Designed for Nonstop Throughput

The Form 3BL is thoughtfully designed to maintain ideal print conditions with minimal operator intervention.

The Form 3BL is the large format dental 3D printer that raises the bar for dependable high-production dental 3D printing, designed to work day and night with minimal intervention.

Form 3BL is now succeeded by Form 4BL, our next-generation dental 3D printer, which improves upon its foundation in every possible way.

Form 4B is powered by our Low Force Display™ (LFD) Print Engine, setting the new industry standard for blazing-fast speed. Create high-quality dental models and biocompatible appliances fast, with easy workflows, leading reliability, and stunning part quality using the Form 4B ecosystem.

Powered by the same groundbreaking LFD technology, Form 4BL can print more than 100 models per hour with up to 3x fewer interactions than Form 4B, so you can increase efficiency and reduce labor costs.

A build volume of 33.5 × 20 × 30 cm (13.2 × 7.9 × 11.8 in) maximizes throughput for every print job. Print up to 120 models in a day, with just a few printer interactions.

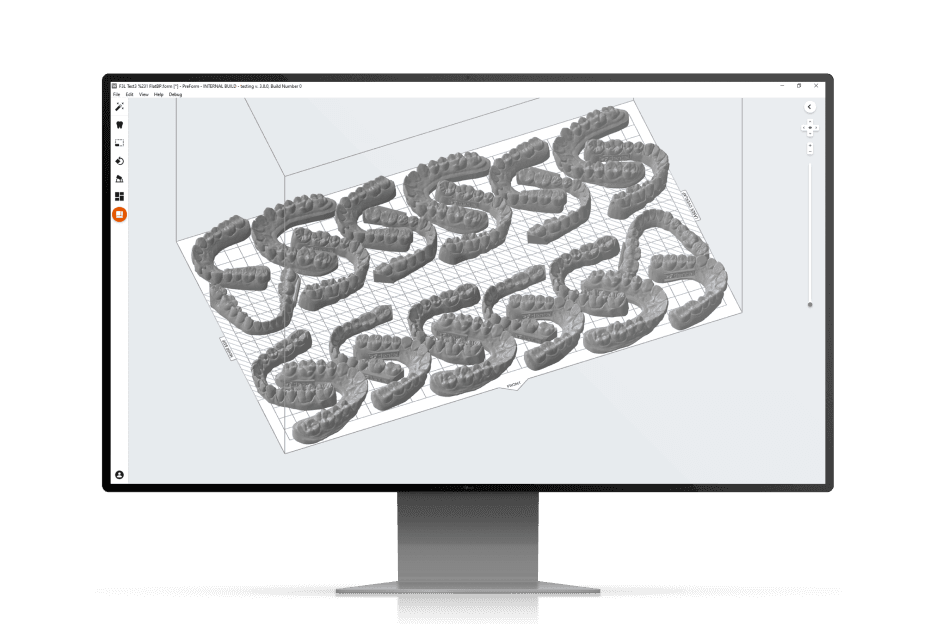

24 orthodontic models, printed flat

Note: print time and cost will vary based on part geometry, material, layout, and orientation.

