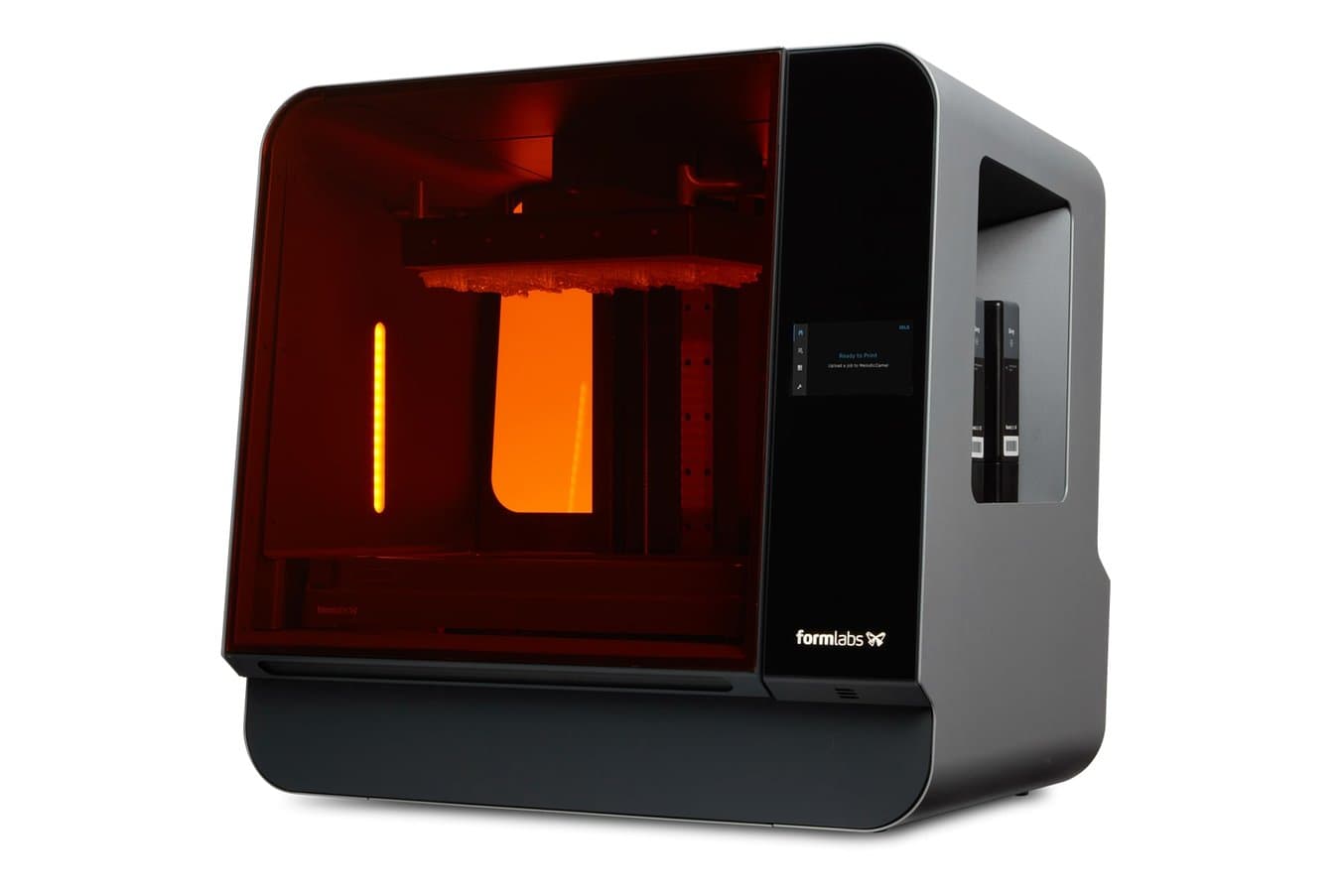

Introducing the Form 3BL, a Large Format Dental 3D Printer for High-Volume Dental Production

Formlabs Dental is pleased to announce the Form 3BL, the large format dental 3D printer that raises the bar for dependable high-volume dental production.

