Print a Model Every 49 Seconds With Fast Model Resin Formulated for Industry-Leading Speed and Accuracy

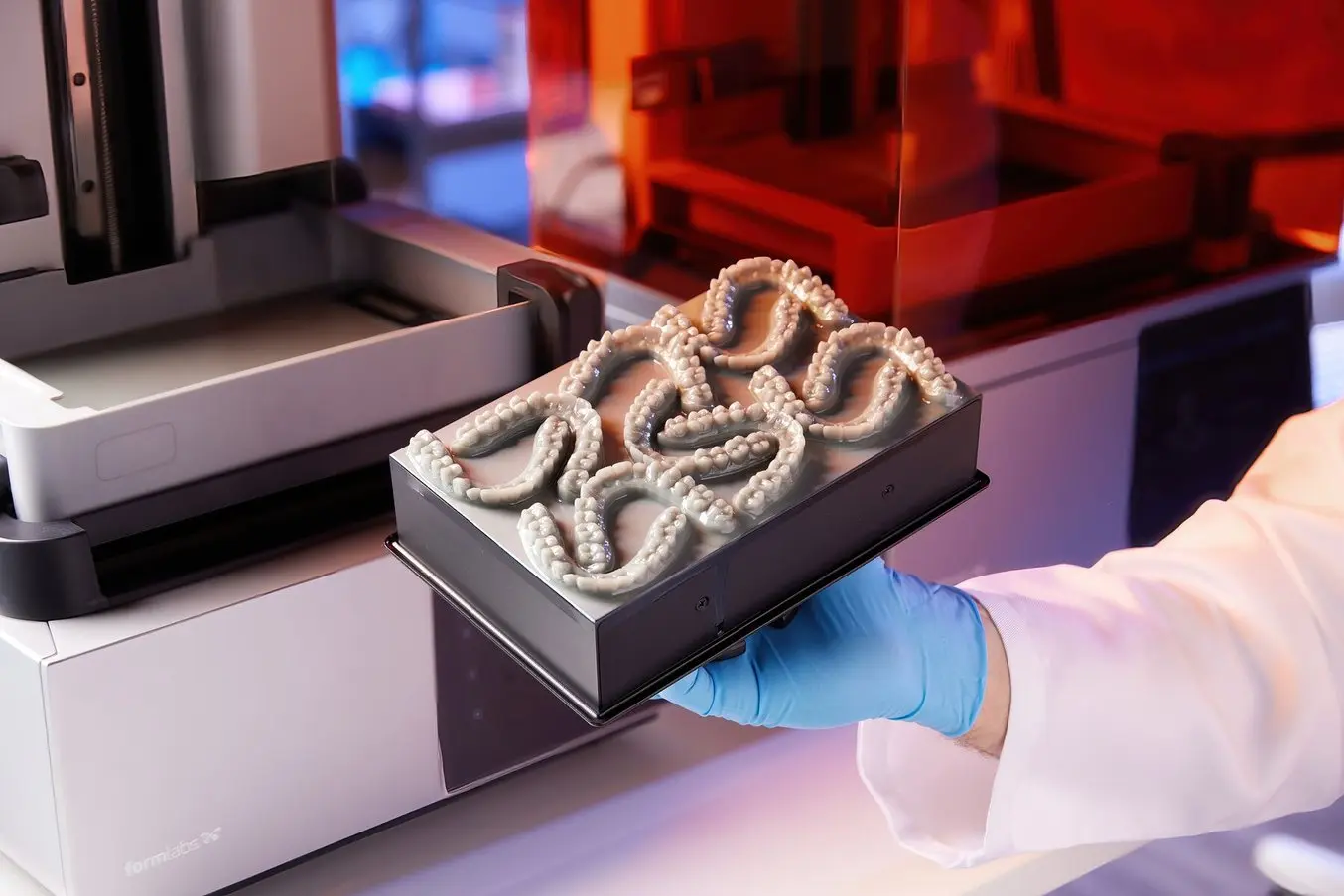

Printing 11 models in nine minutes is now possible thanks to the Form 4B 3D printer and the new Fast Model Resin.

Our in-house materials experts took advantage of the release of Form 4B to co-develop industry-leading materials, including Fast Model Resin. Fast Model Resin is optimized for speed, but without sacrificing accuracy and resolution. By developing resins in tandem with software and hardware, Formlabs can optimize for print speed and workflow efficiency while achieving peak mechanical performance.

