Delivering Consistency: How Protec Dental Laboratories Achieves Precision and Accuracy at Scale

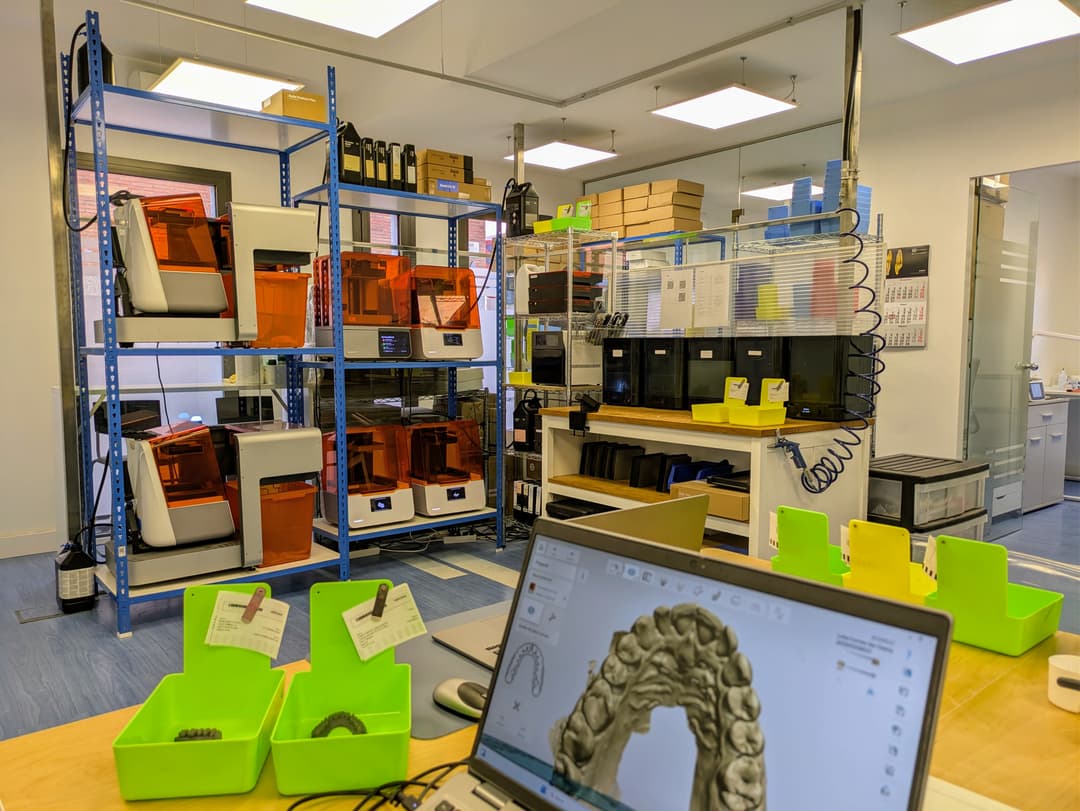

Protec Dental Laboratories in Vancouver, Canada, is a full-service lab serving over 2,500 dentists across Canada. The lab utilizes printers from a number of manufacturers, opting for materials and workflows that meet their exacting standards. Producing over 600 dental models daily with Precision Model Resin on Formlabs Form 4B Series 3D printers, Protec has markedly reduced remakes by refining digital design protocols and leveraging the printers’ consistent accuracy.

“We take pride in meeting the highest standards of precision, accuracy, and reliability,” says Jeff Player, CDT, Managing Partner. “Together, these qualities create the consistency that’s essential to our process,” adds Manuel Stanescu, CAD-CAM Ortho Manager. “Consistency allows us to fine-tune our design settings and ensure a perfect fit every time.”

