Needed From the Dentist

- A physical or digital impression of the patient's dentition

Required Hardware and Materials

- Form 2 or Form 3B SLA 3D Printer

- Form 2 Resin Tank LT or Form 3 Resin Tank V2 or higher

- Temporary CB Resin

- Form Wash

- Form Cure

- Stainless Steel Build Platform (Temporary CB Resin only)

- Finishing kit or secondary wash station

- Desktop scanner (if physical impression or model)

- Low speed dental handpiece with cutting and finishing wheels

- Sandblaster

- Polishing or glazing equipment and materials

- Glass bead blasting material (BEGO Perlablast® recommended)

- Isopropyl alcohol (IPA) ≥99%

Required Software

- PreForm Software (free) 3.6.1 or higher

- Firmware 1.7.3 or higher

- Dental design software or outsourcing to a dental design provider

Note

For full compliance and biocompatibility, Temporary CB Resin requires a dedicated resin tank, Stainless Steel Build Platform, Form Wash, and finishing kit which should not be mixed with any other resins.

Dental design software requires a digital impression of the patient’s anatomy in order to design a temporary prosthetic. To acquire this data, scan the patient directly with a 3D intraoral scanner or scan a physical impression or a poured model with a desktop 3D scanner.

Note

Use PreForm version 3.6.1 or higher and firmware 1.7.3 or higher.

