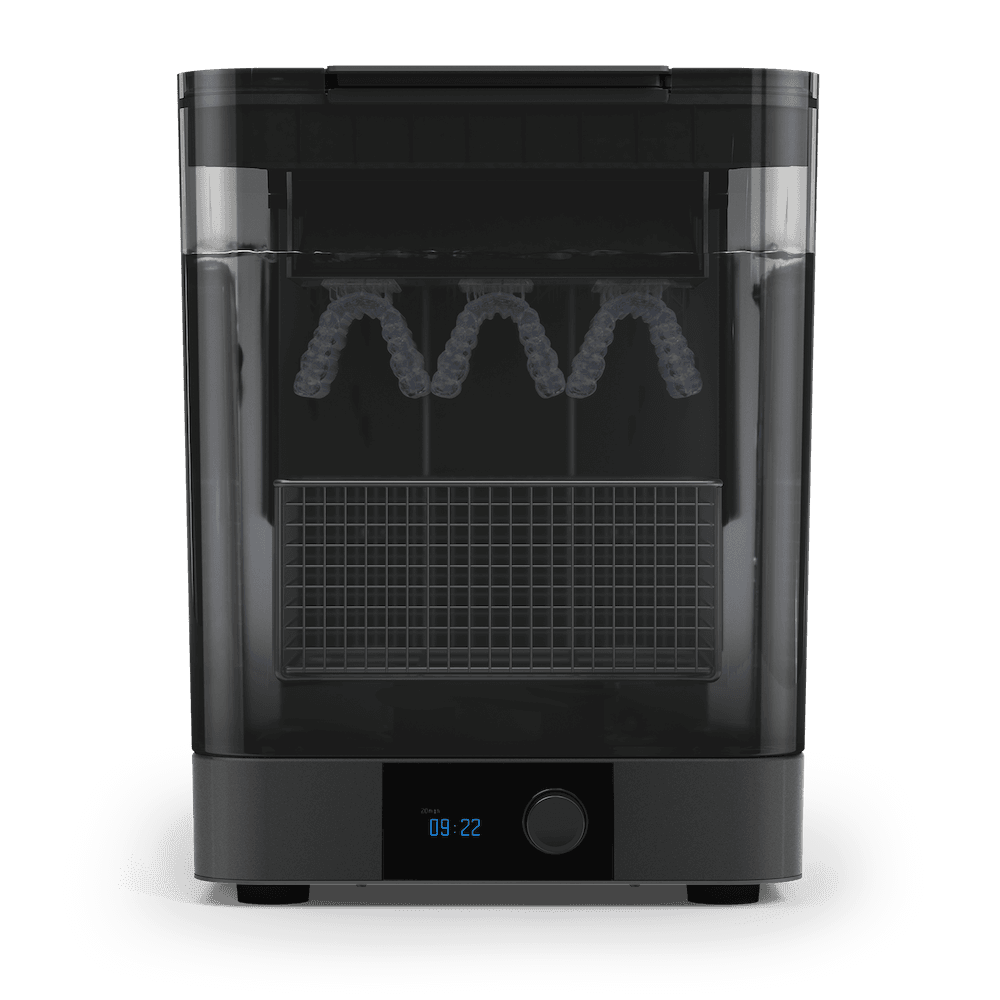

Form Wash V2

FH-WA-03

Estimated delivery: Feb 16 - 18Form Wash automatically cleans printed parts thoroughly and efficiently with IPA or alternative solvents. Keep parts directly on the Build Platform as you transition them from the printer to Form Wash, or remove parts and place them in the wash basket. Parts are precisely and thoroughly agitated in solvent with an impeller, getting every nook and cranny perfectly clean, automatically for the appropriate time. When washing completes, the Form Wash automatically raises parts out of the IPA so they can air dry.

- Form Wash V2

Automate Cleaning With Form Wash

Adaptable to Build Platforms

Seamlessly switch between build platforms with adjustable platform mounts, configurable at various heights and widths.

Improved Agitation

Select your material from a list and let Form Wash auto-clean your parts for the appropriate time thoroughly with 3x more agitation than the previous generation.

Flexible Solvent Volume

Tailor the solvent volume to the size and quantity of your parts. Use lower solvent quantities for smaller parts and builds to increase resource efficiency.

Compatible with Variety of Solvents

Our recommendation is using IPA for the best cleaning performance, but alternative solvents such as TPM are also compatible with Form Wash.

Set It and Forget It

Simply set the appropriate time and let Form Wash get to work.

10

Default wash time when using fresh isopropyl alcohol (IPA).

7 - 15

Flexible solvent volumes to wash parts of all sizes.

120

Number of prints per IPA refill with regular use. Wash 67% more parts before replacing solvent compared to the previous generation.

Form 4 Workflow in Minutes

Form Wash is a part of a 3D printing ecosystem that’s easy to learn and use and requires little intervention or maintenance. Watch the video to learn the basics of how to use Form 4, from the software and materials to printing and post-processing.

Tech Specs

| Form Wash V2 | Form Wash L | |||

|---|---|---|---|---|

| Printer Compatibility | Form 4, Form 4B, Form 3/+, Form 3B/+, Form 2 | Form 3L, Form 3BL, Form 3/+, Form 3B/+, Form 2 | ||

| Dimensions | 31.5 x 29.3 x 40.5 cm 12.4 x 11.5 x 15.9 in Height when open: 71.4 cm (28.1 in) | 78.0 x 46.0 x 67.0 cm 30.7 x 18.1 x 26.4 in Height when open: 113 cm (44.5 in) | ||

| Weight | 8.6 kg (without solvent) 18.9 lbs (without solvent) | 56.7 kg (without solvent) 125lbs (without solvent) | ||

| Bucket Volume | 14.4 L 3.8 US gal | 37.9 L 10 US gal | ||

| Maximum Part Size | 20 x 14.5 x 19.5 cm 7.9 x 5.7 x 7.6 in | 33.5 x 20 x 30 cm 13.2 x 7.9 x 11.8 in | ||

| Suggested Operating Environment | Suggested 18—28 °C Suggested 64—82 °F | Suggested 18—28 °C Suggested 64—82 °F | ||

| Agitation Method | Magnetically coupled impeller | Magnetically coupled impeller | ||

| Included Accessories | a. Wash Bucket b. Wash Basket c. Hydrometer d. 2x Platforms Mounts | a. Wash Bucket b. Wash Basket c. Electric Solvent Pump d. Flexible Scraper e. Scraper f. Flush Cutters g. Rinse Bottle h. Gloves i. Form 3 Build Platform Adaptor | ||

| Power Requirements | 90–240 V 2.0 A 50/60 Hz 50 W | Input (NA) 100 - 120 VAC, 50-60Hz, 1A Input (EU) 220 - 240 VAC, 50-60Hz, 1A | ||

| Compatible Solvents | Formlabs Resin Washing Solution, IPA, TPM, Water | Formlabs Resin Washing Solution, IPA, TPM, Water |