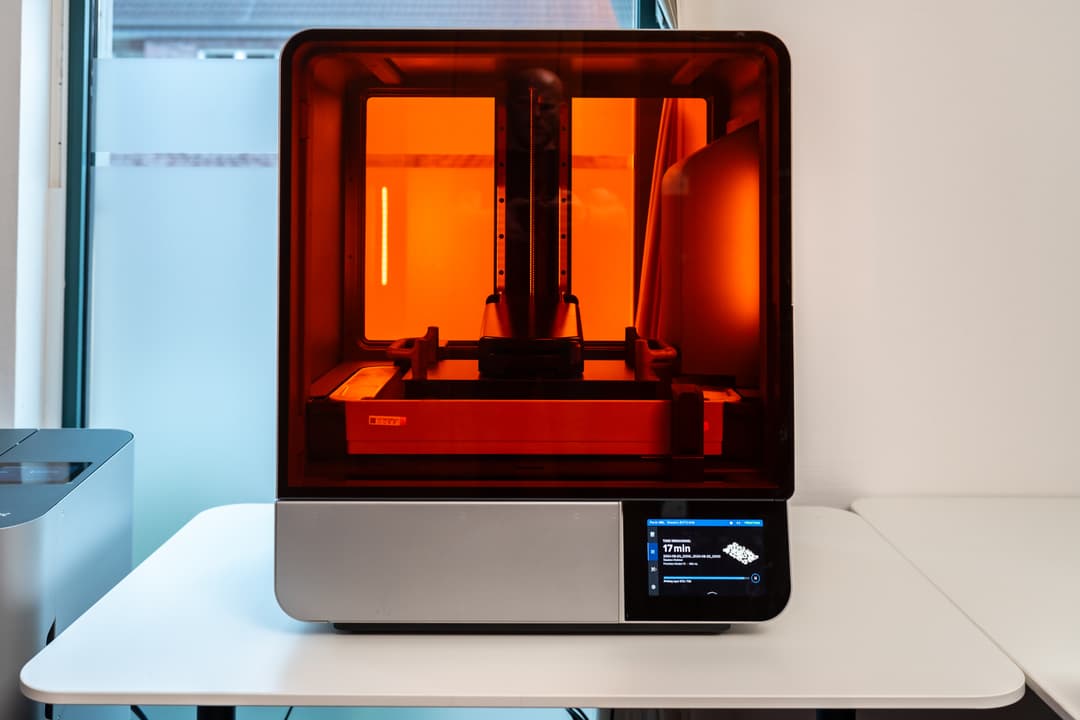

Speeding Into the Digital Future With Form 4B

“The increase in quality and precision was evident from the very first model, especially those intended for prosthetics. Now, with the new technology, we achieve flawless prints that ensure a perfect fit for implant components without the need for additional touch-ups.”

