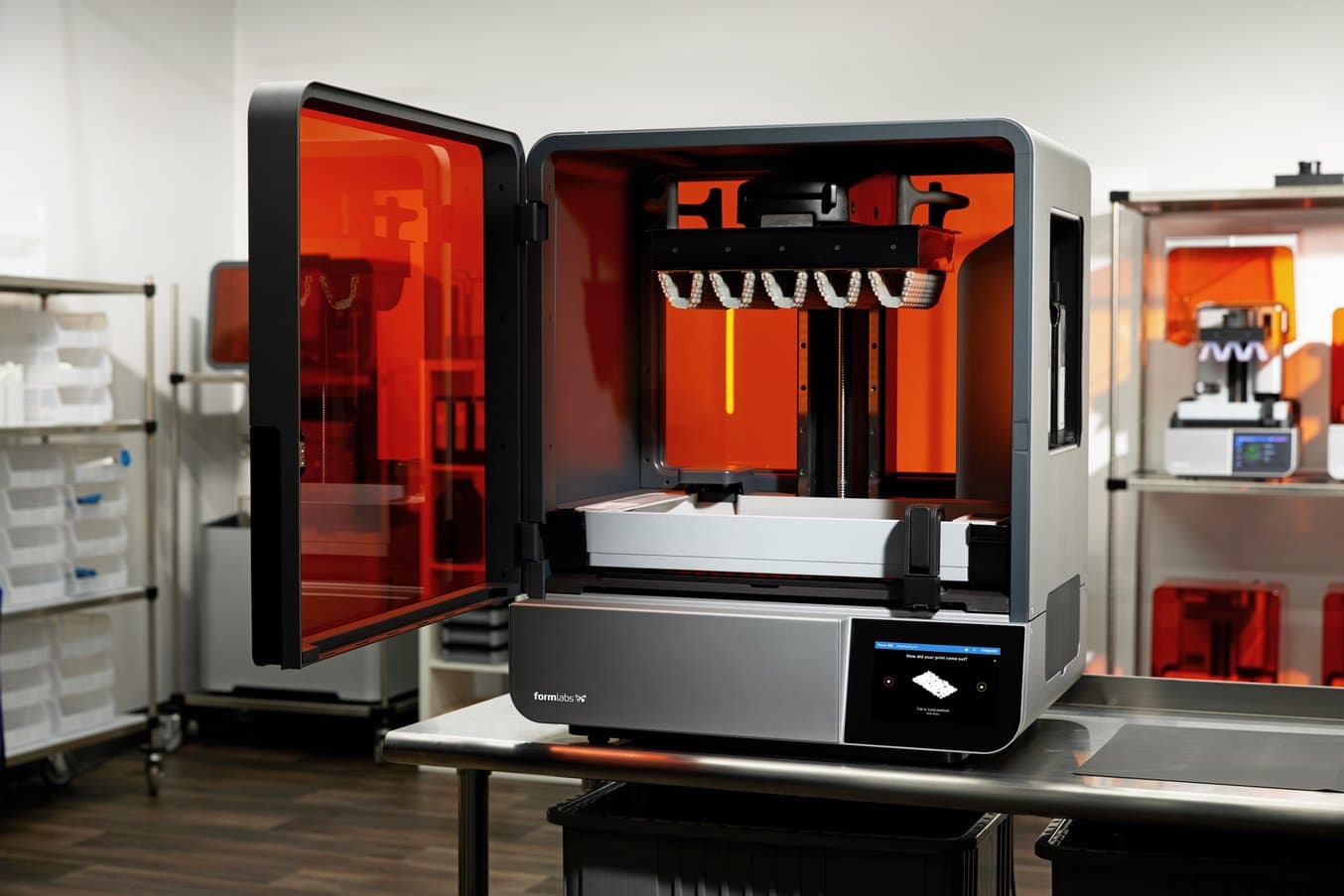

In spring 2024, we released Form 4B, powered by our next-generation Low Force Display™ (LFD) Print Engine that redefines the industry performance standard and delivers unmatched reliability, print speed, print quality, dimensional accuracy, and materials versatility in one printer.

With Form 4BL, we’ve applied the same groundbreaking technology to bring you a large-format dental 3D printer that can print more than 120 models per hour*, so you can achieve high-throughput production at speed.

While Form 3BL was the first truly accessible large-format resin 3D printer available, users experienced long print times. With Form 4BL, we’ve addressed this pain point, bringing blazing speed, reliability, and cost-efficiency to large-format printing, so you can deliver high-quality appliances in record time — all while leveraging the intuitive workflows, material versatility, and quality you’ve come to expect from Form 4B.

*Print times may vary. Estimates based on orthodontic models printed with Fast Model Resin at 160 μm.

