Cutting edge technology, as well as the speed and ease it offers, is what sets apart Baer Dental in Lone Tree, Colorado. Dr. Christopher Baer, DMD, was an early adopter of digital dentistry. In a competitive place like the greater Denver area, technology enhances patient experience, drawing around 220 patients to the practice a week.

“The biggest thing that 3D printing has helped with is communication. When you're talking to people about how you're going to rebuild their smile, there's usually a disconnect between what the doctor's trying to tell them and what they're actually understanding. When you have a model to actually show them, they get it.”

Dr. Christopher Baer, DMD, Baer Dental

While Dr. Baer’s journey began with intraoral scanning, he now utilizes everything from AI design services to in-house milling and 3D printing to boost return on investment. For Dr. Baer, ROI isn’t just about financial and time savings, he also considers the “happiness ROI,” or the positive feedback cycle digital dentistry has from patients, staff, and doctors.

Get in Touch

Whether you need to produce occlusal splints in-house, or are looking for high-throughput production of dental models, we're here to help. Get in touch with a dental expert to find the right solution for your business.

Technology in the Practice

“Our philosophy at Baer Dental is to have treatments that are better for patients. We were seeing costs rise from the lab standpoint, but the quality wasn't increasing comparatively with the cost. We wanted to control costs for the patient and the practice, and I knew we could control a lot of the costs and the quality if we were doing it in-house.”

Dr. Christopher Baer, DMD, Baer Dental

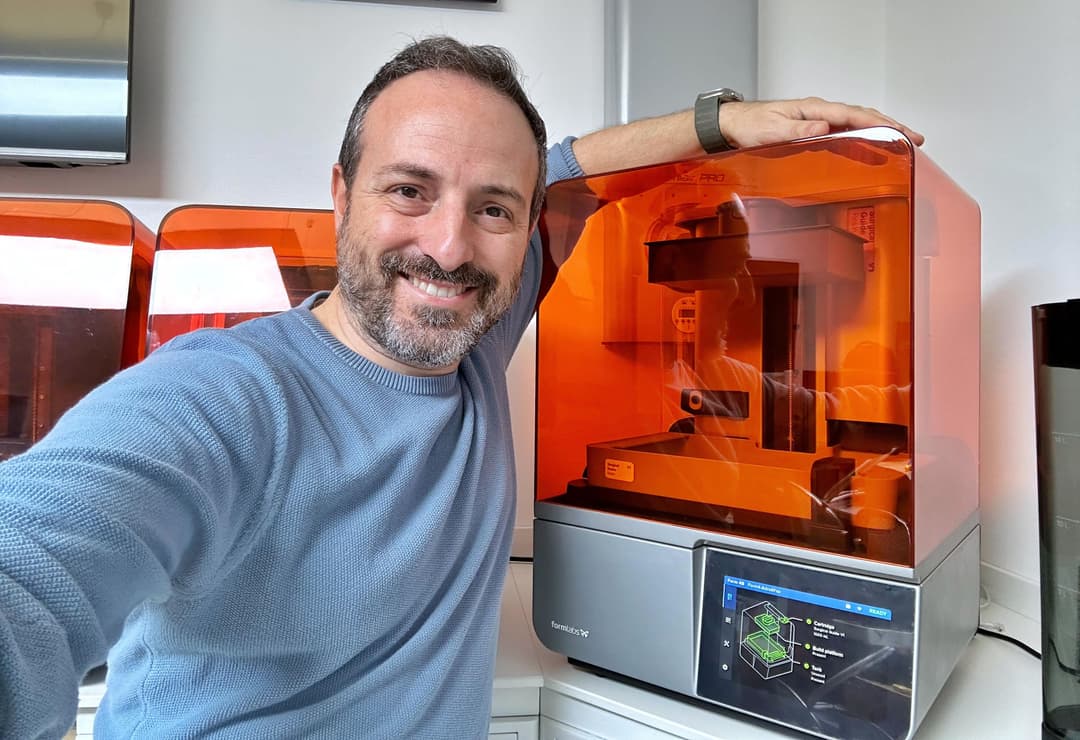

Dr. Baer was an early adopter of intraoral scanning and has stayed on the cutting edge of digital dentistry.

Dr. Baer began scanning 15 years ago, saying, “The digitization of teeth was something that I saw as a future. It saves a lot of time and money, and the accuracy has improved over time.” Then, around 2017, he brought milling in-house. At the same time, a patient recommended he watch the documentary “Print the Legend,” which chronicles the race for market leadership in 3D printing and follows Formlabs right after it was founded.

