Introducing Form 4B: Redefining Dental 3D Printing With Blazing Speed and Unmatched Accuracy

Formlabs is proud to announce Form 4B, our next generation resin 3D printer that redefines the industry standard for speed, accuracy, reliability, and material versatility.

Form 4B represents the next evolution in stereolithography (SLA) 3D printing technology, built upon years of groundbreaking hardware, software, and materials science innovations. With unprecedented speed, Form 4B can deliver a model a minute, without ever compromising on dimensional accuracy or surface finish.

Form 4B combines a new print engine with updates to the Formlabs Dental materials library of 15+ unique resins for dental applications, as well as new accessories and post-processing solutions, and an improved user experience. These updates reaffirm Formlabs’ dedication to the motto “Dentistry Made Easier.”

Product Demo: Form 4B+ Dental 3D Printer

Blazing speed meets unmatched accuracy in the next generation of dental 3D printing. Explore the latest innovations in our webinar.

The Next Step in Dental 3D Printing

Since 2019, with the introduction of our first biocompatible resin printer, Formlabs has been dedicated to producing powerful 3D printing tools for dental and healthcare professionals. By making advanced 3D printing technology accessible, early versions of our printers powered the development of digital workflows for new indications while reducing cost and time limitations. With the release of the Form 4B, we continue to raise the bar for dental 3D printers.

A 3D printer needs to be a tool that can print at the speed of a dental cleaning, so a patient never needs to leave the chair, and maximize the production of dental appliances that fit perfectly every time. By working with dental professionals – dentists, orthodontists, and labs — at the cutting edge of 3D printing, we identified pain points in the 3D printing process, and have worked to continuously improve our products to address them and take workflows to the next level.

Form 4B offers unprecedented speed, unrivaled accuracy and reliability, a streamlined workflow, and 15+ unique resins for dental applications.

Form 4B creates opportunities for dentists, orthodontists, and labs, accelerating print speed, increasing build volume, expanding the material availability, and enabling accuracy anywhere on the build platform — all with effortless workflows that save time.

Print speeds of up to 100 mm per hour, optimized dental materials, and consistent surface accuracy mean you can now have blazing speed, unmatched accuracy, and increased production volume — with the new Form 4B.

Unprecedented Print Speeds

Speed is the primary pain point of dental professionals working on tight timelines. Form 4B is faster than ever, with the ability to print a model every minute — without compromising on accuracy. Print jobs are completed up to four times faster than with any other Form Series printer, regardless of whether you’re printing one part or a full build platform.

The speed of the Form 4B makes it easier than ever to create retainers in under 30 minutes.

Up to eight occlusal splints and nightguards can be printed in 35 minutes, so patients can leave the office with their new appliance.

The blazing speed of Form 4B allows dentists and orthodontists to accomplish more, freeing up their time for higher-value tasks. It’s now possible to unlock chairside procedures with restorative workflows in under one hour from start to finish – from single units to bridges. Single models for retainers are now available in 15-20 minutes for efficient turnaround and maximum productivity.

