The future of dentistry and orthodontics is digital. With cutting-edge digital technologies for impressions, treatment planning, design, 3D scanning, and 3D printing, digital technologies are transforming thousands of dental practices, orthodontic practices, dental labs, and orthodontic labs worldwide. As CAD/CAM continues to replace traditional workflows and become the standard of dental care, digital solutions have become a necessary consideration for any dental or orthodontic business.

Costs are the primary concerns of dental professionals looking to adopt in-house 3D printing. Does this printer make sense for my business? Will the investment break even? What’s the return on investment (ROI) going to be?

Dental 3D printer prices range from a few thousand dollars to $100,000 or more, with costs scaling depending on the printing process, throughput required, manufacturer, services and support, materials, and more. However, a higher price doesn’t always mean a better solution.

In this guide, we’ll walk you through:

- The true cost of investing in and using various dental 3D printers

- Comparisons between outsourcing and in-house production

- The various factors you should account for to calculate cost per part

- The considerations beyond cost when comparing various 3D printing solutions and other production methods

Book a Free Consultation

Get in touch with our dental 3D printing experts for a 1:1 consultation to find the right solution for your application, receive ROI analyses, test prints, and more.

Choosing a Dental 3D Printer

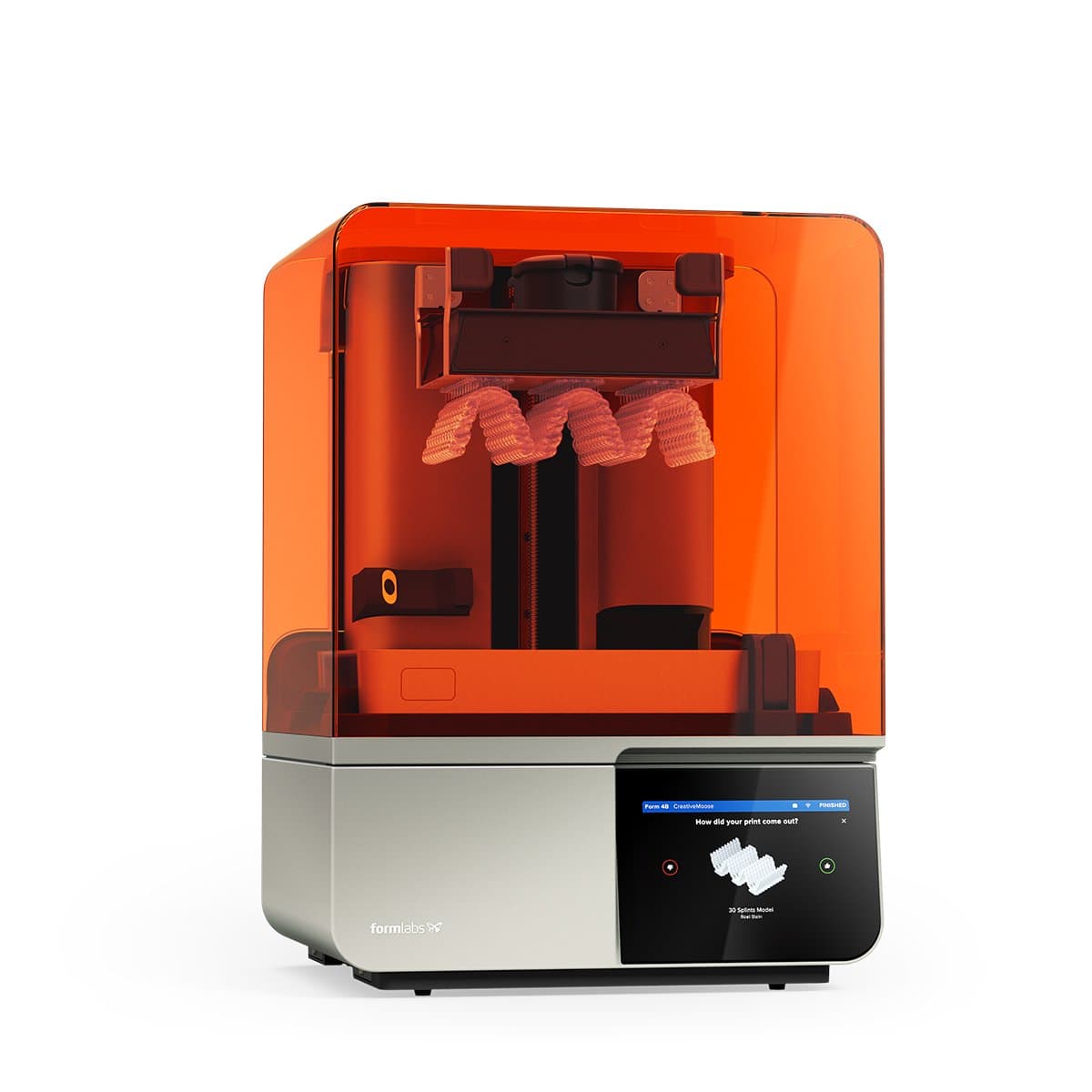

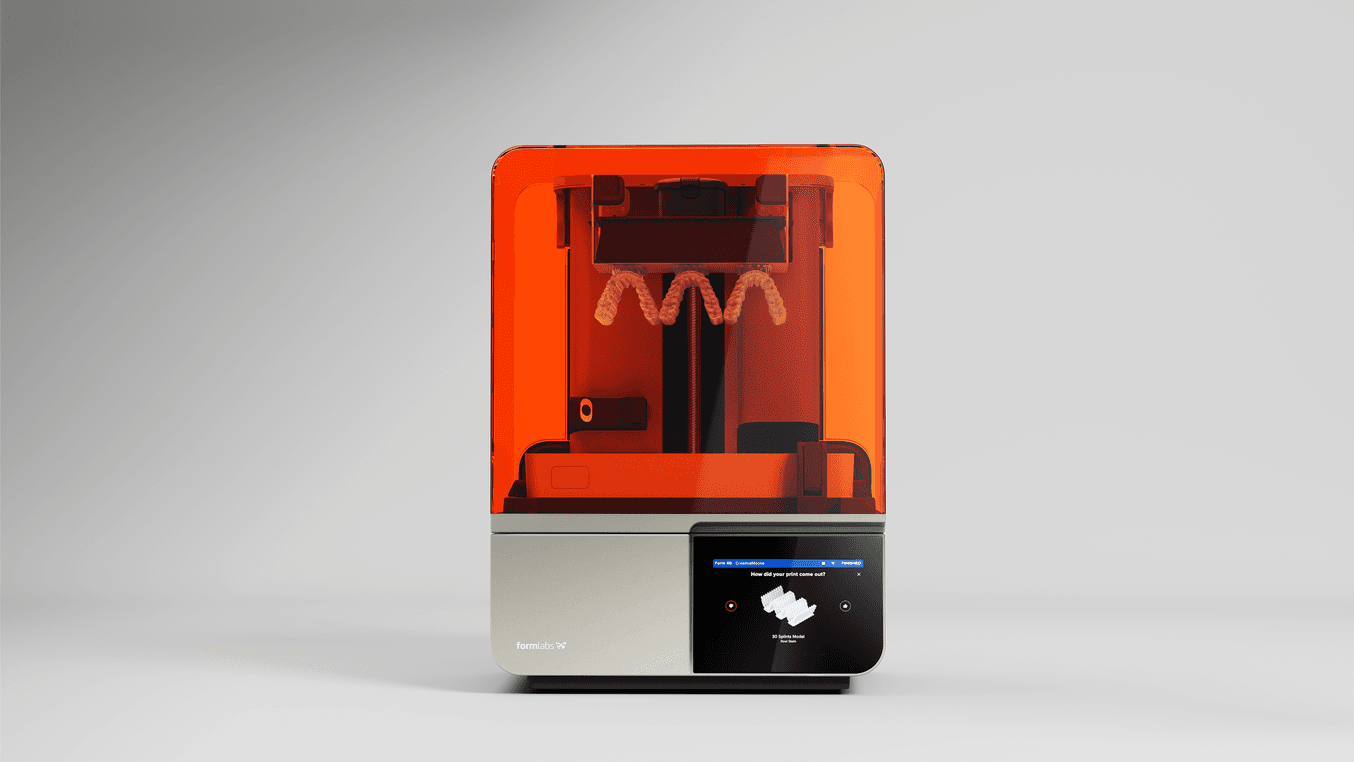

Form 4B dental 3D printer was designed for speed, accuracy, and reliability, with intuitive workflows that make printing easy and efficient.

When choosing a dental 3D printer, there are a few things to consider in addition to price. In general, dental professionals should be concerned with:

-

Accuracy: Guaranteeing high-quality, accurate final parts is the most important concern for any dental professional. Accuracy and precision depend on many different factors: the quality of the 3D printer, the 3D printing process, materials, software settings, post-processing, and how well-calibrated all of these systems are.

-

Reliability: Dental professionals run on tight timelines. Whether printing a same-day appliance or running 24 hours a day for peak production, print failures result in additional costs and missed deadlines.

-

Maintenance: Consider the types of everyday interactions and maintenance the printer will need once it is up and running. Servicing and maintenance costs can be expensive without a service plan.

-

Ease of Use: There are big differences in the software used to prepare 3D models for printing, the complexity and the number of steps to set up and operate printers, the availability of post-processing tools and degrees of automation, and the resources available for learning new application workflows.

-

Materials: The materials available for a single 3D printer and the ease of switching between materials affect the range of appliances it’s possible to print — one of the most powerful aspects of digital dental technologies.

-

Production Volume: It’s important to consider print setup, post-processing time, and production volume when investing in a dental 3D printer. Preparing the printer, setting up the prints in your dental software, and post-processing the parts are all steps not immediately made visible in a basic print time metric.

