Dr. Scherer and Dr. Shotell on the Resin Revolution Empowered by Open Material Mode

“I’ve always believed that the best tech makes clinicians better, not busier.”

Dr. Michael Scherer, DMD, MS

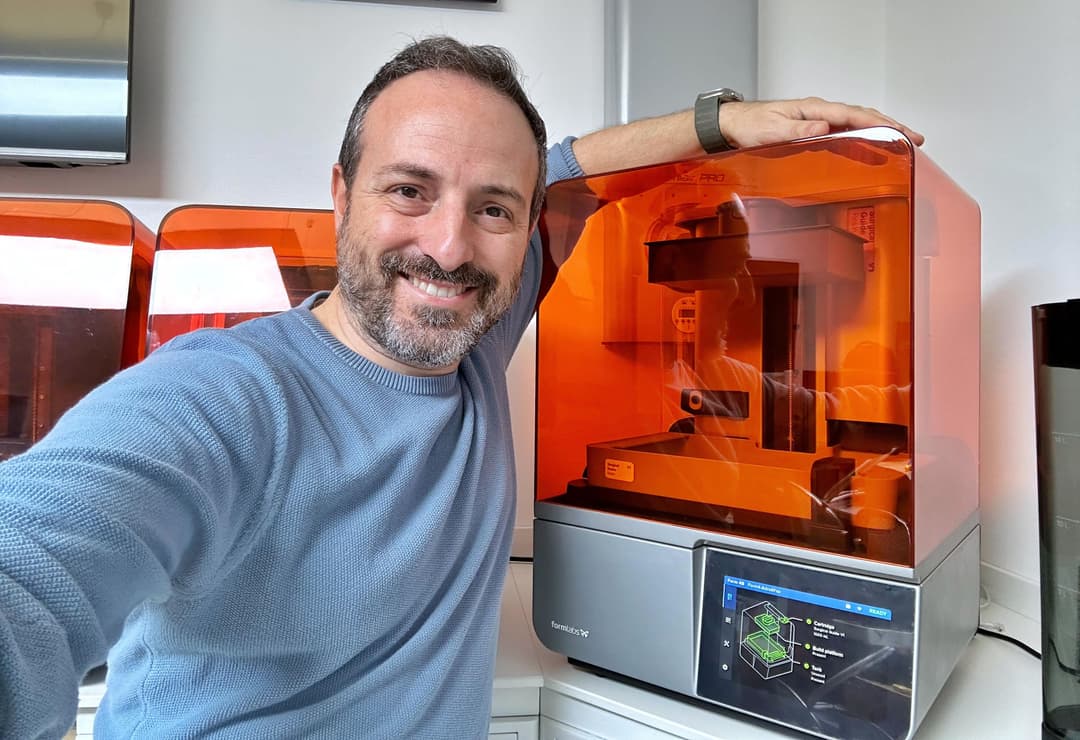

As an avid technology and computer hobbyist, Michael Scherer, DMD, MS, brings his zeal for technology into his dentistry, pioneering digital approaches and 3D printing workflows. Dr. Scherer and his wife, Dr. Melissa Shotell, DMD, MS, ABO certified Orthodontist, have been testing Open Material Mode (OMM) on Form 4B, bringing their extensive experience both with patients and as university faculty to their evaluations.

In this guest post, Dr. Scherer shares his insights and enthusiasm for the “resin revolution” enabled by open 3D printer platforms and how it can empower dental practitioners.

Get in Touch

Whether you need to produce occlusal splints in-house, or are looking for high-throughput production of dental models, we're here to help. Get in touch with a dental expert to find the right solution for your business.

3D Printing Is Perfect for Dentistry

Let’s face it, going to the dentist isn’t fun for patients. From goopy impressions to waiting for what feels like forever for teeth to be fixed because of having to wait for teeth to be made by outsourcing at a laboratory, the patient experience isn’t ideal. Enter digital technology!

I am a digital dentistry and 3D printing enthusiast. I have long thought that dentistry is perfect for 3D printing, and 3D printing is perfect for dentistry! We are moving from alginate and stone models to digital impressions, hand-waxed dentures to 3D printed ones, and now we’re at the edge of a resin revolution.

Highly detailed diagnostic model printed with Precision Model Resin.