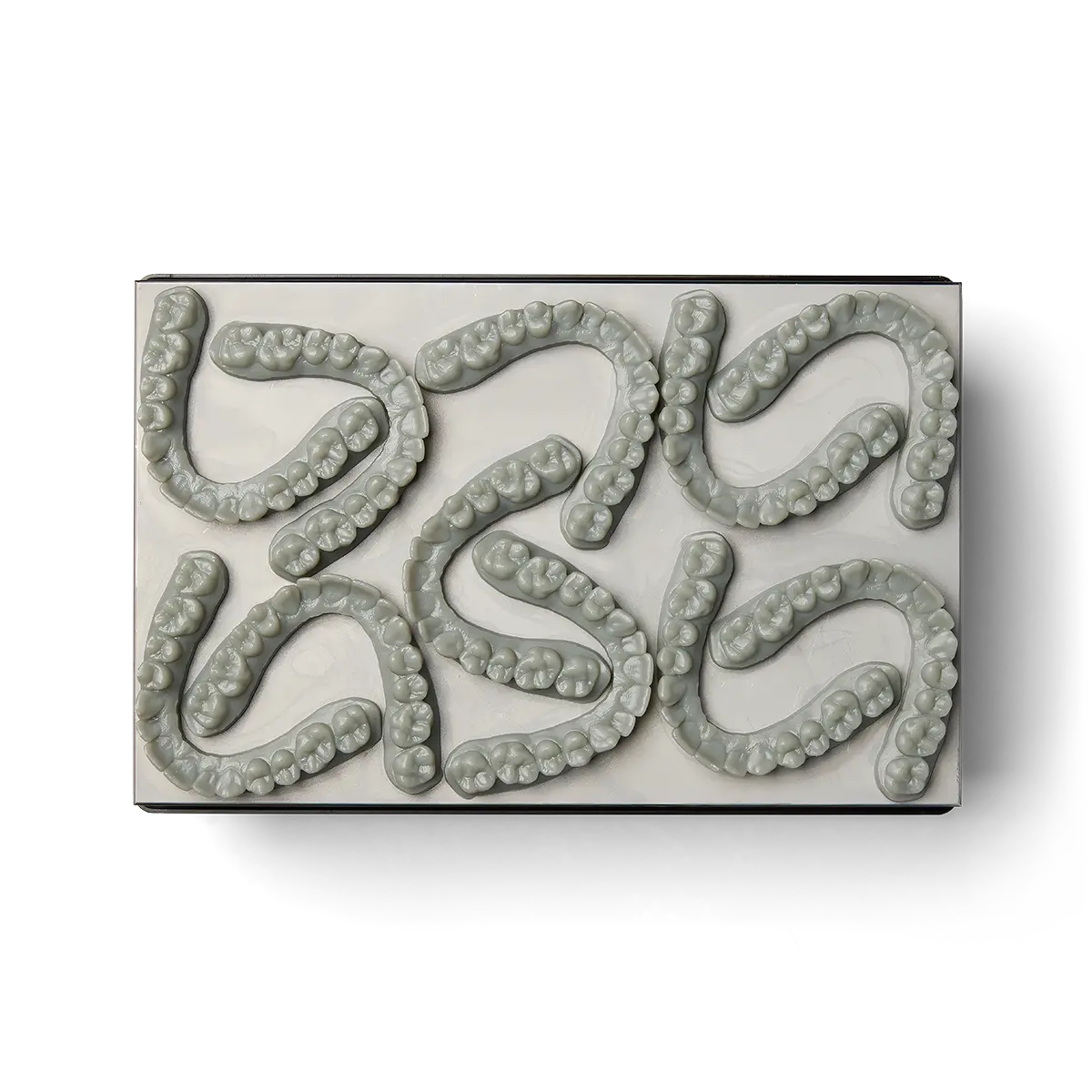

Dental and orthodontic labs can reach new levels of throughput. A 20% larger Build Platform fits up to 11 models for maximized productivity versus eight models in our standard Build Platform. Plus, print speeds enable the printing of 400 models every eight hours.

Print Speeds on the Form 4B

| Appliance | Quantity | Print Time |

|---|---|---|

| Surgical guides | 12 | 48 min |

| Dental models | 11 | 9 min |

| Splints | 8 | 49 min |

| All-on-X | 9 | 55 min |

| Crowns and Bridges | 5 | 25 min |

Note: Time is consistent for the quantity range as print time is the same across the build platform. Quantity is the number of prints that can be printed on one build platform.

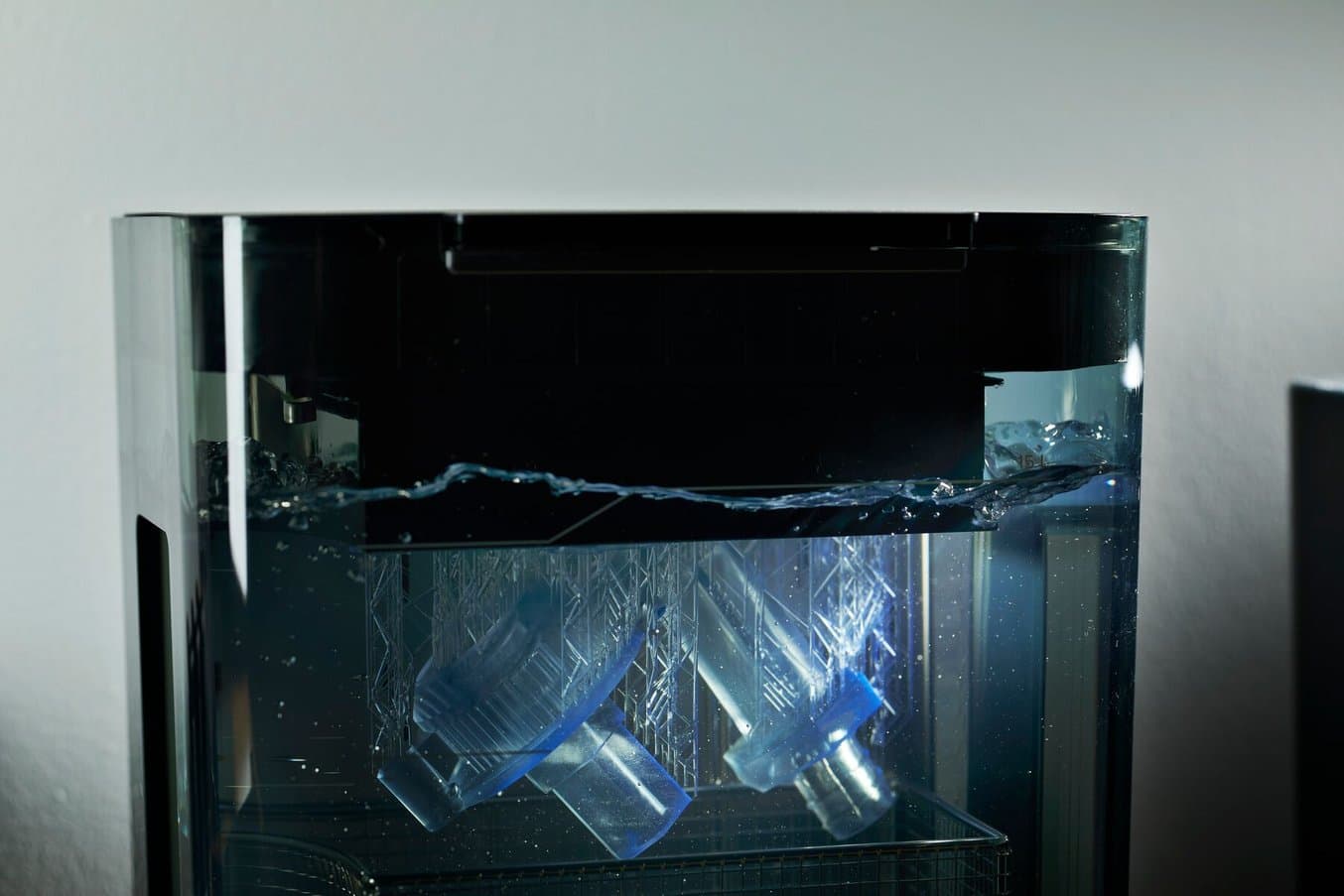

Form 4B’s speed is driven by Formlabs’ new Low Force Display™ (LFD) Print Engine, a powerful combination of ultra-high power LEDs, collimating lenses, optical filters, and a robust liquid crystal display, that cures each layer of resin instantly — regardless of part size or quantity. Print speeds are no longer affected by how much of the build platform is covered, so whether you’re printing one part or a full build platform, your print time is roughly the same.

