Most stereolithography 3D prints require support structures for successful printing, but there’s no one-size-fits-all solution.

In PreForm 3.4.6, the latest version of our software, we’re excited to announce improved 50 micron settings and new light-touch supports for Castable Wax Resin for the Form 3B, designed specifically for dentistry. With tailored supports for your specific dental workflow, post-processing and setup are easier than ever.

Simplified Support Removal

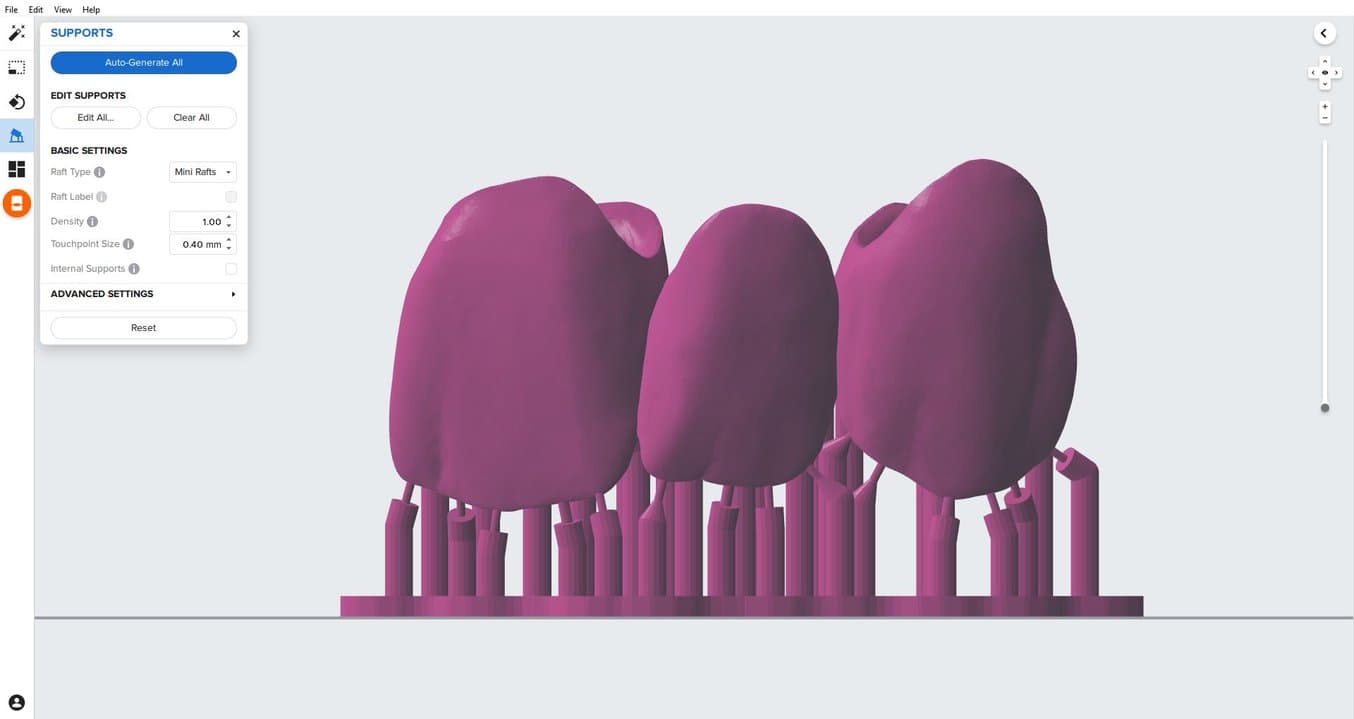

Different types of 3D prints require different types of support structures. For larger models, support structures help stabilize the part horizontally during the print process, and can facilitate easier removal of the supports in one piece after printing. However, for lightweight, small parts like dental restorations, increased supports can lead to entangled prints or excessively strong nests of supports that complicate removal.

With this in mind, we’ve reduced support structures to a minimum for small Castable Wax parts on the Form 3B. This makes it easier to remove supports and saves you time in post-processing.

Preserve Important Surfaces With Improved Tip Geometry

Support touchpoints play a role in the quality of your 3D printed parts. That’s especially true for casting resins, where a pit from support removal can ruin the surface of a cast or pressed restoration.

With Castable Wax light-touch supports, we’ve reduced the likelihood of supports leaving a dimple in the part after removal. The new peg-shaped support tips are designed to break slightly away from the print. Usually, this leaves a small positive nub rather than a dimple — making it possible to clean up the mark by lightly sanding either the printed pattern or the metal casting.

This means you can easily sand down extra material, rather than dealing with an unsightly divot.

Improved Accuracy for Superior Fitment

The latest settings have been tuned specifically to improve fitment for dental restorations and partial denture frames on the Form 3B. Updating to the latest PreForm software helps you get the most consistent results when 3D printing pressing and casting patterns.

Download the latest PreForm release and start printing the best dental casting and pressing patterns yet.

Try It Now

You’ve come to expect a high level of ease of use in Formlabs software. If you’ve had trouble post-processing fine-featured dental parts, we hope these updates will make your workflow more convenient.

To get started, download PreForm 3.4.6, choose Castable Wax Resin as your material, select the Form 3 Virtual Printer, and build support structures. Easily slice the model to see exactly where supports are needed and spend less time on support removal.

We’re committed to continuing to expand the capabilities of all Formlabs printers through continuous software updates, so keep an eye out for future improvements and dental-specific features in the coming months.