Powering Productivity Through Automation at Dane Dental Lab and Hatcher and Frey Orthodontics

For orthodontic and dental labs, efficiency is key to meeting production goals. But for labs wanting to increase production, space, time, and staffing can be major hurdles. One solution for entering the next step of digital production is the adoption of the Formlabs Automation Ecosystem.

Dane Dental Lab, a full-service orthodontic lab, was looking to replace two older printers with one while maintaining production levels. Meanwhile, Hatcher and Frey Orthodontics, a large orthodontic lab, was growing to support five offices. When they saw a Form Auto at work and learned about the Formlabs Automation Ecosystem, they knew they’d found their solutions.

Nonstop Production With the Formlabs Automation Ecosystem

Learn more about how to scale your lab without increasing printer management complexity with an in-depth walkthrough of the Formlabs Automation Ecosystem.

Adding Automation

Dane Dental Lab

Dane Dental Lab is a full-service orthodontic lab in Cottage Grove, Wisconsin. The lab has 10 full time employees, with two of those being dedicated 3D printing techs. Shannon Neubauer is an orthodontic technician there, focusing on 3D printing for the lab.

The lab had been 3D printing since 2016, and were well versed in it. Before that, though, Neubauer says “it was all analog. It was all hands-on. The overall turnaround time for appliances often was days longer than what we can do now because we would have to wait for models or impressions to get shipped to us.”

Moving to digital workflows and 3D printing, “definitely increased our productivity,” says Neubauer. “Errors are a lot less. Remakes due to distorted impressions are no longer an issue. Scanning is extremely accurate. You are not breaking your models during appliance fabrication causing potential discrepancies. An added bonus is doctors receive unbroken models they can retain for future use.”

With 3D printing, a key component of the lab’s workflow, having working, up-to-date printers was essential for their business. But in 2023, Dane Dental Lab was facing a problem. Two of their older printers were facing decommission and they were looking to replace both of them with a single, newer model. They headed to LMT Lab Day and when they saw the Form Auto, they knew they’d found a solution.

“We saw the Form Auto last year at LAB DAYS. And we were just like, "That's what we need. That's exactly what we need." I mean, it really wasn't a question.”

Shannon Neubauer, Orthodontic Technician, Dane Dental Lab

Hatcher and Frey Orthodontics

Caitlin Zurick is the lab coordinator at Hatcher and Frey Orthodontics, one of two people who focus on 3D printing. She says, “3D printing is a whole new world compared to the old school impressions back in the day. It's more flawless, more accurate for scans for retainers.” A growing business, the orthodontic lab now supports five offices, with more on the way. With such growth, the lab needed to find a way to scale up their 3D model production.

Like Dane Dental Lab, one potential solution was to have more printers so that more print volume could be handled. But additional printers would require additional work, as prints would need to be manually removed from all the printers, build platforms cleaned, and then printing initiated. This would take valuable time away from other tasks.

By adding a Form 3B+ Stereolithography (SLA) 3D printer and a Form Auto, Hatcher and Frey could print 24/7 without taking Zurick away from other tasks. Instead, Form Auto took care of removing prints and prepping for the next batch while Fleet Control software queued up and initiated the next print.

Ramping Up to 24/7

Form Auto is the hardware component of the Formlabs Automation Ecosystem. It works with a Form 3B+, seamlessly removing finished parts from the Build Platform 2 and starting the next print without the need for operator interaction, enabling 24/7 printing without downtime.

The automation enabled by Form Auto meant that Dane Dental Lab could use one Form 3B+ printer to print 24 hours a day, not only effectively replacing the printing time of two printers, but exceeding it. Neubauer says that “Getting the Formlabs printer, getting it set up, and learning the software was pretty easy. It's very user-friendly.” If she ran into something she didn’t know, she “was able to go into [Formlabs’] Dashboard and education section and just read up on whatever those little differences were. The education section is great, it has everything a person would need.”

