Permanent Crown Resin 1kg (0.7 L)

Dental

SLA

Multiple Shades

116 MPa

4,090 MPa

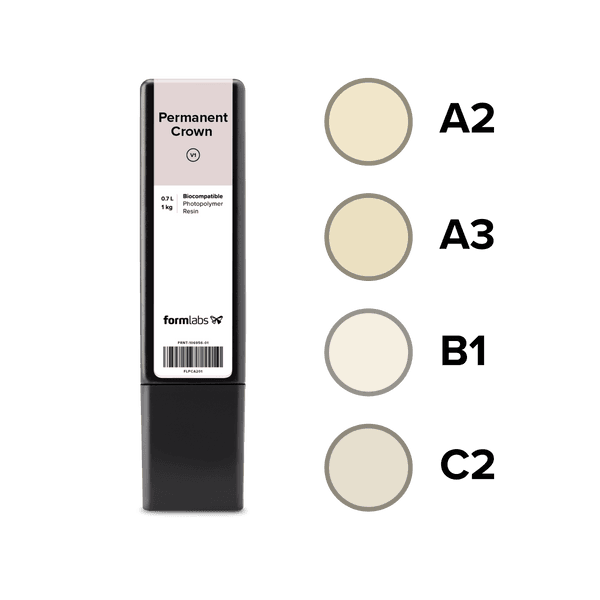

Resin Shade

| Bulk order quantity (L) | Discount % |

|---|---|

| 1 | 0% |

| 30 | 15% |

| 60 | 20% |

| 120 | 25% |

| 240 | 30% |

| 1,000 | 35% |

| 2,000 | 40% |

| 3,000 | 45% |

Permanent Crown Resin is a tooth-colored, ceramic-filled resin for 3D printing of permanent single crowns, inlays, onlays, and veneers. Permanent Crown Resin produces high strength, long term restorations with an accurate and precise fit. Low water absorption and a smooth finish ensure restorations made from Permanent Crown Resin have a low tendency to age, discolor, or accumulate plaque.

Available in four VITA shades (A2, A3, B1, C2).

Read our Application Guide to learn the complete digital workflow and best practices for making 3D printed permanent restorations on your Formlabs 3D printer.

Note: Permanent Crown Resin V1 will no longer be available for direct purchase beginning on Sunday, March 1, 2026. Formlabs recommends upgrading to Form 4B printer and switching to BEGO™ VarseoSmile® TriniQ® Resin V1.

Permanent Crown Resin 1kg (0.7 L) has been added to your cart.

Why Choose Permanent Crown Resin?

Low water absorption and a smooth finish ensure restorations made from Permanent Crown Resin have a low tendency to age, discolor, or accumulate plaque.

High Strength

Produce a rigorously strong and precise permanent restoration with a validated workflow that ensures consistent production.

Aesthetic

Leverage a tooth-colored, ceramic-filled resin to create confident patient smiles.

Affordable

With an accessible price point and low cost per part, high-quality restorations are within reach for dental businesses of all sizes.

Biocompatibility

Provide the patient and clinician the peace of mind they deserve.

Applications

Permanent Crown Resin produces high strength, long term restorations with an accurate and precise fit.

Consider Permanent Crown Resin for:

Material Properties*

Permanent Crown Resin

Density

Viscosity

Flexural Modulus

Water Solubility

Water Sorption

* Material properties may vary based on part geometry, print orientation, print settings, and temperature. Test samples were printed with a Stainless Steel Build Platform on a Form 3B printer with 50 μm Permanent Crown Resin settings. The printed samples were post-processed as recommended in the Instructions for Use. Screen reader support enabled

Post-Processing

Washing

The foundational step in any SLA post-processing workflow is to remove excess resin on the surface of the parts through an alcohol wash. Please refer to the material's manufacturing guide/IFU for washing instructions.

Curing

For biocompatible materials, post-curing is necessary to achieve the safety standards determined by regulatory agencies. Please follow the material’s manufacturing guide/IFU for proper post-processing.