How a Small Dental Practice Digitized Its Workflow Without Prior Technological Knowledge

In 2017, Marua Hawi opened her own practice, a small dental clinic in Braunschweig, Germany, about an hour east of Hanover. Though she had no previous experience with digital dentistry workflows, she resolved to teach herself and her team to digitally design and 3D print models, splints, crowns, bridges, and more.

By taking on one new indication at a time, and working together with Digital Smile Design experts and Formlabs Dental support team, Hawi has successfully digitalized her analog workflow, reducing her reliance on external providers and empowering her small team through their mastery of digital technical workflows.

5 Key Points for Successful In-House Adoption of 3D Printing

In this webinar with Dr. Jennifer Bell you learn about what things you need to know to decide which 3D printer to acquire, other questions that arise along the way as well as the long-term impact it had in her practice.

Taking the First Step: Digitizing the Workflow

Hawi started her journey towards digital dental workflows from ground zero as “an absolute digital beginner, that is not so much into technical things.” After attending a Digital Smile Design Residency in Spain, she knew the first step towards digitalization was integrating an intraoral scanning workflow. As she and her team acclimated to using the scanning procedures in their daily work, she looked for software that would best suit her practice.

Not feeling comfortable with technological applications in general, Hawi planned to adopt new digital procedures incrementally to avoid overwhelming herself and her team. She looked for software that was affordable and had an accessible workflow. In the beginning, “we only wanted to print models as a first step, so €10,000 as a software fee was far too much,” Hawi says. She decided on MeditLink, which is free of charge, and includes multiple apps, allowing her to get used to new workflows risk free.

Scan To Smile With Simplified Chairside 3D Workflows

Join Dr. Christopher Baer to discover how the seamless integration between your intraoral scanner and 3D printer can help you gain chairside efficiency. In this webinar, Dr. Baer will share with you the simplest and most efficient workflow to get started with chairside dentistry.