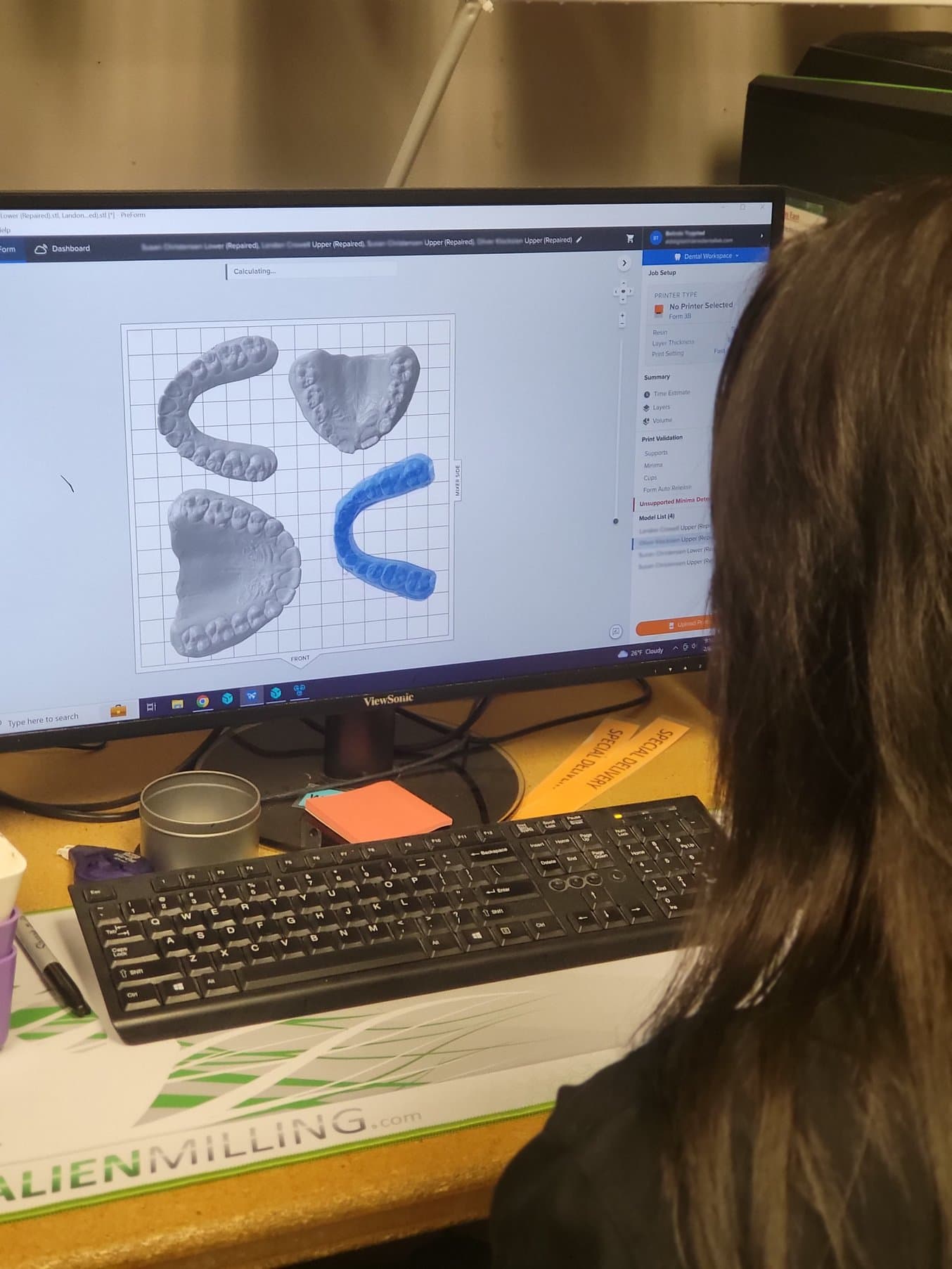

At Dane Dental Lab, Shannon Neubauer prepares orthodontic models for printing utilizing PreForm Dental.

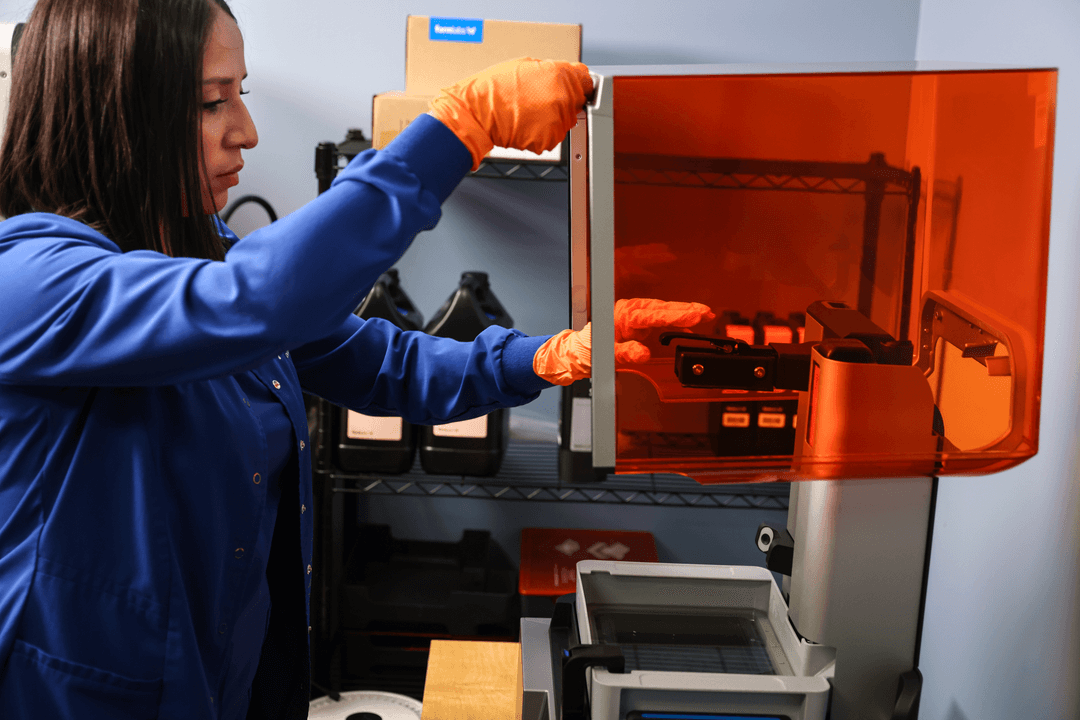

At Dane Dental Lab, models are printed with the Form Auto and post-processed utilizing the Form Wash and Form Cure.