We put together a free dental 3D printer buyers guide that covers these metrics in more detail. For a deeper dive into these key metrics by specialty, download white papers for Dental Labs, Orthodontics, or Dental Practices.

Calculate Your Time and Cost Savings

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs dental 3D printers.

Dental Printer Technologies: SLA, DLP, MSLA

Form 4B is a masked stereolithography (MSLA) 3D printer, and uses the light from LEDs and an LCD as the light-processing solution to cure resin rapidly and accurately.

Let’s start with some basic definitions and technology overviews. Dental 3D printers are predominantly resin 3D printers. Today, three resin 3D printing technologies are common in dental and orthodontic practices and labs: traditional laser-powered stereolithography (SLA), digital light processing (DLP), and masked stereolithography (MSLA, also often used interchangeably with LCD 3D printing). The most common method is inverted resin 3D printing, where a build platform descends into a resin tank with transparent bottom to create parts upside down, layer by layer, as the light source cures a thin layer of resin through the bottom of the tank.

The difference in technology emerges in how light is used to cure the resin.

Stereolithography (SLA): SLA printers, such as Form 3B+, use a laser and mirror galvanometers, which direct the light to the correct coordinates on a series of mirrors, focusing the light upward through the bottom of the tank and curing a layer of resin. Formlabs SLA 3D printers utilize Low Force Stereolithography™ (LFS). LFS reduces the strain created on a part when peeling it from the resin tank between layers, producing parts with a smooth surface finish, clarity, and accuracy.

Digital Light Processing (DLP): DLP 3D printers use a digital projector as the light source and a micromirror device as the optical system to selectively solidify the resin. With DLP, the entire layer gets cured at the same time.

Masked Stereolithography (MSLA): MSLA is the newest process that uses the light from LEDs and an LCD as the optical system to cure an entire layer rapidly and with high accuracy. Formlabs’ Low Force Display™ (LFD) is an advanced form of MSLA, developed for Form 4B and Form 4BL, for large-format 3D printing. LFD introduces a brand new technology stack including a backlight unit, light processing unit, release texture, and integrated camera, and significant improvements with updates to the flexible film tank, resin cartridge, automatic resin handling, and intelligent control systems to deliver the speed, reliability, and part quality that professionals need, all in a single printer.

Product Demo: Form 4B+ Dental 3D Printer

Blazing speed meets unmatched accuracy in the next generation of dental 3D printing. Explore the latest innovations in our webinar.

Best Dental 3D Printers: Price Comparison

In this section, let’s take a look at some printers currently available and dive into their costs, which include both upfront costs and long-term maintenance costs. When purchasing a dental 3D printer, users should consider all types of costs associated with 3D printing.

| MASKED STEREOLITHOGRAPHY (MSLA) | STEREOLITHOGRAPHY (SLA) | DIGITAL LIGHT PROCESSING (DLP) | |

|---|---|---|---|

| Models and Manufacturers | Formlabs Form 4B, Formlabs Form 4BL | Formlabs Form 3B+, Formlabs Form 3BL | SprintRay, Asiga, Desktop Health, Carbon3D |

| Equipment Ownership | Desktop printers start at $7,699, complete solution for $12,006. Large-format printers start at $16,249, complete solution for $29,899. | Desktop printers start at $3,499, complete solution for $4,440. Large-format printers start at $6,999, complete solution for $14,600. | Desktop printers start around $10,000, complete solutions around $18,000. Large format solutions start around $25,000 and go beyond $100,000. |

| Materials and Consumables | $99 per L for model resins, $199+ for biocompatible resins. | $150 per L for model resins, $250+ for biocompatible resins. | $150 per L for model resins, $250+ for biocompatible resins. |

| Labor | Low. Advanced post-processing tools are available to minimize labor needs. | Low. Advanced post-processing tools are available to minimize labor needs. | Depends on the manufacturer. Advanced post-processing tools are available, but generally at a higher cost. Many solutions require manual labor to set up prints, pour resin, and more. |

| Maintenance | Minimal maintenance. | Minimal maintenance. | Depends on the manufacturer, some printers require extensive maintenance and calibration. |

| Service Plan | Depends on the manufacturer and package purchased. For Formlabs dental 3D printers, a comprehensive service plan is included in the price of the complete solution. | Depends on the manufacturer and package purchased. For Formlabs dental 3D printers, a comprehensive service plan is included in the price of the complete solution. | Depends on the manufacturer, can be lacking or costly (up to 20% of the price of the printer per year). |

The upfront costs of bringing these printers in-house varies, but higher prices for DLP 3D printers and other "made for dentistry" 3D printing solutions doesn't necessarily mean better quality or more features. Besides having the biggest installed base of 3D printers in the dental industry, Formlabs develops, manufactures, and sells printers for many other industries. This means Formlabs sells more 3D printers in a month than most dental 3D printing companies sell in a year. With that volume comes economies of scale, which Formlabs can then share with customers allowing the price to be affordable and competitive.

