Your dental 3D printing workflow just got faster — introducing Form Cure V2, offering blazing fast curing for any dental part in 1-10 minutes for faster time to part and consistent, validated results, so you can deliver dental parts in record times.

In addition to the release of Form Cure V2, new printer fleet features have been added to Dashboard, simplifying collaboration, streamlining workflows, and increasing productivity. Additionally, PreForm Dental now includes a 100 μm layer print setting for Precision Model Resin for faster production of restorative models.

Post-Cure Models in 60 Seconds With Form Cure V2

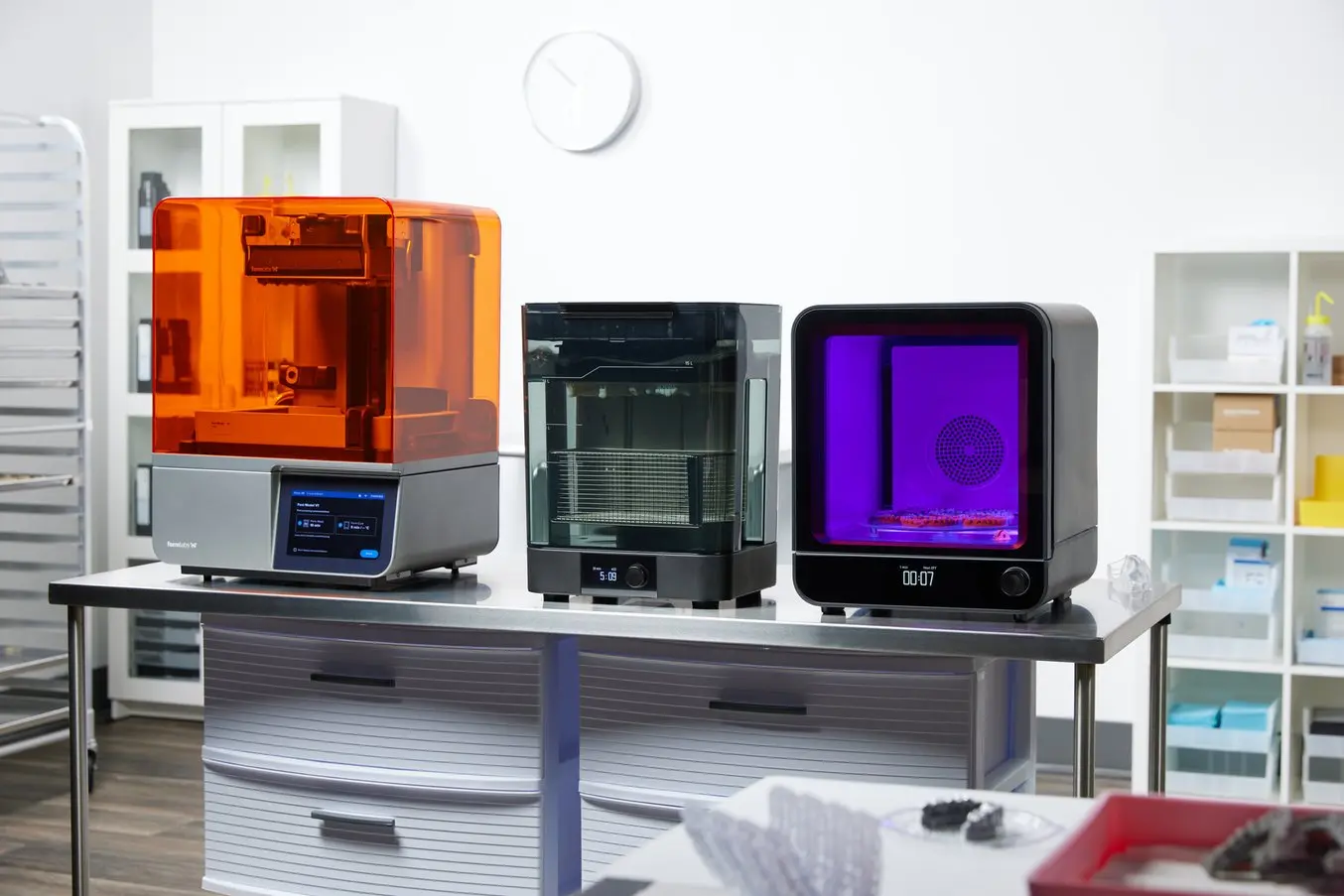

The complete Form 4B ecosystem: Form 4B, Form Wash V2, and Form Cure V2.

Form Cure V2 offers blazing fast curing for any dental part in 1-10 minutes, saving up to 50 minutes from the cure time with the original Form Cure. Form Cure V2 heats to 60 °C in just 60 seconds*, saving valuable workflow time.

