For a dentist, every minute spent operating a 3D printer is a trade-off for billable time with patients. So how can you take your practice digital without hurting your bottom line?

By leveraging the power of automation, even a small practice dentist can easily manage 3D printing in their practice. Form Auto and the automation ecosystem gives dentists and their staff the ability to print while safeguarding their time, so they can focus on patient care.

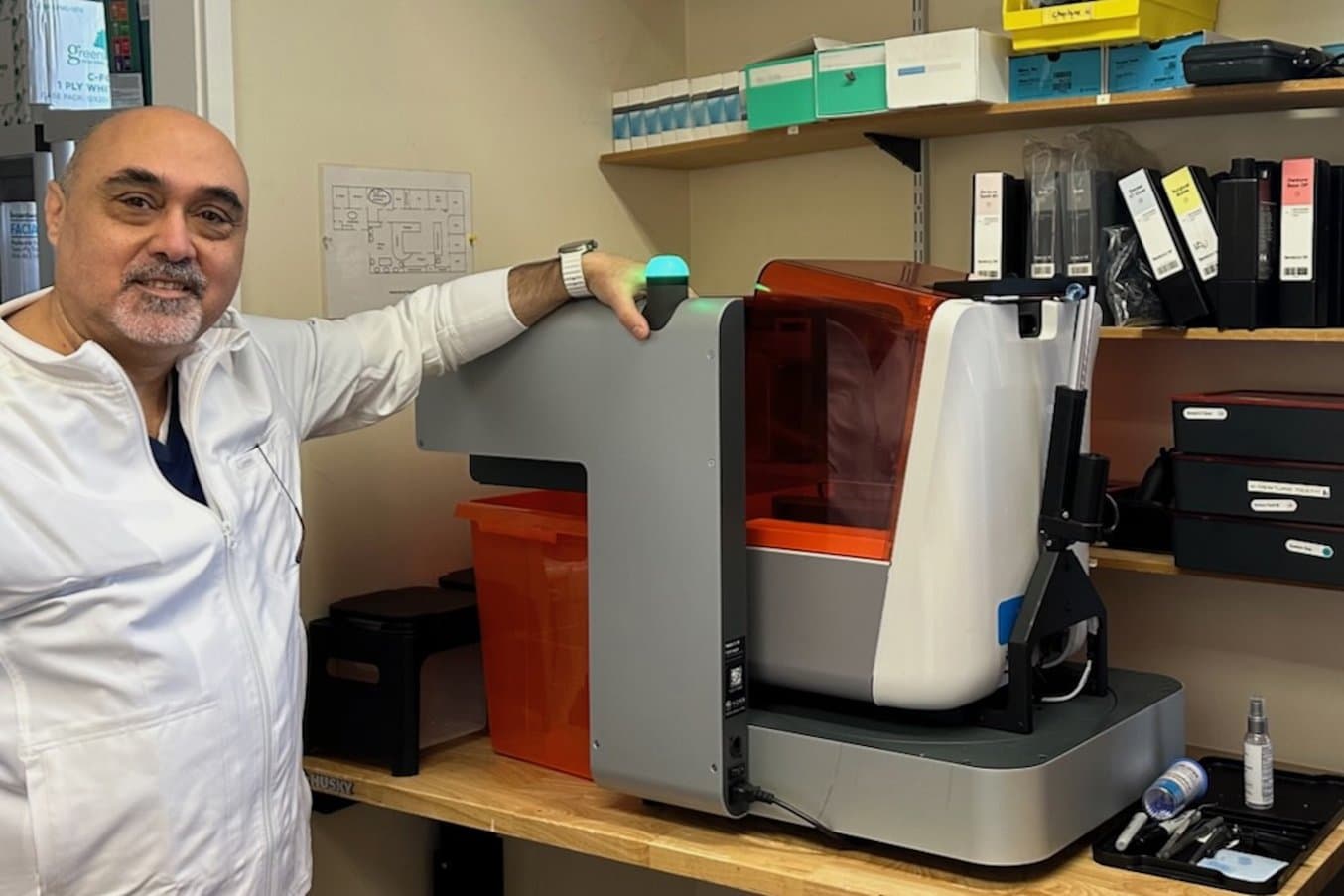

For Dr. Ali Fatimi of Fatemi Family Dentistry in Maryland, discovering the power of 3D printing has revolutionized his practice. As someone who likes to be on the cutting edge of technology, Dr. Fatemi acquired a Form 3B+ stereolithography (SLA) 3D printer in 2022 and quickly scaled up, adding printers and the power of automation with Form Auto and the Formlabs Automation Ecosystem.

Though Dr. Fatemi is the only one overseeing 3D printing for his two practice locations, the ease of use and the addition of automation allow him to both practice and print, enabling him to provide occlusal splints, surgical guides for implants, custom trays, dentures, and aligners to his patients in less time than it would take to outsource, and at a lower cost.