Formlabs manufactures our Biomed and Medical Device Resins at our FDA Registered facility in Ohio under a Quality Management System that is ISO 13485 and EU MDR certified. By doing this, we control the quality of our product while also being able to offer affordable resins.

Labor costs are one of the areas where major differences arise. For example, Formlabs MSLA and SLA 3D printers require minimal setup and can refill resin automatically, while some DLP printers require frequent calibration, lengthy setup, and a technician to manually refill the resin and pour it back into the bottle when the printer is not in use.

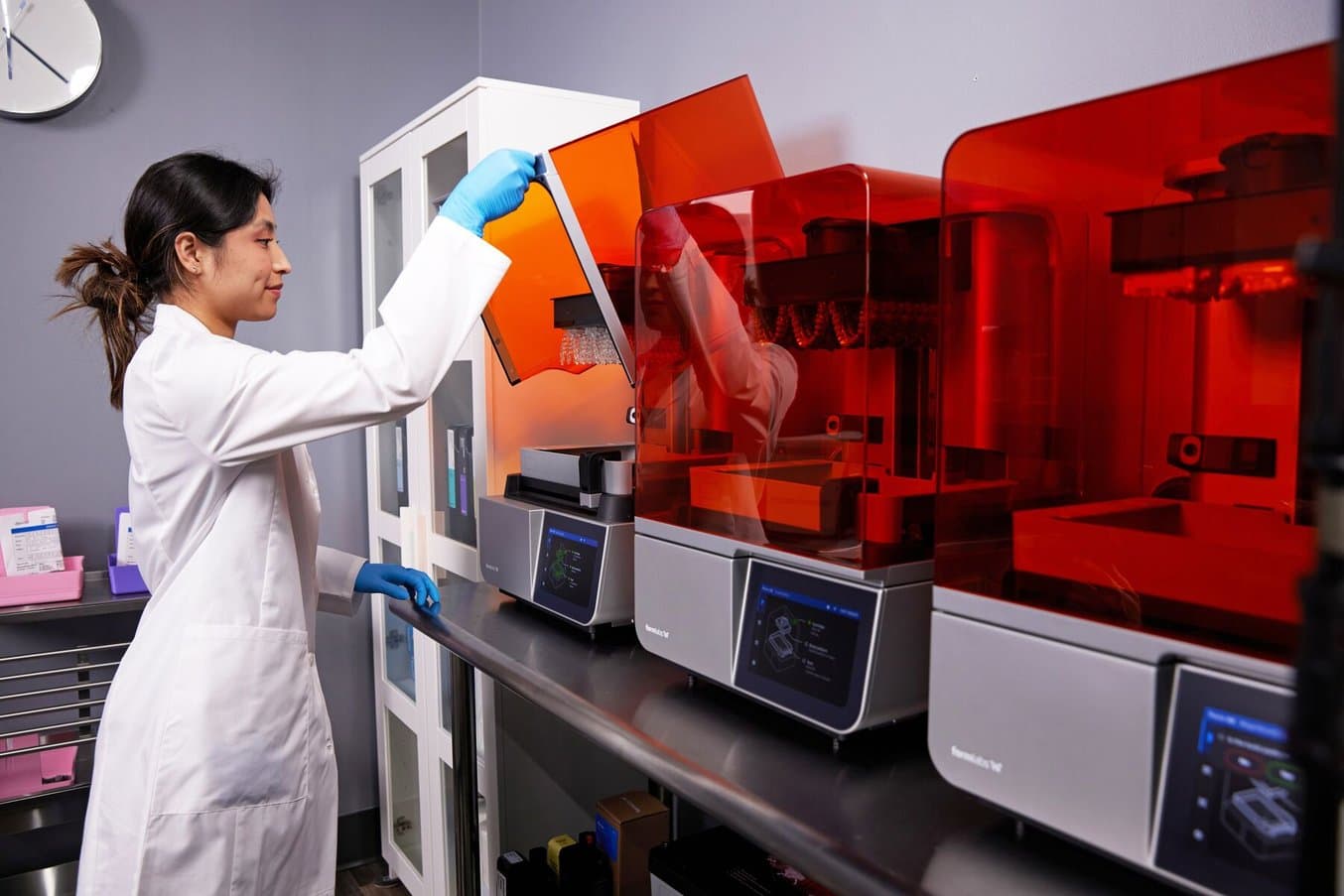

Post-processing is also more streamlined with some solutions than with others. The Formlabs Form 4B and Form 4BL can be used with Build Platform Flex and Build Platform Flex L, respectively, and Form 3B+ can be used with Build Platform 2. These flexible build platforms enable the quick and easy removal of parts from the build platform without tools in seconds.

Automated post-processing units such as Form Wash and Form Wash L, and Form Cure and Form Cure L, also speed up the cleaning and post-curing process, meaning your dental workflows can go from print to final part as soon as possible, reducing completion times and labor costs.