Unrivaled Accuracy

3D printed dental appliances need to be precise to ensure a perfect fit every time. Whether they’re restorative models with removable dies and implant analogs or final restorations that need to look life-like and adapt perfectly, surface accuracy is key. Speed should never come at the cost of accuracy and precision.

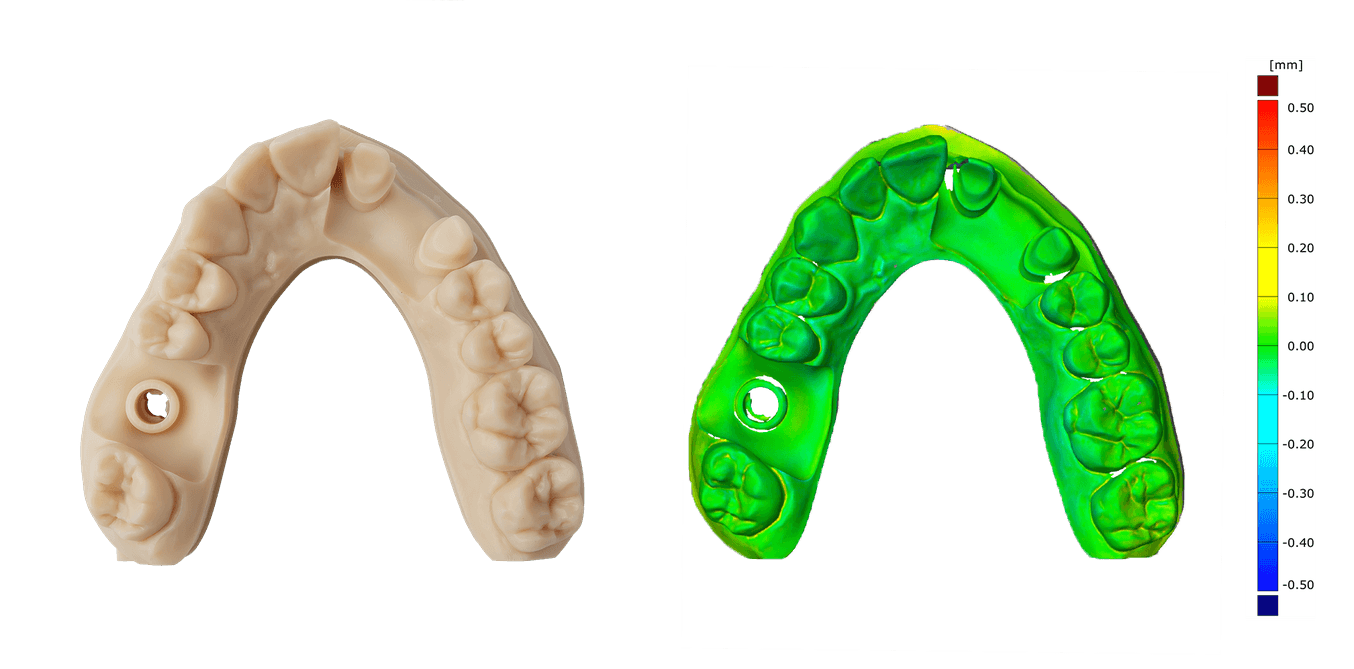

Form 4B prints dental parts with an industry-leading surface accuracy that is consistent across the build platform for a perfect fit, every time. Achieve smooth surfaces and fine features for premium dental appliances you’ll be proud to deliver thanks to Form 4B’s Light Processing Unit (LPU), a high-resolution display module that delivers a 50 µm XY resolution. And, experience identical prints anywhere on the build platform with unmatched optical uniformity for a perfect fit no matter where the print is placed.

Print dental parts with industry-leading accuracy across the build platform.

With repeatable tolerances that match initial designs, dental appliances can quickly and easily be reprinted if backup occlusal splints or replacement dentures are needed — all with the accurate fit of the original. Fine surface quality means that, depending on the application, you can use post-processed dental parts as they are, or enhance them with traditional techniques such as polishing, staining, or glazing. Reduce case remakes and ensure a high quality product you’re proud to deliver with the accuracy of Form 4B.

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part printed on the Form 4B to your office.

15 Minutes to Your First Print

Before earlier iterations of the Form Series introduced accessible, high-quality 3D printing, SLA workflows were often complicated. Some required dedicated operators, complex infrastructure, and large spaces for oversized machinery.

With the Form Series, Formlabs proved that accessible 3D printing meant more than just affordable prices — it also meant that the workflow could be easy to learn and that the printer could fit into your existing space, including at dental and orthodontic practices. Form 4B takes that one step further, simplifying the printer set-up, monitoring, and material change-over, so that anyone can go from new user to high-quality print in 15 minutes.

In addition to the speed improvements made possible by the print engine and material settings, new automatic resin handling features reduce the time it takes for prints to start. Automatic resin dispensing uses a series of smart sensors to maximize uptime, so that the printer works as hard as you do.

Form Series printers are being used for a wide range of dental indications including clear aligner models, surgical guides, permanent restorations, full dentures, temporary All-on-X appliances, and more. When 3D printing is being used to create dental indications that are impactful, the actual printing should be the easiest step, and Form 4B makes that possible. From receiving your printer to starting your first print, spend only 15 minutes on set-up and watch prints take shape in minutes.

Ease of Use, Step By Step

The full Formlabs Dental ecosystem is designed to maximize efficiency and reduce the potential for print errors. Formlabs free print preparation software, PreForm Dental, automatically analyzes the part and determines the optimal orientation and support placement. Formlabs' software engineering team continuously improves software settings to ensure that print speed, materials settings, and automatic orientation and support are perfected.

Print parts directly on the Build Platform Flex without supports. The Quick Release Technology of the Build Platform Flex enables the removal of parts in seconds.