Powered by Low Force Display™ Technology

Form 4BL is a masked stereolithography (MSLA) 3D printer, a photopolymerization process where a light source is selectively covered or masked by an LCD screen, and an entire layer of a print is exposed and cured. This results in vastly improved print speed, but often comes at the cost of surface finish, reliability, resolution, or hardware longevity. The technology of Form 4BL solves these issues, for fast, reliable production of models and appliances with fine details, high accuracy, and smooth surfaces.

Form 4BL is built on the same technological developments as Form 4B.

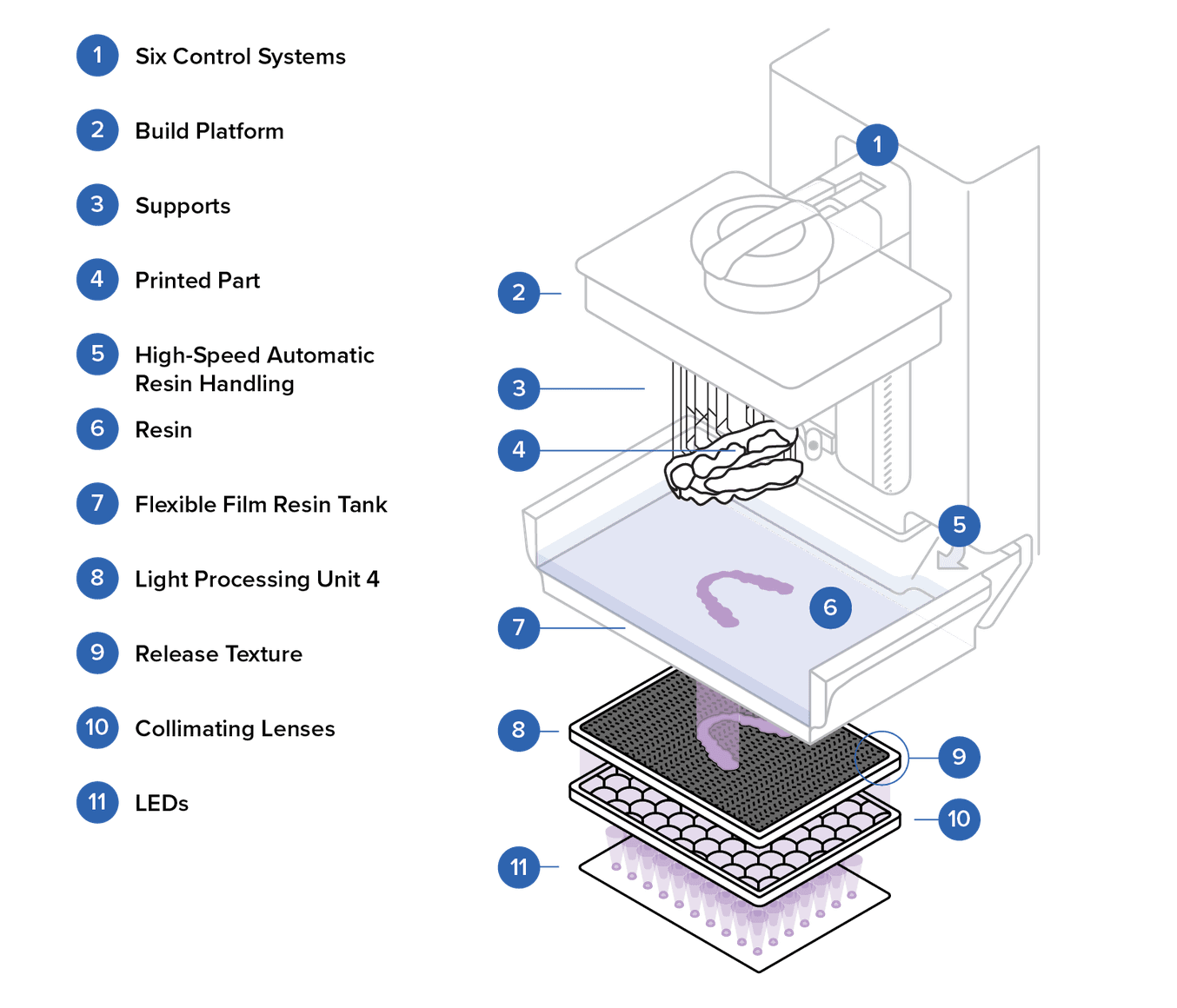

Form 4BL is built on the LFD Print Engine, at the core of which is the Backlight Unit, an ultra-high power light source of 145 LEDs and collimating lenses that deliver an optical power intensity of 16 mW/cm2. From here, the light passes through the Light Processing Unit (LPU) 4L, where it is formed into the shape of the printed layer using a series of polarizers, optical coatings, and a custom LCD screen, achieving blazing fast print speeds with excellent print quality and accuracy anywhere on the Build Platform.