With a large build volume of 33.5 × 20 × 30 cm (13.2 × 7.9 × 11.8 in), the Form 3BL is ideal for dental labs looking for a robust, production-ready printer built on tried and tested Formlabs technology.

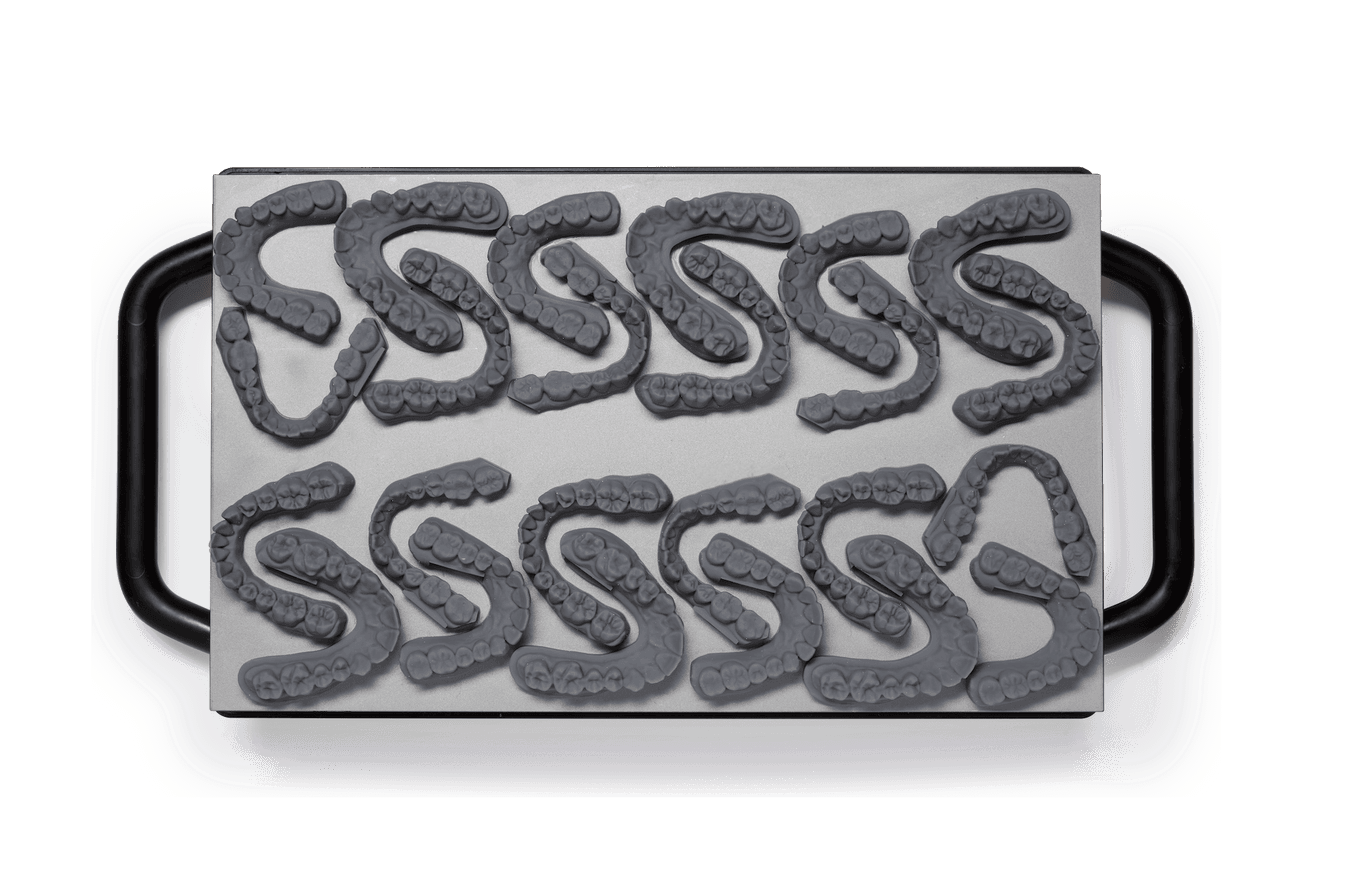

Print orthodontic models for vacuum forming aligners, surgical guides, maxillofacial models, and more—up to 48 models in a day, with only two printer interactions.