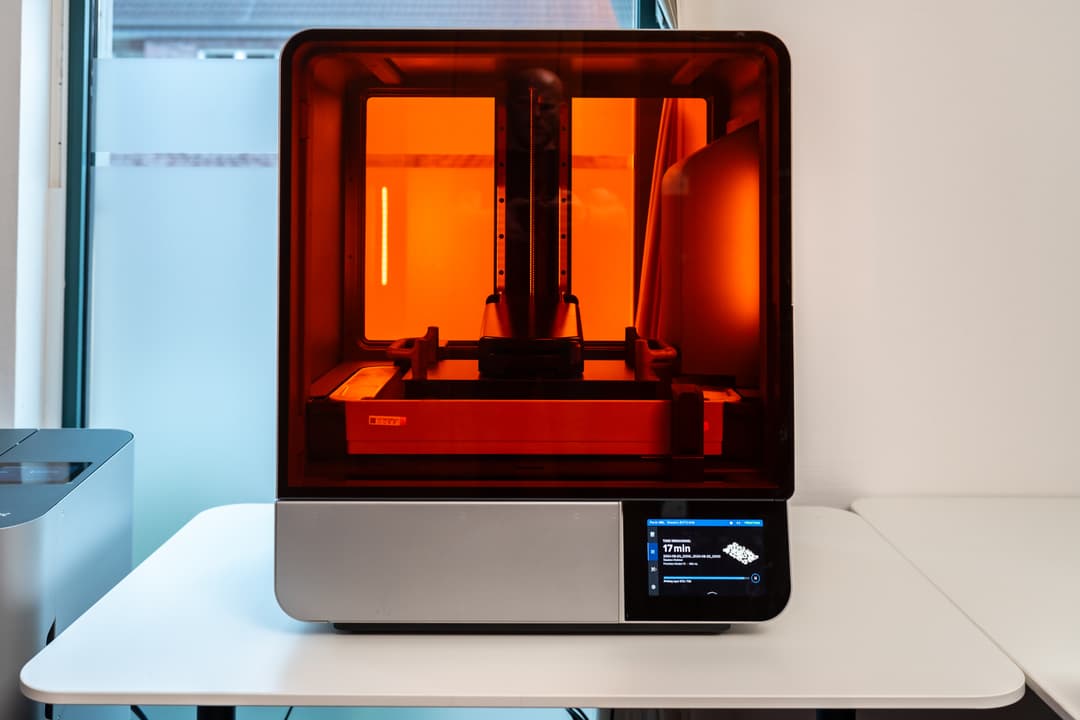

The Formlabs Dental ecosystem delivers precision, accuracy, and process reliability essential for Protec’s orthodontic production environment. Through the systematic expansion of their Form 4B printer fleet over the past fifteen months, Protec has realized measurable gains in fit consistency and has driven remake rates to levels at or below established industry benchmarks.

Get in Touch

Whether you need to produce occlusal splints in-house, or are looking for high-throughput production of dental models, we're here to help. Get in touch with a dental expert to find the right solution for your business.

Consistent Results With a Complete Ecosystem

Form 4BL and Form 4B are used for printing models, which are post-processed in Form Wash, Form Cure, and Form Cure L. Presets for washing and curing help with consistency no matter who is printing.

Predictable, consistent results mean appliances that fit clinically, lower return rates, as well as fewer remakes, saving time for both the ortho lab and their customers. With some 3D printers, the prints would come off of the printer and then need to be manually post-processed, often using wash and cure units from a variety of manufacturers. As Stanescu explains, “Post-processing is also very important in the whole 3D printing process because poor or unclear systems can actually give you inaccurate models.” The more manual the process, the greater likelihood of someone skipping steps or simply doing them differently, resulting in inconsistencies in models.

“When we started looking around for a different technology we were looking for something that has a complete post-processing system.”

Manuel Stanescu, CAD-CAM Ortho Manager, Protec Dental Laboratories

A reseller pointed the Protec team in the direction of Formlabs Dental’s end-to-end ecosystem. Form Wash has presets for each resin, as well as the capacity to save custom settings, with the basket automatically lifting from the wash when it’s complete. The Form Cure for post-curing also has presets, ensuring resins are cured to the correct time and temperature.

“With the post-processing system that we have from Formlabs, it's difficult to miss or mix-up a step, because everything is preset.”

Manuel Stanescu, CAD-CAM Ortho Manager, Protec Dental Laboratories

Protec’s experience with Formlabs started with a sole Form 4B desktop 3D printer. After trying the workflow for a handful of months, measuring the consistency and accuracy of the models, and doing a cost and production analysis, they added another Form 4B, later followed by two Form 4BL 3D printers for large-format printing. With the same intuitive workflows, it was easy to scale up.

In addition to automated post-processing, small things make a difference in the workflow, like the Flex Build Platform. The ability to place the entire build platform in the wash and then pop models off of it saves time on cleaning the models, the build platform, and the workspace.

Reliability is key in achieving consistent results, and the ortho department currently has a success rate of 98-99% for models printed on Formlabs printers. Most importantly, consistency and reliability mean timely delivery of appliances that fit clinically, ensuring Protec’s customers receive high-quality appliances in under a week.

Request a Free 3D Printed Restorative Dental Model

Curious to see the quality firsthand? Pick a material and we'll ship you a free sample part 3D printed on the Form 4B to evaluate.

