A Century of Dentistry Reimagined With 3D Printing: How Clínica Ramírez is Reducing Appointments by 50%

“3D printing has completely changed the way that we are working in our practice. We have the possibility of a much better interaction with the patient. We have almost halved appointments for patients.”

Dr. Pablo Ramírez, Dentist and Co-director, Clínica Ramírez

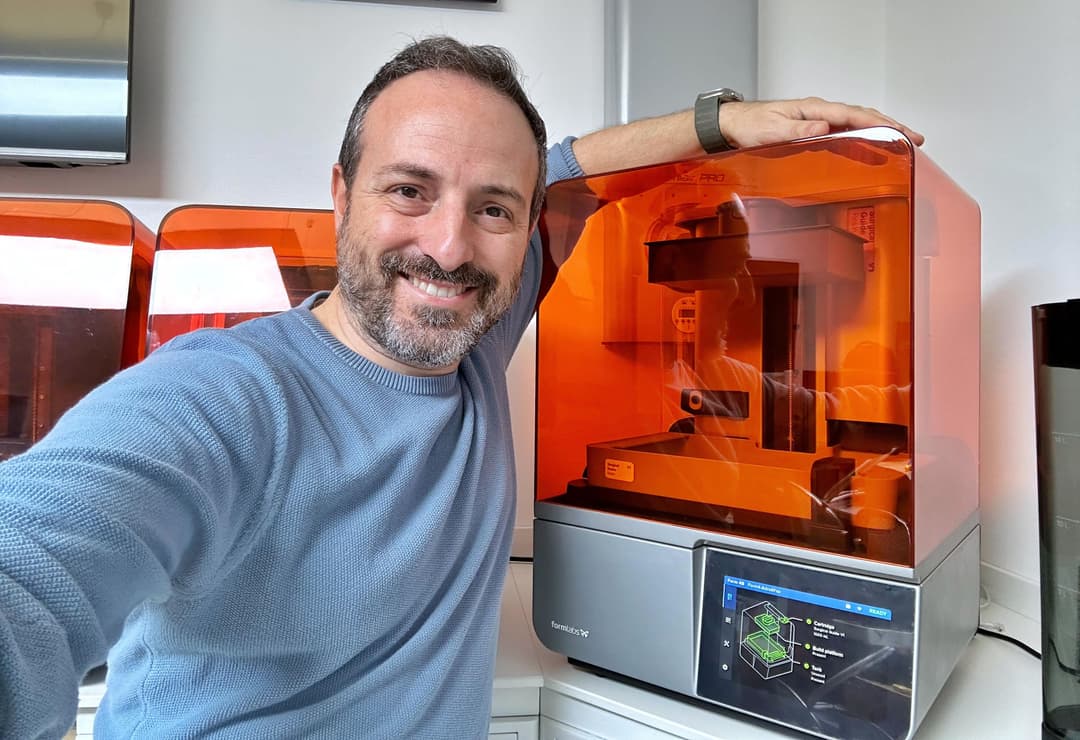

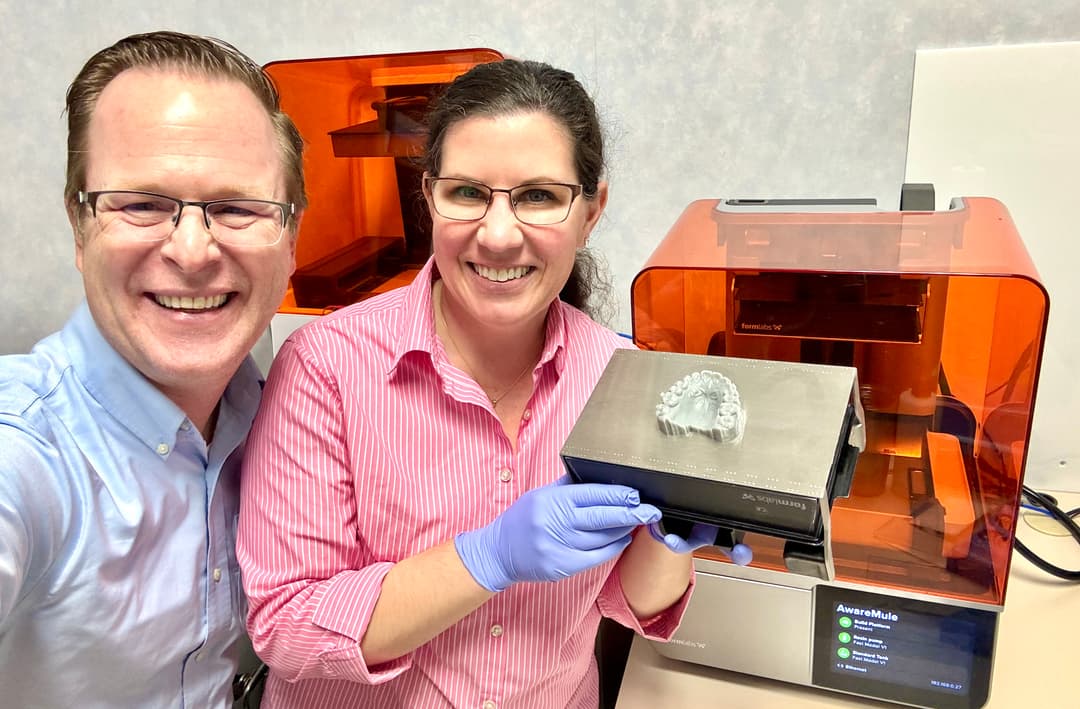

For nearly 100 years, Clínica Ramírez has been a trusted name in dentistry in Las Palmas, Gran Canaria, Spain. Now, third-generation dentists Pablo and Alejandro Ramírez are using technology to provide same-day dentistry and reduce appointments by 50%.

“We’ve always been focused on caring for patients from a biological point of view,” explains Dr. Pablo Ramírez. “Technology allows us to deliver treatments faster, more precisely, and with a much better patient experience.” With their team of 15, Clínica Ramírez combines tradition with innovation, using three Formlabs printers — Form 2, Form 3B+, and Form 4B 3D stereolithography (SLA) 3D printers — to deliver restorations and appliances with precision, predictability, and speed.

Drs. Pablo and Alejandro Ramírez are third-generation dentists bringing digital dentistry to their 100 year-old family practice.

Get in Touch

Whether you need to produce occlusal splints in-house, or are looking for high-throughput production of dental models, we're here to help. Get in touch with a dental expert to find the right solution for your business.

Interdisciplinary Treatment Plans With Digital Dentistry