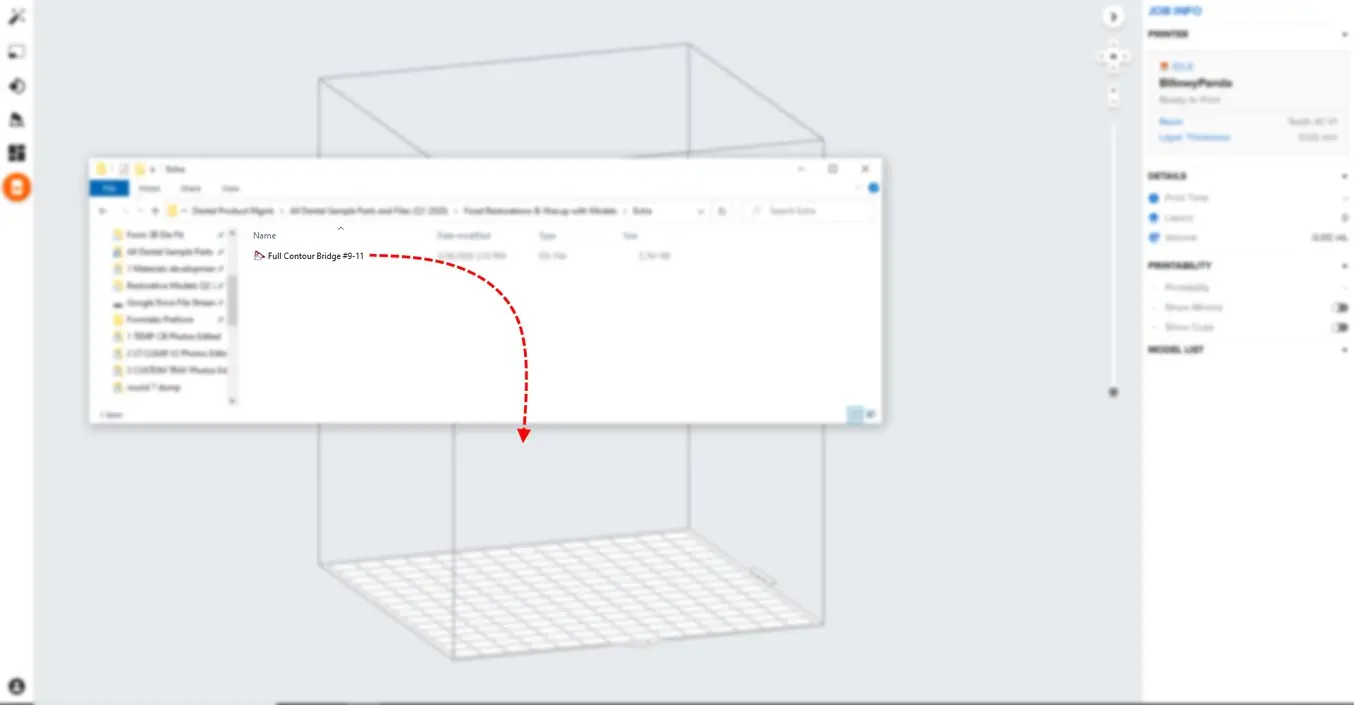

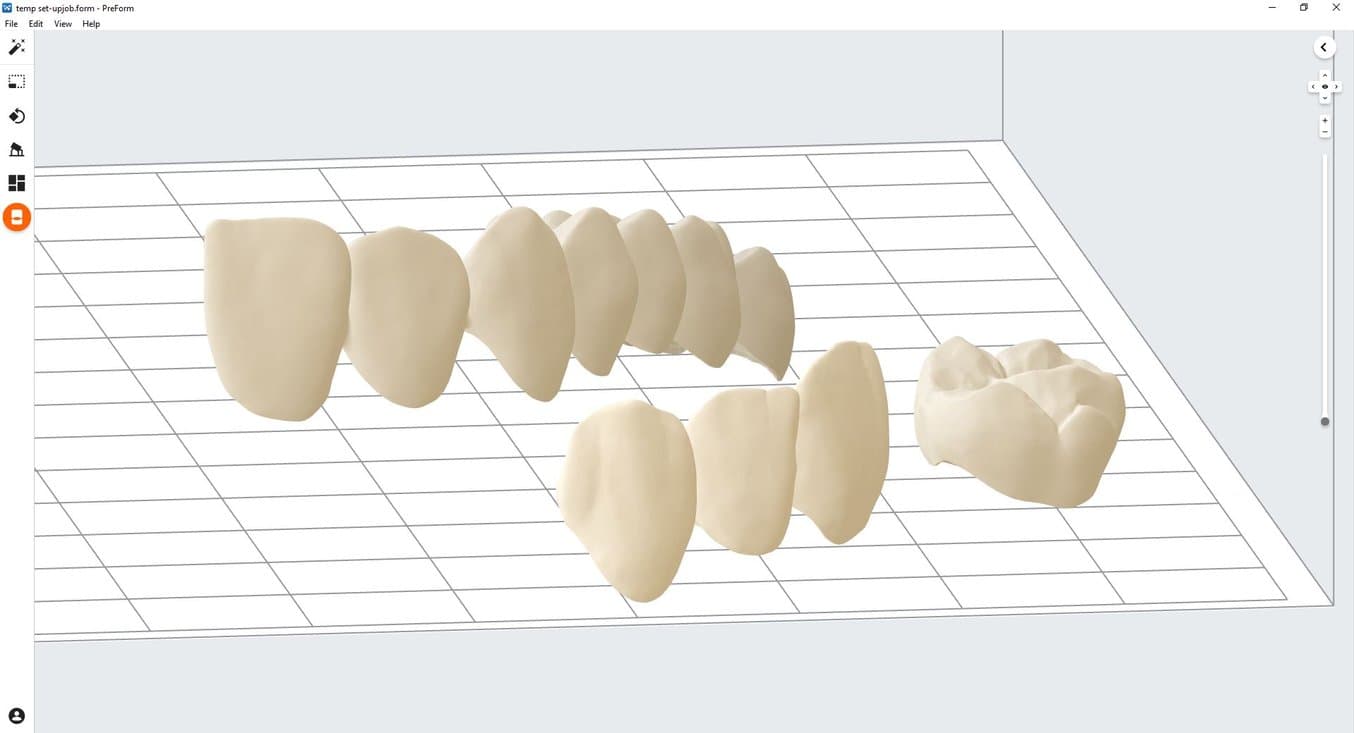

Import or open the design file(s) by dragging them into Preform or opening them using the “File” menu and locating them on your computer or network.

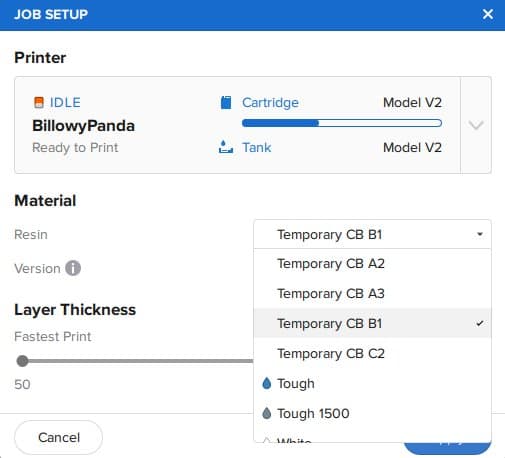

Select the material for printing by clicking the printer box in the “Job Info” menu on the right hand side.

Locate Temporary CB in the material pull down and select the appropriate shade (A2, A3, B1, C2).