Baer recalls, “It was easy to see that Formlabs was a leader in printing technologies. I started looking at the products that Formlabs had and looking at resins that we could use to be able to print dental models. I looked at the ROI and realized, if I buy this printer, I'm going to be able to make all of these models in-house and not have to pay this company to make the models. So we purchased a Form 2 and started printing models. It was amazing.”

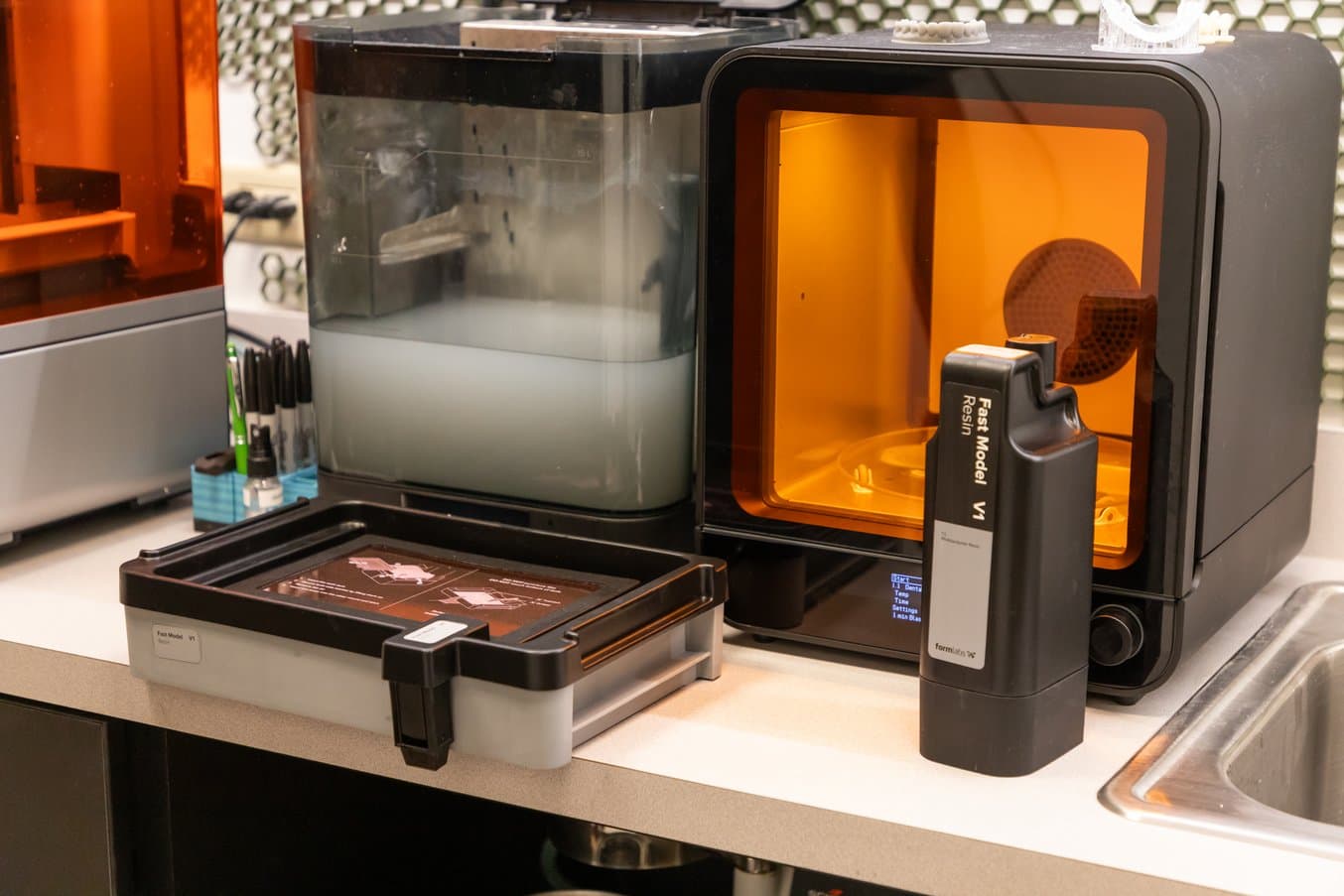

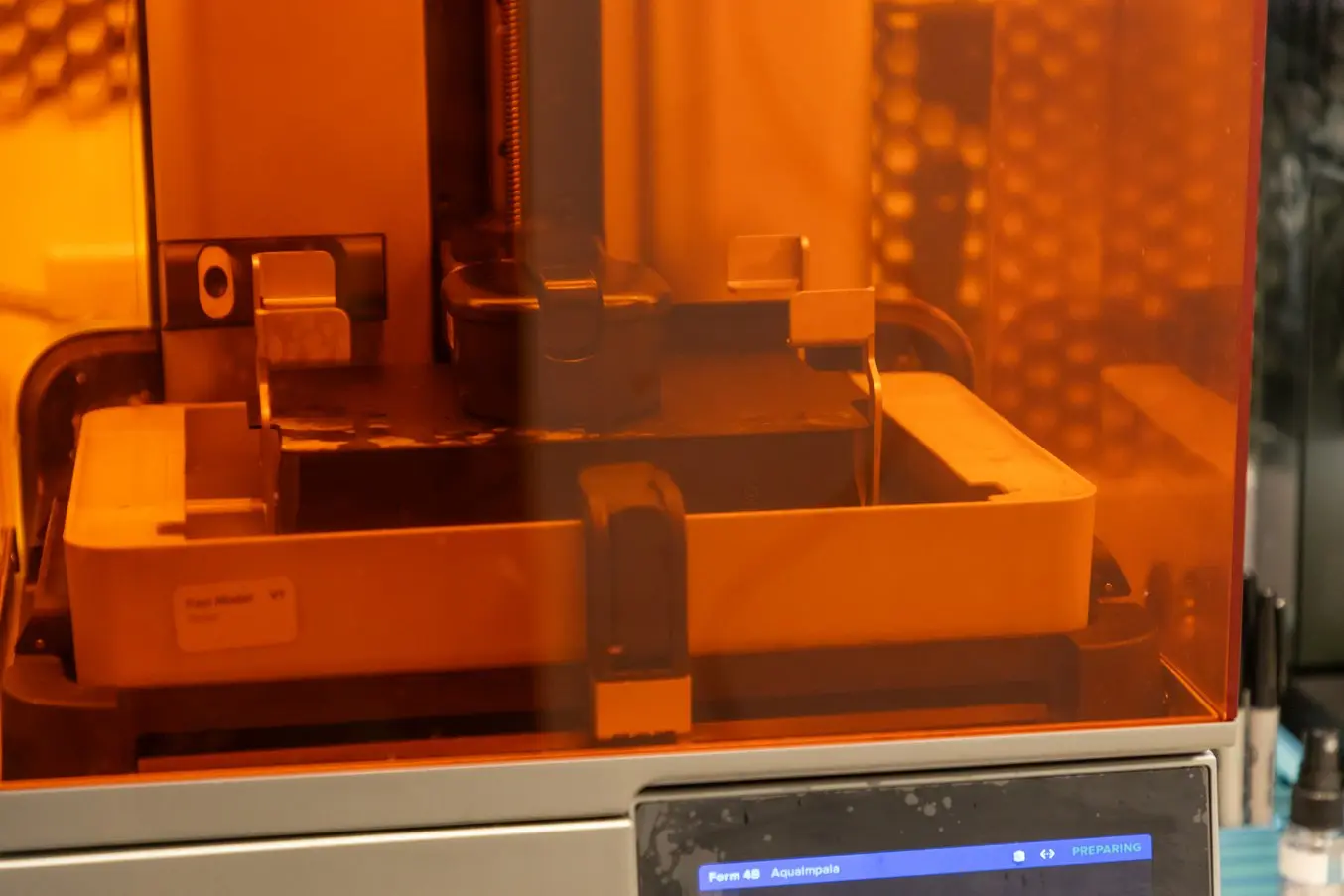

Baer Dental has since used the Form 2, Form 3B and, now, Form 4B, as well as Form Wash and Form Cure. Using a number of resins from the Formlabs Dental Material Library, Dr. Baer says that “Pretty much anything that we can print, we try to print.” Learn more about Dr. Baer’s first impressions of Form 4B here.