Delivering a Precise Fit

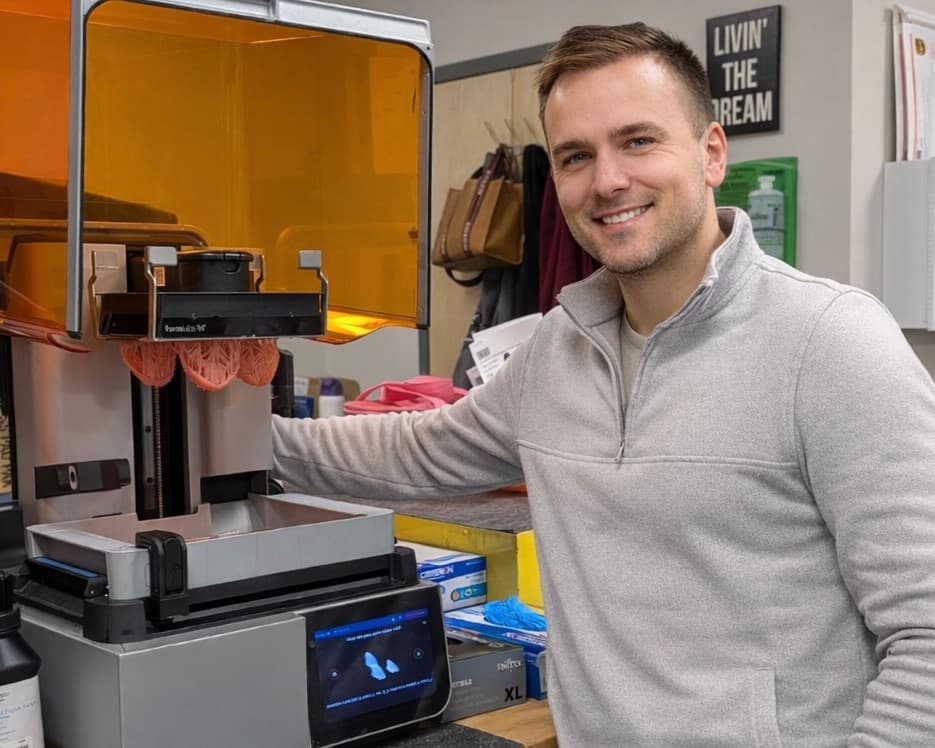

“We were used to using big industrial printers,” says Player. “We heard about Formlabs but we saw it as a small unit that was inexpensive, allowing smaller labs or even doctors' offices to get into printing. We felt it wasn’t really targeted at us.” That all changed when they saw a video of Form 4B and started hearing feedback from their trusted partners.

Precision is always important to Protec. Accurate models mean accurate appliances, for fewer remakes. Production delays add time to delivery, so the more remakes that are eliminated, the better it is for practitioners and their patients.

“Each week, we conduct an in-house validation test where we scan a selection of models and compare them against the original digital files. The results consistently fall within our defined specifications, demonstrating the reliability and repeatability of our process.”

Manuel Stanescu, CAD-CAM Ortho Manager, Protec Dental Laboratories

Stanescu says, “This weekly check allows us to trust our settings for our appliances. Consistency allows us to nail down our design settings and our fit.”

Print speed also plays a role in delivery time to practices. Because Protec can fabricate appliances in under three to five days, if there is an issue in the final step, or the appliance doesn’t meet their high standards, they can remake the appliances and still deliver them on time. “It gives us time for more careful reflection on how perfect this appliance is,” says Player. “Because it’s fast and easy to reprint, we tend to remake appliances that, in the past, might have been adjusted or repaired,” ensuring a high-quality product with no added lead time.

Accurate Parts With Precision Model Resin

“The Precision Model Resin really stood out to us. Even though accuracy requirements for orthodontic models can be less stringent, we still want to ensure we’re printing highly precise parts. That resonated with us — we want every model we produce to be an exact replica of the scan we receive.”

Jeff Player, CDT, Managing Partner, Protec Dental Laboratories

Internal Formlabs testing has found that printing with Precision Model Resin on Form 4 Series 3D printers results in models with 95% of the surface within 50 μm of the CAD model and 99% of the surface within 100 μm of the CAD model.

Precision Model Resin is a high-accuracy material often used for restorative models. While many dental professionals use Fast Model Resin at a layer height of 100-200 μm when producing models for thermoforming appliances or for fitment check of splints, Protec uses Precision Model Resin at 50 μm for an exceptionally smooth surface and precise fit.

Helping People By Applying Technology

In addition to Form 4B/L, Form Wash, and Form Cure, Stanescu uses Formlabs’ PreForm Dental to set up models for printing on Formlabs printers and Dashboard to monitor resin consumption for more accurate ordering.

When nesting models for printing, Stanescu appreciates PreForm’s one-click print set-up, saying, “In a fast-paced environment, I like to have automatic supports.” If it is necessary to edit supports, he finds it easy to edit.

Through partnerships, people, and technology, Protec works with dental professionals to provide a complete range of restorations and orthodontic products. Focusing on workflow consistency and accurate parts, Protec minimizes remakes and delivers a precise fit to their partners. The end-to-end Formlabs Dental ecosystem is one of the cutting-edge technologies Protec utilizes to achieve their accurate parts with consistency.

Learn more about the Formlabs Dental ecosystem or contact a reseller. To evaluate Formlabs Dental materials, including Precision Model Resin, for yourself, request a free sample part.