Request Free Thermoforming Models

Curious to see the quality firsthand? We'll ship two dental models to your office, both printed in Fast Model Resin, Compare one dental model at the 160 µm Fast Arch setting for maximum speed and throughput, and one at the 100 µm Fast Arch setting for a smoother finish.

Speed and Accuracy

“I can print models in less than 10 minutes. That means this is approaching the point where models can be printed almost as fast as we can scan a patient.”

Dr. Christopher Baer, DMD, Baer Dental

The aesthetics of Fast Model Resin (top) were notably improved, with printed parts appearing more opaque and matte than Draft Resin (bottom).

For models used in thermoforming applications, dental professionals seek a material that hits that sweet spot: fast print speeds without sacrificing accuracy and resolution. Models for thermoforming require enough accuracy that the resulting thermoformed appliance correctly fits the patient. However, speed is of the essence when delivering an appliance by the end of an appointment, or when maximizing throughput at a laboratory or orthodontic practice.

On Form 4, Fast Model Resin can be used to print a full build platform of 11 models in just nine minutes. This efficiency carries over to post-processing, as well, with a five-minute wash and five-minute room temperature post-cure. This means that with continuous printing, more than 60 arches can be printed and processed in an hour.

The individual case, and the specific appliance that’s being printed, determines the settings that should be used for printing. In PreForm Dental, Formlabs’ print preparation software, users can set a layer height and select printer settings, with each offering slight tradeoffs between accuracy, resolution, and speed, so you can select the optimal balance for each print batch.

| Layer height / setting | 100 μm | 200 μm | 160 μm Fast Arch |

|---|---|---|---|

| +/- 100 μm tolerance | 97.6 | 94.7 | 97.9 |

| +/- 50 μm tolerance | 77.7 | 70.6 | 80.7 |

| Orientation on build platform | Flat or vertical | Flat or vertical | Flat only |

| Print time for a full build platform of 11 models (min) | 22 | 9 | 9 |

When it comes to resolution, printing at 100 μm allows users to capture more of the critical details, such as undercuts or unique shapes in teeth. Those details may not print correctly with higher layer heights. However, the individual case will determine what level of accuracy and resolution are needed and, therefore, what layer height settings should be used.

The 160 μm Fast Arch setting is both fast and accurate and should be the dominant setting for printing arches for aligners. However, optimal settings should be selected based on the specific application and patient dentition.

Putting Fast Model Resin to the Test

Fast Model Resin was put to the test by dental professionals in both dental laboratories and practices. Feedback from these key opinion leaders shows that they opted for different layer settings in PreForm depending on the application, so they could achieve the precise speed and accuracy desired for their workflows.