*Based on the 230 V version. The 120 V version will heat to 60 °C in 90 seconds.

“The pre-programmed settings make working with the new Form Cure super easy, and of course the speed is fantastic."

Dr. Rick Ferguson DMD, DABOI, DICOI, FACD, Implant Educators Academy

Form Cure V2 appears orange when it is not actively curing.

When Form Cure V2 is in use, the window appears purple, so you can see, at a glance, that it’s curing.

Form Cure delivers consistent results for Formlabs Dental resins with pre-programmed and validated cure settings. Safely cure biocompatible resins without guesswork and a workflow that is easier than ever — simply select the resin and start the cycle. For curing third-party materials printed with Open Material Mode (OMM), it’s possible to save custom profiles for the resins you regularly print, or set the time via the dial.

| Material | Form Cure V1 | Fast Cure | Form Cure V2 |

|---|---|---|---|

| Precision Model Resin | 5 min | 30 s | 1 min |

| Fast Model Resin | 5 min | 1 min | 1 min |

| Surgical Guide Resin | 30 min | 5 min | 5 min |

| Dental LT Clear Resin V2 | 60 min | 6 min | 10 min |

With a larger build volume than both Form Cure and Fast Cure, Form Cure V2 can fit 15 models, for a throughput of 15 models per minute. With this capacity, one cure unit can serve multiple Form 4B printers while decreasing the number of interactions required.

Form Cure V2 is designed for easy operation in small workspaces. The door opens from the side, allowing easy access within a compact footprint, while high clearance enables easy part placement and removal. Additionally, the sleek new design and glass turntable are easy to clean.

| Form Cure V1 | Fast Cure | Form Cure V2 | |

|---|---|---|---|

| Maximum Part Height | 185 mm | 65 mm | 245 mm |

| Turntable Diameter | 193 mm 7.6 in | 180 mm 7.1 in | 235 mm 9.25 in |

| Maximum Cure Chamber Temperature | 80 °C | N/A | 100 °C |

The blazing print speed of Form 4B combined with the time savings of Form Cure V2 allow the production of occlusal splints at 100 μm layer height more than 4.8x faster than with Form 3B+ and Form Cure.

Time to manufacture occlusal splints at 100 μm layer height with Dental LT Clear Resin V2

| Number of parts | Print time | Wash time | Post-curing time | Total time | |

|---|---|---|---|---|---|

| Form 4B & Form Cure V2 | 8 | 49 min | 15 min | 10 min | 1 h 14 min |

| Form 4B & Form Cure V1 | 8 | 49 min | 15 min | 1 h | 2 h 4 min |

| Form 3B+ & Form Cure V2 | 7 | 4 h 45 min | 15 min | 10 min | 5 h 25 min |

| Form 3B+ & Form Cure V1 | 7 | 4 h 45 min | 15 min | 1 h | 6 h |

Form Cure V2 is compatible with Form 4, Form 4B, Form 3/B/+, and Form 2 and replaces both Form Cure and Fast Cure in our dental ecosystem.

Fleet Control Management Features Now in Dashboard

If you have a fleet of Formlabs 3D printers, it’s now possible to manage and monitor the entire fleet via one centralized dashboard. This simplifies collaboration, streamlining workflows and increasing productivity. These previously paid features — called Fleet Control — are now free and integrated into Dashboard, giving all users access to Group Queues for automated print assignment, Cloud Slicing for faster processing, and Bulk Firmware Updates for seamless printer maintenance, all in one easy-to-use platform.

New Dashboard updates include:

-

Group Queues: Print jobs can be sent to a shared queue, and the next available printer will automatically start the job.

-

Cloud Slicing: Print files can be processed in the cloud instead of locally, reducing the strain on a user’s computer.

-

Bulk Firmware Updates: Users can update all their printers at once, rather than one at a time.

These updates enable streamlined printing and easy team collaboration, so you can:

-

Monitor prints in real-time

-

Manage multiple printers from one interface

-

Track resin usage, print history, and maintenance needs

“There is the world of dental 3D printing and then there is Formlabs. When you have multiple 3D printers — and this is the future for dental — you need a good way to manage all those 3D printers. And there is nothing close to the Dashboard and the ecosystem from Formlabs.”

Dr. Antonino Cacioppo, DDS, PhD, Prosthodontist

To start using these features, sign up for Dashboard or log in to your account.