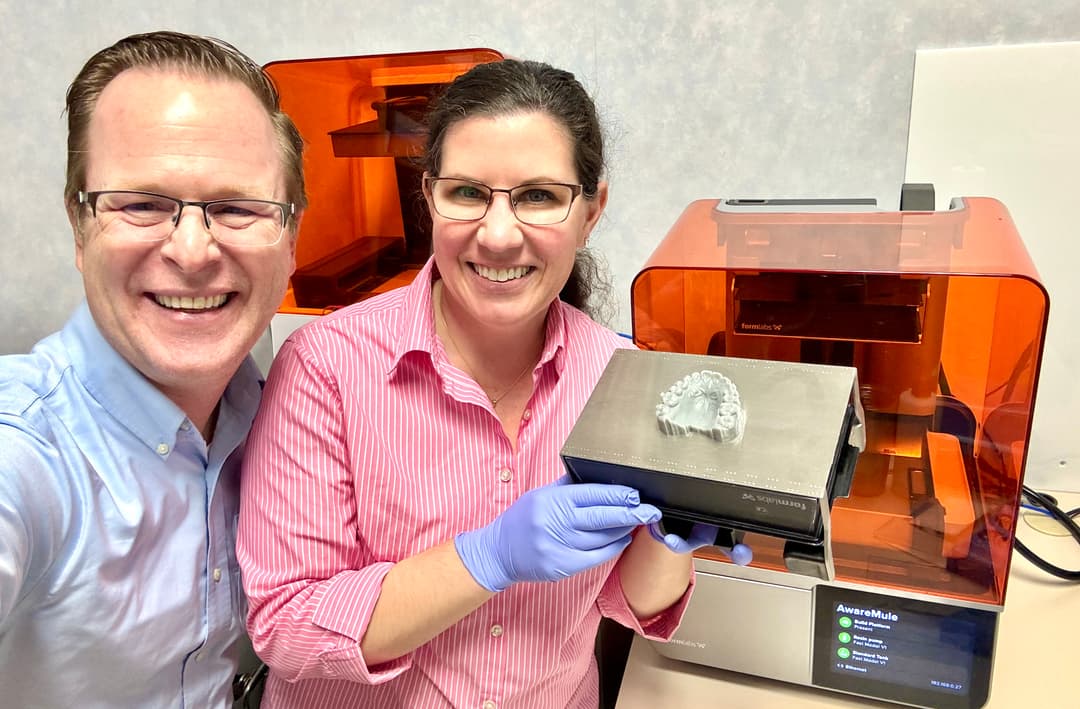

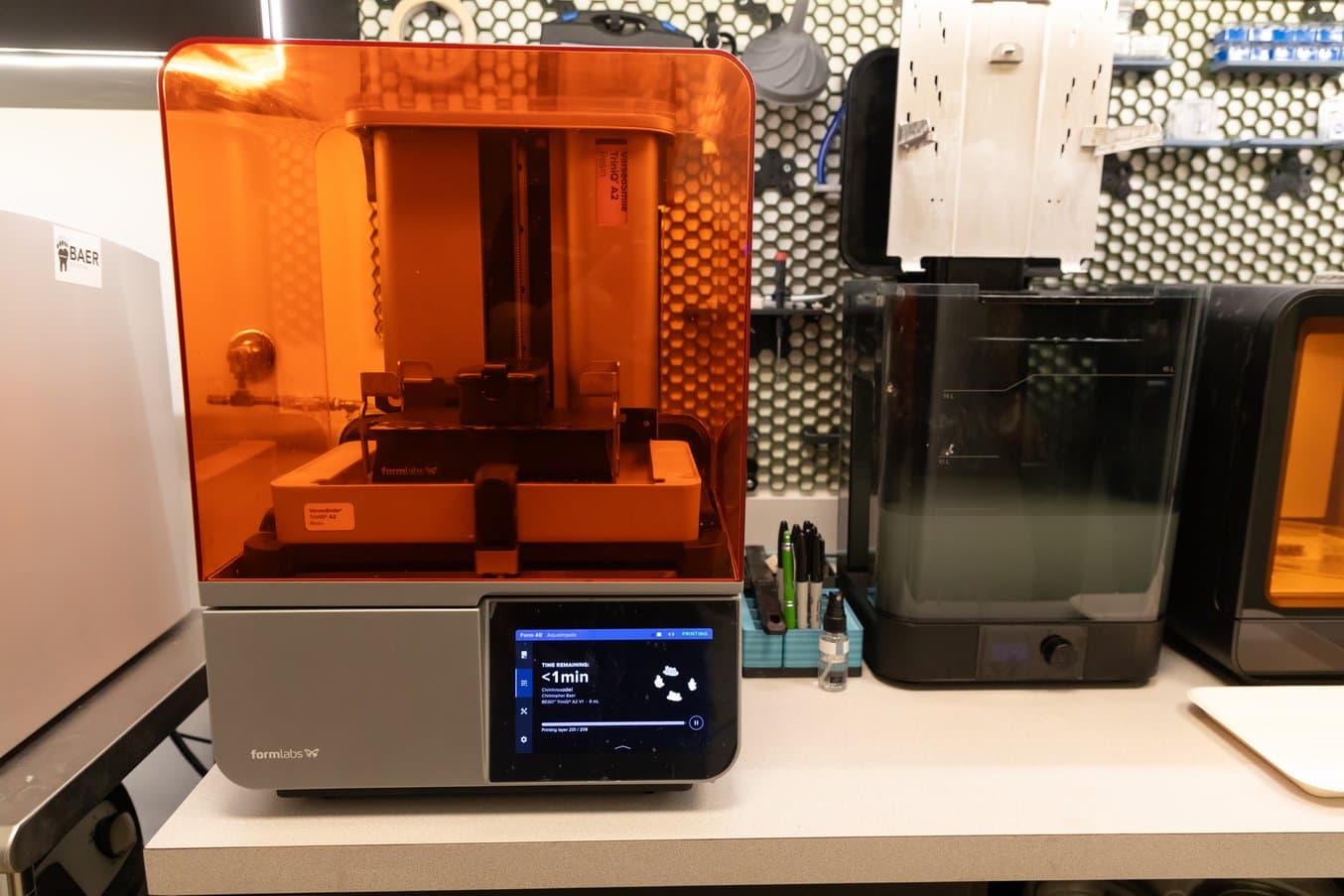

The print lab at Baer Dental includes a Form 4B 3D printer, Form Wash, and Form Cure.

“The Form 4B has definitely changed how we work, because we're able to do things quite a bit faster. With night guards, we've seen a dramatic improvement, making same-day dentistry possible. For restorations, whether it's a temporary restoration or a final restoration, we have probably about a 50% time savings in doing that for our whole entire process.”

Dr. Christopher Baer, DMD, Baer Dental

In implementing technology as it was introduced, Baer Dental had a different experience from a practice adding digital technologies today. “We basically had the garden hose — now you’ve got a firehose of information,” says Dr. Baer. But now there are more resources. Classes, guides, and technologically savvy staff can all help with the adoption of new technologies, as can design services.

Product Demo: Form 4B Dental 3D Printer

Blazing speed meets unmatched accuracy in the next generation of dental 3D printing. Explore the latest innovations in our webinar.

Appliance and Restoration Design in Less Than 15 Minutes

If a general dentist can’t step away to design, other options are available, including lab technicians, tech-savvy assistants, dental resource centers, and even AI design services.