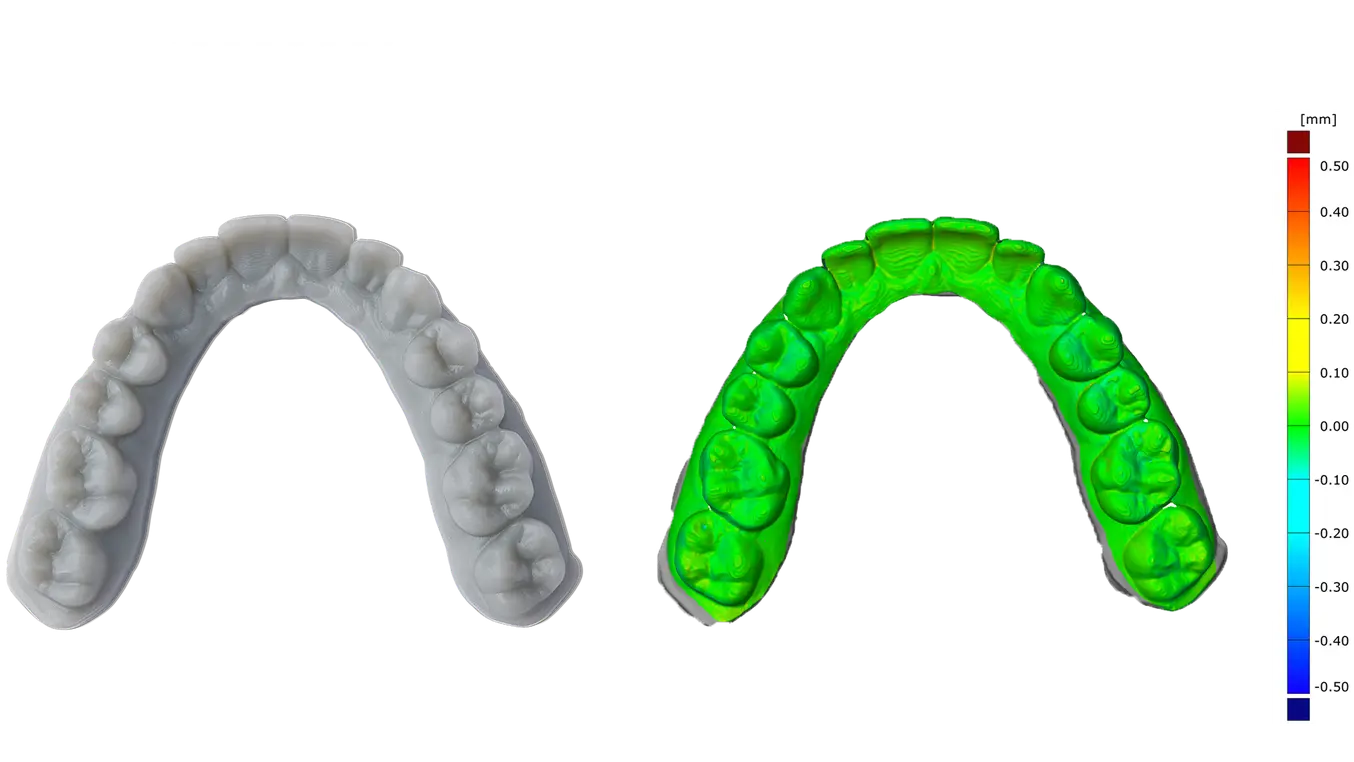

Parts printed with Fast Model Resin at 160 μm layer height have 97.9% of the surface within 100 μm of the CAD model.

Stephan Kreimer, master dental technician and director of Kreimer Dentallabor GmbH & Co. KG, says, “The 160-micron Fast Arch settings impress me for very quick models. It’s incredible to produce models within 30 minutes, including post-processing.” Even printing at this speed, the models are highly accurate, with 97% of the surface within 100 μm of the CAD model.

At Baer Dental, Dr. Christopher Baer, DMD, says that for cases with more complicated tooth anatomy or more angles and undercuts on the teeth, he’ll print at a 100 μm height. “Patients have preferred the thermoformed retainers we make off of the 100 μm layer height. They tend to fit better, especially in patients with more detailed anatomy.”

Dr. Baer has found Fast Model Resin to be useful for chairside dentistry as well as for producing aligners. In the case of a patient who broke some composite bonding, it was easy enough to print a model and thermoform a tray to use as a template for repairing the tooth, all over the course of one appointment.