Think Big: A New Choice for High-Volume Dental Production

Watch our webinar with Sam Wainwright, Dental Product Manager, and Phil Carlino, Head of Dental Sales, for a technology demo of the Form 3B and learn how you can reclaim more time in your day.

Watch the Webinar NowA Robust, Large Format Printer at an Unbeatable Price Point

Maximum Productivity With Fewer Printer Changeovers

Labor is one of the most valuable resources in any dental or orthodontic lab. While 3D printing is a powerful technology that continues to replace manual processes for a growing range of indications, the small build platform of conventional desktop 3D printers limits the number of dental parts that can be produced in a single build. This means that technicians have to attend to the printers multiple times a day to remove and post-process printed parts and start new prints, which disrupts the workflow.

The Form 3BL is designed for maximum productivity with minimum intervention—it works full time, so you don’t have to. Launch a print job in the morning and one before leaving the office to 3D print 48 models in a day, with only two printer interactions.

A Large Build Platform Without a Six-Figure Price Tag

The Form 3BL is built around two of the same Light Processing Units (LPUs) found in the Form 3B to more than double the build platform’s size to 33.5 × 20 cm (13.2 × 7.9 in). Tried and tested on thousands of printers, this fifth-generation stereolithography 3D printing technology provides a solid basis for dependable production. To ensure maximum uptime, the LPUs are also user-replaceable.

Dental 3D printers with comparable build volumes typically come with a six-figure price tag. Formlabs Dental is proud to offer the Form 3BL, with everything you need to start printing and a one-year Dental Service Plan, for only €12,999.