The LPU 4L is engineered and manufactured for a long lifetime and reliable printing, delivering 600,000-1,900,000 layers of consistent print performance before replacement, depending on the material and layer height printed. If needed, the robust LPU 4L can quickly and easily be replaced.

Form 3BL, as a stereolithography (SLA) 3D printer, uses lasers to trace each shape. By moving to MSLA and LFD, Form 4BL achieves blazing fast speeds without compromising on print quality.

Dive deeper into the technology underlying Form 4B Series printers here.

Speed That Scales

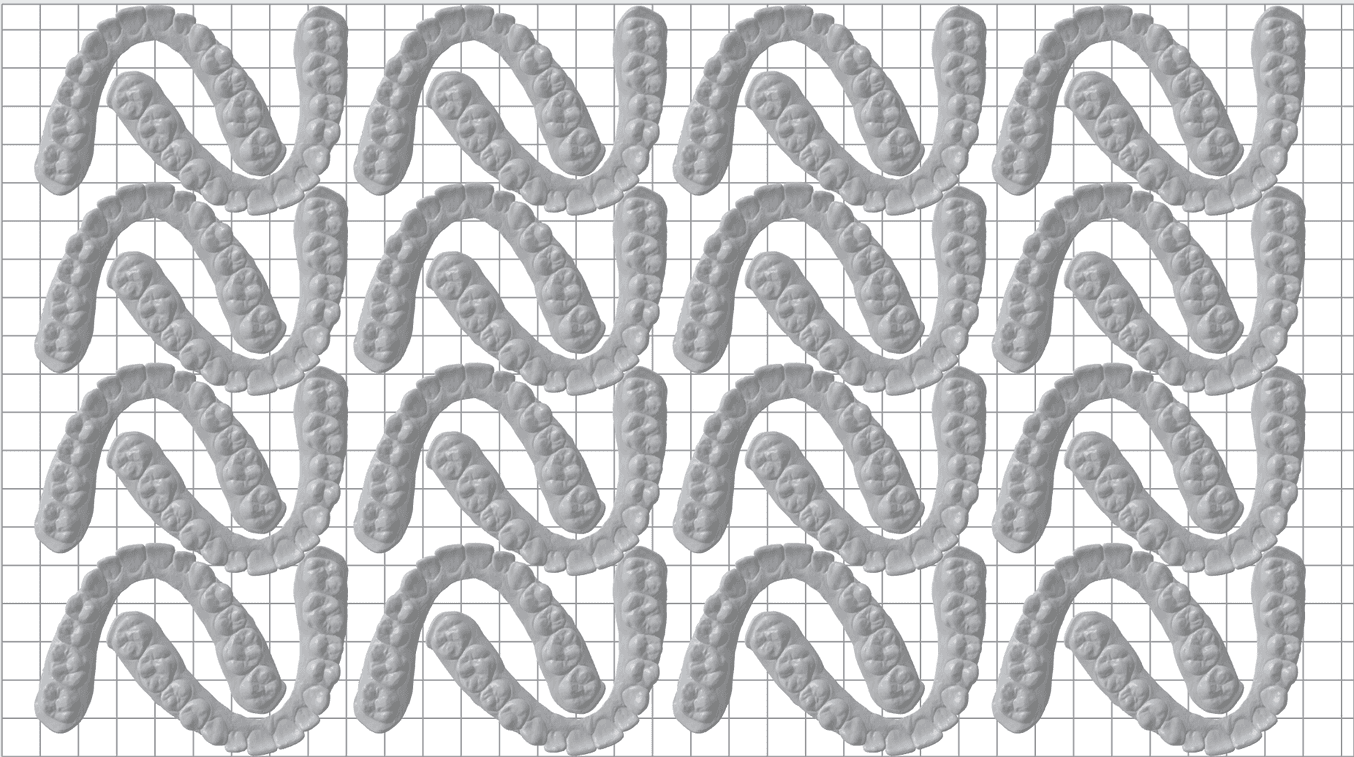

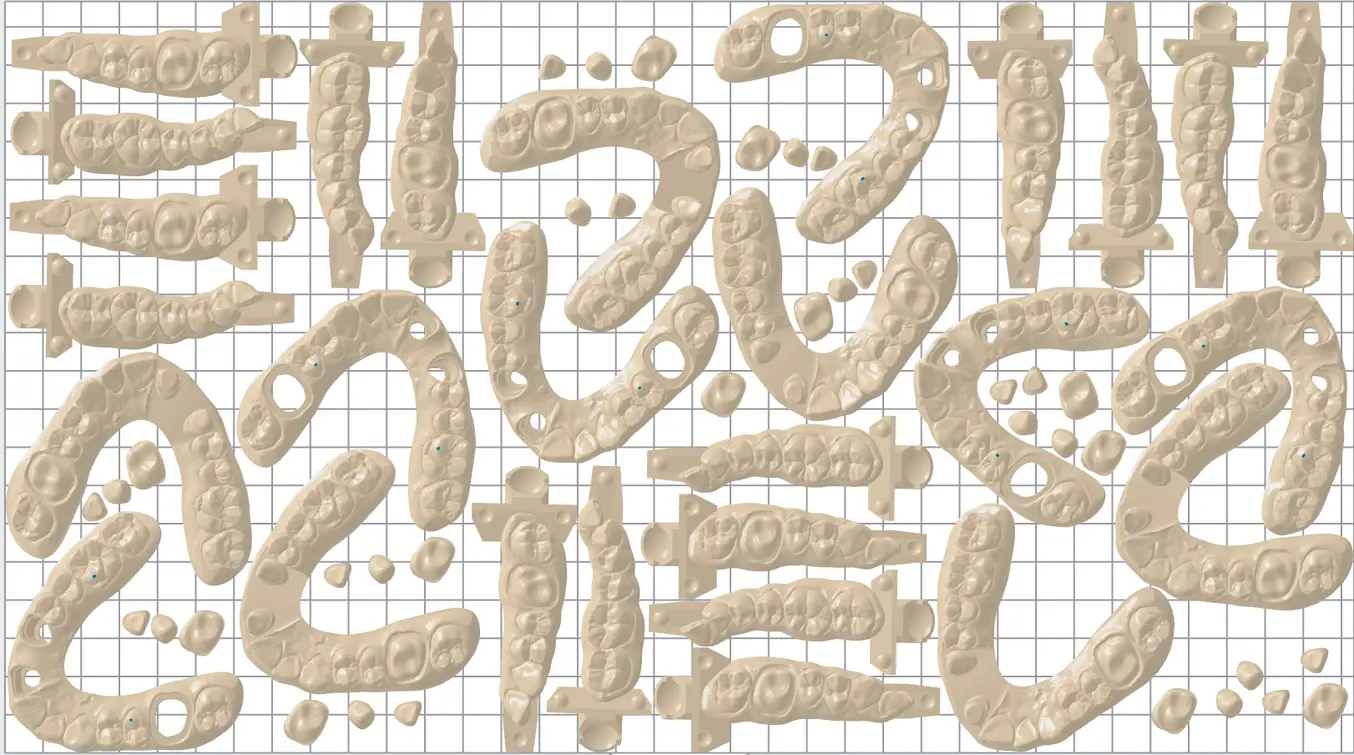

Form 4BL prints 2-4x faster than Form 3BL, with 2.7x the build area of Form 4B. This means 32 models can fit in one print batch on Form 4BL, versus 11 on Form 4B, for higher throughput.

| Form 4BL | |

|---|---|

| Maximum Speed | 80 mm/h with Fast Model Resin* |

| Average | 30 mm/h** |

| Range | 10-80 mm/h depending on the material |

*Max print speed using Fast Model V1 Resin and 200 μm layer height. Based on actual print times from a collection of test parts covering common dental applications.

**Average print speed using 100 μm layer height, averaged across all materials. Print speed will vary depending on material, layer height, and part geometry.