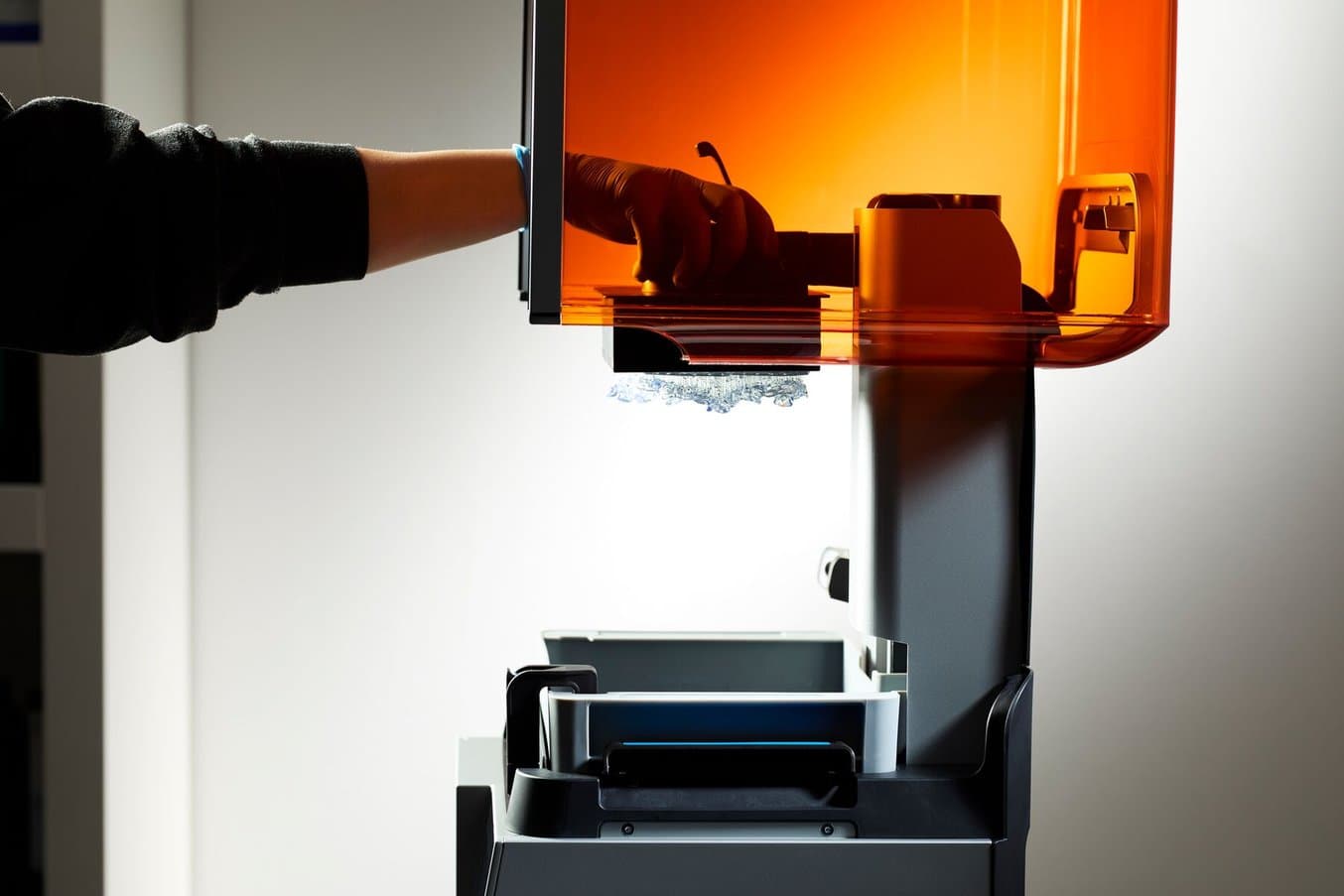

From the moment the printer finishes your part, the workflow is designed for ease, repeatability, and efficiency. The Quick Release Technology of the Build Platform Flex enables quick removal of the part and reduces instances of breakage. Parts are then automatically washed in the new Form Wash, with improved isopropyl alcohol agitation for a faster, cleaner process. The new Form Wash can adapt to fit build platforms from any Formlabs desktop printer. After washing, if parts need a post-cure step, the pre-set Form Cure and Fast Cure settings ensure that parts can reach their optimal mechanical properties.