Zurick agrees, finding that getting up to speed on the Form Auto “was actually a lot easier than I thought. It took a day or two to get the hang of it.” Changes in tools, technology, and workflows have the potential to usurp valuable production time with onboarding. But the intuitive system and extensive educational resources meant Neubauer and Zurick could get their Form Autos up and running with minimal interruptions to production.

Remote Control With Automation Software

Anything that can be done on a traditional stone model can be done on a printed model, from thermoforming retainers to soldering to removables. Neubauer notes that with traditional stone models, they dealt with errors, discrepancies, and breakage, plus the additional time of shipping. With IOS and 3D printed models, their productivity is up, and it’s only been accelerated by the addition of the Formlabs Automation Ecosystem.

“I can't say enough good things about the Form Auto. This device was life-changing for us. We went from being able to put in, and this is per machine now, maybe 10 print runs in a working day to 20 print runs in a working day because it can run all night continuously.”

Shannon Neubauer, Orthodontic Technician, Dane Dental Lab

For labs that aren’t staffed nights and weekends, the Form Auto is “like having a second shift employee,” says Neubauer.

“The Form Auto is really helpful on the weekends because I work remotely on Fridays. It gives me the chance to be able to work remotely but continue the prints throughout,” says Zurick. Adding a Form Auto can more than double print production, printing through nights and weekends without requiring hand-on attention.

Both Zurick and Neubauer utilize Fleet Control, advanced printer management software that includes one centralized Dashboard queue for tracking and prioritizing prints. Dashboard allows them to view print status — right from a phone — so they’re up to speed when they return to the office.

Calculating ROI for the Formlabs Automation Ecosystem

In this whitepaper, we’ll walk through three manufacturing scenarios to explain cost per part and return on investment (ROI) calculations.

Five Times the Supply With Resin Pumping System

In any lab, minimizing time spent interacting with a printer frees up time for higher value tasks. Both Dane Dental Lab and Hatcher and Frey Orthodontics utilize Resin Pumping System, part of the Formlabs Automation Ecosystem, which decreases time spent changing resin cartridges, improving operational efficiency, streamlining the SLA 3D printing workflow, and reducing waste by 86%.

Part of the Formlabs Automation Ecosystem, Resin Pumping System delivers resin from a 5 L container to the printer without cartridge changeover. As Zurich says, “it was a very easy set up.” From installation to use, the Resin Pumping System is seamless.

“We intend on purchasing another [Resin Pumping] System for our second Form Auto because of how successful it has been for us.”

Caitlin Zurick, Lab Coordinator, Hatcher and Frey Orthodontic

Optimized for Speed

Both Dane Dental Lab and Hatcher and Frey Orthodontics dedicate their Form Autos to model production, printing with Draft Resin, which was developed to be Formlabs’ fastest printing material, capable of printing a dental model in under 10 minutes.

Orthodontic models printed in Draft Resin at Hatcher and Frey Orthodontics.

“The Draft Resin is honestly my favorite resin. It prints a lot faster than what we used to use, which we love because of the volume of the office.”

Caitlin Zurick, Lab Coordinator, Hatcher and Frey Orthodontic

Draft Resin is highly accurate with a smooth surface finish, making it the ideal material for thermoforming models, diagnostic models and orthodontic appliance models

Aside from resins being optimized for faster prints, Fast Arch Printing are printer settings specifically developed for maximizing existing hardware to be able to produce dental arches at a higher speed without sacrificing accuracy. Available for Draft Resin and Grey Resin, Fast Arch Printing improves print times by up to 120% when printing at 200 microns. When used in combination with the Formlabs Automation Ecosystem and Fast Cure, these settings accelerate efficiency.

Draft Resin

A cutting-edge material designed to print accurate orthodontic models – fast.

Automation Made Easier

For both Dane Dental Lab and Hatcher and Frey Orthodontics, the Formlabs Automation Ecosystem has allowed for increased production without increases in staff time or energy. Hatcher and Frey Orthodontics “started with just one Form Auto, to see how it went,” says Zurick, but “we quickly adopted the second.”

“Because of this machine, we have been able to increase our productivity without having to increase employees.”

Shannon Neubauer, Orthodontic Technician, Dane Dental Lab

With the Formlabs Automation Ecosystem, it’s possible to streamline workflows, improving production and efficiency without adding staff or taking time away from high value tasks. Learn more about the Form Auto or talk to a Formlabs Dental expert today to see how the Formlabs Automation Ecosystem can help you reach new levels of productivity.