3D printing has revolutionized the dental industry by transforming the way dental professionals approach their work. Through hardware, software, and materials science innovations, 3D printing makes treatment easier for the dental professional and more successful and personalized for the patient.

Formlabs dental experts, Dr. Elisa Praderi and Bernhard von OppeIn-Bronikowski, MDT, are often faced with common questions from dental professionals looking to incorporate a 3D workflow into their practice or lab. The following article will cover the three most popular questions, but to see each question answered in detail, you can watch the full webinar Q&A on-demand.

How Do I Get Started? Is There a Quick Win?

Bringing new technology in-house can definitely be daunting. It might be hard to change workflows that have served you or your patients for years. Maybe the most common question we get at Formlabs Dental from dental professionals looking to bring digital workflows in-house, is where can they start for quick wins. This question often arises due to a concern that using 3D printing will require an immediate, major overhaul of their existing workflows and business operations.

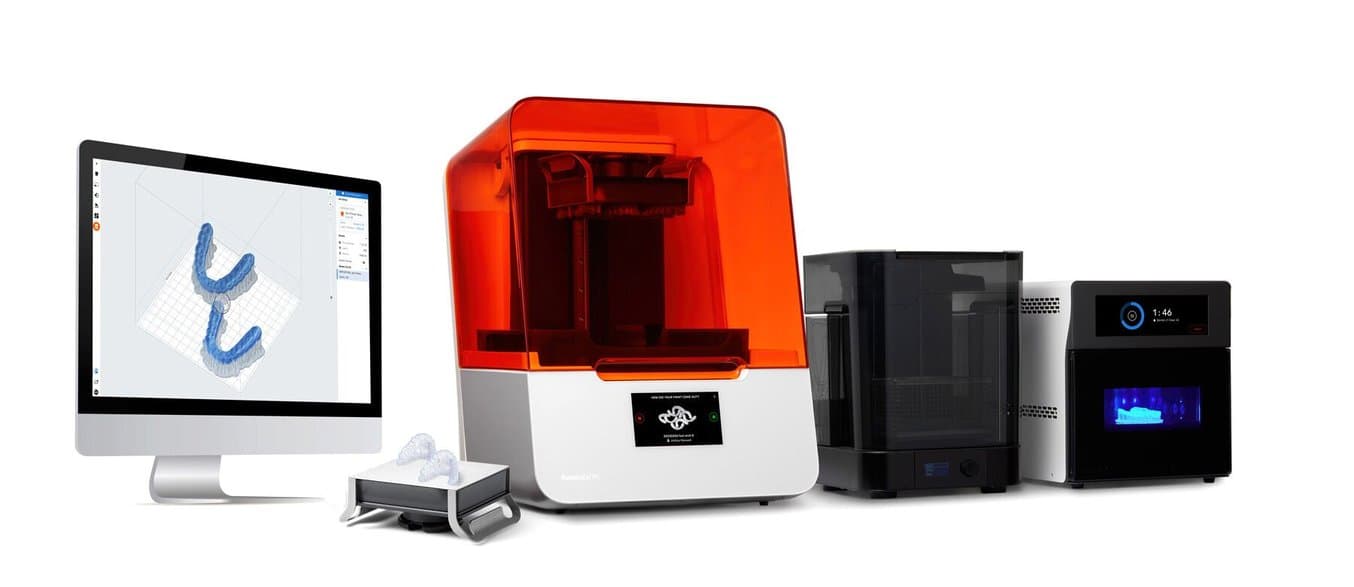

The best way to get started is to simplify — start with an application that doesn't require CAD skills and familiarize yourself with the printer workflow first, then add design skills later. Formlabs’ software, PreForm, is free, and simplifies the print preparation process. Within PreForm there is a feature called Scan to Model, which allows users to easily create 3D diagnostic models, without any CAD design work or alterations. Both the 3D model creation and the print process are easy to learn and require very little training, making them easily delegated to staff.

