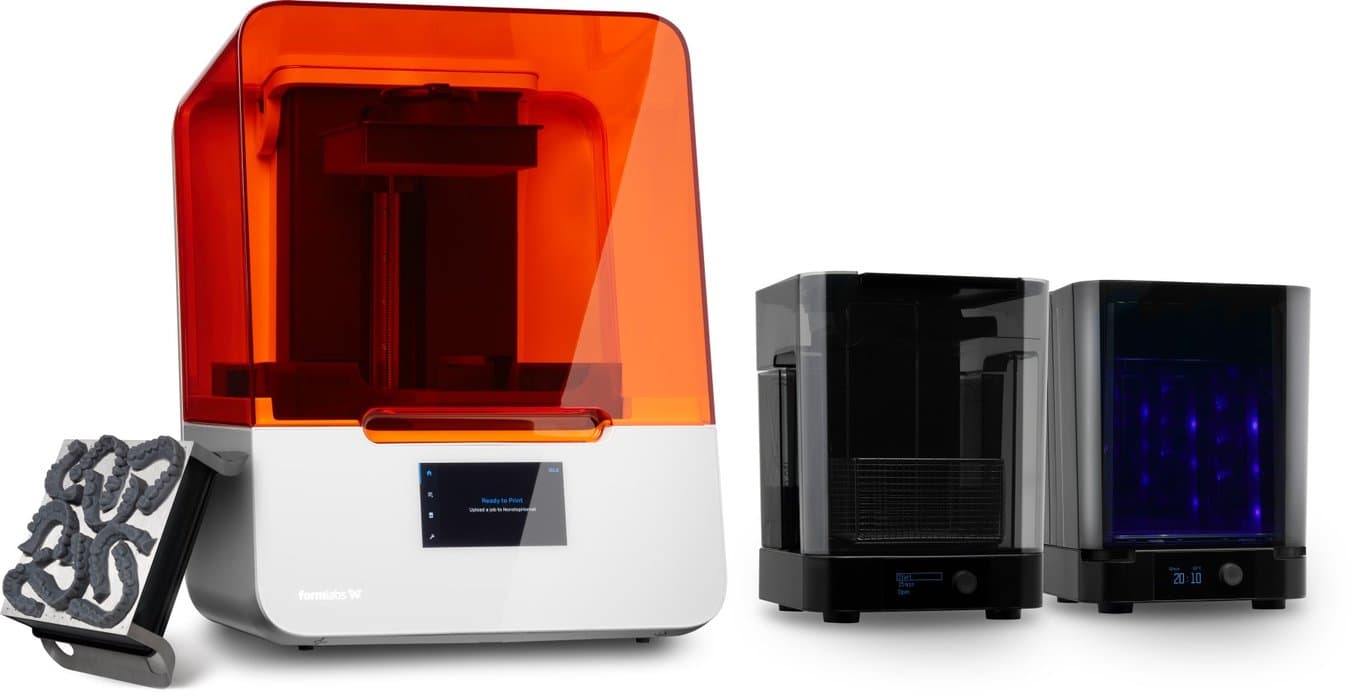

Introducing the Form 3B+: New Improvements to the Best Selling Dental 3D Printing Ecosystem