32 Clear Aligner Models (Flat)

Form 4BL: 14 min with Fast Model Resin at 160 μm

Form 3BL: 1 h 21 min with Draft V2 Resin at 200 μm

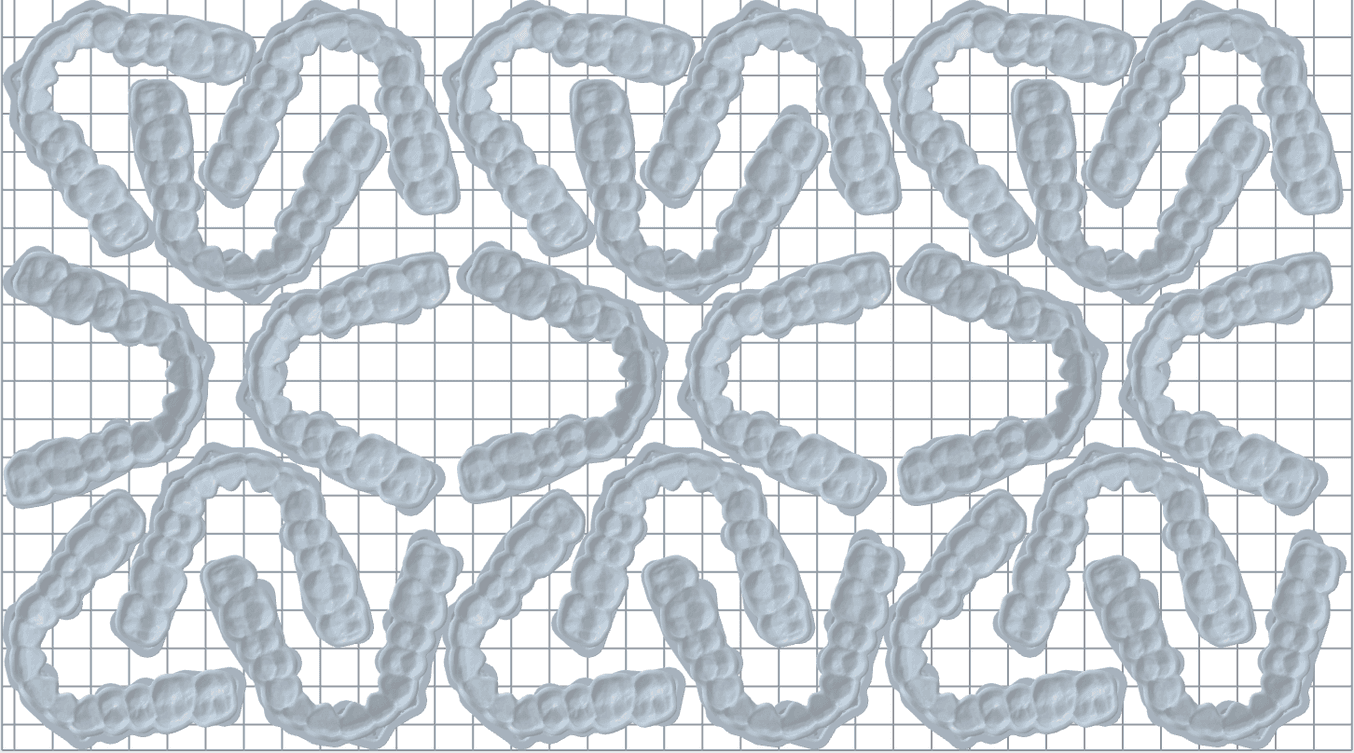

75 Clear Aligner Models (Vertical)

Form 4BL: 1 h 46 min with Fast Model Resin at 100 μm

Form 3BL: 6 h 59 min with Draft V2 at 100 μm

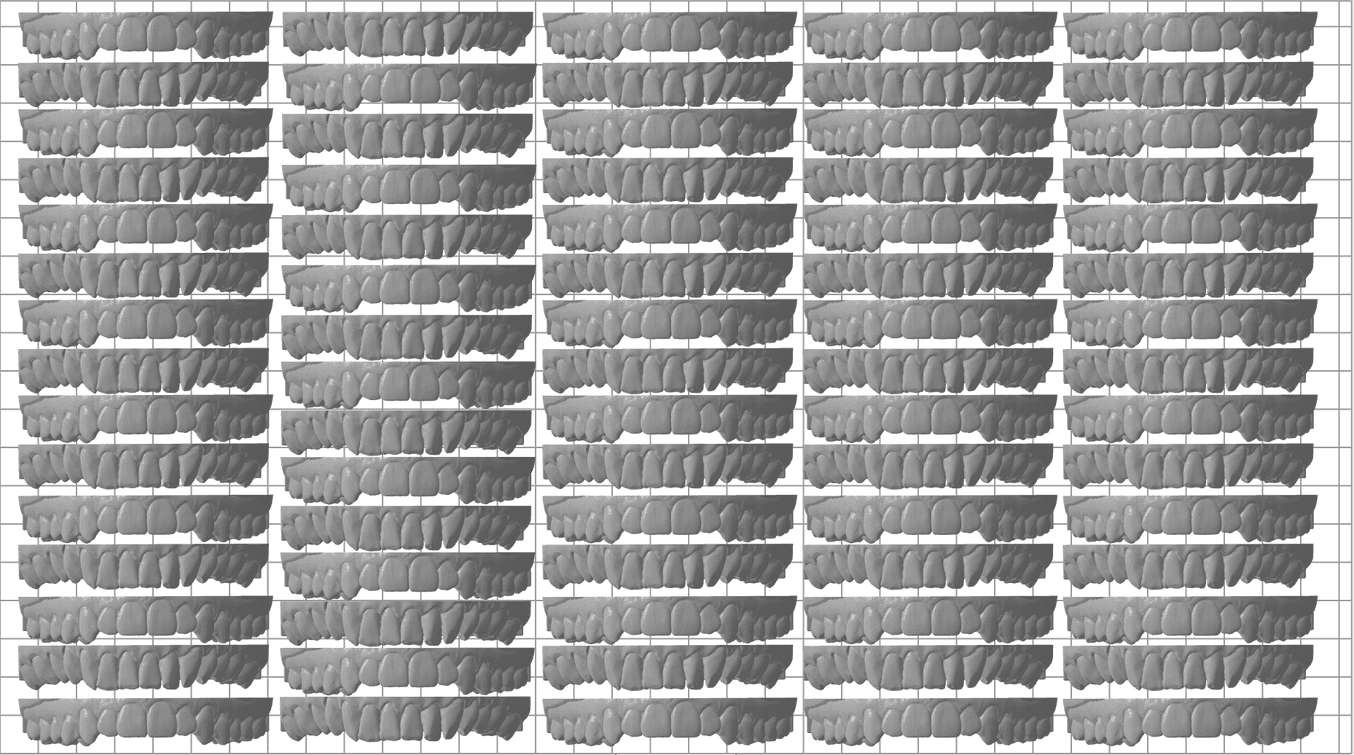

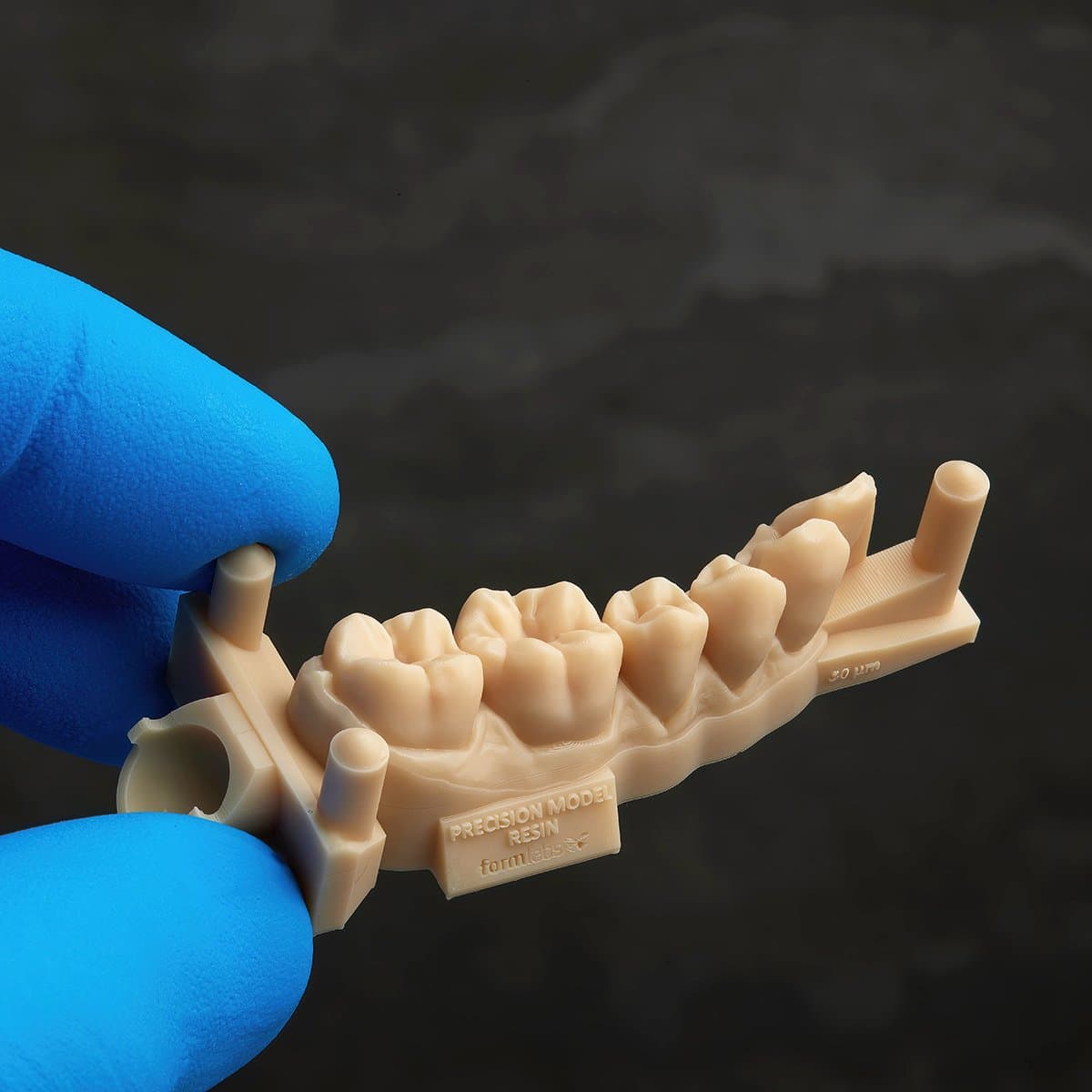

28 Restorative Models

Form 4BL: 2 h 48 min with Precision Model Resin at 50 μm

Form 3BL: 9 h 25 min with Model V3 Resin 50 μm

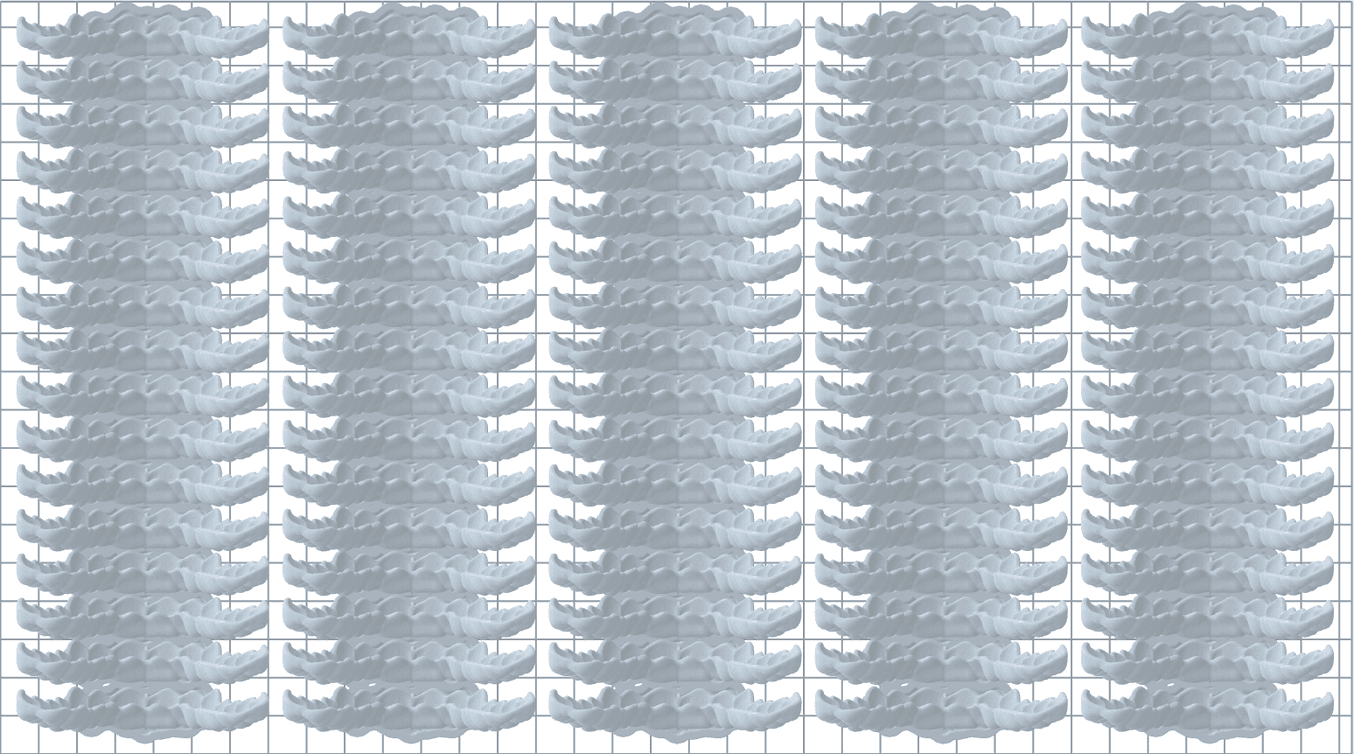

24 Occlusal Splints

Form 4BL: 1 h 19 min with LT Comfort Resin at 100 μm

Form 3BL: 4 h 32 min with LT Comfort Resin at 100 μm

80 Occlusal Splints (Vertical)

Form 4BL: 2 h 10 min with LT Comfort Resin 100 μm

Form 3BL: 18 h 14 min with LT Comfort Resin 100 μm

Print time and cost will vary depending on part geometry, material, layout, orientation, and layer height. However, Form 4BL’s LFD Print Engine will significantly reduce print time for comparable parts. Plus, the bigger build platform of Form 4BL can fit 2-3x the models or appliances as Form 4B, thereby batching prints and saving post-processing time.

“Compared to some of the more expensive printers we use in our lab, the Form 4BL stands out for its efficiency. We can fit two to three times more models on its build platform, all with a similar print duration and exceptional reliability and accuracy. The result? Our throughput has doubled, even tripled, which has been a game-changer for us!"

Milos Markovic, Director of Cad-Cam and Implantology, Aurora DTC

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part printed on the Form 4B to your office.

Reliable Production

Speedy prints propel efficiency, but only if the print is successful. Failed prints cost time, waste resin, and interrupt workflows. This is compounded for large format 3D printing, as large builds can be more prone to failure and the costs of these failures are also higher.