Production-Optimized Workflow

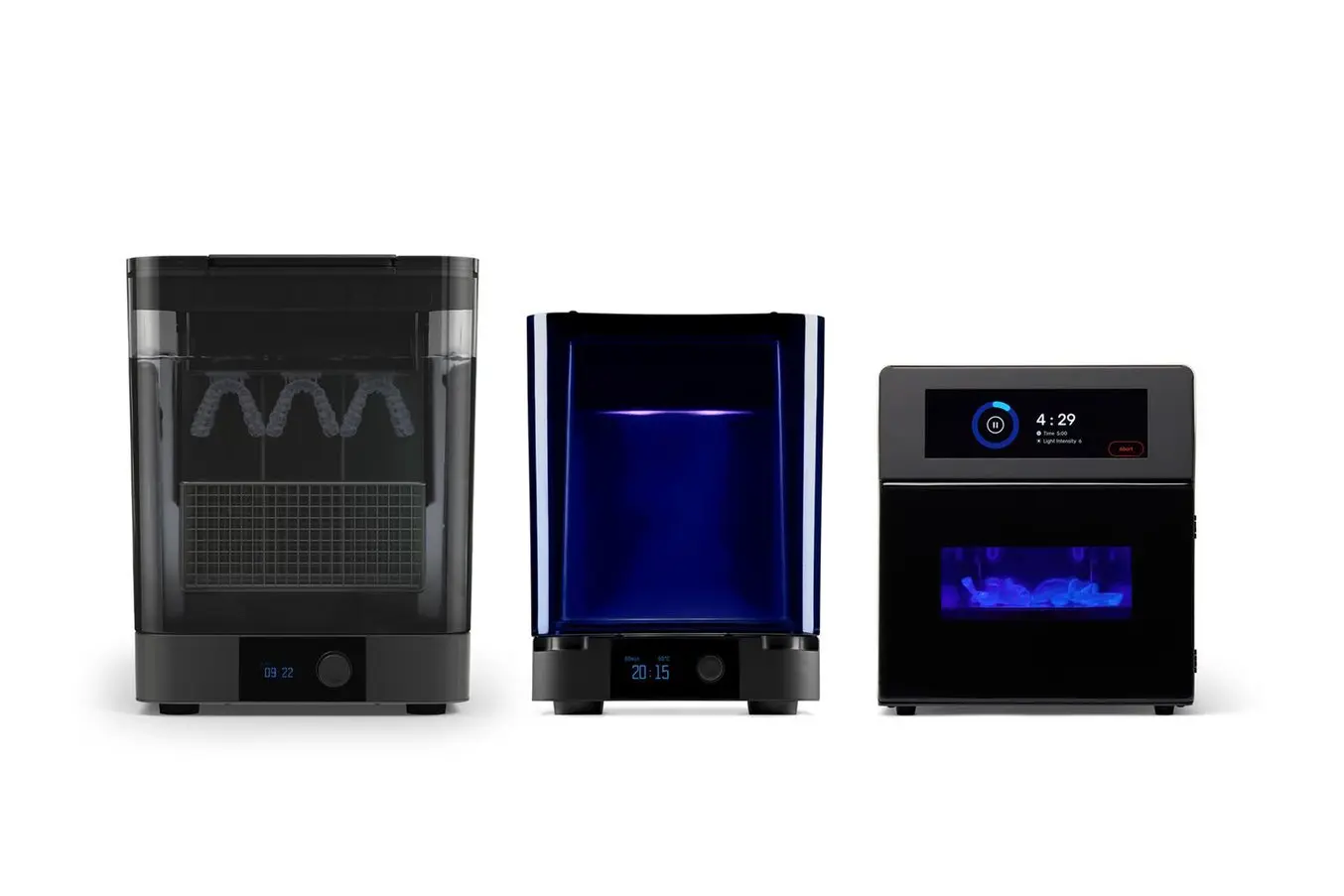

Speed improvements are not limited to print time, but post-processing time as well, for a more efficient, optimized workflow that’s easy to learn.

1. Scan

Scan the patient’s dentition with an intraoral scanner or scan a physical impression or poured model with a desktop 3D scanner.

2. Design

Import your scans into the appropriate orthodontic or dental computer-aided design (CAD) software and execute your designs, exporting your model as an STL or OBJ file.

3. Print

In PreForm Dental, select your material and desired print settings and import your STL or OBJ file. Orient parts directly on the build platform. Or, if you need to fit more models per print, orient parts vertically, with supports.