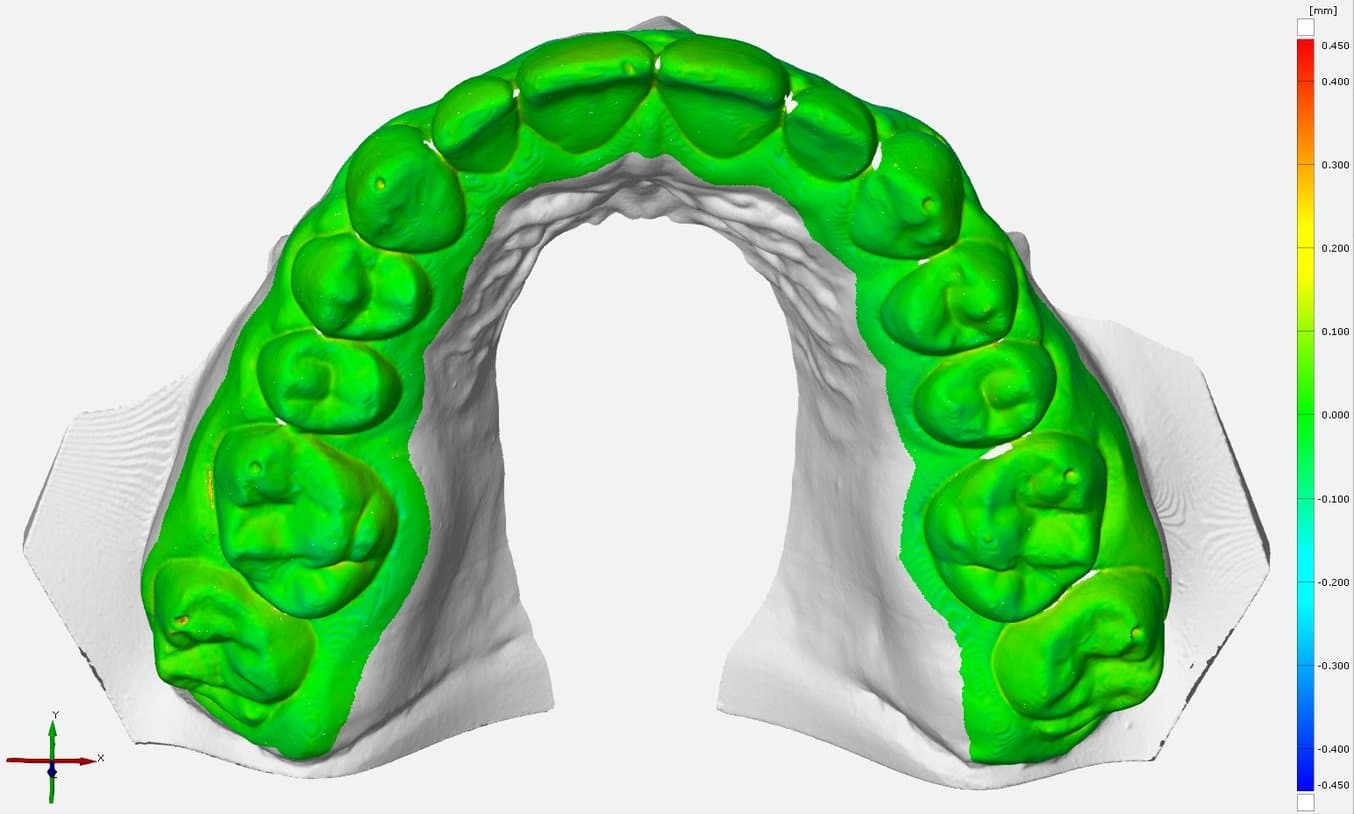

Validated Indications for High Accuracy

As with the Form 3B, our desktop dental 3D printer, each dental indication for the Form 3BL passes through a thorough validation process by our dental team to meet the accuracy requirements for dental production.

With one of our first validated indications, orthodontic models for vacuum-forming aligners and retainers, our testing showed that 94% of surfaces were within 100 microns with consistent part quality and accuracy across the entire build plane.