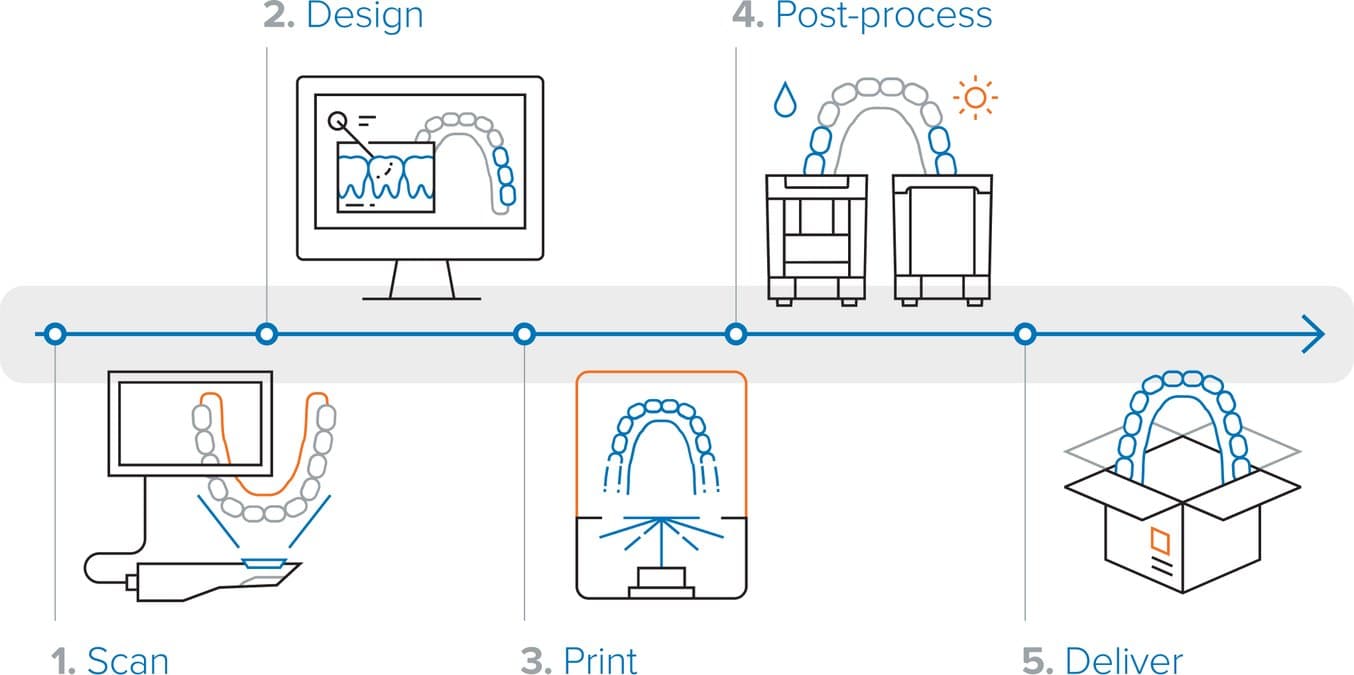

The Form 3BL works full time so you don’t have to. Intuitive nesting software and automated post-processing options make custom manufacturing easy.

Watch our webinar with Sam Wainwright, Dental Product Manager, and Phil Carlino, Head of Dental Sales, for a technology demo of the Form 3B and learn how you can reclaim more time in your day.

Grey Resin at 100 micron layer thickness

| Accuracy Range | ± 100 µm | |||

|---|---|---|---|---|

| Surface in Accuracy Range | 94% ± 8% |

Validation parts were printed using Grey Resin on Form 3BL printers. Results may vary.

The Form 3BL is thoughtfully designed to maintain ideal print conditions with minimal operator intervention.

Remotely monitor and inspect your fleet of printers and track resin and tank usage over time with the online Dashboard.

Enable SMS and email notifications to receive notifications when prints are completed or your printer needs attention.

Our automated resin system dispenses resin as parts print. The Form 3L holds two cartridges of resin to avoid mid-print interruptions.

The Light Processing Units, rollers, and optics window can be replaced in-house, so you don’t have to wait for a replacement printer if something goes wrong.

Behind Formlabs Dental is a dedicated team of certified Dental Support Specialists who know exactly how to help when you need it. Our Dental Service Plan includes personalized onboarding training, proactive check-ins, and the best phone and email support in the industry.

Prepare files for printing in PreForm and manage printers and teams through your online Dashboard.