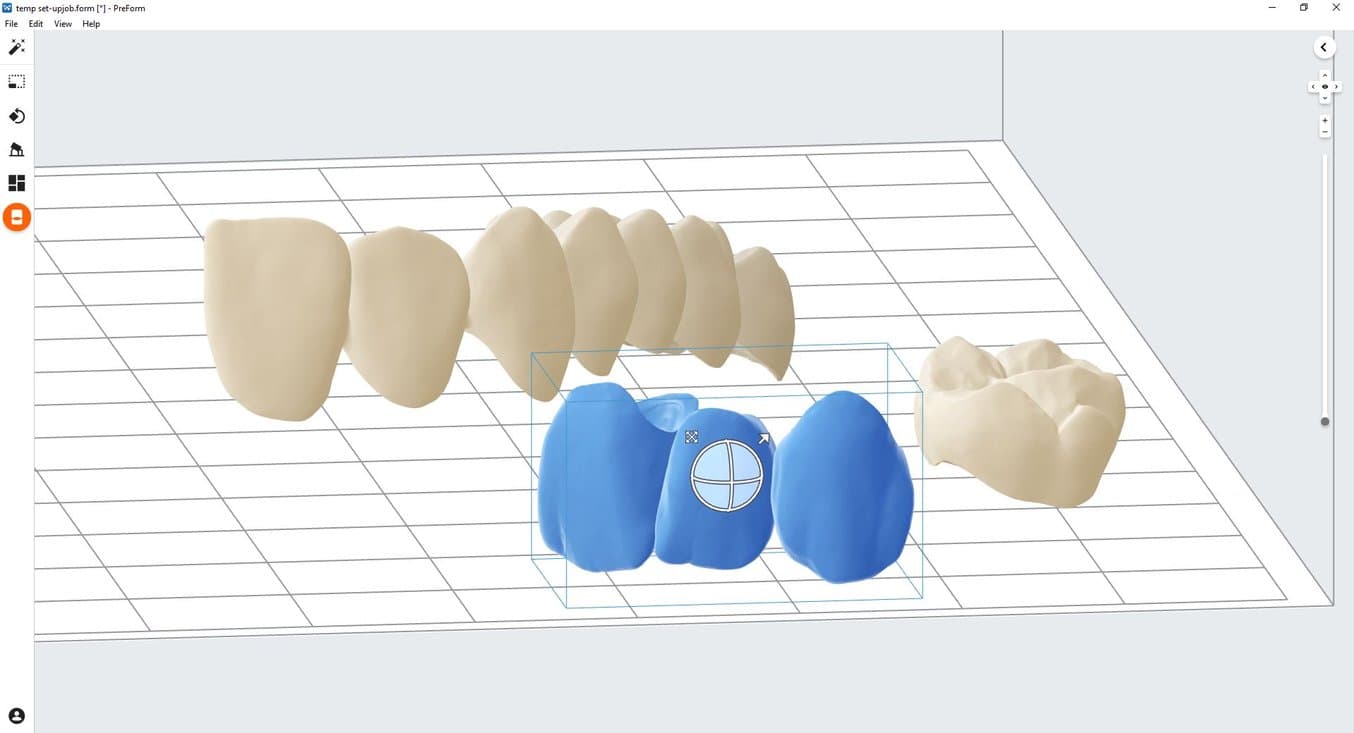

Proper part orientation is critical to ensure part accuracy and fitment.

Always position the restoration(s) horizontal to the build platform with the occlusal plane facing the build platform.

To rotate a restoration, click on the part and “click and drag” the sphere.