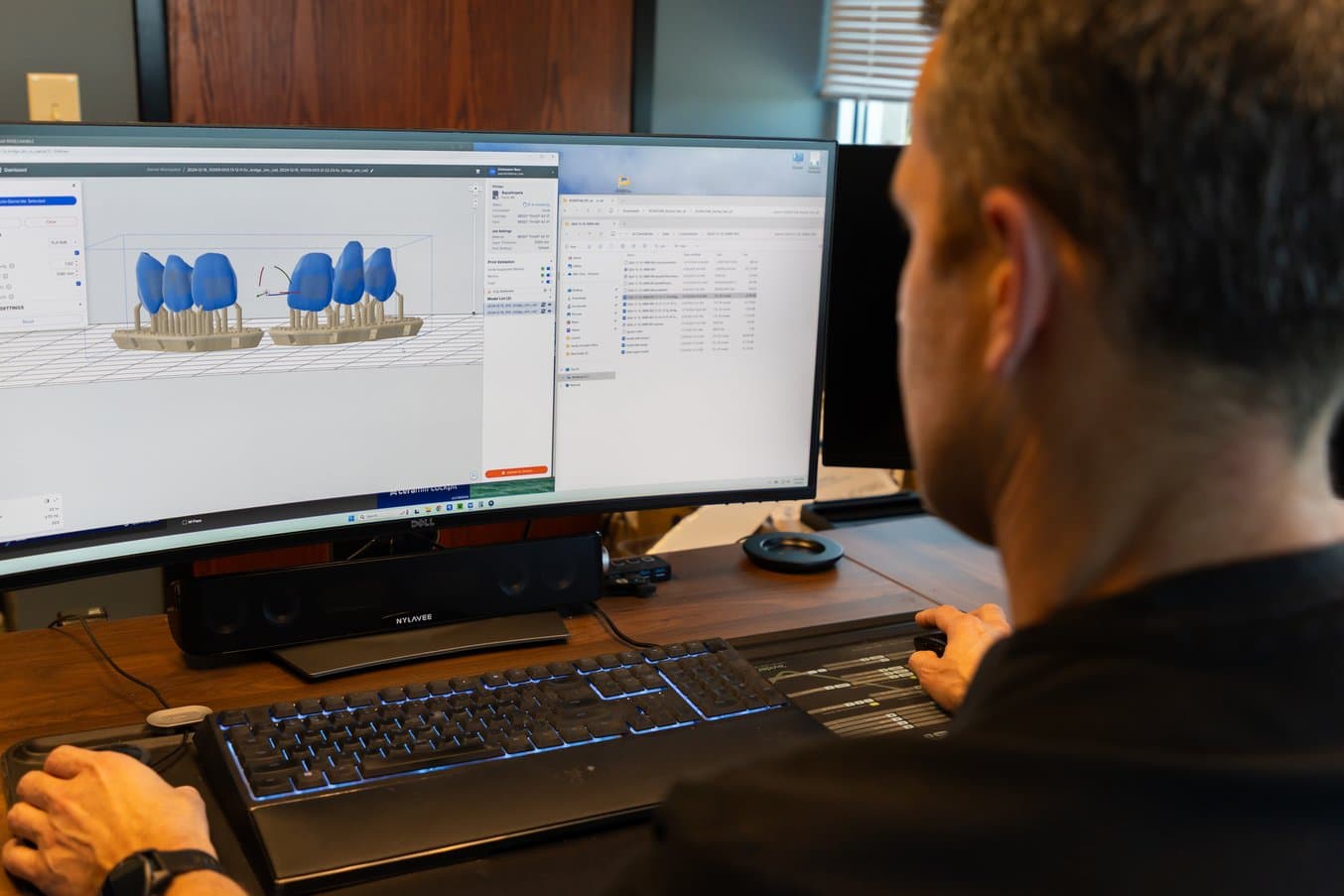

While Dr. Baer can design single units and bridges in 15 minutes or less, sometimes it’s more efficient to delegate the design. For more technical cases, he’ll work with a lab technician who can turn around the design in 1-3 days. For less technical cases, he’ll work with Evident or 3shape Automate to get an appliance or restoration design. These design services offer 24-hour turnaround for human designs or, in some cases, even a five-minute turnaround with AI design options to enable same-day dentistry.

Once a restoration is designed, the file is brought into PreForm Dental for print preparation.

“One of the reasons why we love utilizing 3Shape is they have what's called 3Shape Automate, an automated AI-designed crown,” says Dr. Baer. “You can get that back in under five minutes. That's generally faster than anybody's going to be able to train an assistant that has minimal experience.”

For occlusal splints, Dr. Baer says, “We’ve switched completely over to AI design — those designs take about 10 to 15 minutes to get back.” During busy seasons, Baer Dental uses more design services, shifting back to in-house design when there’s more time.

With AI design, occlusal splints are one of the easiest applications to print and can be designed and manufactured by the end of an appointment.

Dr. Baer adds, “We're always about getting things to the best person for the job. If we're busy and we're trying to focus on treatment, we don’t have as much time to do all of the design work.” This is also true for complicated cases, which will be sent to a dental technician during times when Dr. Baer doesn’t have the time to design them himself.

By combining in-house design, outsourced work to a dental technician, and AI design solutions, Baer Dental can be flexible, meeting the needs of patients and staff schedules while optimizing efficiency. This model can also be helpful for practices adopting digital dentistry or adding indications to their 3D printing workflows.

3D Printing as a Practice Builder

“Being able to print a model for a patient in under 10 minutes opens up so many avenues, not just for treatment, but also for revenue generation.”

Dr. Christopher Baer, DMD, Baer Dental

3D printing in-house offers financial savings. The cost per part of manufacturing appliances and restorations on the Formlabs ecosystem is significantly lower than outsourcing.

Cost Per Part

| In-house with the Formlabs Dental Ecosystem | Outsourced | |

|---|---|---|

| Models/Wax-ups | $2 | $100-200 |

| Occlusal Splints | $4-6 | $60-150 |

| Temporary Crowns | <$1 with Premium Teeth Resin | $3-6 per tooth with PVS index and BisAcryl |

| Permanent Crowns | $1.20-2 with BEGO™ VarseoSmile® TriniQ® Resin | $3-6 per tooth with PVS index and BisAcryl |

Looking at one of these applications, producing a four-tooth wax-up model, the cost savings would be ~$86 in-house with Form 4B versus outsourcing to a lab, and would take ~30 minutes (including 15 minutes of active assistant time), versus the 3-7 days outsourcing would take.