“We focus on interdisciplinary dentistry, including ortho and restorative, to achieve the goals of treatment to the patients. With technology we are able to achieve a much better connection and interaction between all the disciplines in dentistry.”

Dr. Pablo Ramírez, Dentist and Co-director, Clínica Ramírez

The clinic’s digital workflow includes intraoral scanning, CBCT imaging, and 3D printing on the Formlabs Dental ecosystem. They began by using CAD/CAM technology 10 years ago for diagnostics, but with the evolution of the technology, now use it for building a treatment plan through execution.

CBCT imagining is part of the digital workflow at Clínica Ramírez.

Imaging includes intraoral scanning as a part of the Digital Smile Design workflow.

Facial scanning is used for treatment planning through execution.

Form 4B is used for printing models, surgical guides, occlusal splints, and restorations.

“At the very beginning we were only printing models — orthodontic models, diagnostic models, bleaching trays.” says Dr. Ramírez. “But now, with faster and more accurate technology, we cover almost the entire spectrum of dentistry: restorative, surgical, and preventive.”

Clínica Ramírez runs three printers full-time, producing:

-

10–20 models per day for diagnostics, orthodontics, and smile design

-

7–10 surgical guides per week for implantology and crown lengthening

-

Occlusal splints, often delivered the same day

-

Restorations, an area that is expanding rapidly

“Printing is part of our family now,” Dr. Ramírez says. “We use it daily for diagnostics, for execution, and for patient communication.” Running three printers daily requires coordination, but the Formlabs ecosystem has made delegation simple.