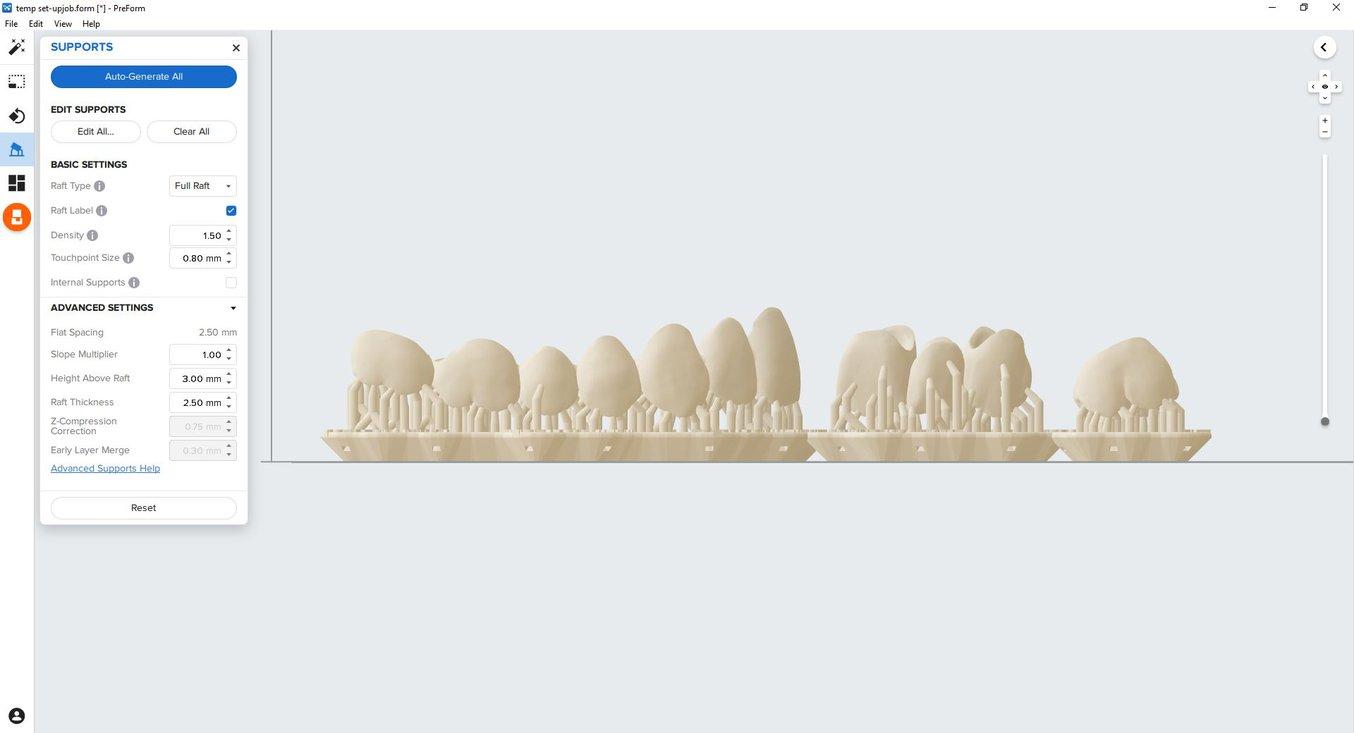

3.4 Generate Supports

3.4.1 Automatic Support Generation

Click the “Supports” button on the left side of PreForm and click the “Auto Generate Selected” or “Auto Generate All” button.

Note: The default support settings were developed to include optimal fit of complex large span bridges. For less elaborate cases, support density and touchpoint sizes may be lowered if needed.