Alan Alves, Director, Smileep

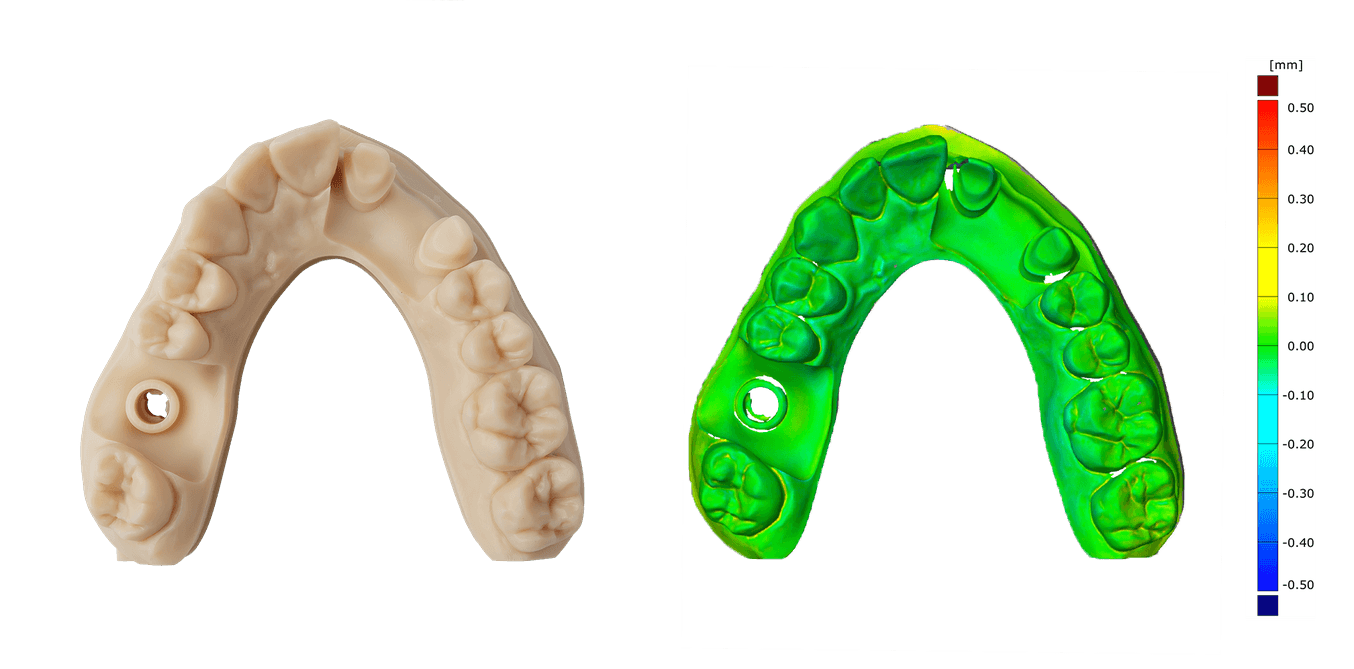

Models, appliances, and restorations printed with Form 4B have a fine surface finish and fine details with precision and accuracy that ensure appliances and restorations fit perfectly. Alves has found that, “With the new technology, we achieve flawless prints that ensure a perfect fit for implant components without the need for additional touch-ups. Speed also plays a key role, as we need to meet fast delivery times for our clients,” says Alves, who also calls out the low cost per part, scalability, and ease of use of Form 4B.