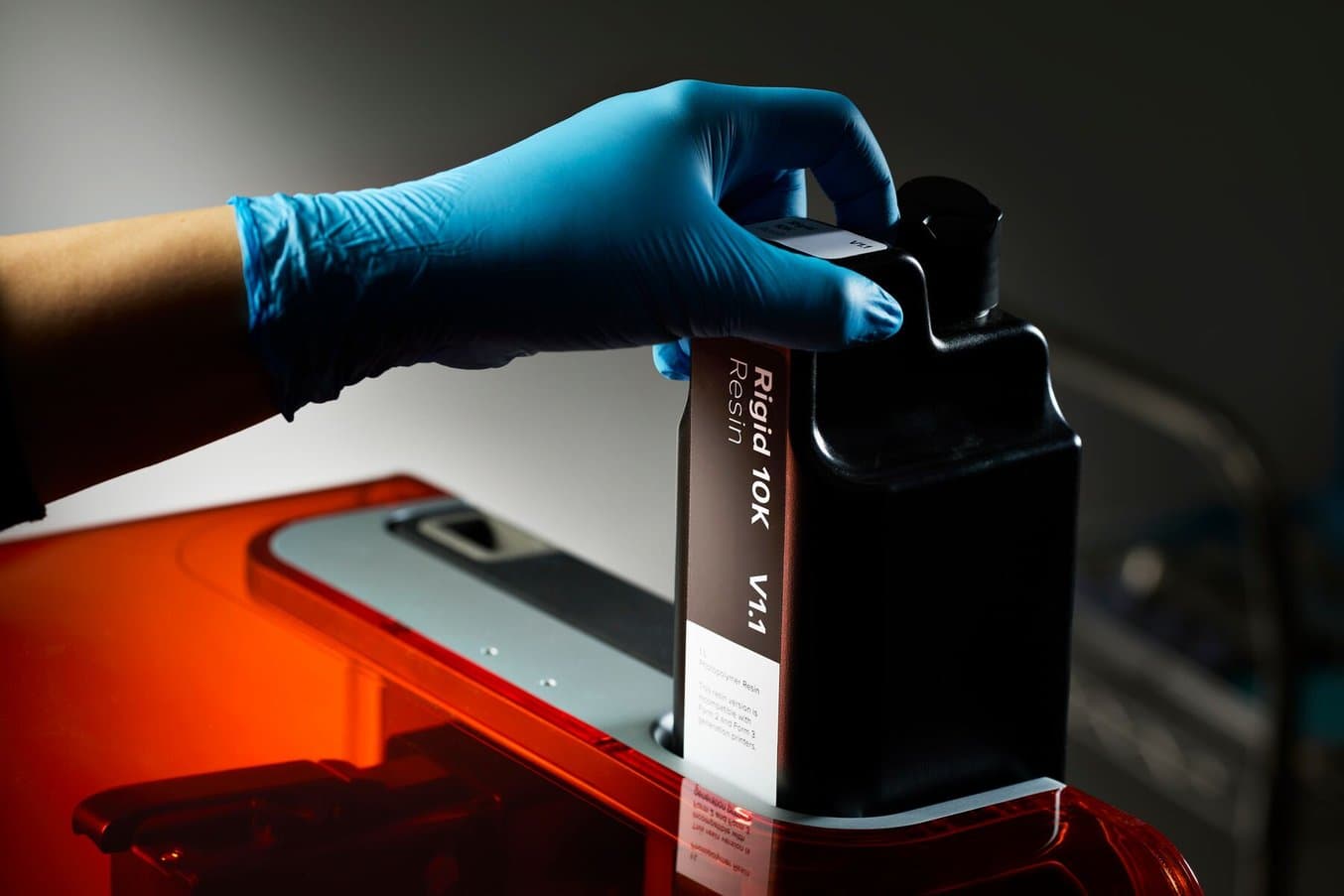

Storage and consumables management is easier than ever with easy-stacking resin tanks and tank covers. Even with 15+ dental materials to choose from, managing resin cartridges and resin tanks is easy with the new resin cartridges — they use 60% less plastic, but still fit a full liter of material.

The second generation Form Wash is adaptable for multiple build platform sizes and improves the liquid agitation process, so parts get cleaner, quicker.

The new resin cartridge design uses less plastic and still delivers one full liter of material, making storage and maintenance that much easier.

High-Volume Reliability Made to Last

For the Form Series, accessibility also means reliability. Even for users printing all day, every day, the printer won’t let you down. The Form Series set a high standard for print success and repeatable, reliable, high-volume use, but Form 4B surpasses it.

Two different Build Platforms are available to optimize printing and easy removal of printed parts. A spare Build Platform can speed up your workflow and allow for nonstop printing.

Form 4B’s reliability is in part due to the time spent in the manufacturing process on quality control — each printer will undergo 60 checkpoints for functionality before it leaves the factory, ensuring that every unit will be the most consistent, high-performing part of your workflow. Furthermore, Formlabs’ print optimization team has spent years printing thousands of parts to dial in the settings for each material, so that even complex geometries in different materials will print with industry-leading reliability.

Both the central printer engine and components like the Resin Tank and Build Platform have been re-engineered to function more smoothly and last longer, even in high-volume applications. Resin Tanks can be relied upon for over 75,000 layers (or about a year of daily printing), extending the uptime of the printer and reducing operational costs and the number of touchpoints necessary to continue high-volume production.

Form 4B’s automatic diagnostics and integrated sensors alert you to potential issues with each print, giving customers a chance to avert the consequences of a poorly set-up job and to understand how to optimize their printer usage. The integrated sensor system ensures that Form 4B will remain up and running, even in high-volume applications, for years to come. Reliability shouldn’t dip as the printer gets more use — the Form 4B is a tool that improves as your own process evolves.