Not long ago, 3D printing in dentistry was a novelty – something tucked away in the R&D lab or reserved for techie/nerdy dentists. In my clinical practice I have personally used over 20 3D printers in various applications over the years. The biggest challenges I have experienced are simplicity and flexibility. When I first got my original Form 1 over 10 years ago, it was a game-changer from a technological point of view. A simple-to-implement, affordable 3D printer that could print dental models easily, wow!

A big limitation of implementing 3D printing over the years was finding biocompatible materials that could be used for intraoral applications. Over the past years, the world of dental 3D printing has heavily focused on materials. It feels almost like we are in a new era, a quasi-revolution of dental materials. And yes, I’ll make a claim that we are in a resin revolution.

Fast forward to today…. 3D printing is prime time.

Open Material Mode: Because We Want Freedom

Recently, I have been diving deep into the world of the Formlabs Form 4B, a machine that’s fast, precise, and now, Open Material Mode takes it to the next level.

“Now, we can print with materials we already enjoy working with, like Dentsply Lucitone Digital Print Denture™ SystemLucitone Digital Print Denture System, and Pac-Dent Rodin resins right on an ecosystem that we enjoy working with today.”

Dr. Michael Scherer, DMD, MS

If you’re like me, you love a good, validated workflow. But sometimes, the best materials aren’t always locked inside a walled garden. That’s where OMM on Form 4B comes in.

Form 4B with OMM allows the clinician to break out of the “only use our resins” mold and print with third-party resins — yes, even with materials like:

-

Lucitone Digital Print Denture™ System from Dentsply Sirona: Strong, biocompatible, and one of the industry standards for printing full dentures and LOCATOR overdentures.

-

Rodin Denture Base and Titan Teeth Resins from Pac-Dent: Fantastic aesthetics, excellent performance, and impressively cost-effective for standard dentures and LOCATOR overdentures.

-

Rodin Titan from Pac-Dent: The next-gen ceramic-infused nanohybrid resin for full-arch prosthetics, both for interim and long-term applications that is perfect for LOCATOR FIXED prosthetics.

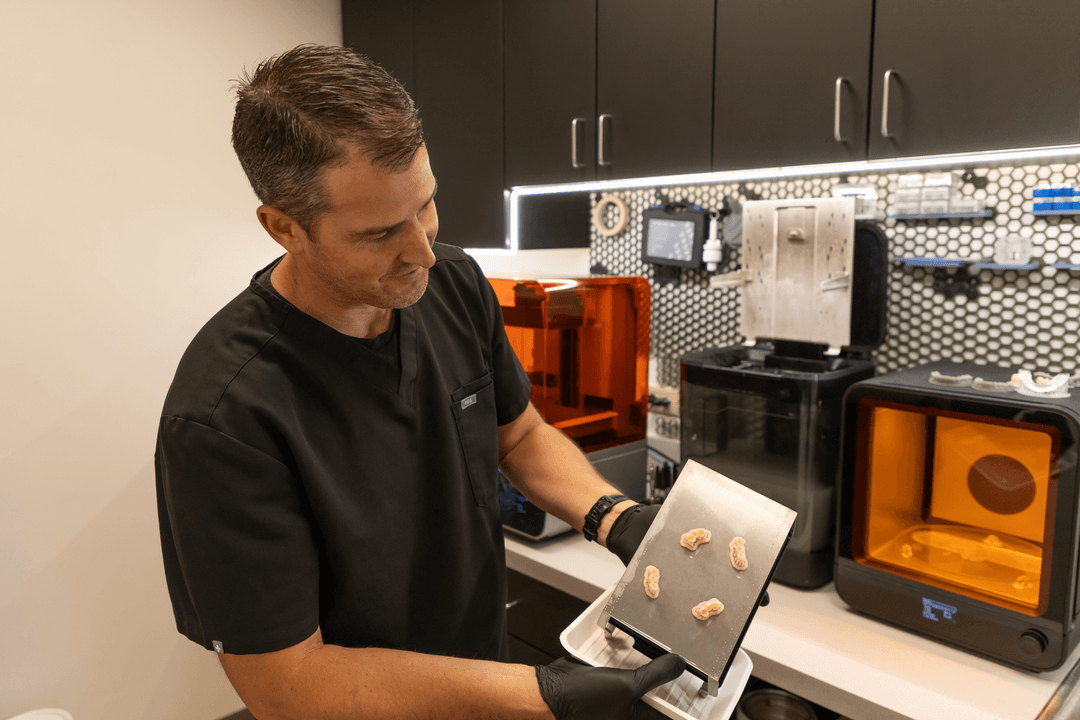

Printing denture bases on Form 4B with OMM using Lucitone Digital Print Denture™ System from Dentsply Sirona. Photo: Dr. Scherer