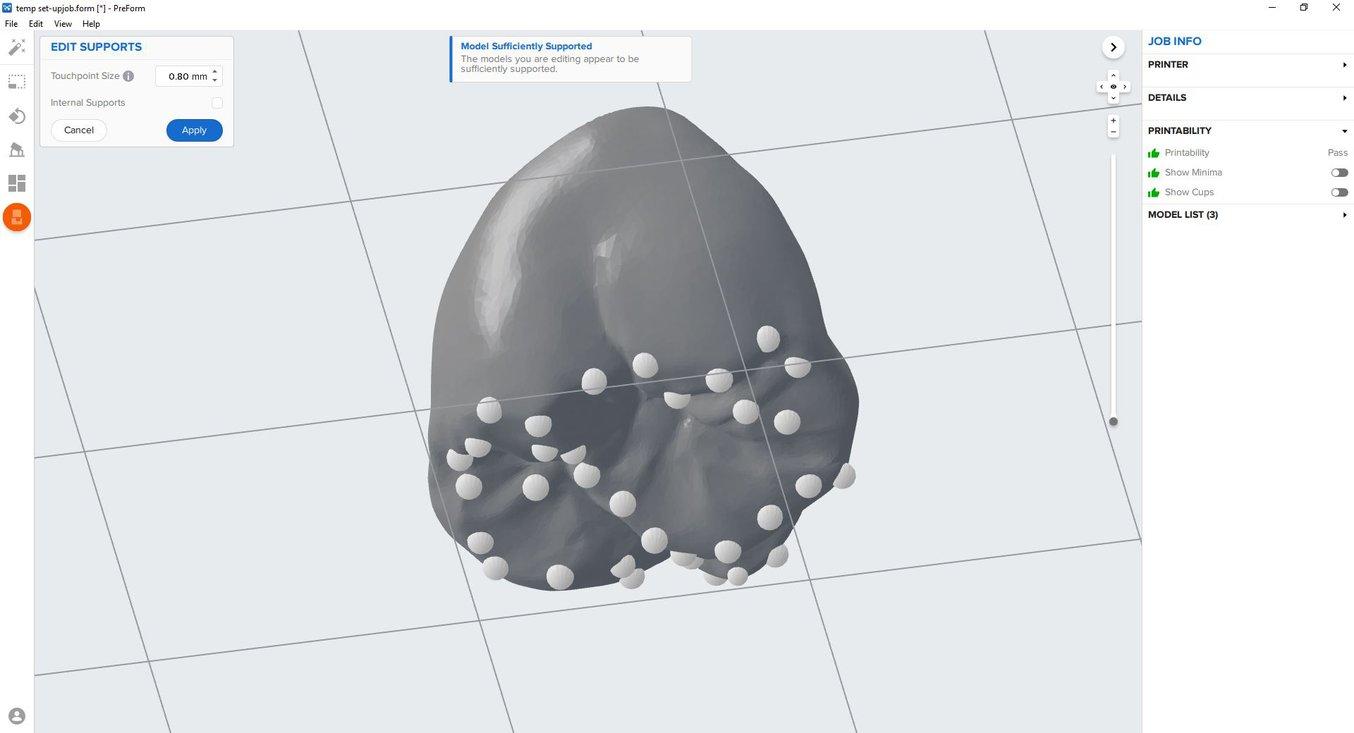

3.4.2 Manual Support Editing

If a support point is not in an ideal location, it can be moved after automatic generation by clicking the “Edit…” button in the Supports menu.

Always properly support the parts of the anatomy closest to the build platform.

PreForm will indicate in red what areas might require additional support.

Confirm under the “Job Info” menu bar on the right side of the program that “Printability” has green thumbs-up.