ROI for Wax-Up Models

| In-house | Outsourcing | |

|---|---|---|

| Resin cost | ~$1.15 | |

| Cost of other consumables | ~$1.50 | |

| Labor cost | ~$10-12 | |

| Total cost | ~$12-14 | ~$100 |

| Lead time | ~30 min | 3-7 days |

This doesn’t include the chairtime savings of in-house production — a return appointment isn’t needed for in-house production.

“Saving patients a return visit is a practice builder.”

Dr. Christopher Baer, DMD, Baer Dental

Dr. Baer says that when 3D printing temporary restorations, “you're going to save a considerable amount of money buying a cartridge of resin versus buying a cartridge of injectable material, and then it's going to save you quite a bit of time and headache.” Additionally, money is saved on plastic tips.

Recurring costs are top of mind for dental professionals, so it’s important to factor in the cost of consumables for a practice. With Form 4B, Formlabs worked to increase the longevity and bring down the cost of consumables.

Consumable costs and lifetime, including those of resin tanks and cartridges, should be considered when comparing ROI.

“The tank life is phenomenal; there's a considerable cost saving on those consumable products. And when you look at 3D printing, it's not necessarily the initial printer cost, but it's the cost of all of those consumables that you're going to have. And Formlabs has done a wonderful job of making all of that affordable for people and trying to make it accessible to everybody.”

Dr. Christopher Baer, DMD, Baer Dental

Time Savings: Printing on a Schedule

“One of the advantages of having the digital technology we have in the practice is being able to utilize it for all facets of treatment. If you start to have that digital mindset, you're thinking, what can I do for the patient and utilize all of the technologies that we have, at the same time making sure things are scheduled correctly in that process?”

Dr. Christopher Baer, DMD, Baer Dental

Printing in-house for same-day delivery saves on return visits and makes it possible to provide timely solutions for trauma patients. In an active town like Denver, this can mean a patient getting same-day temporaries following a bike accident, enabling them to eat and smile with ease in one emergency appointment.

Batching and scheduling prints frees up Form 4B for printing during the day, enabling the delivery of occlusal splints, bleaching trays, and a response to trauma cases.

But in order to ensure a printer is ready for same-day printing, a schedule needs to be maintained. To execute this, batches of appliances, models, or restorations for future appointments are scheduled at the end of the day, ensuring reliable prints. By batching prints for these times, the printer is then freed up for any on-demand printing that may be required during appointments, from a replacement occlusal sprint, whitening tray, or even emergency restorations. Dr. Baer recommends having one person on staff delegated to managing the printer during the day, including managing the printer schedule as well as resin tank and cartridge changes.

“Think about how you’re going to schedule printing, similar to how you schedule your patients for the day.”

Dr. Christopher Baer, DMD, Baer Dental

Scheduling out expected prints ensures the printer is then free for whatever arises during patient visits, for a positive patient experience.

Happiness ROI

“If a trauma case patient comes in and you're lucky enough to have a scan of that patient beforehand, you can 3D print a temporary restoration in under 30 minutes for them and have that ready to deliver, so that you can get them back to smiling.”

Dr. Christopher Baer, DMD, Baer Dental

In addition to considering the financial and time savings of digital workflows with Formlabs 3D printers, Dr. Baer considers what he calls the happiness ROI. Investing in making the patient experience as positive as possible results in glowing recommendations and reviews; a happy patient is a practice builder.

“In under an hour and a half, you've got an occlusal splint that you can deliver to a patient. So if you've ever had a patient that's in pain, they're having jaw symptoms, being able to do something like that same day for them can be life-altering.”

Dr. Christopher Baer, DMD, Baer Dental

Preparing a whitening tray by the end of a cleaning or a replacement occlusal splint adds value for patients. Meanwhile, providing same-day restorations minimizes the return visits a patient may have to schedule. And, of course, intraoral scanning is always preferred over sticky alginate impressions.

“Being able to make whitening trays in 10 to 15 minutes is huge, because a patient can leave the hygiene appointment with them in hand. And that's also a game changer because they go out and they tell their friends, their coworkers.”