With OMM, Titan Teeth Resins can be printed on Form 4B. Photo: Dr. Scherer

With Form 4B and OMM, you’re not just getting flexibility, you’re taking back control of the digital workflow.

Request a Free 3D Printed Restorative Dental Model

Curious to see the quality firsthand? Pick a material and we'll ship you a free sample part 3D printed on the Form 4B to evaluate.

Clinician to Clinician: What Open Workflows Mean in the Real World

While I love “nerding out” about microns, layers, and z-axes with my fellow geeks, at the end of the day, it’s about practice efficiency and taking care of our patients. Here’s what open workflows mean in the real world.

Custom Denture Workflows

I can design a complete denture in exocad or 3shape, slice it in PreForm, and print it using either Formlabs validated resins or, now, resins that are validated from Dentsply, PacDent, and others. This is possible simply by downloading the FPS file that is available from the resin manufacturer.

More Control for the Clinician

Clinicians love flexibility. With Formlabs printers, I can print prosthetics using Formlabs Denture Base Resin and Premium Teeth Resin. Now, with Formlabs printers and Open Material Mode, I can now also print Lucitone Digital Print Denture™ System or PacDent Denture Base & Teeth resins on my Form 4B — all in a single workflow.

Printing Long-Term Restorations

While our patients love great aesthetics, clinicians love the ability to print long-term restorations using lower cost technology compared to traditional manufacturing. Additionally, the ability to print resins such as Rodin Titan on the Form 4B quickly, often in less than 60-90 minutes, opens up a huge world of implant opportunities.

Form 4B is super-fast. With its new Low Force Display™ (LFD) Print Engine, we’re seeing build times for full dentures in under one hour. Think about that for a moment — a complete arch, printed, washed, and cured before you return from lunch. Add to that the ability to use high-precision printing with biocompatible workflows including third-party resins, we’ve hit that sweet spot where clinical meets cool.