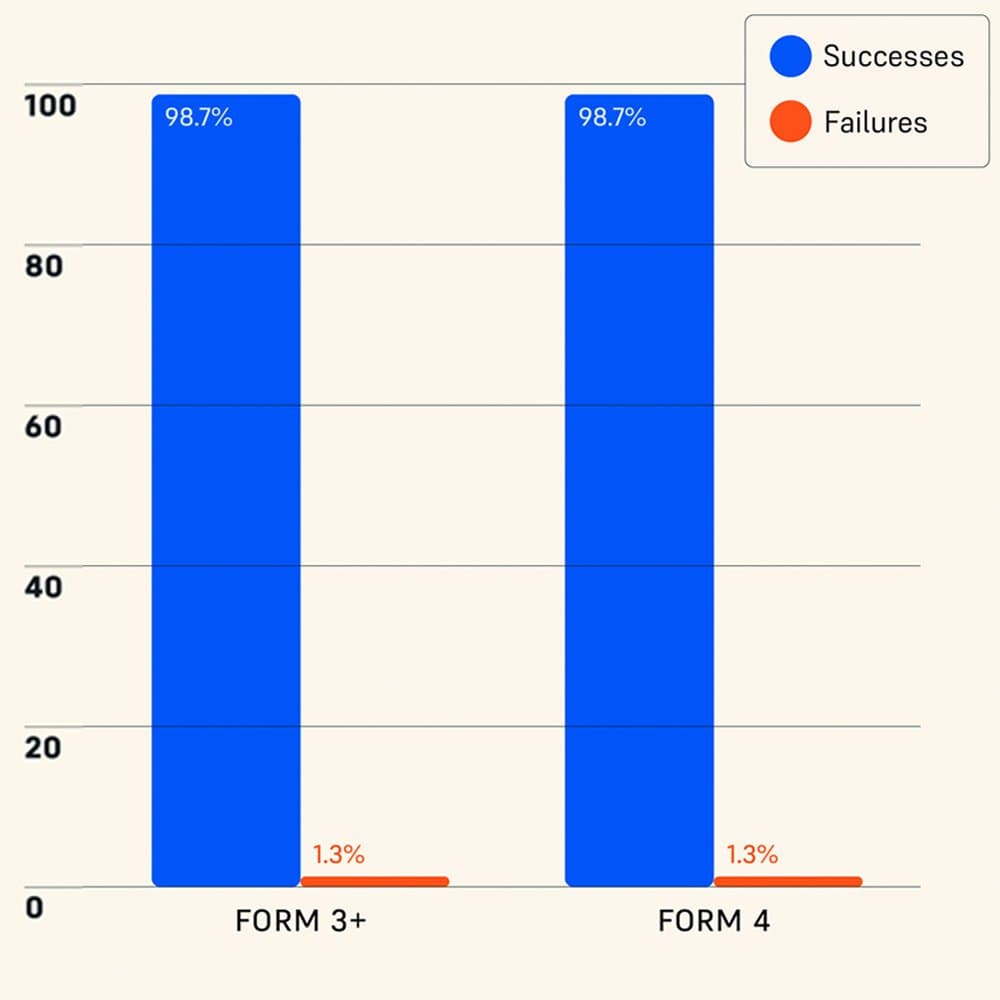

Independently Tested Reliability of Form 4 and Other Resin 3D Printers

Formlabs Form 4 was measured to have a 98.7% print success rate by an independent global leader in product testing. Read a complete description of the test methodology and see the results in our white paper.

Outsourcing vs. In-House 3D Printing

Print one to six occlusal splints in 35 minutes on the Form 4B 3D printer.

Many dental professionals, labs and practitioners included, start their digital journey by outsourcing some of their indications. This makes sense for low production volumes and for dental professionals just getting started with 3D printing or dental CAD/CAM. However, the cumulative cost of outsourcing quickly climbs and can far exceed in-house production costs in just a few months. One of the greatest benefits of 3D printing is its speed compared to traditional manufacturing methods, which quickly diminishes when an outsourced part takes multiple days or even weeks to arrive. With growing demand and production, outsourcing rapidly becomes expensive.

