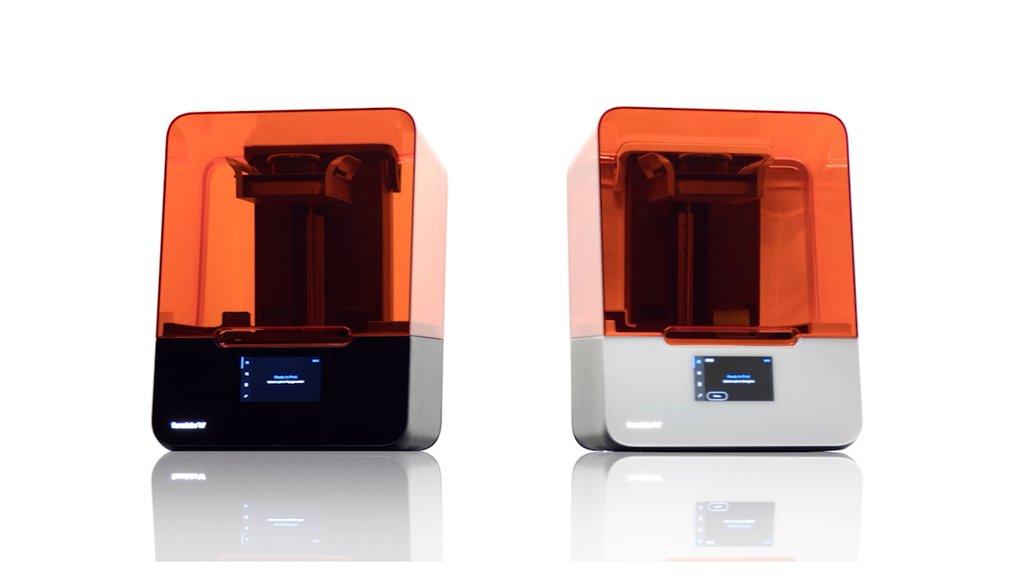

Form 3B+

The Most Trusted Dental 3D Printer

The Form 3B+ provides dental professionals with maximum performance and versatility with an easy workflow. 3D print a wide variety of dental applications in-house with minimal interaction and unrivaled print accuracy and surface finish.

Form 3B+ is now succeeded by Form 4B, our next-generation dental 3D printer, which improves upon its foundation in every possible way.

The Next Generation of Dental 3D Printing

Form 4B is powered by our Low Force Display™ (LFD) Print Engine, setting the new industry standard for blazing-fast speed. Create high-quality dental models and biocompatible appliances fast, with easy workflows, leading reliability, and stunning part quality using the Form 4B ecosystem.

Speed That Scales

Powered by the same groundbreaking LFD technology, Form 4BL can print more than 100 models per hour with up to 3x fewer interactions than Form 4B, so you can increase efficiency and reduce labor costs.

Fully Validated Workflows for the Practice and the Lab

The Formlabs Dental 3D printing ecosystem enables plug-and-play integration with your existing workflow for a seamless experience. The Form 3B+ is an all-encompassing digital workflow solution, including intuitive and innovative software, a resin portfolio for 10+ indications, including a wide variety of biocompatible materials, and simple, automated post-processing.

No matter if you are ready to scale or engage for the first time in digital dentistry, the Form 3B+ is ready to produce high-quality parts you’ll be proud to deliver, without hassle, or prohibitive costs.

Meet the Form 3B+

Industry Leading Print Quality

The Form 3B+ is powered by our unique SLA printing process, delivering precise, unmatched surface finish and print accuracy across multiple dental applications when compared to other 3D printers.

The Form 3B+ delivers:

The Easiest 3D Printer to Learn and Use

Bring digital dentistry to your practice or lab for the first time, or scale to dozens of machines, the Form 3B+ is ready to grow with your business.

Your Form 3B+ comes with:

Simple, Low-Maintenance Resin Handling

The Form 3B+ Resin Tank lasts up to four months, reducing wasted resin and maintenance. Our cartridge system is designed to prevent spillage and keep your workspace clean, while minimizing resin waste at the same time. Spend less time cleaning your workspace and more time focusing on growing your business. After printing, use Form Wash and Form Cure streamline and automate rinsing and post-curing of prints.

The Printer for Maximum Performance and Versatility

Produce a wide range of dental applications with our versatile printer and our dedicated dental resins, delivering high-performance parts with peace of mind through regulatory compliance and certified biocompatibility.

Draft Resin

8

$2-3

20 minutes

Note: print time and cost will vary based on part geometry, material, layout, and orientation.

Maximize Your 3D Printer Fleet’s Throughput with Seamless 24/7 Production

Reach new levels of productivity with a fully automated fleet of Form 3B+ 3D printers that you can operate from anywhere. Skyrocket your ability to produce high-quality, affordable dental models and appliances with 24/7 back-to-back production with the Formlabs Automation Ecosystem: Form Auto, Fleet Control, and Resin Pumping System.

Quick and Easy Part Removal

Build Platform 2 with patented Quick Release Technology allows you to remove parts from the build platform without tools in seconds, minimizing interaction time and speeding up part removal.

Complimentary, Powerful Software

A suite of efficient, smart, and intuitive tools to enable your productivity in an easy way. Our software is designed to help your team work more efficiently. PreForm makes print production easy, accessible from anywhere, and scalable at every growth stage.

Materials Developed by Formlabs

Formlabs resins are developed to work seamlessly with the Form 3B+. We’ve done rigorous testing so you don’t have to.

Automated Wash and Cure

Deliver ready-to-use parts with less time and effort. Form Wash and Form Cure streamline and automate rinsing and post-curing of prints.