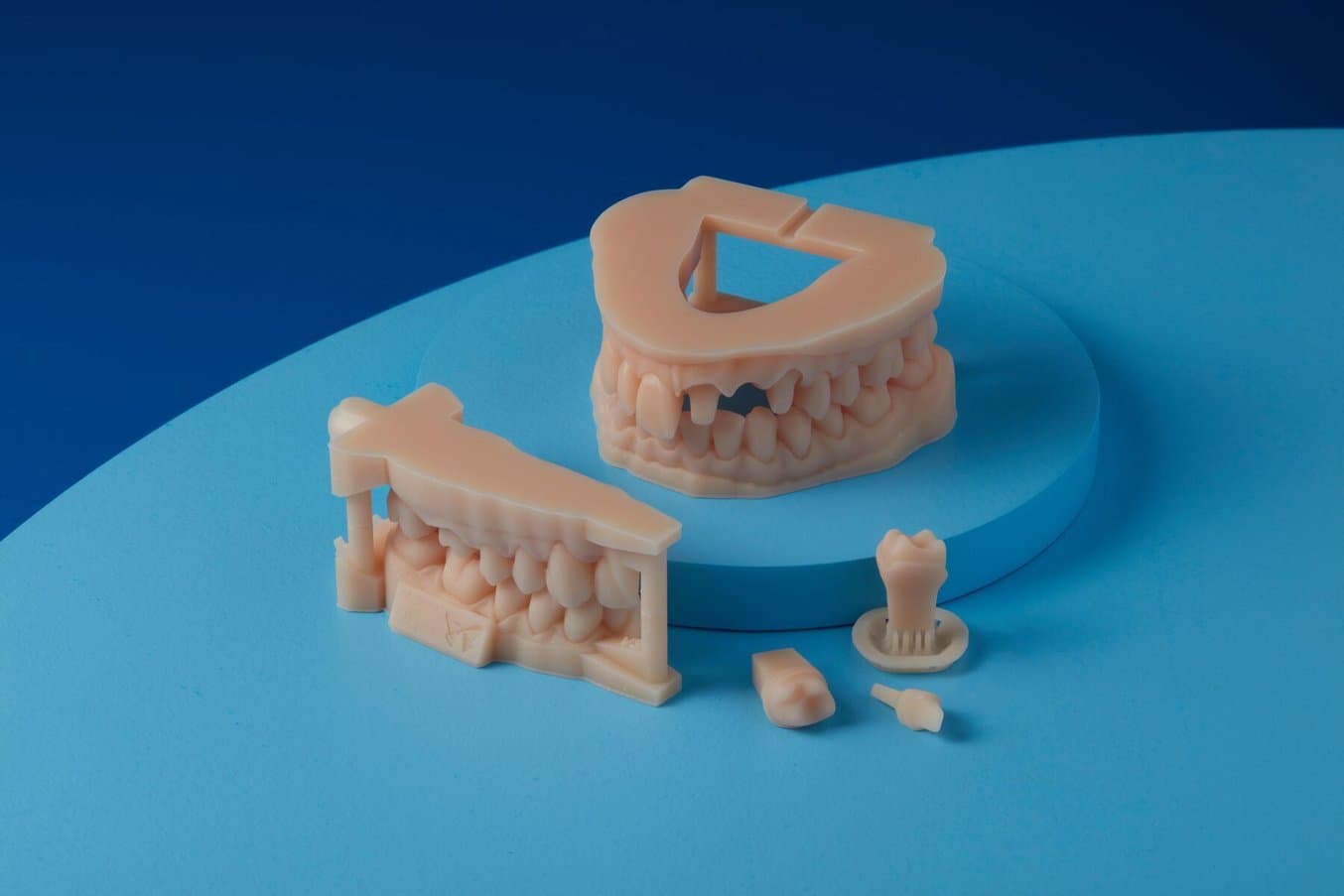

Create high-quality dental models, appliances, and prosthetics faster than ever with the Form 3B+, Formlabs’ latest version of the best-selling line of professional SLA 3D printers, now shipping to customers across the world. The Form 3B+ is rich with improvements that make it simple to quickly and reliably produce dental products in any environment and builds off of Low Force Stereolithography (LFS) technology originally introduced on the Form 3 and Form 3B.

Formlabs prides itself on making easy to use, user friendly 3D printing products, and we’ve furthered our commitment to improving the entire 3D printing workflow with the introduction of Build Platform 2, our next generation build platform with patented Quick Release Technology that allows quick, clean, and easy removal of parts after printing to improve post-processing efficiency.

For any dental products, the Form 3B+ and Build Platform 2 make it faster and easier than ever to fabricate digitally.

Reliable, High Quality Parts

The introduction of LFS technology with the Form 3 and Form 3B set a new industry standard for consistent print quality and reliability.

One of the innovations introduced with LFS technology and the Form 3 and Form 3B was the Light Processing Unit (LPU), a laser system that moves beneath the resin tank and delivers a laser path that is always perpendicular to the print plane. The combination of this linear movement and the system of mirrors inside the LPU means you get a consistently perpendicular round laser spot no matter where on the print bed the laser is aiming. This is important for producing accurate, highly-detailed parts and leads to better surface finish.

The Form 3B+ includes new hardware and software that tightens laser movement parameters and smooths the motion within of the LPU, minimizing any deviation from the curing path. The more stable LPU creates smoother finishes, finer details, and more transparent parts when printing translucent resins like Dental LT Clear Resin for occlusal splints.

We know customers install our printers in different environments and are operating them in various ambient temperatures. The Form 3B+ printers also include a new heating system with improved sensors that more quickly and accurately heat the print bed to the optimal temperature for each resin. This development creates quicker and more consistent printing for each material for high quality parts, every time.

