“It’s easy, innovative, open, and robust.”

Dr. Rick Ferguson, DMD

In September of 2024, Formlabs announced that Formlabs 3D printers are open with the release of Open Material Mode (OMM). OMM unlocks the ability for expert users to print with validated third-party resins like those from Pac-Dent and Lucitone, as well as any 405 nm photopolymer resin. OMM gives users access to the reliability and technology of Formlabs 3D printers while printing with the resin of their choice.

What is a validated third-party resin?

To validate resins, resin manufacturers are doing the regulatory work to ensure the mechanical properties and biocompatibility are achieved through a defined workflow. For manufacturers with validated materials, the manufacturing guidelines including print settings and post-processing workflows can be downloaded from their official documentation.

Manufacturers are constantly testing and validating new resins, including Detax, Vita, Keystone, and Graphy, expanding what it’s possible to print.

Can you print with resin that is not validated by the resin manufacturer?

Yes, users can develop their own settings for any 405 nm resin. However, that user will also need to do their own validation including mechanical properties and biocompatibility. Learn more about regulatory compliance in dental 3D printing here.

Get in Touch

Whether you need to produce occlusal splints in-house, or are looking for high-throughput production of dental models, we're here to help. Get in touch with a dental expert to find the right solution for your business.

Dr. Ferguson: Direct Printing of Restorations With Pac-Dent and Aligners

Since 2016, Dr. Rick Ferguson, DMD, has been printing models for thermoforming aligners using the Formlabs ecosystem, which, he says, “has been very efficient for us.” He likes the Formlabs Dental ecosystem for its ease of use and intuitive workflows, which make it easy for his team to print with minimal training, but he is also excited for the potential of directly printing aligners on Form 4B.

“You don’t have to actually print the models as much anymore, and this is something that is one of the most exciting things when it comes to aligner therapy in-office, being able to print the aligners directly.”

Dr. Rick Ferguson, DMD

OMM enables Dr. Ferguson and his team to leverage the speed, reliability, and workflows of the Formlabs ecosystem while printing the material of choice.

In one case, a patient who worked for Pac-Dent needed a replacement appliance as his old one had fractured. Dr. Ferguson was able to scan him, have an appliance designed in 30 minutes, and then print the appliance with Rodin Titan Resin, which is validated by Pac-Dent for printing on Form 4B with OMM. Dr. Ferguson says, “The design part probably took longer than doing the actual print.” With Form 4B and OMM, Dr. Ferguson was able to deliver a same-day appliance for the patient.

The appliance printed in Pac-Dent on Form 4B with OMM. Photos: Dr. Ferguson

After printing, the appliance was finished with the Rodin® Palette N2-Free Naturalizing Kit. Photos: Dr. Ferguson

“We’ve been very happy with the Formlabs ecosystem — it's still one of the most used printers in our practice, even though we have pretty much all the different printers out there.”

Dr. Rick Ferguson, DMD

Dr. Ahmad Al-Hassiny: OMM is an Exciting Development

In a review for the Institute of Digital Dentistry (IDD) Dr. Ahmad Al-Hassiny writes that “Perhaps the most exciting development for the Form 4B is the recently launched Open Material Mode.” He adds, “I’ve tested several third-party resins and the results have been impressive, quite frankly, including Pac-Dent Titan for those who want to print full-arch restorations.”

A full-arch restoration printed in Pac-Dent Titan on Form 4B with OMM. This is directly off the printer with no post-processing. Image from iDD.

“With Open Material Mode, you're no longer restricted to Formlabs resins, opening up competitive options from other manufacturers. You can select materials based on specific case requirements, cost considerations, or personal preferences.”

Dr. Ahmad Al-Hassiny, Director, Institute of Digital Dentistry

Dr. Al-Hassiny specifically calls out the validation of two third-party resins: Pac-Dent and Lucitone. Dr. Al-Hassiny says, “The Formlabs Form 4B emerges as the general all-rounder that provides excellent economic value, particularly now with its open material capabilities.”