3D Printing in a Small Practice? No Problem

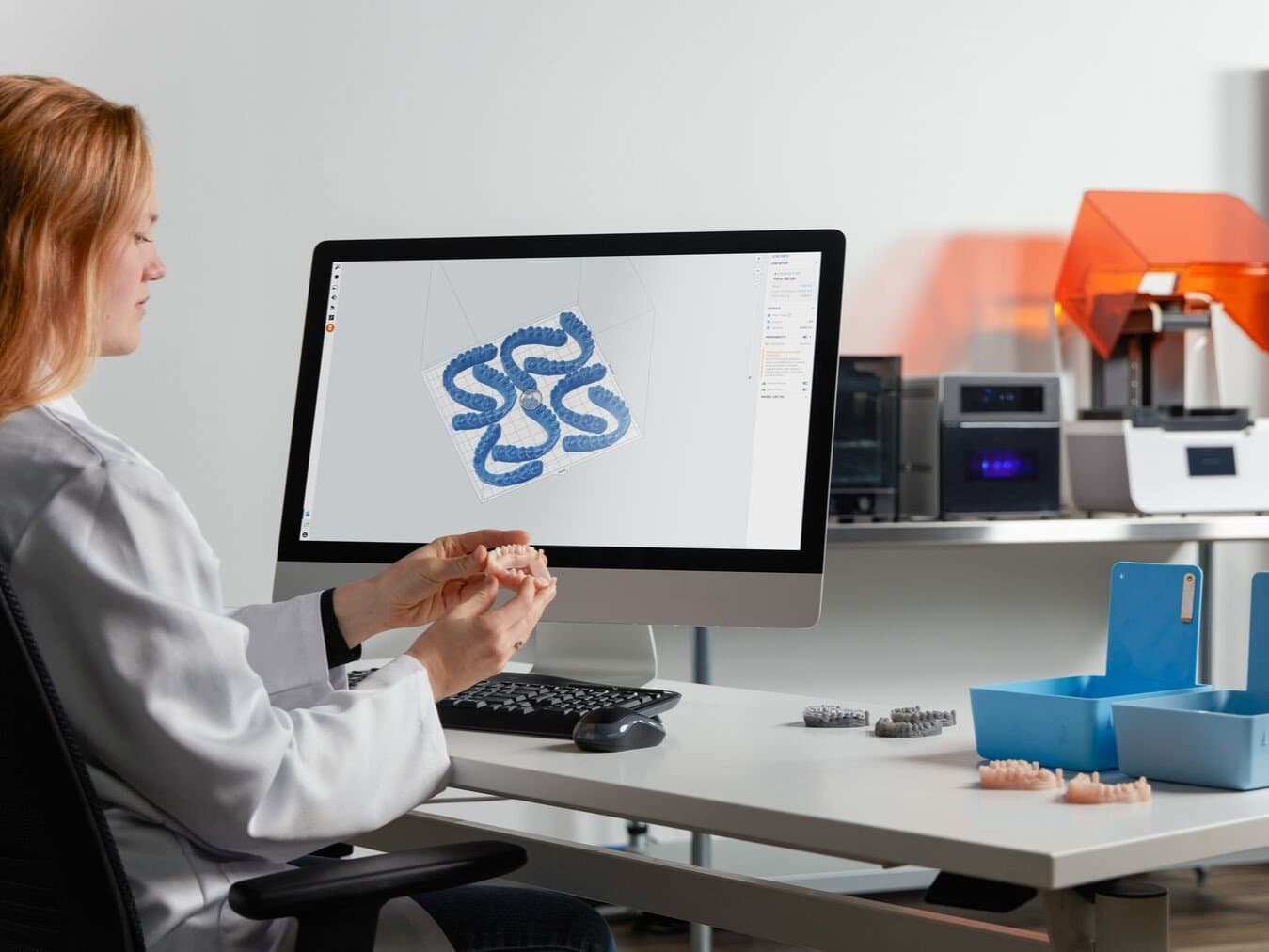

As the only dentist in a small practice with no dental technicians, it was especially important for Hawi to find a 3D printer that was accessible for her entire team. When she saw the Form 3B+ stereolithography (SLA) printer at her second DSD Residency, and realized how fast and easy to use it is, she decided to implement it in her practice.

It was clear that I could use [the Form 3B+] well and the price was great.

Marua Hawi, Dentist

But how uncomplicated printing with the Form 3B+ really is, Hawi had yet to experience. The printer and workflow proved to be just as easy and intuitive as she had hoped.