Dr. Christopher Baer, DMD, Baer Dental

The happiness ROI also extends to staff; ensuring that staff see the benefits 3D printing has on their work and their patients makes them more engaged in the process. Dr. Baer gives an example of temporary restorations. “When you're trying to take temporaries off that break, or having to remake a temporary…you'll find that the staff is a lot happier from not having to go through all that remake process.”

Additionally, the cleanup of cement on a 3D printed restoration is easier than traditional ones. “The assistants have picked up on that and are a lot happier because there's a lot less work that they have to do on the back end of things, and the process is much more predictable.”

The Flex Build Platform makes it easy to remove parts without risking damage to a part or injury.

Beyond this, the technology itself can be engaging. Dr. Baer says, “We use the Flex Build Platform for almost every print that we can, because it's so easy to take the prints off. We're less likely to have somebody who potentially gets injured, and I think the team all enjoys just that little flex and hearing that little pop as it comes off.”

Using Technology to Enhance Patient Experience

“I would say one of the coolest things about 3D printing is being able to create options for patients.”

Dr. Christopher Baer, DMD, Baer Dental

Dr. Baer had a 96-year-old patient who’d lost a crown. The patient lives at an assisted living center that requires a lot of coordination to get him to the dental office and back. “You look at that and say, we have the technology now to be able to provide this treatment that's cutting edge for you and provide a definitive and affordable restoration that's going to be timely,” says Dr. Baer.

“We were able to provide a digital scan and 3D print his final restorations and deliver those the same day, having to keep him from another appointment coming back. And he was just super excited about the whole process and all of the technology that we utilized.”

Dr. Christopher Baer, DMD, Baer Dental

By utilizing digital workflows and the speed of Form 4B, Dr. Baer was able to deliver final restorations that day, saving the patient from the hassle of a return visit.

In another example, an elderly patient required restorations for periodontal involved teeth with bone loss and tooth mobility. Dr. Baer’s goal was to deliver something aesthetic, durable, and affordable, while working out the occlusion before going to final restorations.

Preparing the 3D printed restorations on a 3D printed model. Restorations printed with BEGOTM VarseoSmileⓇ TriniQⓇ Resin on Form 4B require minimal polishing.

The restorations, once delivered.

Designing the restorations from scans, Dr. Baer 3D printed the restorations in BEGOTM VarseoSmileⓇ TriniQⓇ Resin, a versatile ceramic-filled biocompatible material. Dr. Baer says, “We've had a great response from patients as far as the aesthetic look of it. It polishes up really nice. Once it's polished, it blends in and the A2 is an actual A2; it blends in seamlessly with ceramic crowns, too.”

In addition to the restorations, the patient needed a soft occlusal splint to wear at night. He wears a CPAP and has a history of clenching and grinding, so an occlusal splint is necessary to protect the temporaries. Because the teeth were digitally prepared, Dr. Baer was able to print a model representative of the mouth with the new temporaries and thermoform an occlusal splint so that it was ready to deliver along with the temporaries.

While Dr. Baer directly prints occlusal splints in Dental LT Comfort Resin or, for harder splints, Dental LT Clear, for this patient he wanted an even softer material than Dental LT Comfort. With Fast Model Resin on Form 4B, a model for thermoforming can be printed in eight minutes, for a finished occlusal splint in under 30 minutes.

By applying a digital mindset, Dr. Baer could deliver a soft occlusal splint in the same appointment as the restorations by thermoforming over a model.

Applying the Digital Mindset

“We look at technologies that are emerging and what we want to be able to provide for patients. We evaluate these products as they're coming to market. And if it can change the workflow and create a better outcome for the patient, then that's when we utilize it.”

Dr. Christopher Baer, DMD, Baer Dental

With the speed of Form 4B and the robust Formlabs Dental material library, Dr. Baer and his team are providing same-day appliances and restorations with accuracy and reliability, saving time, reducing costs, and delivering exceptional patient experience.

“Looking back, I think people will only find that they're going to wish they'd adopted 3D printing sooner, because of all the opportunities that it creates within the practice,” says Dr. Baer. He encourages fostering a digital mindset in teams, focusing on how technology can be used to create a better experience for patients.

“Most patients tend not to want to be at the dental office anyway because of fear. If you can create an environment where you can scan patients and then you can provide restorations and appliances within a short period of time, you have the ability to impact a patient's wellbeing far beyond any analog workflow that we've had.”

Dr. Christopher Baer, DMD, Baer Dental

To learn more about adding digital dentistry workflows to your business, explore Dental Resources and Form 4B. Ready to press print? Find a dental reseller.