In an interview with Dr. Luken de Arbeloa on Quarterback Dentist, Dr. Al-Hassiny says, “By opening up their printer, they now allow any resin manufacturer to work with them. And this gives more choice for dentists who are searching for different indications.” He goes on to explain, “Why this is important is because now in the industry we have best-in-class resins. We have resins that people are deciding on a printer because they want to use this resin.”

But Dr. Al-Hassiny also goes on to caution that post-processing is key for producing appliances that are medical devices. “We need to follow the instructions of the manufacturer. There's a reason these instructions exist.” One way to streamline this in a workflow is to “simply buy a reputable curing box or invest in a system that has the complete system like Formlabs etc. that has a printer, a wash, and a cure.”

The Formlabs Dental ecosystem with Form 4B, Form Wash, and Form Cure. Form 4BL, Form Wash L, and Form Cure L are also available for large-format printing for high-throughput.

Ultimately, open printers like the Formlabs Dental ecosystem are enabling professionals to use the optimal resin for a given application, with end-to-end ecosystems making it easier and more intuitive to print. However, it’s always important to follow the precise manufacturer’s guides for biocompatible appliances.

Request a Free 3D Printed Restorative Dental Model

Curious to see the quality firsthand? Pick a material and we'll ship you a free sample part 3D printed on the Form 4B to evaluate.

Dr. Scherer: The Edge of a Resin Revolution

“If you’re like me, you love a good, validated workflow. But sometimes, the best materials aren’t always locked inside a walled garden. That’s where Open Material Mode on Form 4B comes in.”

Dr. Michael Scherer, DMD, MS

Dr. Michael Scherer, DMD, MS, is a digital dentistry and 3D printing enthusiast who has been using Formlabs 3D printers since he adopted Form 1 as an affordable 3D printer for manufacturing dental models.

In the early days of 3D printing, Dr. Scherer says that the biggest limitation was biocompatible materials for intraoral applications. However, “Over the past years, the world of dental 3D printing has heavily focused on materials.” Dr. Scherer adds, “It feels almost like we are in a new era, a quasi-revolution of dental materials.”

While validated workflows make it easy to print models and appliances, having an open platform gives dental professionals the freedom to select from the entire range of materials available, while leveraging the print speed, reliability, and ease of use of the Formlabs ecosystem. As Dr. Scherer says, “The ability to print resins such as Rodin Titan on the Form 4B quickly, often in less than 60-90 minutes, opens up a huge world of implant opportunities.”

“The Formlabs Form 4B is fast and precise, and now, Open Material Mode takes it to the next level. Now, we can print with materials we already enjoy working with, like Dentsply Lucitone Digital Print Denture™ System, and Pac-Dent Rodin resins right on an ecosystem that we enjoy working with today.”

Dr. Michael Scherer, DMD, MS

Pac-Dent Rodin Titan and Dentsply Lucitone Digital Print Denture™ System are two of the materials Dr. Scherer prints. Rodin Titan enables him to print long-term restorations time-efficiently on Form 4B, for more implant opportunities, while Dentsply Lucitone Digital Print Denture™ System is part of his streamlined denture workflow.

Dr. Scherer uses Lucitone Digital Print Denture™ System from Dentsply Sirona for printing full dentures and LOCATOR overdentures. Photo: Dr. Scherer

Dr. Scherer prints Rodin Titan from Pac-Dent on Form 4B with OMM, manufacturing full-arch prosthetics, both for interim and long-term applications. Photo: Dr. Scherer

Ultimately, Scherer thinks that OMM opens up the ability to deliver great aesthetics to patients while lowering the cost of production compared to traditional manufacturing.