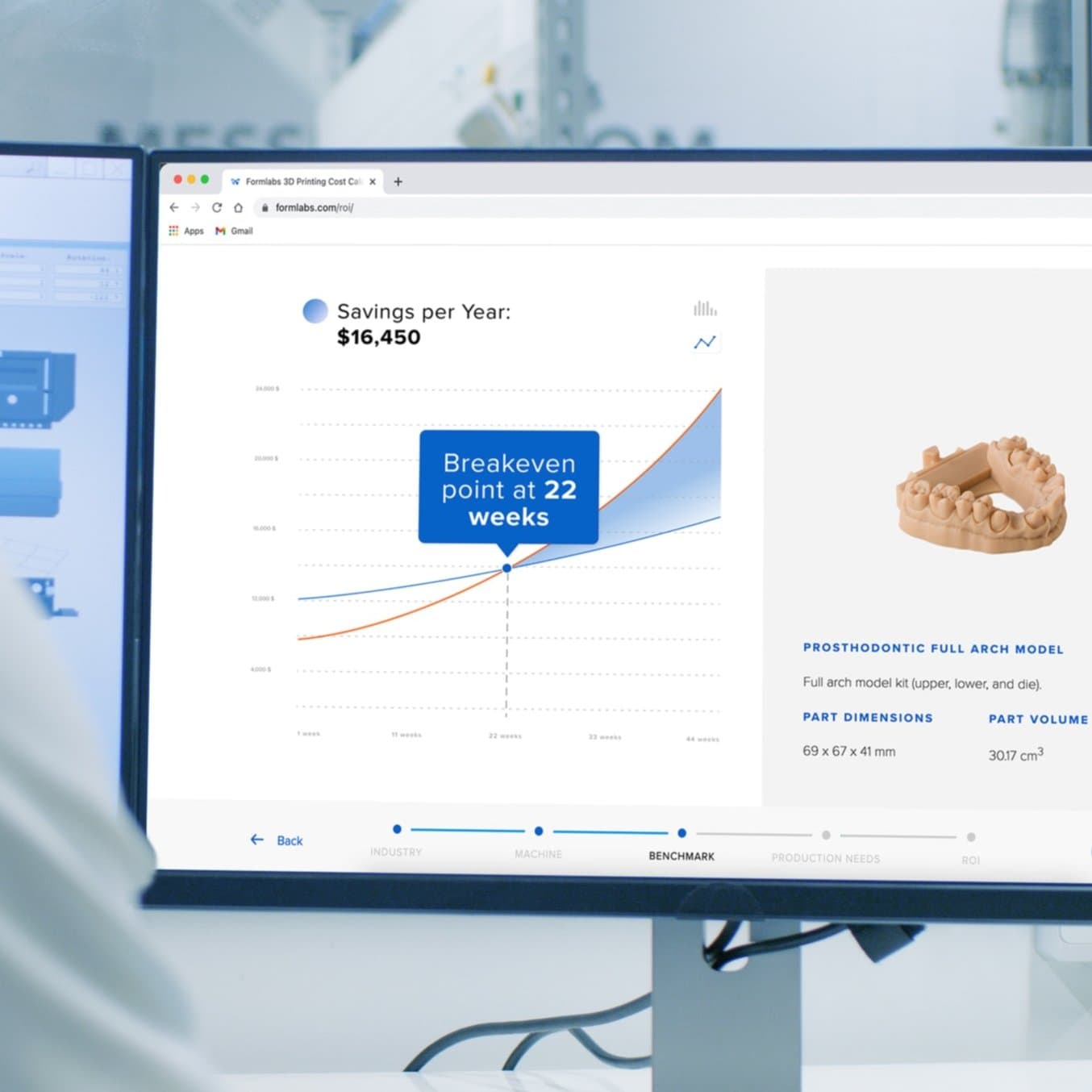

Calculate Your Time and Cost Savings

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs dental 3D printers.

Pro Tips From My Lab Bench

The Form 4B ecosystem includes the Form 4B 3D printer, Form Wash, and Form Cure.

If you are diving into Open Material Mode, here are a few pearls:

- Download validated resin profiles: Download a validated resin profile directly from the resin manufacturer for Form 4B. You can get them from Dentsply, PacDent, and others that validate the FPS profiles for Form 4B.

- Dial in with test prints: Don’t wait for the patient sitting in the chair to do your first print. Do a few test prints ahead of time to fine-tune your settings (layer height, exposure time, etc). You’re driving manual, but that’s what makes it fun.

- Get consistent: Create a log of settings. Once you get a combo that works, replicate it. Full-arch prosthetics demand precision. Verify passive fit intraorally before delivering the prosthesis. LOCATOR FIXED and chairside pick-up techniques makes this part SUPER easy, by the way.

- Post-process properly: Look up the Instructions for Use (IFU) from the manufacturer! Many resins like Lucitone require a validated curing workflow (like the Dentsply Denture Cure system and Pac-Dent’s LC Cure system for Titan) to meet FDA and strength requirements. Get a Form Wash — it makes life simple. Don’t wing it, do it right.

Final Thoughts

I’ve always believed that the best tech makes clinicians better, not busier. With Open Material Mode on Form 4B and materials like Lucitone Digital Print, Rodin Denture Base, and Rodin Titan, we are not just catching up to the digital future, we are defining it.

Print your way, choose the resin you want, whether it’s a Formlabs resin or a third-party resin. Deliver clinical excellence and, most importantly, have a blast doing it. This isn’t just fun and nerdy technology anymore, it’s serious prosthetics with style.

Stay nerdy, stay innovative, and keep printing the impossible.

Explore Form 4B and OMM to learn more or find a reseller to start printing.

About Dr. Scherer

Dr. Michael Scherer serves as the Chief Clinical Officer for Zest Dental Solutions, is an Assistant Clinical Professor at Loma Linda University, a Clinical Instructor at University of Nevada – Las Vegas, and maintains a successful practice limited to prosthodontics and implant dentistry in California and Las Vegas. He is a Diplomate of the American College of Prosthodontists and the American Board of Oral Implantology.