“As a dental lab, reliability is essential for us to deliver our products on time. With Formlabs’ ecosystem, our 3D print success rate is now close to 100%. Compared to other 3D printers we’ve used in the past, Formlabs shows much higher performance and reliability.”

Stephan Kreimer, MDT, Kreimer Dentallabor

The technological improvements to Form 4BL have directly addressed reliability. Beta testers and our in-house engineers put hundreds of prints to the test, pushing Form 4BL to the limit. In addition to the LFD Print Engine, systems inside Form 4BL work to ensure fast, accurate, and reliable prints.

Reliability starts at the factory, where every printer undergoes a 60-point calibration and quality control inspection. Once you start printing, systems and smart sensors inside Form 4BL work to ensure reliable prints. Six integrated sensors precisely control resin temperature, resin level, print forces, and print status. High-speed conduction resin heating with infrared temperature sensing auto-heats resin to 25-45 °C (77-113 °F), depending on the material.

A mechanically coupled mixer is both faster and more reliable, able to mix resins with higher viscosities, unlocking high-performance materials. More reliable and faster cartridge dispense prevents pauses in printing, for uninterrupted printing in the projected time.

A Z-Axis Force Sensor automatically optimizes print quality and print speed based on part geometry and selected material. An integrated camera enables you to monitor your prints from anywhere while preventative maintenance reminders keep Form 4BL up and running reliably.

Form 4BL vs. Form 3BL at a Glance

Form 3BL empowered users to print larger batches of models and appliances while leveraging our versatile materials catalog and the fine surface finishes of SLA 3D printing. With Form 4BL, we’ve redesigned and re-engineered our large format printer, cutting down print times while achieving highly accurate and precise parts.

| Form 4BL | Form 3BL | |

|---|---|---|

| Technology | Masked Stereolithography (MSLA) | Stereolithography (SLA) |

| Printer engine | Low Force Display™ (LFD) | Low Force Stereolithography™ (LFS) |

| Key components of the print engine | Backlight Unit Light Processing Unit 4L (LPU 4L) Release Texture Redesigned Flexible Film Resin Tank Intelligent Control Systems High-Speed Automatic Resin Handling | Laser Light Processing Unit (LPU) Flexible Film Resin Tank Automatic Resin Handling |

| Light source | Backlight Unit (LEDs) and collimating lenses | Laser |

| Light processing unit | LCD and Release Texture | Galvanometer, mirrors, and spatial filter |

| Build volume | 35.3 x 19.6 x 35.0 cm 13.9 x 7.7 x 13.8 in 24.2 liters | 33.5 × 20 × 30 cm 13.2 × 7.9 × 11.8 in 21.4 liters |

Unlocking Access to 10+ Dental Materials & Open Material Mode

The new technology of Form 4BL unlocks the ability to utilize 10+ dental-specific resins, including seven biocompatible resins. Formlabs biocompatible resins are developed and manufactured within our robust Quality Management System that is ISO 13485 and EU MDR certified. Scale occlusal splint production with Dental LT Comfort Resin or Dental LT Clear Resin, or maximize surgical guide production to meet the needs of your customers.

Precision Model Resin Precision is the next generation of Model Resin that leverages the technology of Form 4 Series 3D printers to print three times faster, while offering better accuracy and improved aesthetics.

A next-generation resin cartridge with 5-10x faster filling (depending on material viscosity) means prints start faster. Plus, cartridges have been designed for 63% less waste and 30% less shelf space. Like Form 3BL, Resin Pumping System (RPS) is available for Form 4BL, providing 5 L of resin to the printer to enable less frequent cartridge changes and unlock discounted resin prices for time and cost savings.

Large prints don't have to mean high costs. Resins for Form 4BL are less expensive than previous versions and consumables are longer-lasting, more durable, and, if replacement is needed, lower cost.

Formlabs' open ecosystem is available also for Form 4BL. Print with third-party materials using Open Material Mode (OMM) or leverage the powerful hardware and nuanced Print Settings Editor to develop custom resins, empowering researchers and expert users to push the boundaries of 3D printing.

Explore the Formlabs material library or request a free sample part to evaluate our resins for yourself, or buy OMM to start printing with third-party materials.

Formlabs Dental Materials Overview: Discover What You Can Print With the Form 4B

This webinar will guide you through the various benefits and applications enabled by Form 4B, including its existing biocompatible materials and newly developed formulations for model production such as Fast Model Resin and Precision Model Resin.

Upgrade Your Productivity

Form 4B set a new standard for accurate and precise printing at blazing speed. Form 4BL takes this to the next level, revolutionizing the throughput potential of MSLA production. Print 120 orthodontic models an hour, or produce 80 occlusal splints in one print batch.

To increase your throughput of highly-accurate models and appliances, buy Form 4BL now. Watch the webinar to learn more about Form 4BL, or contact sales to discuss how Form 4BL can power your lab.