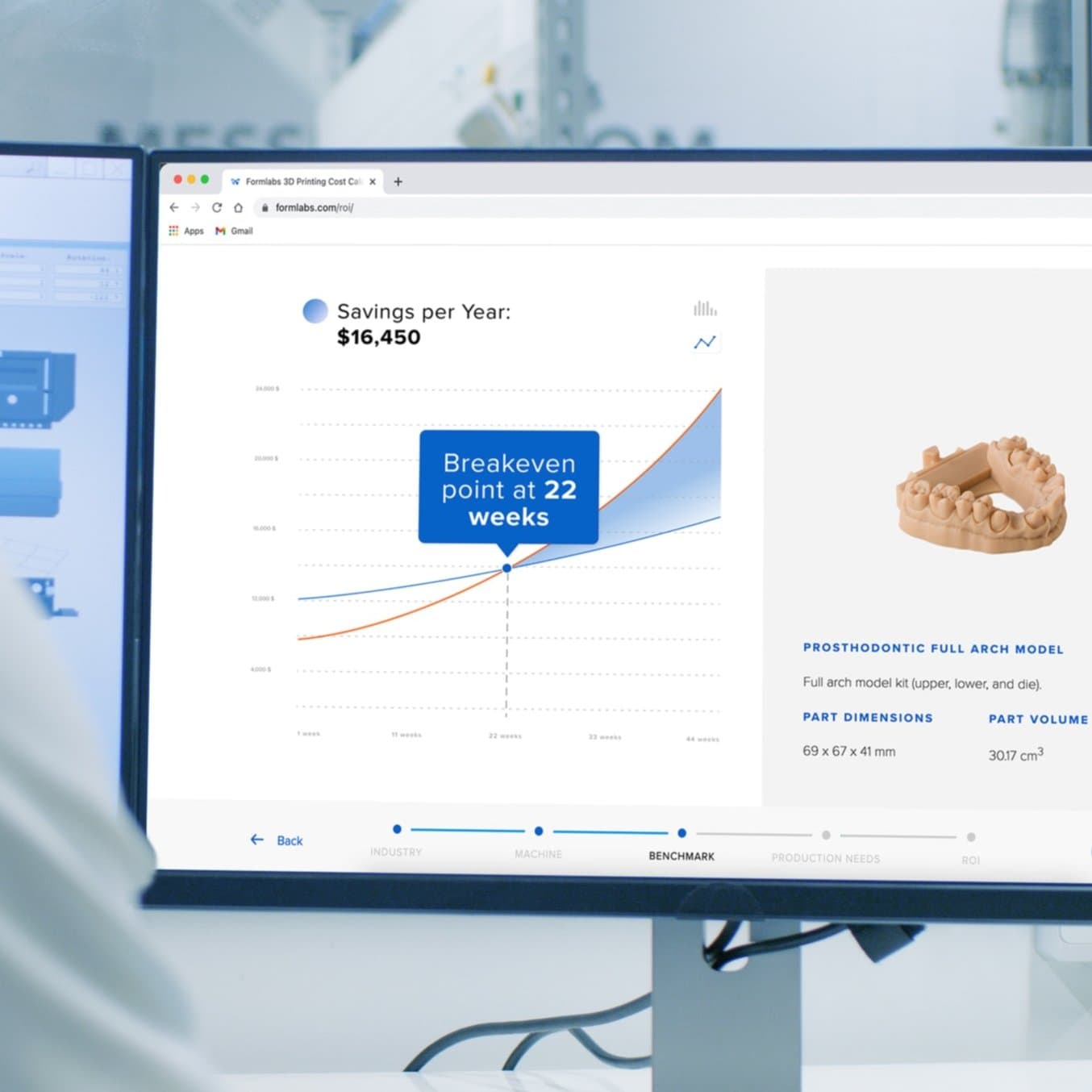

Let’s take a look at a dental office that is producing 10 aligner models per day. The office’s fixed labor cost is $20 per hour, and they expect to keep the production level set all year, creating 3,650 parts in one year.

Outsourcing comes with no upfront investment costs, and each order costs $15 per part with a lead time of one week.

Under these criteria, the break even point is just seven weeks. That is, outsourcing is cheaper than in-house printing for the first seven weeks, and then becomes increasingly more expensive after that. Bringing production in-house will save this dental business more than $40,000 in a single year.

Formlabs Dental created an interactive ROI calculator so you can input the parts per week and labor costs and generate your own report to compare the cost of in-house production and outsourcing.

Some common questions dental professionals might ask when they are considering outsourcing or in-house 3D printing production:

-

How many parts per week will you need? As we’ve seen, at only 10 aligner models per day, outsourcing quickly adds up to far exceed the cost of in-house production in less than two months.

-

What indications will you produce? Outsourcing costs for more complex biocompatible appliances for intraoral use can be substantially higher, resulting in even faster ROI for 3D printing.

-

How quickly will you need your parts? If you find yourself often with rush cases, then long outsourcing lead times can be a deal breaker.

Besides a 3D printer, what else do you need to get started? Both practices and labs generally require a scanning and software solution to complete the workflow, but outsourced design options are available for the latter. Learn more about it in our extensive guide.

Dental 3D Printing Cost Per Part Examples and ROI

Start by outsourcing your CAD/CAM work or print just a few appliances before scaling up.