Hitting "Print"

Dr. Fatemi had been using digital workflows for years before discovering the Form 3B+. Until then, he’d been sending intraoral scans to dental labs to have appliances designed and produced. He first shifted to outsourcing the design of occlusal splints and then printing the files onsite with his Form 3B+. Once he learned exocad and exoplan, he quickly moved to “designing all my occlusal splints, dentures, all my surgical guides, anything that I could do.”

“I'm doing a lot of occlusal splints and next-day dentures and Formlabs has really helped me out with the printing process.”

Dr. Fatemi, Fatemi Family Dentistry

He takes the time between patients or during lunch to design in exocad, but notes that for people who don’t want to learn to design, the benefits of printing onsite are still apparent, “there are lots of places that can design for you — they can get it back in one day and then you can print it.”

Excited by the possibilities 3D printing opens up, Dr. Fatemi finds that his patients appreciate that he is up-to-date with the latest technology, and that leveraging that technological edge allows for them to receive a faster turnaround on appliances.

Expanding Indications

Dr. Fatemi started with a single indication, learning the workflow to design and print occlusal splints. It now takes him 10 minutes to design a splint, which he can batch with others to then simultaneously print and process.

“You can start with printing your occlusal guards because 70% of the patients probably need occlusal guards.”

Dr. Fatemi, Fatemi Family Dentistry

Once Dr. Fatemi had mastered the workflow for occlusal splint, he added indications one at a time, including dentures, surgical guides, and models for aligners. Now he designs and prints anything he can in-house, and is continually working on adding indications. He found that by printing in-house, he can adjust designs quickly and affordably. For example, making changes to a denture so that a patient receives the most comfortable appliance possible.

Always one to stay on the cutting edge of dentistry, Dr. Fatemi continues to learn new workflows and add materials to his library, expanding what he can offer his patients.

3D Printing Occlusal Splints with Formlabs SLA 3D Printers

This application guide demonstrates each step for making 3D printed occlusal splints on Formlabs SLA 3D printers.

Control Production Time and Expenses

Printing onsite means the production timeline is controlled. Dr. Fatemi doesn’t have to wait for the one or two weeks it takes for a lab to design, produce, and send an appliance. “I can do an occlusal guard in half a day, instead of waiting for it for a week [from the lab]. It really saves a lot of time.”

Having multiple printers is also a time saver. While it is simple to swap out what type of resin is being used on a printer, having dedicated printers for each material means each can be used for a specific purpose — and print simultaneously. Dr. Fatemi says, “If I'm doing a denture, one printer is printing the base, the other printer is printing the teeth.” Then, all he has to do is assemble, without waiting for the next component to print, and while printing models on yet another Form 3B+.

Time savings are apparent for both patient and dentist. “If someone comes to your practice and has a front tooth missing and they need something right away and your lab is not available, 3D printing allows you to resolve this right away. You can see the patient in the morning and at 6:00pm you have the appliance. That allows you to have next-day crowns. You could have next-day dentures. So 3D printing allows you to do things much faster.”

This quick turnaround time ultimately minimizes chair time and the wait time between an issue and a resolution.

Bringing production in-house also enables greater flexibility without a large price tag. For Dr. Fatemi, this can mean dialing in a design to ensure it’s exactly what the patient requires without worrying about additional outsourcing fees.

Thermoforming Clear Appliances With 3D Printed Models

Producing thermoformed clear aligners and retainers enables practices and labs to provide a valuable service to patients and clients while saving time and costs. This application guide details the clear aligner and retainer workflow using a Formlabs 3D printer, from start to finish.

Leveling Up With Form Auto

Dr. Fatemi has two offices, and is the only person on his team who works with 3D printers. For clear aligner production, Dr. Fatemi outsources design, and then prints models on a Form 3B+ set up with a Form Auto. The Form Auto enables him to print continuously with the same material without needing to be at that office.

“I could start printing all my models and I don't have to be there to get the models out of the printer, then clean the platform and put it back in again. Form Auto makes it automated for me to do 20, 30 models at a time, and that helps a lot.”

Dr. Fatemi, Fatemi Family Dentistry

Dr. Fatemi utilizes a Form Auto, Form 3B+, Form 3, Form Wash, and Form Cure. When he’s at his other office, he monitors printing remotely via Dashboard.

Form Auto is a hardware component of the Automation Ecosystem, and automatically removes prints from the build platform and then prepares the printer for the next job, for 24/7 printing. The Dashboard enables Dr. Fatemi to remotely monitor the queue, so he can check on the status of his prints no matter where he is. Since no one else works with the 3D printers, Form Auto not only speeds up the printing process, but means Dr. Fatemi can print models unsupervised and even when he’s at his other practice location.

“If you're doing your clear aligners, you could really speed up your process and do clear aligners with Form Auto. It brings down the cost a lot and makes it more convenient.”

Dr. Fatemi, Fatemi Family Dentistry