“Once you have the initial print process set up, it is easy to scale and add workflows for different indications. By starting slow and increasing adoption of 3D printing over time, you can ensure each member of your team feels comfortable and confident, and your patients will receive the best, most personalized care,” says Dr. Praderi.

The most common sequence for dental professionals to scale their operations over time is:

For labs, the pathway looks similar — labs should start with models as they are the lowest level of complexity with the quickest ROI. “After initially producing models, then it really gets interesting when you actually come to directly printing restorations. That's where the future starts for us and for 3D printing and dentistry. You can make dentures. You can make restorative crowns and bridges. So you're no longer using a model as a helper object but you're actually printing the final object with the 3D printing,” says von OppeIn-Bronikowski.

Which Scanners and Software Can Work With Formlabs?

Using a 3D printer in a dental environment requires a 3D scanner. While Formlabs does not sell scanners, there are many high-quality options on the market. Any type of modern intraoral scanner will output either STL or OBJ file types, both of which work seamlessly with the entire Formlabs ecosystem. For diagnostic or thermoforming models, you’ll only require a scanner and the Formlabs free PreForm software along with the printer, thanks to the Scan to Model feature.

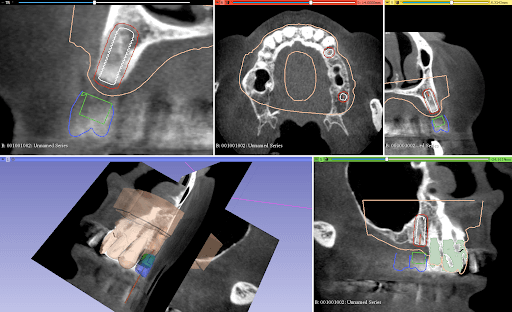

Once you’ve mastered the model printing workflow, you’ll need CAD software for surgical planning and restoration design in order to move onto these more advanced applications. Formlabs Dental works hard to make sure the full workflow for each indication is easy and accessible for our customers. “We work closely with scanning and software partners to ensure that the software and hardware work seamlessly together. Formlabs products integrate easily with any kind of modern intraoral scanner and the biggest names in dental CAD,” says Praderi.

For example, using the advanced design software Exocad, you’ll be able to click ‘Print’ when finished with your design and it will export the design automatically into PreForm. Similarly, at IDS 2023, Formlabs Dental launched new integrations with 3Shape. For 3Shape users, you now only need one click to move a file into PreForm and have it ready to print. These partnerships make your workflow faster, easier, and more efficient, benefits which get passed to the patient in terms of both successful treatments and lower costs.

How Fast Can I Print A Part?

This is a very common question, as dental professionals have to serve clients in a timely manner. At Formlabs Dental we think it’s more accurate to re-frame the question by thinking about the entire dental workflow, since much more goes into addressing your patients’ needs than just printing parts. Though print speed is used as a common metric by our competitors, it often leaves out longer post-processing requirements like cleaning, post-curing, or removing supports. Formlabs printers are designed to ensure a reliable, efficient, and highly accurate workflow. While that does include high speed printing for some indications, the overall benefit to the Formlabs workflow is found in our ability to support such a broad range of applications and to minimize extra post-processing work.

“The real question we have to answer here is, ‘What is the overall time to part?’ In addition to printing and post-processing, you have to consider time for the scan, integration, design, and print preparation. Once you are familiar with the different steps and requirements for each indication, you’ll be able to make the process faster and faster. For example, restorative models might need a 50-micron layer height for higher accuracy, while diagnostic models can be printed in Draft Resin at 200 microns and finish in 35 minutes. It’s about the total workflow time,” says von OppeIn-Bronikowski.

Learn More By Watching the Webinar Now

In the full video, the Formlabs Dental team answers 21 important questions submitted by the audience. Other questions answered during the roundtable include:

-

What is different about the Form 3B?

-

How do I know if the Formlabs Automation Ecosystem is for me?

-

How do I prepare my office for setting up a 3D printing ecosystem?

-

Which material is best to print models?

-

Can I combine printed bases and other teeth solutions?