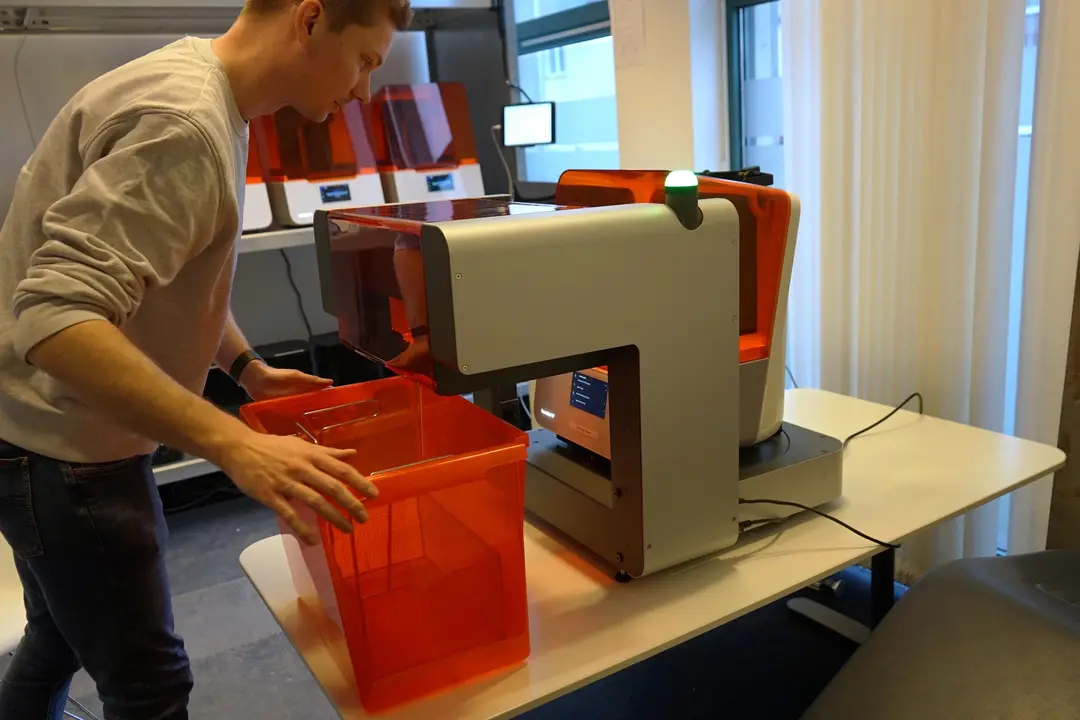

Immediately after installing the printer, Hawi turned it over to her dental hygienist. Thanks to the intuitive interface of the Form 3B+, and the variety of well-structured resources and courses by Formlabs Dental, Hawi’s colleague successfully printed her first part while Hawi treated two patients. “I only prepared the room, set the printer up and told my employee that she can find everything she needs on the Formlabs Dental Website. Then I went to see my patients and as I came back afterwards, she had already made her first print,” Hawi recalls.

Hawi’s team successfully printed their first diagnostic model in Model Resin within a few hours of installing the Form 3B+.

For Hawi, the intuitive workflow of Formlabs Dental printers is crucial, enabling everyone in the practice to print with confidence. The accessibility of the Form 3B+ makes it easier to create a flexible schedule for everyone, so there is never only one person tied to 3D printing, scanning, or hygienist work.

The printing process itself is no problem. Everybody in my team can do this and I would say actually just anybody could do it. Just go to the Formlabs Dental website and you find everything written down or you just watch a video. It's very easy.

Marua Hawi, Dentist

Hawi’s team quickly grew confident with the 3D printing workflow for models, and they began to think about adding more indications. “We simply started with printing two or three models a week. After only three months we started printing occlusal splints, too,” Hawi says. She has recently begun 3D printing prosthetic cases to quickly produce mock-ups and try-ins.

Even for me as an absolute beginner and our small practice, getting used to 3D printing is really fun, because I quickly understood that this is a very easy thing to do. We only needed a very small room. Now there is no mess in the lab. Everything is clean. It's so easy.

Marua Hawi, Dentist

Hawi is constantly implementing new applications with the Form 3B+, such as printing indexes with IBT Flex Resin to transfer the digital wax-up designed in CAD and using it to do the mock-up in the patient's mouth.

DSD x Formlabs Dental Masterclass: Unlocking the Potential of 3D Printed Direct Composite Restoration Indexes

In this webinar, Dr. Luken de Arbeloa, Education Content & KOL Manager at Digital Smile Design and Dr. Elisa Praderi, Senior Clinical Protocols & KOL Manager at Formlabs Dental walk you through the evolution of the guided direct restoration technique.

Efficient, Controlled, and Streamlined Production With a Fast ROI

Before implementing 3D printing in-house, Hawi had to rely completely on external labs for models and appliances. Coordinating with the external lab could be complicated and, for every order, she had to wait at least a week, which slowed down her process and tested the patience of her patients.

For occlusal splints in particular, Hawi had issues with her previous, external lab workflow. Receiving the splints could take a week, and they often arrived with a poor fit for the patient. This led to frustrated patients, unnecessary work for her team, and ultimately loss of profit. “The external lab always did the splints too small or too big, so we had problems many times. Either the patient had to come back again or I needed to work on the splints for half an hour, from which I didn’t earn anything. With 3D printing the money stays in my office,” Hawi says.