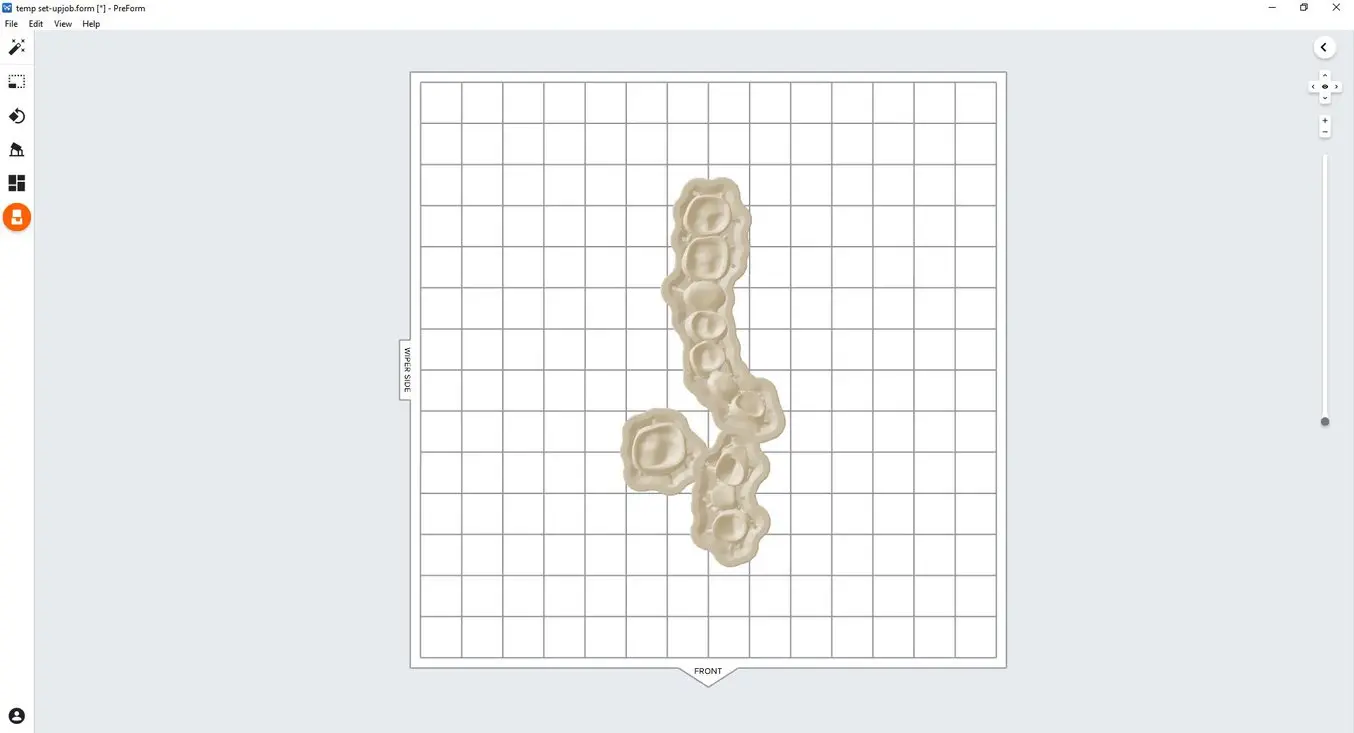

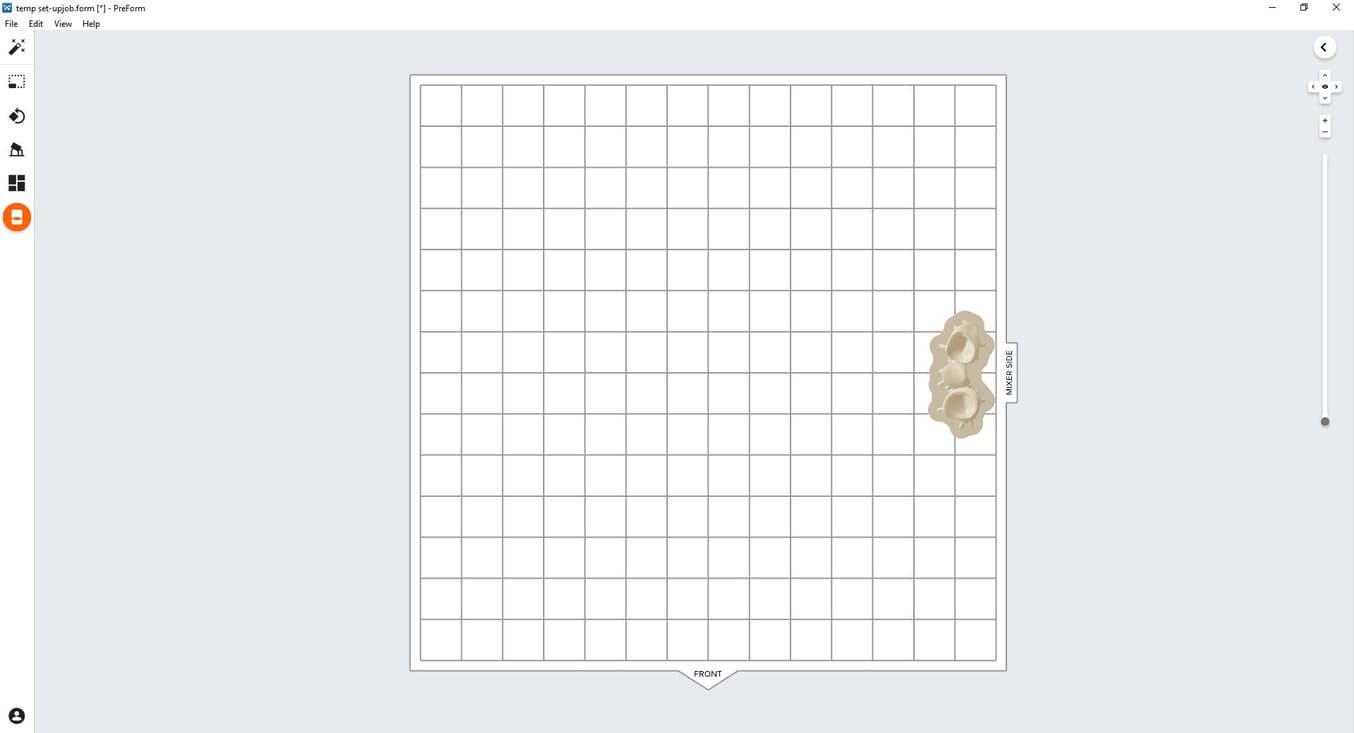

3.5 Printing Layout

Standard Printing

For most jobs it is best to place parts toward the middle of the build platform.

Tip: When printing multiple cases, overlapping rafts can optimize the use of the build volume and save material.