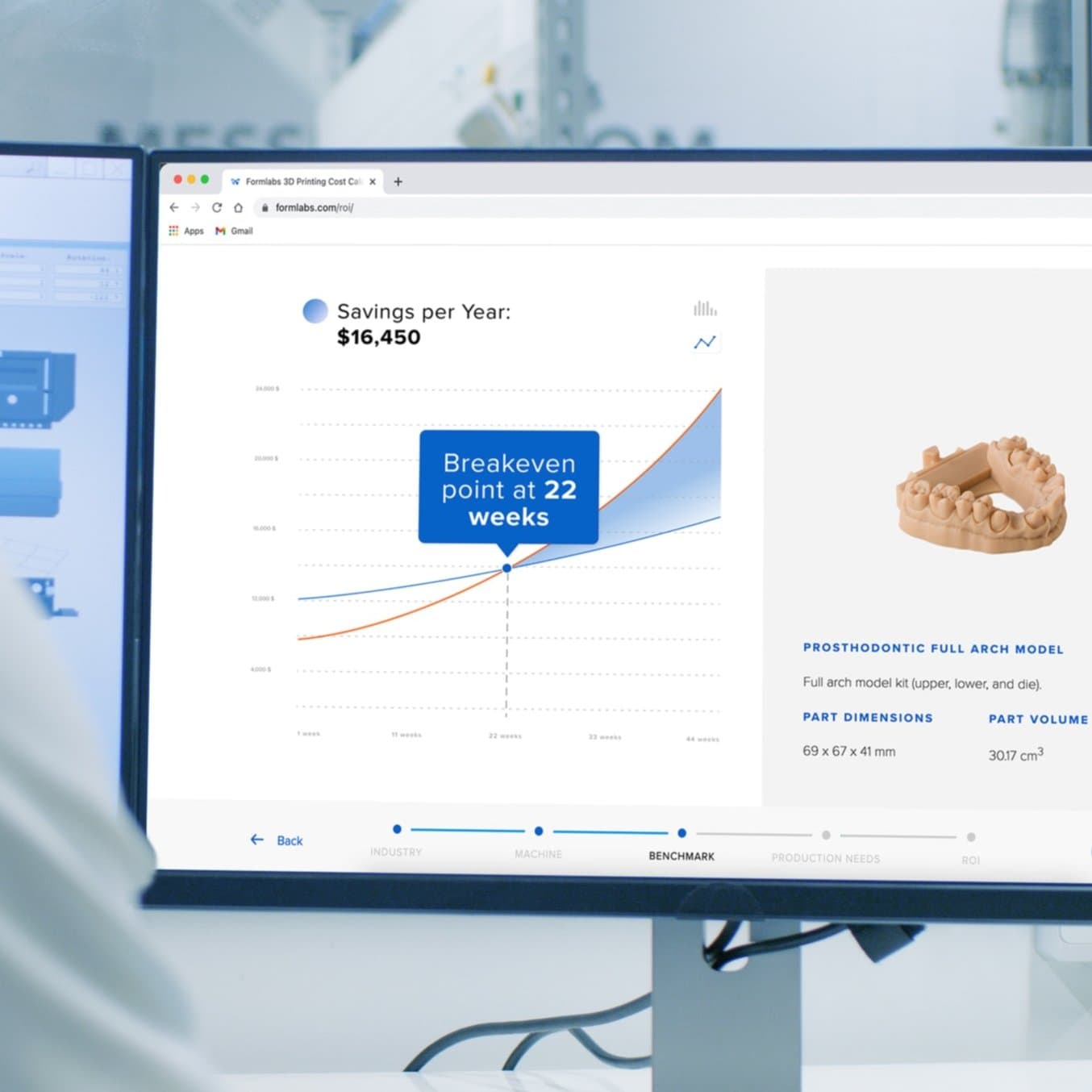

Calculate Your Time and Cost Savings

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs dental 3D printers.

Access the Dental Materials You Need

The Formlabs Dental Materials library includes 15+ validated materials. With validated settings for print set up, printing, and post-processing, printing Formlabs materials on the Formlabs Dental ecosystem is intuitive.

By opening the Formlabs Dental ecosystem, expert users can offer patients the optimal materials for any indication while leveraging the reliability, ease of use, and technology of Formlabs printers.

Ready to print? Explore the Formlabs Dental Materials Library or get OMM. To discuss what’s best for your business or start printing with the Formlabs Dental ecosystem, find a reseller.