Form 3BL vs. Form 3B

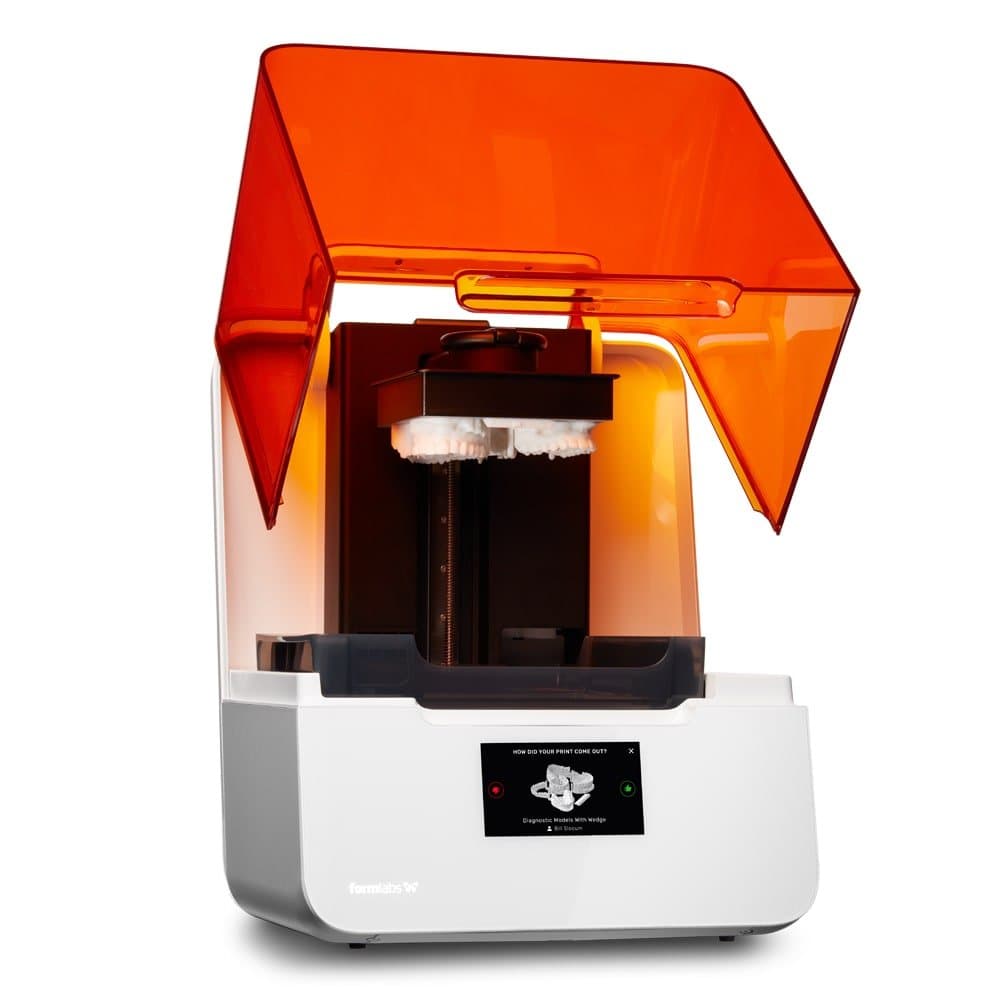

With the new Form 3BL, we’re expanding our line of dental 3D printers. The Form 3B, our desktop dental 3D printer, has a compact footprint ideal for both labs and practices, and can be used to manufacture our full range of 9+ validated indications.

The Form 3BL is a larger version of the Form 3B tailored to labs and high-volume production with minimum user interactions.

When exactly should you pick one over another? Here’s a quick breakdown to help you decide:

The Form 3BL is ideal for:

-

Dental and orthodontic labs

-

Manufacturing aligner models, occlusal guards, maxillofacial models, surgical guides, splints (soon), custom impression trays (soon)

-

Minimum user interactions

-

Printing large batches of parts

-

Printing the same indication continuously

The Form 3B is ideal for:

-

Dental and orthodontic labs and practices

-

Manufacturing any of our validated indications

-

Multiple quick prints per day

-

Printing a single part or smaller batches

-

Switching between indications or printing multiple different indications concurrently on multiple printers

| Productivity Comparison | Form 3BL | Form 3B | ||

|---|---|---|---|---|

| Orthodontic models flat to the build platform at 100 micron resolution | 24 models per print in ~10 hr 48 models in 24 hours, overnight, two interactions | 7 models per print in ~5 hr 21 models in 24 hours, overnight, three interactions | ||

| Surgical guides | 24 guides (14 full arches and 10 quad surgical guides) per print in 7.7 hours, one interaction | 8 full arches per print in 4 hours or 29 quad surgical guides per print in 5 hours |

Note that we expect these estimated print times to decrease and the productivity of the Form 3BL to increase further as we continue to develop print settings for our materials. For example, thanks to the latest update to our PreForm software, aligner models and restorative models now print 25–35% faster on the Form 3B than before.

Compatibility With Your Existing Formlabs Ecosystem

The Form 3BL is designed to integrate with existing dental workflows and Formlabs products as seamlessly as possible, so you can spend less time troubleshooting and get existing employees and new hires up to speed quickly.

From print preparation to handling the 3D printer, post-processing, and finishing the final products, using the Form 3BL should feel familiar to anyone who has produced dental indications with a Formlabs SLA 3D printer.

You can prepare print jobs with Formlabs’ intuitive and acclaimed PreForm software. The Form 3BL also uses our standard resin cartridges that are cross-compatible with the Form 3B and the Form 2.

There’s no need for new post-processing tools either. Since dental parts are small, Form Wash and Form Cure will meet your needs for dental production. For optimal throughput, we recommend 2 x Form Wash and 2 x Form Cure units per full Form 3BL platform.

Please note that biocompatible resins like Dental LT Clear Resin (V2) or Surgical Guide Resin will require Form Wash and Form Cure to meet indicated use laid out in the instructions for use.

Find Out More About the Form 3BL

Curious to learn more about the Form 3BL? Watch our webinar with Sam Wainwright, Dental Product Manager, and Phil Carlino, Head of Dental Sales, for a technology demo of the Form 3B and learn how you can reclaim more time in your day.