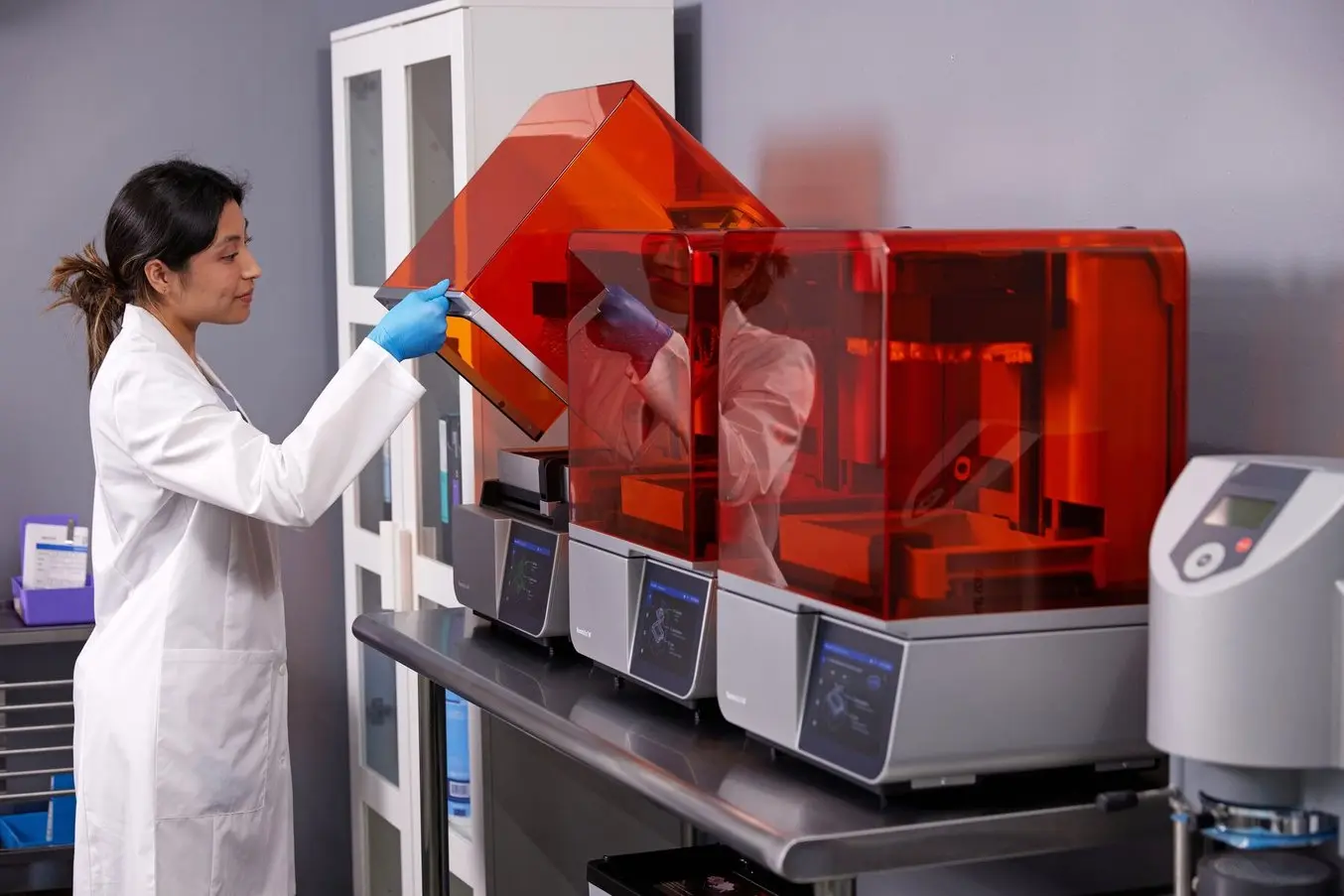

Upload the print and prepare the printer by inserting a resin tank, Fast Model Resin cartridge, and clean build platform into the printer.

4. Post-Process

Remove printed parts from the build platform and wash the printed parts in 99% isopropyl alcohol (IPA) in the Form Wash for five minutes. Modify this wash time based on part geometry and solvent purity.

After washing, cure for five minutes at room temperature. If supports were used, remove supports.

5. Thermoform

Use a dental thermoformer machine on the printed model to make the appliance. Always start by using the recommended settings for the equipment and material being used.

Cut out and finish the appliance.

Formlabs Dental Materials Overview: Discover What You Can Print With the Form 4B

This webinar will guide you through the various benefits and applications enabled by Form 4B, including its existing biocompatible materials and newly developed formulations for model production such as Fast Model Resin and Precision Model Resin.

Mechanical Properties

While developing Fast Model Resin, Formlabs engineers were able to achieve blazing fast print speeds and also deliver superior mechanical properties. Compared to parts printed with Draft Resin, the predecessor of Fast Model Resin, parts printed with Fast Model Resin are stronger, stiffer, and more resistant to fracture. These mechanical properties make Fast Model Resin an ideal choice for printing models for thermoforming.

| Fast Model Resin | Draft Resin | |

|---|---|---|

| Ultimate Tensile Strength | 55 MPa | 36 MPa |

| Tensile Modulus | 2.48 GPa | 1.7 GPa |

| Elongation at Break | 15% | 5% |

| Flexural Strength | 98 MPa | N/A |

| Flexural Modulus | 2.60 GPa | 1.8 GPa |

| Notched Izod | 30 J/m | 29 J/m |

Data for parts post-cured five minutes at ambient temperature.

Three Workflows to Produce Clear Aligners In-House: More Options for You and Patients

3Shape and Formlabs experts will take you through three flexible workflows from an intraoral scan to clear aligners.

Print With Blazing Speed

As a vertically integrated company, we can tune every aspect of development, production, and printing to achieve industry-leading performance, which wouldn’t be possible by simply making adjustments.

The blazing print speeds of Fast Model Resin open up opportunities for same-visit dentistry, and for scaling production capacity at laboratories and orthodontic offices, as more prints in less time add up to more prints over the course of an hour, a shift, or a work week.

In the five minutes it takes to read this article, you could print six models. Purchase Fast Model Resin for Form 4 to start printing now, or watch our materials webinar to learn more.