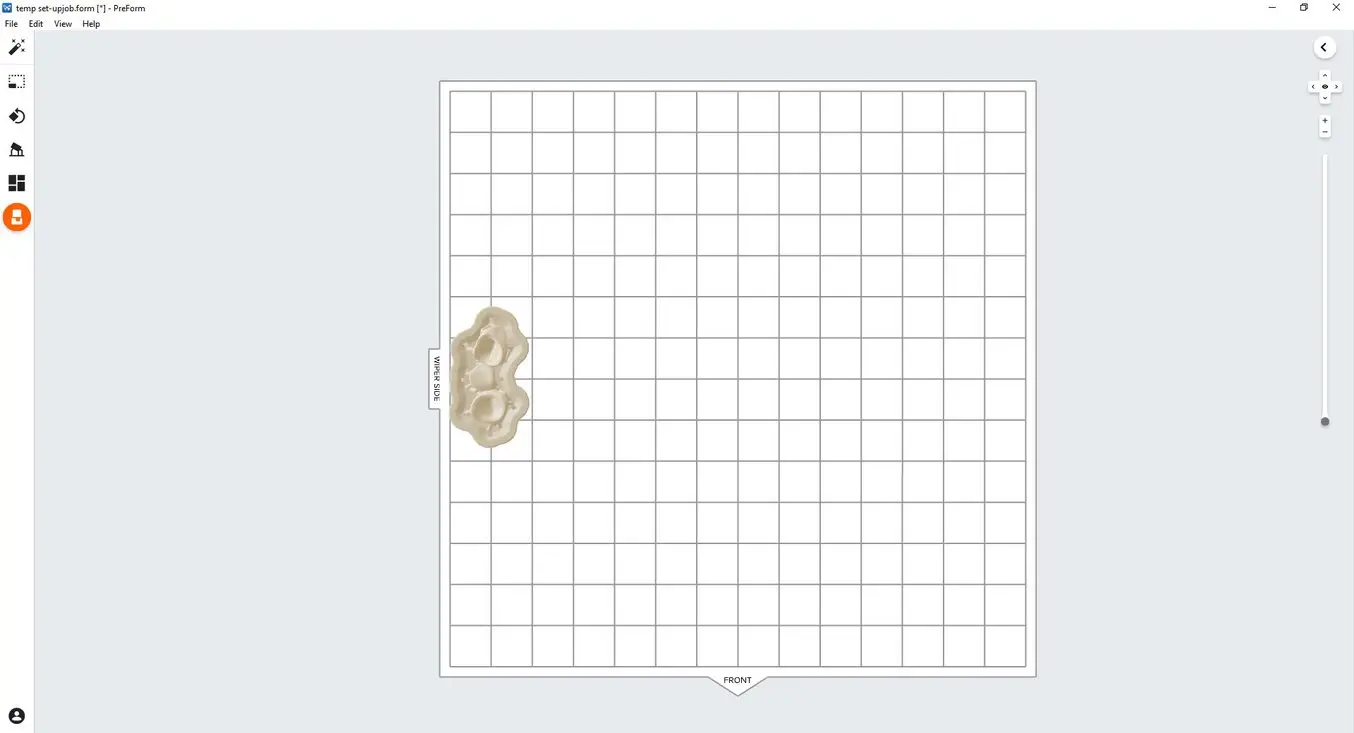

Fastest Printing on the Form 2

If the fastest print time is needed, move the parts toward the wiper side of the build platform indicated in PreForm.

Fastest Printing on the Form 3B

If the fastest print time is needed, move the parts toward the mixer side of the build platform indicated in PreForm.