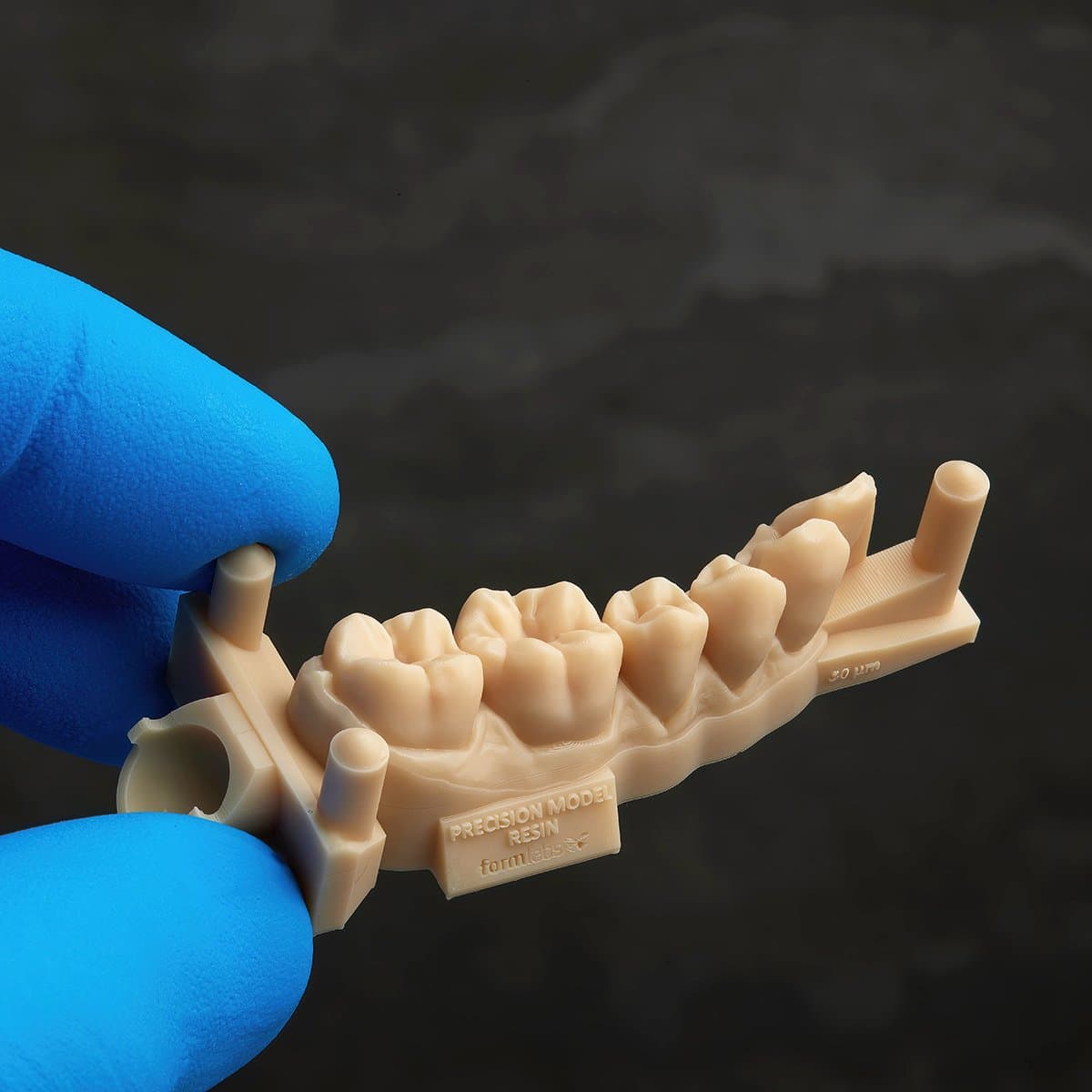

Print Restorative Models Faster Than Ever

The latest releases from Formlabs Dental continue our mission to make dentistry easier. Along with the release of Form Cure V2 and new Dashboard features come new print settings for Precision Model Resin. The 100 μm layer setting in PreForm Dental empowers dental labs to achieve higher throughput of restorative models with faster print times.

We recommend printing with 50 μm layer height for high-accuracy models, e.g., implant models, crown fit models, etc. The new 100 μm layer height maintains >90% accuracy within 50 μm for faster printing of antagonist models. All Precision Model layer height settings are available on the Form 4 Series 3D printers.

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part printed on the Form 4B to your office.

Improving Speed & Throughput

From print setup through post-curing, we’re constantly optimizing workflow efficiency, ease of use, and increasing time-savings so you can efficiently and cost-effectively provide patients with the best possible care.

Speed up your curing with Form Cure V2 or contact a dental specialist to discuss your unique business goals.