“For me, one of the most relevant things about Form 4B is how easy it is to use. After a short training, our team members can run the printers confidently,” says Dr. Ramírez. “The predictability and stability of the system allow us to delegate, which is essential for efficiency.”

The clinic often batches cases together — printing multiple restorations or several splints at once to maximize productivity. “This helps us organize our workflow better and keeps the clinic running smoothly,” says Dr. Ramírez.

Same-Day Dentistry With Form 4B

“Having the Form 4B has completely changed the way that we are executing the cases. For example, in cases where we are doing ortho and we need a fast model for a retainer, using the Fast Model Resin we are able to produce a model in eight to nine minutes so the patient can stay in the clinic.”

Dr. Pablo Ramírez, Dentist and Co-director, Clínica Ramírez

CAD/CAM is used to digitally design occlusal splints.

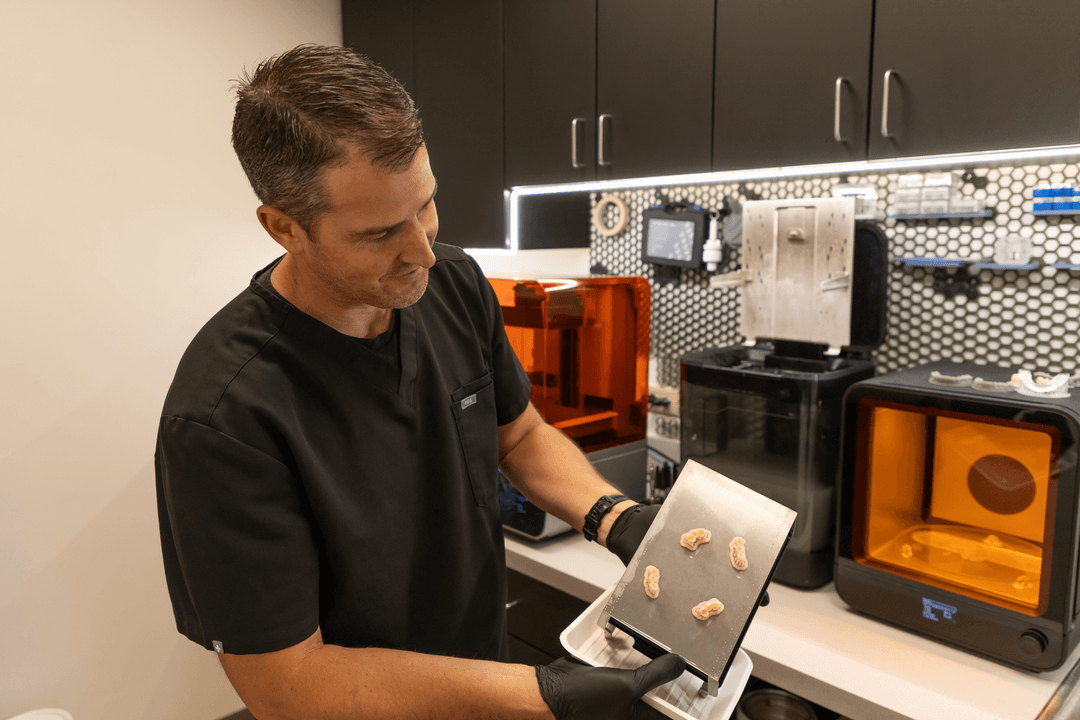

Occlusal splints are printed on Form 4B, washed in Form Wash, and then post-cured in Form Cure (pictured).

A 3D printed occlusal splint can be delivered same-day with in-house 3D printing on the Formlabs ecosystem.

With the speed and reliability of Form 4B, Clínica Ramírez can deliver occlusal splints and retainers same-day. Now, with the addition of AI design, some restorations can also be delivered same-day.