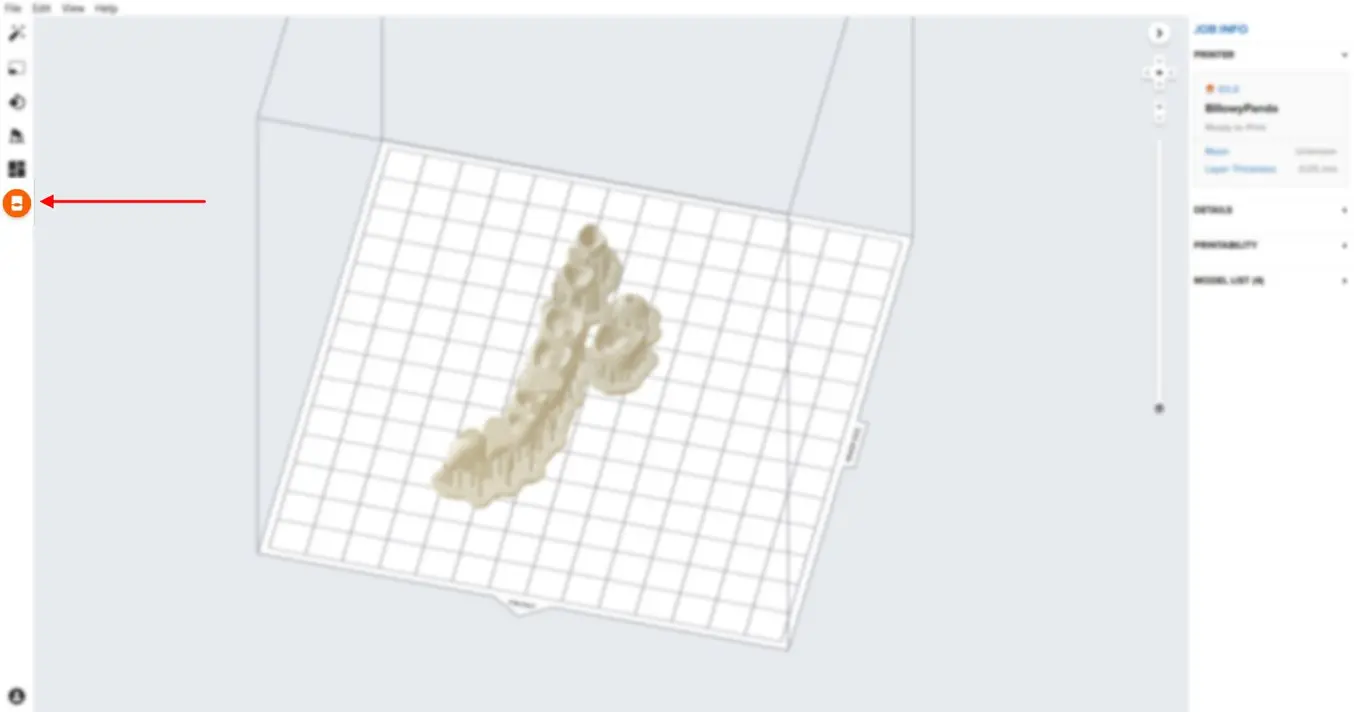

3.6 Transferring Job to the Printer

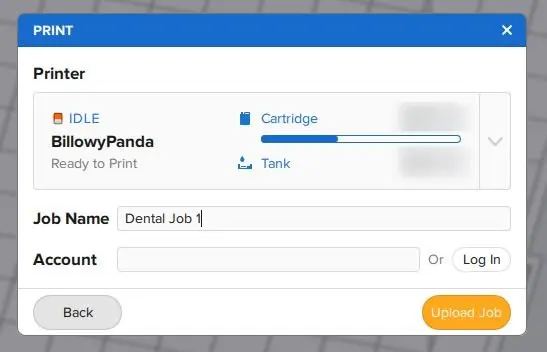

Send the job to the printer by clicking the orange printer icon on the left.

The “Print” dialog box will open to select the printer.

Click the orange “Upload Job” button to begin the transfer of the job to the printer.

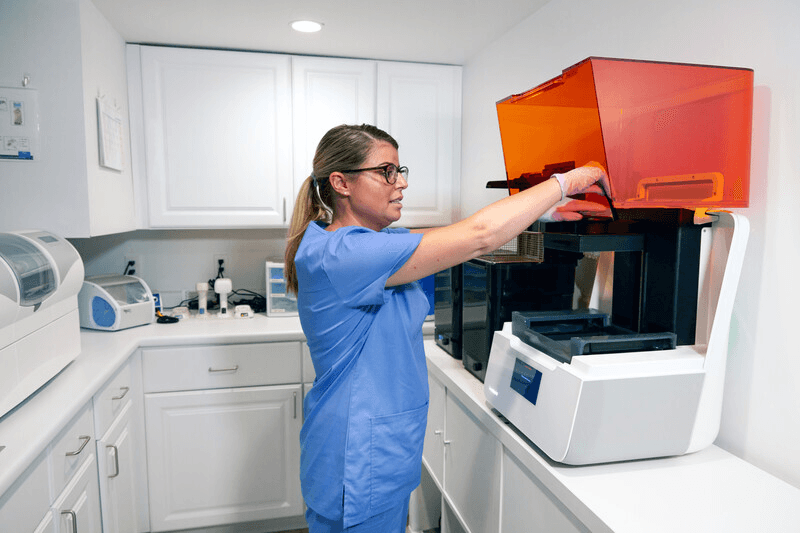

3.7 Set up the Printer

Shake the Temporary CB Resin cartridge and then insert the cartridge, a Stainless Steel Build Platform, and a compatible resin tank into the Form 2 or Form 3B printer.

- Begin printing by selecting the print job from the printer’s touch screen

- Follow any prompts or dialogs shown on the printer screen

- The printer will automatically complete the print

Note

To ensure the correct build platform is being used, check the top of the build platform. The Stainless Steel Build Platform includes a white CB mark laser etched by the Formlabs logo on the build platform handle. Temporary CB Resin has only been validated with the Stainless Steel Build Platform. Deviating from recommended instructions may adversely affect performance, biocompatibility, and aesthetics of the printed provisionals.

Attention

For full compliance and biocompatibility, Temporary CB Resin requires a dedicated resin tank, Stainless Steel Build Platform. Only use the Form Wash with other Formlabs biocompatible resins, such as Surgical Guide Resin.

Always use gloves when handling uncured resin and parts.