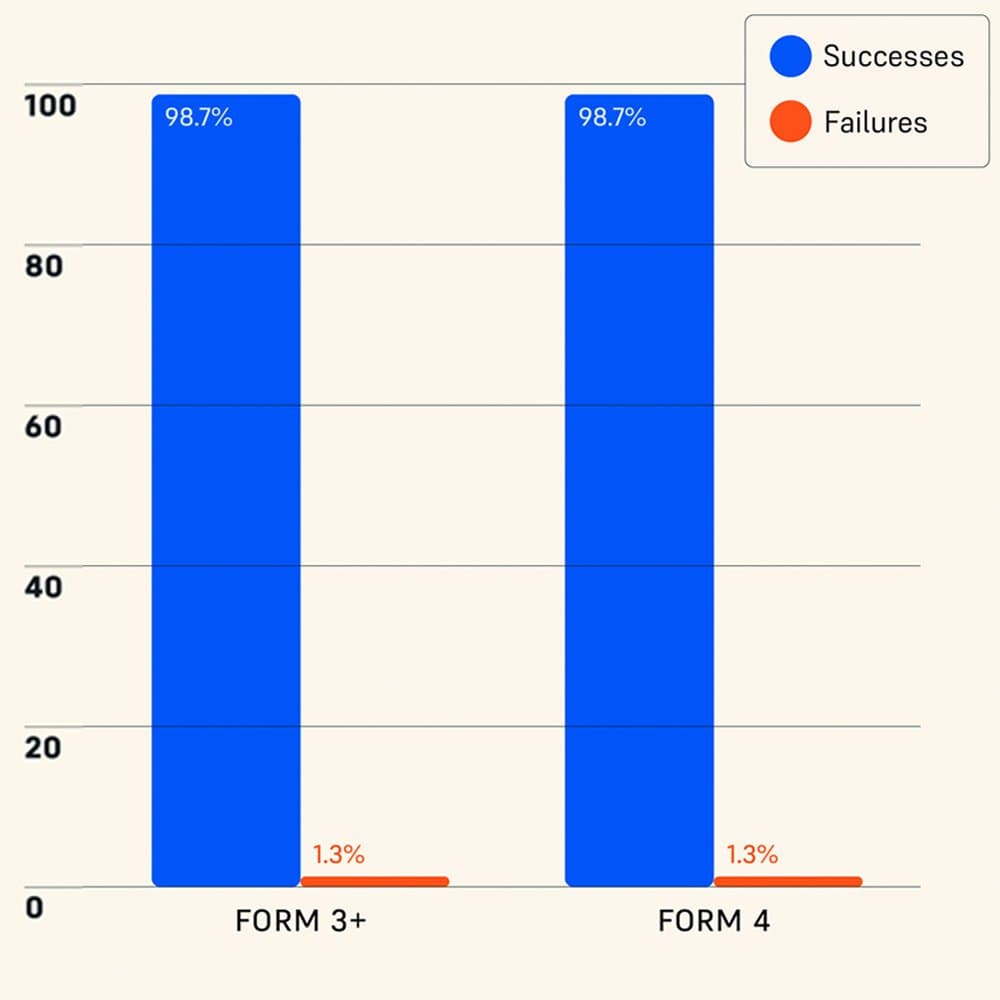

Independently Tested Reliability of Form 4 and Other Resin 3D Printers

Formlabs Form 4 was measured to have a 98.7% print success rate by an independent global leader in product testing. Read a complete description of the test methodology and see the results in our white paper.

Unlock New Applications Through the Expansive Materials Catalog

Formlabs offers 15+ materials for dental applications. Our BioMed and Medical Device Resins are manufactured at our FDA-registered facility in Ohio. These materials are designed and manufactured within our robust Quality Management System that is ISO 13485 and EU MDR certified.

Formlabs printers combine high-precision hardware engineering and groundbreaking software to create a workflow that delivers accurate dental appliances, every time. Formlabs 15+ materials for dental applications, including biocompatible resins for denture teeth and temporary All-on-X appliances, surgical guides, and flexible or rigid occlusal splints, is what unlocks the potential for a full array of indications. With the introduction of Form 4B, three new materials are now available, and at a discounted price.

Fast Model Resin is formulated for speed, making it optimal for the production of orthodontic models for thermoforming aligners and retainers.

Grey Resin V5 is a highly versatile resin for the production of general dental models.

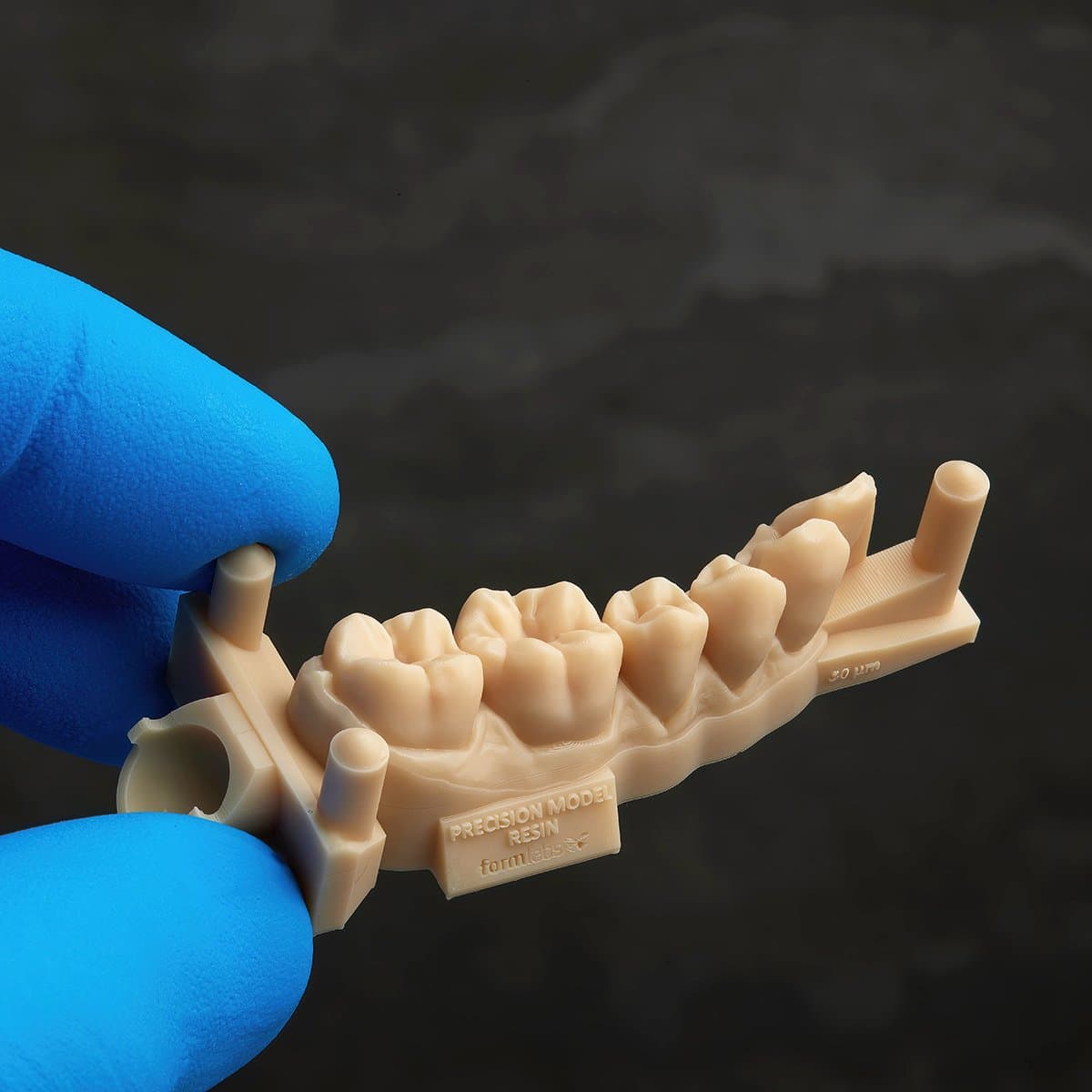

Precision Model Resin is highly accurate and recommended for the production of restorative and implant models.