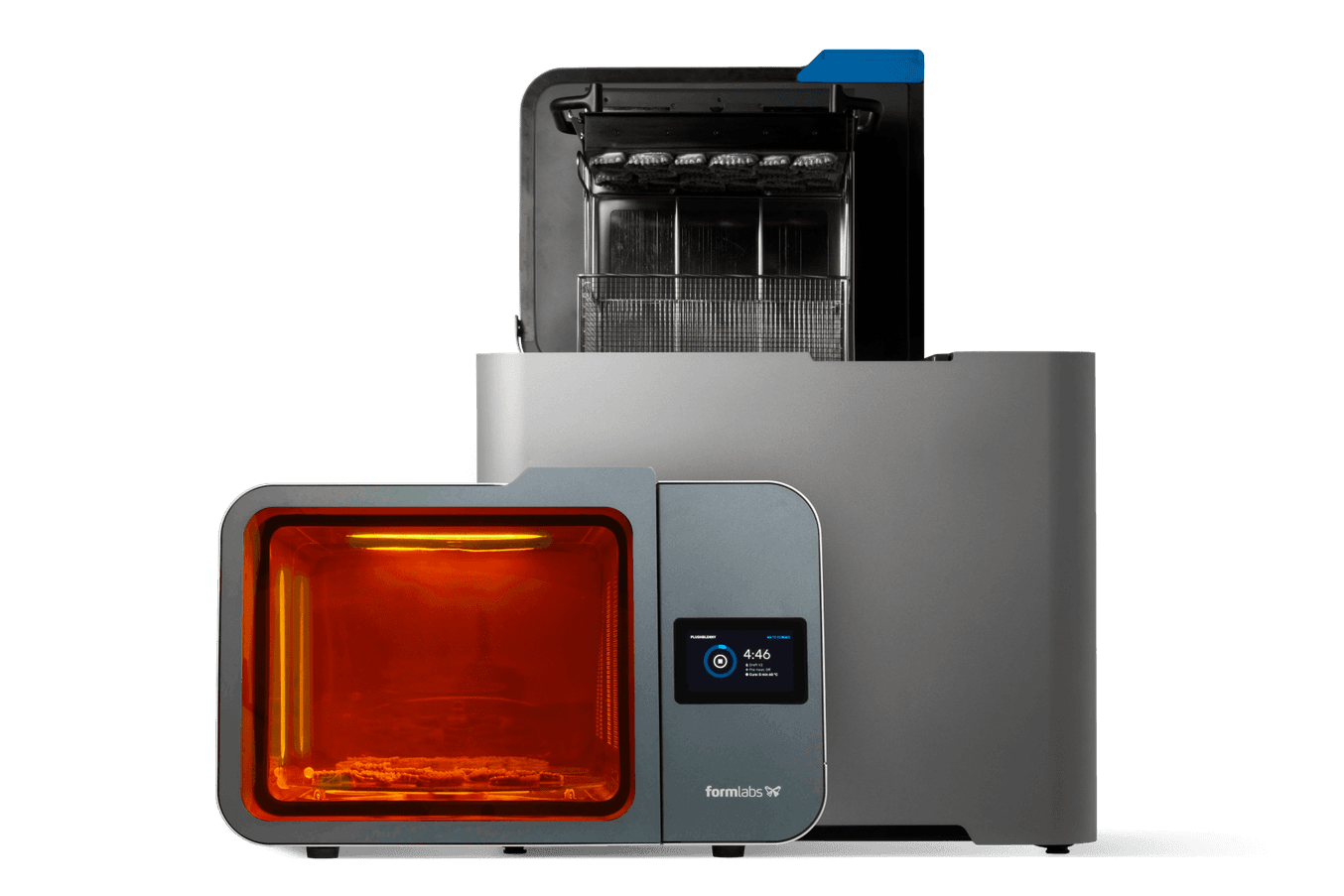

Streamline your workflow and consistently batch-produce high-quality dental parts with our automated high-volume post-processing solution. Form Wash L and Form Cure L have been validated and are compatible with our ISO 13485 compliant materials for biocompatible use.

With 75+ support and service staff and 150+ engineers, Formlabs backs its products with the strongest team in 3D printing.

Reclaim your time and produce parts you’ll be proud to deliver, without the hassle or prohibitive costs. Formlabs brings unprecedented reliability, quality, and ease of use, with validated workflows tested by a team of dental experts.