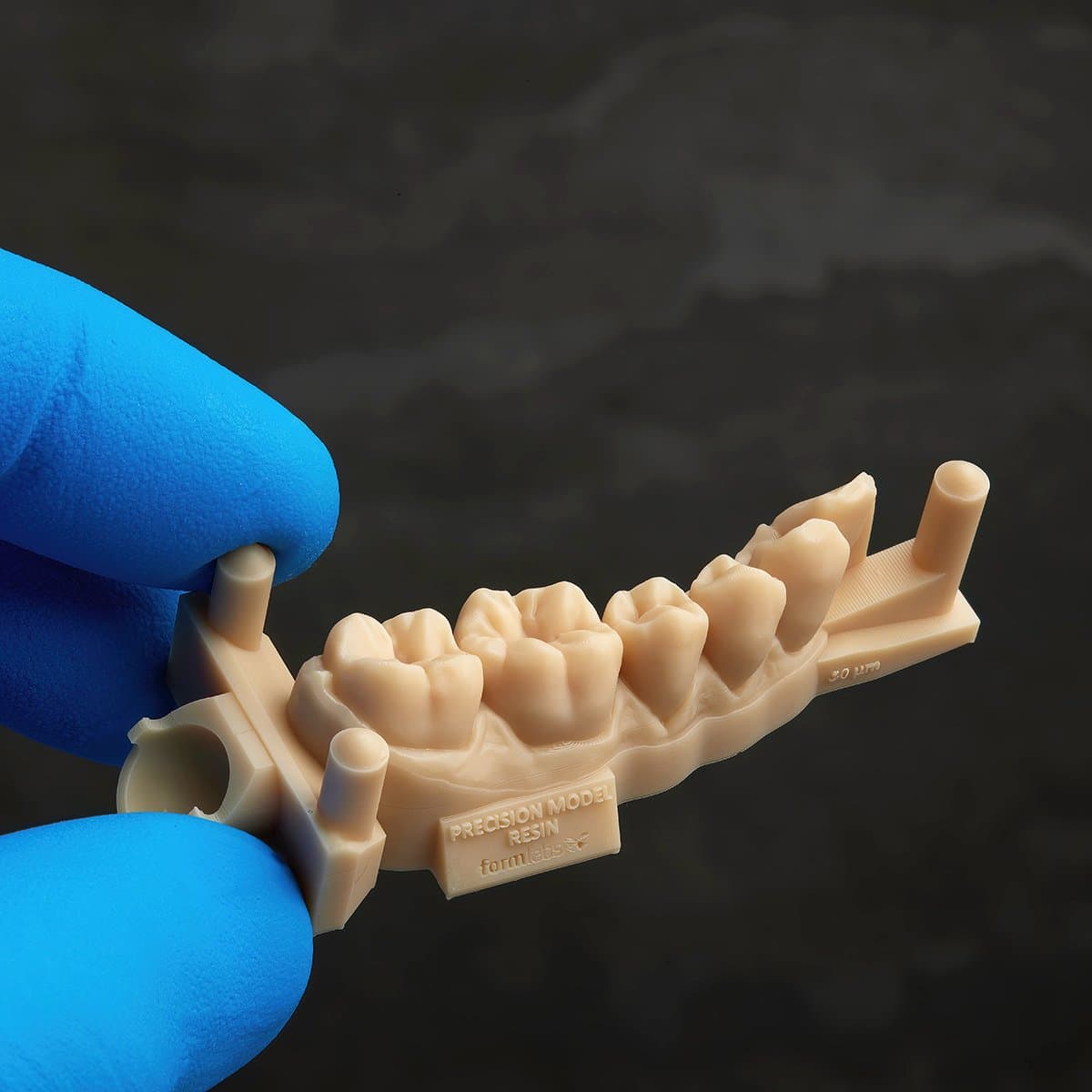

Restorative models printed with Precision Model Resin on Form 4B have 95% of the surface within 50 μm of the CAD model and 99% of the surface within 100 μm of the CAD model.