Form 4B’s upgraded automatic resin dispensing is up to four times faster than the Form 3B+ dispensing mechanism. Plus, new heating capabilities make it possible for Formlabs to develop materials that were previously out of reach, like those with very high viscosity or that are highly filled.

For customers looking to experiment with resins not currently available in the Formlabs library, Open Platform will be available for Form 4B — so users can opt for even more versatility with certified third-party materials, customizable print settings, and complete freedom to print with an optional Open Material License.

Dental professionals require materials where optimal clinical performance, comfort, and fit are key. For years, material limitations meant that dentists, orthodontists, and labs had to rely on traditional methods of production and couldn’t take advantage of the on-demand power, affordable cost, and design freedom of 3D printing. Materials make the difference. Form 4B has been developed alongside our library of purpose-built resins, so that pre-programmed settings deliver appliances with performance and fit, every time.

Formlabs Dental Materials Overview: Discover What You Can Print With the Form 4B

This webinar will guide you through the various benefits and applications enabled by Form 4B, including its existing biocompatible materials and newly developed formulations for model production such as Fast Model Resin and Precision Model Resin.

Impressions From Our Beta Testers

Stephan Kreimer: Putting Quality to the Test

Stephan Kreimer, master dental technician and director of Kreimer Dentallabor GmbH & Co. KG, has focused on advancing digital dentistry and 3D printing since 2015. As someone who tripled production at his lab, efficiency, production optimization, and precision are top of mind. “I work in the lab all day, using the printers constantly. If there are significant improvements, it is a game changer for our workflow,” says Kreimer.

Kreimer has been printing on Form Series printers since the Form 2. Trying the new Form 4B, he says, “I think Formlabs is like Apple; you just pull the printer out of the box, put it on the table, and within five to 10 minutes it's up and running.”

As someone running a lab, the ease of use by all employees is important. Kreimer says of the Form 4B, “The entire ecosystem, including PreForm and Fleet Control, along with the hardware improvements, is amazing. I was so happy when I first plugged it in. The build quality and the significantly improved print speed make the printer a great choice for professionals."

In addition to performance, quality is top of mind, and Kreimer ran extensive tests on the Form 4B. “I printed many dental models, particularly those that the previous version struggled with. These models were scanned, and then the STL file of the scanned model was compared to the original STL. The surface comparison yielded some of the best results I have ever measured on a 3D printer. Moreover, the fit of inner geometries, like implant analogs and removable dies, has significantly improved.“

“Formlabs has listened to user feedback and delivered. The combination of improvements, such as increased printing speed and more consistent print quality with great surface accuracy, makes this printer an excellent choice for dentistry.”

Stephan Kreimer, Master Dental Technician, Kreimer Dentallabor GmbH & Co. KG

For a good dental printer, speed or accuracy alone is not enough. To meet production needs while providing quality patient care, speed, accuracy, and workflow efficiency are all required – and the Form 4B delivers.