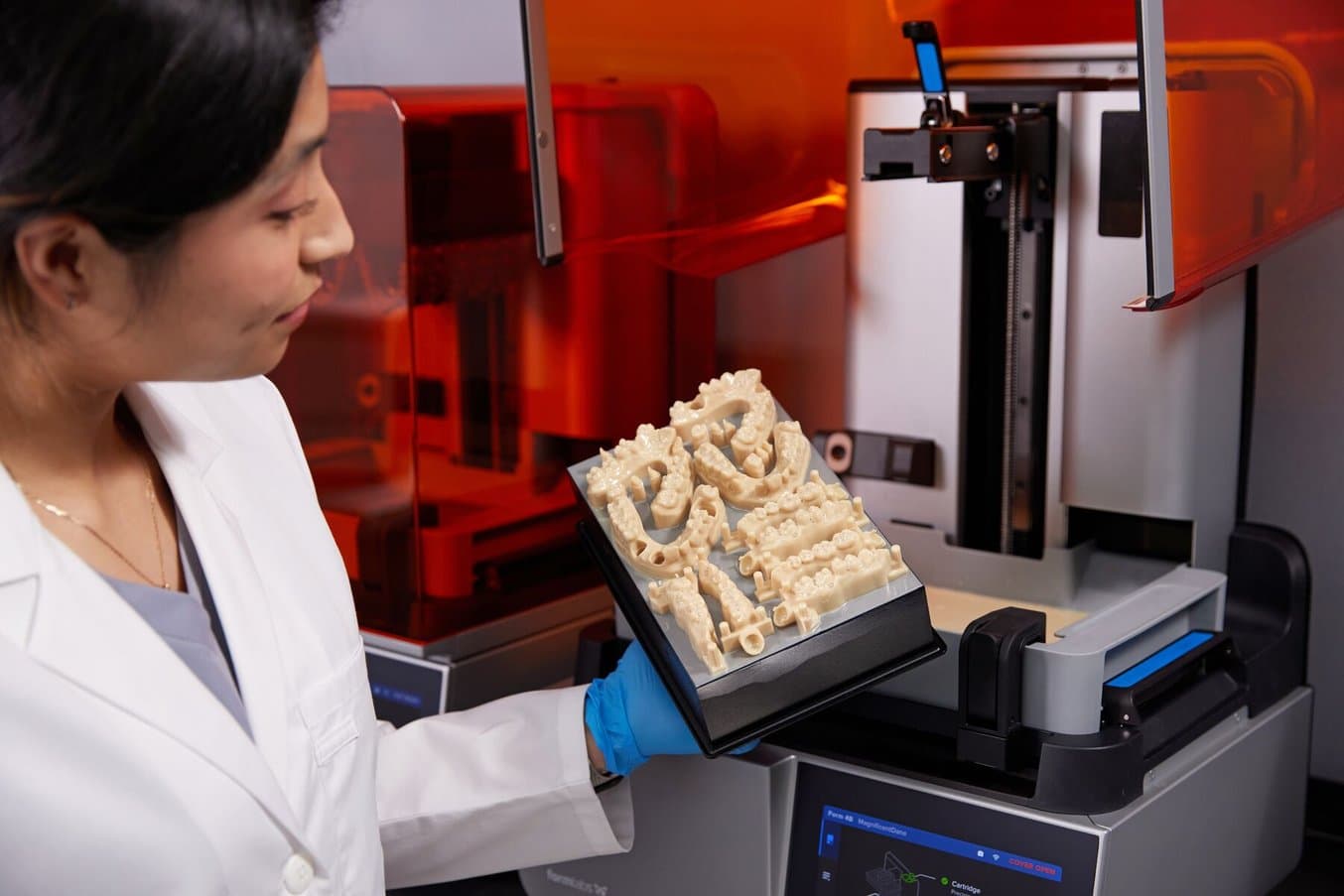

Let’s take a look at some examples of costs per part based on dental indications created with Form 4B. We’ve already established that in-house 3D printing quickly becomes more affordable than outsourcing those same parts, but how much do various parts actually cost to print?

For labs with high-volume applications, Form 4BL, Formlabs’ large-format 3D printer, offers higher throughput with fewer interactions, saving on labor time when printing multiple builds a day.

| Appliance | Printing Material | Cost Per Print* | PRINT TIME: FULLY PACKED BUILD PLATFORM ON A FORM 4B | PRINT TIME: FULLY PACKED BUILD PLATFORM ON A FORM 4BL |

|---|---|---|---|---|

| Orthodontic Models & Clear Aligner Models | Fast Model Resin | $2-3 | 11 models in 9 min | 32 models in 14 min |

| Occlusal Splints | Dental LT Clear Resin or Dental LT Comfort Resin | $4-5 | 8 splints in 49 min | 24 splints in 1 h 19 min (15° orientation) 80 in 2 h 10 min (vertical orientation) |

| Crowns | Premium Teeth Resin | $1-2 | Single crown in 18 min | |

| Digital Dentures | Premium Teeth Resin & Denture Base Resin | ~$10 | Full denture in under 1 hour (2 separate builds) | |

| Surgical Guides | Surgical Guide Resin | $2-4 | 12 guides in 48 min | 36 guides in 1 h 9 min |

| Restorative Model | Precision Model Resin | $2-4 | 10 models in 1 h 50 min | 28 models in 2 h 48 min |

*The costs in this table only cover the actual printing cost of materials, and not the cost of the equipment and the labor costs associated with preparing the prints.

