Reclaim Time From Restorative Appointments

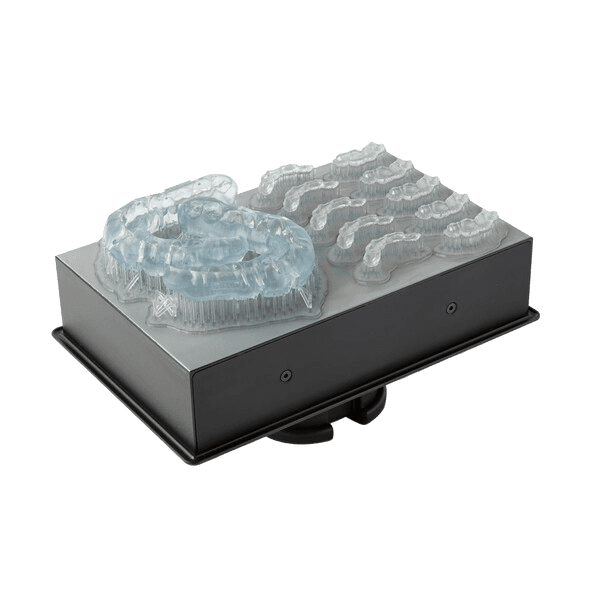

Reclaim time and save costs by leveraging 3D printed guides for direct composite restorations. Utilize a variety of techniques including the injection or pressing of traditional or flowable composite. These minimally invasive techniques allow for the seamless transfer of digital designs to the clinical scenario for increased predictability and time and cost savings.

Enhance Efficiency

Save Time and Money

Deliver Consistent Outcomes

Increase Efficiency and Reduce Costs

| Traditionally PVS Materials | Formlabs IBT Flex Resin | |||

|---|---|---|---|---|

| Cost Per Arch | $10-20 | $3 | ||

| Production Steps | 1. Print model 2. Produce silicone index with custom tray 3. Place in pressure pot 4. Perform the cuts and holes | 1. Print the index |

A Fully Validated System

IBT Flex Resin offers optimized tear strength, translucency, and flexibility for appliances that are easy to plan, easy to use, and easy to remove, so you can give your patients a vastly improved restorative experience.

Our extensive validation and testing process makes sure your prints work every time: quick setup, no in-field calibration, and no messy resin handling.

A Flexible, Efficient Workflow

Delegate digital impression taking, printing, and appliance preparation to staff, and save on chair time.

Scan

Design Tray

Post-Process

Bond

Learn With Formlabs Dental Resources

Virtual seminars, lectures from leading practitioners, and short, helpful videos help you start faster and get the most out of your 3D printer.