How To Produce the Perfect Splint in Your Dental Lab

Join Bill Slocum, Formlabs’ Dental Applications Engineer, in this webinar to discover the main areas of focus for dental laboratories when producing occlusal splints, so your lab can achieve success when it comes to your digital dentistry workflow.

Hawi improved the satisfaction of her patients with in-house printing, not only through faster treatment, but also by creating higher quality splints. Now she is printing with Dental LT Clear Resin V2, which she thinks is “simply better for the job,” as it is not as rigid as the (traditional) material the external lab was using, “that felt like you were biting on stone.” By utilizing the optimal resin for splints and using a controlled workflow, Hawi’s team is providing better splints to their patients.

3D printing occlusal splints with Dental LT Clear Resin V2 and the Form 3B+ in-house cuts out the delivery time of the external lab, so Hawi’s patients get faster treatments.

For Hawi, the biggest advantage of implementing 3D printing is the autonomy and flexibility it provides. Her entire team is able to 3D print parts for multiple dental applications and, thanks to the reliability of the Form 3B+, they have gained control over their supply chain and reduced their reliance on external providers.

Keeping all the pieces of the puzzle in-house gives us more control, so it’s easier to do the timing. I’m not dependent on my external lab.

Marua Hawi, Dentist

DSD x Formlabs: 3D Printing Technology in an Ortho-Restorative Practice

Join this webinar with Dr. Christian Coachman, CEO and founder of DSD, and Dr. Pablo Ramírez, Prosthodontic Specialist from Clínica Ramírez, to learn more about the journey of an early adopter of 3D printing, what the key considerations are for a successful adoption and implementation of this solution, how to scale to further applications and the value of the Formlabs ecosystem.

Happy Employees – Now and in the Future

One of the crucial aspects of success when implementing digital workflows is getting your team on board. Besides objective benefits like increased efficiency, 3D printing empowered Hawi’s staff, leading to increased productivity. With every additional application and indication they master, the team becomes more empowered and motivated.

I will always remember the first print my employee did. We were going like crazy. It was a big party here in the office. Everybody was high-fiving the other. Every time anybody has a good [printing] result they are so happy because they have the feeling they made it on their own.

Marua Hawi, Dentist

Implementing 3D printing made working in the small dental office more interesting for young people who, Hawi says, “love modern applications like that and are excited to use this.” For her, adding digital workflows is “blending perfectly in the mix of dental work [for young people]: Sometimes you work with a patient, sometimes you order materials and now they also have the opportunity to sit on the computer and design something.” As the dental sector is impacted by the general shortage of skilled workers in Germany, finding ways to attract and retain younger workers is necessary for Hawi to secure the future of her practice.

Top Tips for Starting a Digital Dental Workflow

As exhibited by Hawi’s practice, even pure technological beginners are able to successfully integrate the innovative tools and processes from Formlabs Dental. For every dentist considering adopting new digital workflows and 3D printing she has clear advice: be patient – especially if you have a small practice. “The first and most important thing is to stay patient. I'm the only dentist working in my practice and I only have six team members, so everybody already has things to do,” Hawi says.

Dentistry Made Easier: 3D Printed Restorations With the Latest Materials, Now Faster Than Ever

In this webinar with BEGO, you will learn more about the materials used for printing restorations, as well as the step-by-step digital workflow for producing these parts using the Form 3B+ and Permanent and Temporary Crown Resin from Formlabs. You will also learn characterization techniques for achieving optimal results and the benefits of SLA 3D printing.

For dentists who are well-trained in traditional procedures, staying within an analog comfort zone can be tempting. But as Hawi has shown, progressing towards digital dentistry can be done in every practice and without prior knowledge.

It's a consistent thing: To learn. To grow. Just step after step. We started with printing models and now we feel safe with them. We wanted to print splints and now we are really confident with the splints. And, just like this, every month we try to implement something new.

Marua Hawi, Dentist

Hawi plans to build on her great success by adopting new use cases including 3D printed custom trays with Custom Tray Resin and provisionals.

Ready to digitize your dental business? Talk to one of our dental expert to learn how you can get started.