Request a Free 3D Printed Sample Dental Part

Curious to see the quality firsthand? Pick a material and we'll ship you a free sample part 3D printed on Form 4B to evaluate.

Evaluate Dental 3D Printing Solutions

Form 4B, Form Wash, and Form Cure are compact enough to fit on a desk, making the entire ecosystem easy to add to a practice or lab.

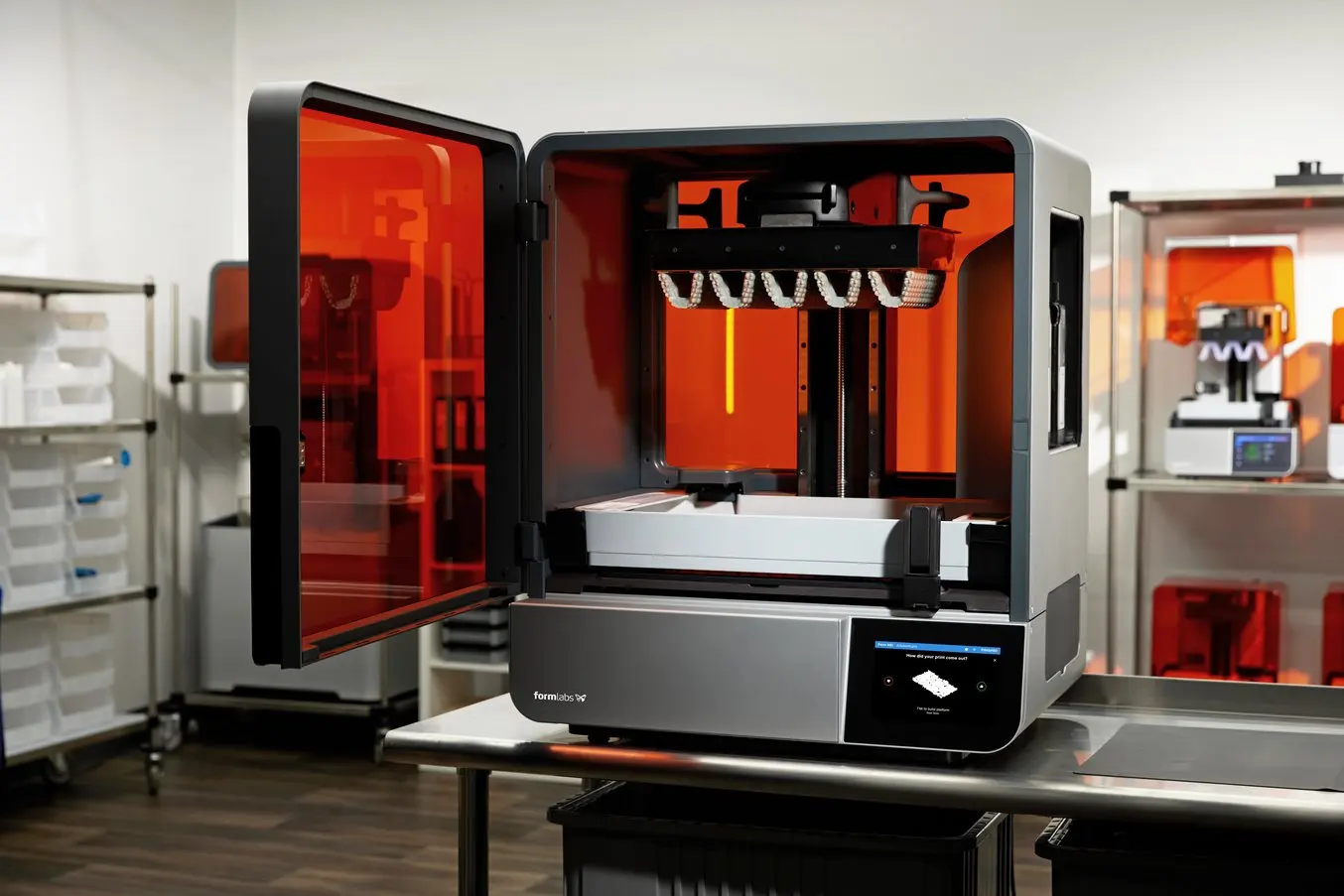

Form 4BL is still compact enough to fit on a desk while offering ~1.8x the throughput of Form 4B, making it an ideal solution for labs with high-volume applications like model production.

There is a lot of information to weigh when looking to invest in a dental 3D printer. Consider the factors discussed above and the needs of your unique business. Make sure to do your research, evaluate actual parts, and calculate your time and cost savings.

What to learn more about dental printers? Explore Formlabs dental printers or talk to our dental 3D printing experts to find the right solution for your business.