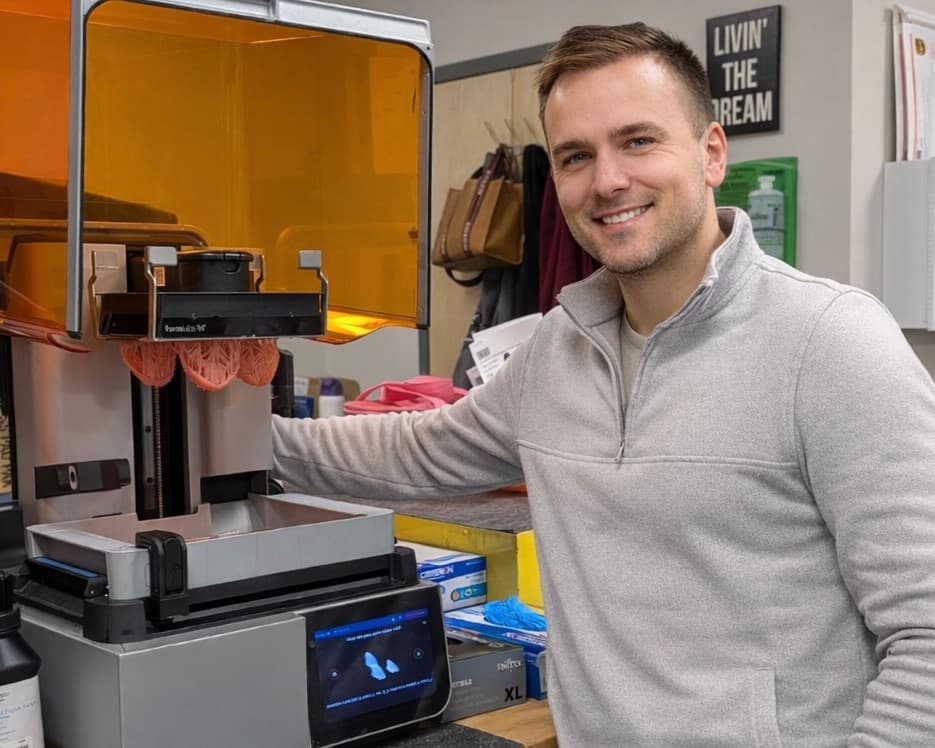

Ease of use has empowered the lab to scale up faster. Technicians with no prior 3D printing experience can easily learn Form 4B workflows, including those for new applications.

“The validated Formlabs ecosystem makes 3D printing scalability easier in our lab. All our technicians, even those with no prior experience with similar technologies, have successfully adopted its use, efficiently integrating digital technology.”

Alan Alves, Director, Smileep

The technology behind Form 4B enables access to specialized resins including Precision Model Resin, Fast Model Resin, and BEGO™ VarseoSmile® TriniQ® Resin.

Precision Model Resin was developed to leverage the hardware of Form 4B to print highly accurate restorative models with crisp margin lines and fine details.

“We've switched from Model V3 Resin to Precision Model Resin due to the superior quality that the Form 4B provides for this application, and we highly recommend it.”

Alan Alves, Director, Smileep

Monolithic zirconia bridge case 3-3, on models printed with Precision Model Resin. Precision Model Resin has high opacity, beige color, and a matte finish to capture fine details.

For permanent crowns and inlay and onlay restorations, Smileep has started using BEGO™ VarseoSmile® TriniQ® Resin, with good results. This resin is a Formlabs Certified Material, meaning it has been rigorously tested and validated by both Formlabs and BEGO™ to ensure the performance and reliability of every printed part.

The material versatility of Form 4B plus the ease of resin changeovers make it easy and efficient to print multiple applications on one printer. Having a fleet of printers with a single printer dedicated to each material or application can further improve efficiency.

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part printed on the Form 4B to your office.

Occlusal Splint Production

Smileep has developed a unique brand for occlusal splints: La Férula de Descarga 3D - Splint Brux®. This solution for sleep bruxism is 3D printed with Dental LT Clear Resin V2, a long-term biocompatible material that’s highly durable and resistant to fracture.

Before CAD design and 3D printing workflows, turnaround for occlusal splint production took five days. Now, Smileep can deliver a finished splint within 48 hours.

Time to Manufacture Occlusal Splints

| Traditional Workflow | 3D Printing | |

|---|---|---|

| Design and production quantity for one technician in one day | 7-8 occlusal splints | 20+ occlusal splints |

| Delivery time to the dentist | 5 days | 2 days |

Smileep’s La Férula de Descarga 3D - Splint Brux® is delivered in premium packaging including a 3D printed model, a brochure with patient usage instructions, and a case to store the splint.

Precision Model Resin and Form 4B: Guide to Making the Most Accurate Restorative Dental Models

The Formlabs Form 4B Masked Stereolithography (MLSA) 3D printer is a game-changer for printing restorative dental models. It features fast printing speeds, reliability, and consistently precise outputs. This article is a guide on how to easily make functional and accurate restorative dental models on Form 4B with Precision Model Resin.

Ensuring Sustainable Growth With Digital Dentistry

“I consider it essential to adopt CAD design and 3D printing technology to maintain a profitable and competitive dental laboratory.”

Alan Alves, Director, Smileep

Smileep has ambitious plans for the coming years, intending to double their size annually. This will include not just scaling up production with the addition of more printers, but adding new 3D printing applications. Alves says, “It’s clear that small and medium-sized laboratories will need to focus on differentiation and technological innovation to stand out and ensure their sustainability.” In the next 10 years, he expects to see 99% of clinics using intraoral scanners, and new materials that can compete with zirconia.

Prepare your lab for the future of digital dentistry: explore Form 4B to start printing, or talk to a dental expert to learn more about Formlabs Dental solutions.