Ecosystem Efficiency Improvements

Resin 3D printing has a reputation for being messy. Formlabs began to address this concern with the Form Wash and Form Cure, our automated post-processing solutions that clean and post-cure parts, and our new Build Platform 2 takes this a step further, improving the efficiency of the overall workflow and reducing labor time from start to finish.

The new Build Platform 2 has a patented Quick Release Technology that fundamentally changes the resin printing workflow. Previously, removing parts from the Build Platform could result in scratches, broken models, or part defects. Now with Build Platform 2, printed parts instantly release from the print surface with one simple movement of the stainless steel side handles. The flexible print surface ensures an instant release of batch parts simultaneously, saving labor time previously spent manually removing parts off one by one. The flexible surface and release mechanism also means there’s no need to use tools that could damage parts.

Further time and labor savings during post-processing are a result of an improved support configuration inherent to the new material settings introduced on the Form 3+ and Form 3B+. Where previous PreForm versions generated a rounded tip attachment of the support to the part, the new PreForm version creates a prism shape for the touchpoints, enabling an easier and cleaner break.

The Form 3B+ and Build Platform 2 help customers’ bottom line, making them the ideal solutions for customers in both practices and laboratories. The Build Platform 2 is compatible with the Form 2, Form 3 and Form 3B, as well as Form 3+ and Form 3B+, enabling access to the improved workflow for any Formlabs desktop SLA user.

Fast Workflows from Start to Finish

Dental professionals rely on the speed of technology to deliver their work quickly and efficiently. With improvements in hardware, software, and materials science, the Form 3B+ can print a single model in as little as 20 minutes, and up to 60 models per working day.

Software Improvements for Speed

Software upgrades are the major contributor to improvements in print speed, specifically materials settings, optimization of laser curing power, and geometry analysis for support generation.

Though the Form 3B+ uses the same type of laser as the Form 3B, the new software upgrade optimizes its curing capabilities, allowing each layer to build more efficiently. The updated materials settings improve print speeds up to 40% on some materials, including White Resin for diagnostic models and Soft Tissue Resin for implant models. No matter which resin, software-powered speed improvements allow you to get a finished part sooner, reducing down time and creating more flexible workflows.

To learn about these newly tuned material settings in more detail, read our technical deep dive article.

Adaptive Layer Thickness, an advanced print mode now available for all materials, reduces print time by adjusting the layer thickness based on part geometry. In order to maximize print speeds while preserving these details, the Form 3B+ is capable of producing parts with varying layer thickness, using smaller layers for more detailed geometry such as occlusal surfaces, and thicker layers for less detailed geometry, like model bases.

Hardware Improvements for Speed

The Form 3B+ also contains new hardware components that improve print speed, particularly in early layers, reducing the time of laser exposure needed for early print layers to adhere to the build platform. This is especially impactful for smaller parts such as crown and bridge models as well as dental models where early print layers have a major impact on print times.

From the start to the finish of every print, improvements to software, firmware, and hardware are making the Form 3B+ print experience faster and more efficient. Whether you need speed to enable true chairside delivery, maximize throughput in the laboratory, or save the day on a rush case, speed matters—without sacrificing accuracy. No matter the deadline, the Form 3B+ delivers on quality and speed.

Fast Materials for Dental and Orthodontic Models

Formlabs has an in-house materials science team that develops cutting-edge 3D printing resins that are designed to work seamlessly with our printers, including the Form 3B+. Two recently released materials were formulated from the ground up for speed: Draft Resin, for orthodontic models, and Model Resin, for restorative models.

Draft Resin is a grey-colored model material that prints at top speeds. It’s capable of printing one orthodontic model arch in as little as 20 minutes.

Model Resin is a stone-colored model material that prints quickly without sacrificing surface finish. It’s capable of printing a high-accuracy restorative model kit in under an hour.

With these two resins, plus Build Platform 2 and our Scan to Model software feature, printing dental and orthodontic models on the Form 3B+ is faster and easier than ever.

Upgrades From Beginning to End

From the beginning of your workflow to the end, the Form 3B+ and Build Platform 2 are the fastest, most reliable way to produce high quality dental models, appliances, and prosthetics. With a suite of improvements designed to start a print easier, build a part faster, and finish a part in minutes, our new flagship desktop SLA printer ecosystem offers the most advanced solution for any dental professional.