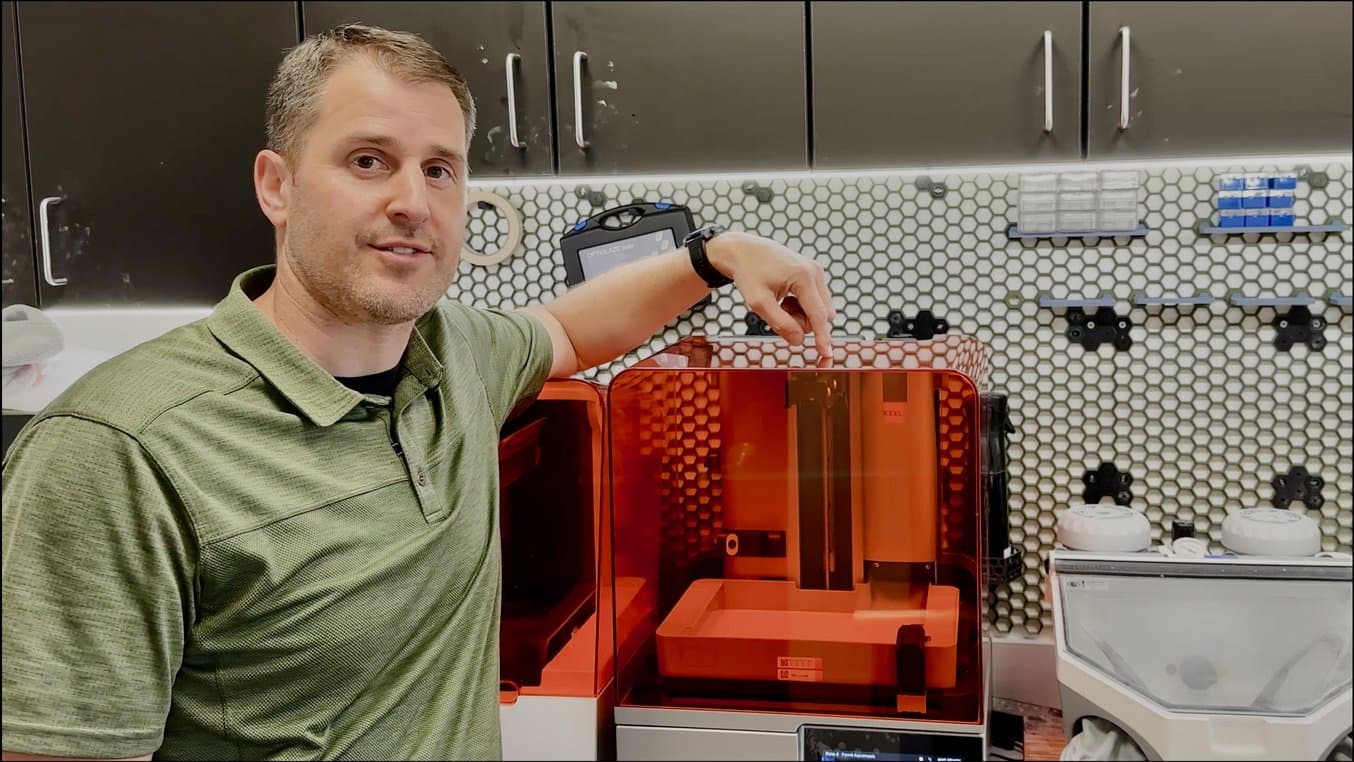

Dr. Christopher Baer: Speedy Appliances, Patient-Preferred

At Baer Dental, a general dental practice in Colorado, Dr. Christopher Baer, DMD utilizes 3D printing for making models for retainers, temporary and permanent restorations, night guards, wax-ups, and crowns. As an early adopter of 3D printing, he uses printers from a number of manufacturers, but he was impressed with the Form 4B from the start. “Just the go speed from pushing start to getting everything to print. With Form 4B, boom, it's ready to go.”

Once he started printing, he found that “It was basically superfast mode. Just the speed for being able to print so many models at once was really nice with the quality. We're going to be able to print eight models now basically in the same time to print one.”

Dr. Christopher Baer runs a general practice where print speed and accuracy are key.

“Form 4B is definitely more accurate, especially from the retainer fit standpoint. Patients have preferred the fit of retainers from Form 4B just because there's a little bit more anatomic contour.”

Dr. Christopher Baer, DMD, Baer Dental

Dr. Baer even found that, when presenting models, patients found the surface quality and accuracy of models printed on the Form 4B more attractive. As Dr. Baer says, “It's kind of like the old school television versus the HD television.”

As a dentist running a general practice, speed is of the essence, and the Form 4B delivers. “We could essentially print a splint the same day for a patient by the time they're finishing with their cleaning visit, which is ideal.”

These speed savings go beyond printing to post-processing. Of other printers, Dr. Baer says, “you spend a lot of extra time polishing.” However, with dental appliances “from Form 4B, with that outer surface being pristine, you could suck down injection, just do light polish, and then everything's good.”

As a dental professional on the cutting edge of digital dentistry, Dr. Baer says of the new Open Platform of the Form 4B, “That's one of the things I think is attractive, being able to try new materials.” With the 15+ Formlabs Dental Resins plus the option to upgrade to an open platform, the Form 4B offers versatility to those at the forefront of dentistry today.

Christina Rivet: High Speed, High Precision

Hybridge Implants is a nationwide network providing full-mouth implant-supported prosthetic appliances. These parts are produced by technicians over a 3D printed implant model, a process that requires the highest precision and accuracy as metal components (implant analogs) need to be screwed into the printed model. Not only do the Hybridge technicians need parts printed quickly, but implant models need to be both extremely precise and strong to withstand the metalwork.

Christina Rivet, Vice President of Lab, says that reliability, build quality, and speed are all important when selecting a 3D printer, and with Form 4B, “We get all the things we love about Formlabs — and that competitive speed.”

“The team and I have been blown away by the Precision Model Resin and the speed at which it prints. My metal department has to screw implant screws into models we make and the threads often do not hold. This issue is non-existent in the new model material.”

Shawn Simpson, CAD/CAM Technician, Hybridge Implants

Before printing Precision Model Resin on Form 4B, Hybridge would print two models, one for the metal department in Rigid 10K Resin, and another for the assembly team in Model Resin V3. Screwing metal components into the models requires tight tolerances and a strong material, while assembly is delicate, precise work.

The tight tolerances and strength of Precision Model Resin printed on Form 4B allow the Hybridge metal department and assembly team to work on the same models.

Metal components can be screwed directly into models printed using Precision Model Resin.

Utilizing the new Precision Model Resin on Form 4B, Rivet found that “Material print speed is phenomenal. The new model material I've raved about. It's strong. It prints fast. It has a lot of options for our prints.” The dimensional accuracy, toughness, and ease of cleaning in the ultrasonic bath mean Hybridge can now print just one model in Precision Model Resin to be used by both teams, saving time and resources.

But it’s not just Precision Model Resin that the team is excited about. With the speed of Form 4B, the more powerful new Form Wash, and the bigger build platform, Hybridge will be able to bring in more cases.

“If I had two to three Form 4Bs, I could double our production.”

Shawn Simpson, CAD/CAM Technician, Hybridge Implants

Blazing Speed Meets Unmatched Accuracy

Form 4B represents the next evolution in stereolithography (SLA) 3D printing technology, built upon years of groundbreaking hardware, software, and materials science innovations.

Form 4B is setting a new standard for dental 3D printing. Combining speed and accuracy, dental professionals can use a powerful new print engine to print with 15+ materials for dental applications, for new levels of versatile production.

Print three times as fast for true chairside dentistry. Maximize production with a larger build platform and produce consistent, precise models at high volumes, without worrying about downtime or reliability issues. Switch between resins with ease to expand indications and increase productivity across your business.

With up to four times faster print speeds, a 30% larger build volume, unmatched reliability and precision, and the most rigorous quality engineering process in the industry, dental professionals can effortlessly create parts for any dental indication with Form 4B.