“The benefit is huge,” Dr. Ramírez explains. “Patients only need to come once, and we can manage the clinic’s agenda much better.” Same-day dentistry benefits both the clinic and patients, enabling them to get back to smiling fast and with less impact to their schedules.

Product Demo: Form 4B Dental 3D Printer

Blazing speed meets unmatched accuracy in the next generation of dental 3D printing. Explore the latest innovations in our webinar.

50% Fewer Appointments

Before adopting 3D printing, workflows like smile design or diagnostic wax-ups and mock-ups required sending scans and models to outside labs. Turnaround times often stretched to two weeks. Now, the same process takes just one to two days.

3D printing is used for diagnostics, execution, and patient communication.

“Especially in cases where we are doing smile design or mock-ups, the timing has been cut in half,” says Dr. Ramírez. “This means patients see results faster, interact with us more meaningfully, and we can execute cases much more efficiently.”

Advances in design software, including AI, and design integrations have also improved speed, “In a few clicks you will have the final design with the correct anatomy, with the correct occlusion,” says Dr. Ramírez. “And then when we jump into the printing part, the time is reduced and we are able to execute the final part in a very fast way. Patients only need to come once, and we can manage the clinic’s agenda much better.”

With Form 4B, surgeries can be scheduled less than three days from an initial appointment.

A 3D printed surgical guide allows for precise implant placement.

In-house 3D printing on Form 4B has also decreased timelines for patients — surgeries can be scheduled less than three days from an initial appointment, depending on the clinic's schedule, as the surgical guide and implant can be printed without the lead times required of outsourcing to a lab.

3D Printed Restorations

Ceramic-filled resins like BEGOTM VarseoSmile® TriniQ® Resin and Premium Teeth Resin have propelled one of the biggest changes in the practice: the direct printing of full and partial restorations including inlays, onlays, tabletops, and overlays, as well as single units for immediate loading cases. Clínica Ramírez is also using Premium Teeth Resin for full-arch aesthetic try-ins.

A full-arch aesthetic try-in printed in Premium Teeth Resin.

A restoration for central incisor 3D printed with BEGO™ VarseoSmileⓇ TriniQⓇ Resin.

“Instead of doing big fillings that don’t have the correct contacts or anatomy, we now scan, design, and print indirect restorations,” says Dr. Ramírez. “The marginal adaptation is truly amazing — both on natural teeth and on implant bases. It’s something milling struggles with.”

“We’re already using 3D printed restorations for single units and provisionals. I believe materials will continue to evolve so we can confidently expand into more complex and aesthetic anterior cases.”

Dr. Pablo Ramírez, Dentist and Co-director, Clínica Ramírez

Digital design is done in-house.

PreForm, Formlabs’ free print preparation software, is used to set up a restoration for printing.

A 3D printed restoration printed in BEGO™ VarseoSmileⓇ TriniQⓇ Resin can be characterized to enhance esthetics.

Dr. Ramírez is impressed with the marginal adaptation of 3D printed restorations.

Request a Free Sample Part

See and feel the Formlabs quality firsthand. We’ll ship a free 3D printed sample part printed on Form 4B to your office.

Continuing a Tradition of Innovation

After nearly a century in dentistry, Clínica Ramírez continues to evolve while staying true to its core mission: creating healthy, beautiful smiles. For Dr. Ramírez, 3D printing is not just a tool, it’s part of the clinic’s identity.

“3D printing is completely a part of our workflow,” says Dr. Ramírez. “It’s part of our family. It helps us be faster, more precise, and more connected to our patients. We cannot imagine working without it.”

Looking further into the future, he sees AI playing an increasingly central role. “The future of digital dentistry is simplicity, connectivity, and personalization. Soon, from just a photo or a short video, we’ll be able to design a smile, communicate with the patient, and move directly into execution.”

Explore Form 4B or find a reseller to start printing. To evaluate Formlabs materials for yourself, request a free sample part.